The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  12 Ga From Hell -WOW

12 Ga From Hell -WOWGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Here's the ultimate brake design made in NZ...  | |||

|

| One of Us |

A 12G Muzzle brake if your going to use Sabots, can NOT have a ID any lager than the bore, nor can it have any venting ports in the brake greater in area than the sabot. Idealy no leading edge of the ports should be sharp edged or greater than 90° than to the flight of the round. The ideal would be a 30° port back towards the Breach. Here is an img of a port setup I intend to try to emulate for the barrel when i get it. Do keep in mind that this is for a Sabot type projectile so it MUST be true bore size only. The good thing is it would still be just fine for any full bore round of any type and also gives a small (very small) extension to the barrel lenght. My barrel will in fact be about 31.5" long before the first port (I hope).   | |||

|

| one of us |

Boomstick- Fritz454 made me some 750 gr .729's out of brass years ago and they worked fine but were just too stubby for my taste and I wanted bigger and heavier slugs. I've got some 2000gr boreriders that were just scaled up AAA 800gr boreriders and even shot them at 1000yrds out of my Borchardt. I could get them to almost 1500fps before it kicked the snot out of me. Man did those things buck the 20mph crosswind at Palomino! Gibs- You have given me a good idea! I'm gonna fill some of my Al hollow base bullets with lead and see where they weigh out! They take only a minute or so to make and the carriers are about 1.9 inches long. There are some pics of them on this thread or the .45 subsonic thread someplace. I never got the accuracy with any sabots that I would accept although I never tried that hard. Thats why a light dart stabilized full caliber bullet appeals to me much more. Add two internal grooves , some lead wire and enough hyraulic pressure to lock the lead into the grooves and you have a highly dart stabilized bullet. Where is Henry 22LR? As far as brakes go, I've tried a lot of different ones on my .50BMGs, Vias, Mcmillian Gills, slat ports with blast cones etc. To be honest the slat ports with blast cones were the best( near 50% felt recoil reduction) but not useable with sabots. The true Vias style with drill produced baffels worked great. However, I also found my simple brake with lotsa holes evenly drilled and counterbored worked just about as well as some very expensive ones. It works good enough and will not get blown apart by a sabot. -Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

Aluminum will work for a MB...I made a couple different shaped and hole sized for my 22-243...clamp on type just in case something went titzup...much easier on the toolbits, endmills and drills and my limited brain capacity. I shot about 100 70 gr max loads and didn't see any problem in ro around the exit hole... I read somewhere someone used an aluminum MB of his design on his AR15 and fired something like 12,000 rounds through it without any sign of a problem. I think some of the plastics might also work as long as the material can stand the dimensional pressure changes and the threads wouldn't strip out. I think the arguement with the sabots is getting outside parameters. Part of the design of the brake holes and shape would include what shape the sabot takes, what materials, how many slits, the bullet fit, when the petals are designed to open and so forth... Using shotshell WAA12 wadcups with the Lyman 525 Sabots works well in both smoothbore and rifled barrels but I wouldn't use them in a brake with the large cutouts or large holes but other harder plastic type sabots designed to use with the different small caliber bullets probably wouldn't get munched. I think the sabot problem/BS noise is moot when considering the "Darwin" type of slugs...they are just too big to work with any kind of sabot and still fit the 12ga bore. If someone specifically designed a 1000 gr plus slug for use WITH a sabot of 0.729" OD, like the aluminum ones already shown, that could be used with the 3.85" brass case and throated for the bullet extension...THEN we have a useful item to discuss...othewise....???? Blowing smoke and needling is part and parcel of this Accurate Reloading forum...sometimes getting a bit to far into the knife end...and not always appreciated. ROB...I want 15 of your brass "Darwins" to go along with my barrel...if I'm not too late ordering. Thanks Luck in your projects. | |||

|

| one of us |

In reality if you could build a brake that has hundreds of small holes, and was bore size inside it would have the least velocity loss and real efficient braking. The idea of angling the holes back on Gibs idea will let wads and sabots though with smaller hole or narrow slots. Slots .050 wide angled back. 2 dozen on each side would be better than 4 bigger ones.Ed MZEE WA SIKU | |||

|

| One of Us |

GIB...That's a BAAAADDDDD looking brake...I would guess the bore/brake area ratio is well above 200%.... ED...Can you give some particulars on your NEF barrel extension...thread TPI and length, OD, ID and material, MB, or any problems with recoil wanting to break off the addition...??? I have a couple of designs drawn up and due to the shape and size, 1.375" for a section and tapered on both ends, I'm wondering about the moment around the threaded protion from recoil with the additional weight. I want to add 6" total additional extention with a 2" threaded section for a total of 8" over all length plus a brake area. Thanks | |||

|

| one of us |

I just took a left over barrel section from back half of Savage barrel. It has same rifling and twist/ Threaded a sleave, and barrel and piece added on and screwed together and lined up rifling. Piece and barrel butt together inside sleave coupler. Ed MZEE WA SIKU | |||

|

| One of Us |

Uh! Ok! MOM!!!!

| |||

|

One of Us |

Let's play nice for the sake of the common good. That good being the 12GFH 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

One of Us |

Yeah they are stubby but for a faster flatter 200 yard trajectory with recoil that will keep you from the dentist... For use on game I see the flat nose monometal 750 being a great compromise weight/SD and should not have a problem doing a Texas heart shot on anything. Thar be enough momentum with that flat point to go through anything. I see the "Hell Hound" as a non DG game getter bullet. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| one of us |

If anyone was still interested in a Zabala Dear Sir, Please contact: -TRISTAR,S.A. 1416 Linn Str. N. KANSAS CITY- USA Telef: 816-4211400 Best regards I. ZABALA http://www.tristarsportingarms.com/ Karl. | |||

|

| one of us |

I know you have all been waiting to see my Satan's single shots so here they are! Here are the pics of the finished NEF/H&R ultra slug converted to 12ga FH. The target was shot at 50 yrds offhand of course with the 1085gr Darwin Beer keg bullets .7290-.7291 diameter, 240gr H50BMG load and the deformed bullet was a recovered 210gr load shot base first ,the other was fired flat nose first. The 12GaFH case has a aluminum dart stabilized carbide carrier in it for effect and is next to a .375 H&H mag for comparison. Most folks who see the 12GaFH simply say "holy Shit". I'v e encluded some pics of the brake also. The last picture is my second NEF converted in 4hrs. Satan single shots! Tomorrow we are fireforming 20 cases for further experimentation. BTW the nice boat tailed aluminum bullet with a 7/16 cavity in the base weighs exactly 365 grs as is. Wonder how fast it will go with the full power load behind it? 4000fps anyone? Pse notice the hole the Darwin Beer Keg slug makes on entry is what a .375 H&H hopes to become on exit. Scopes are leupold 2.5X compacts and have over 4" of eye relief. These beauties will wake you up when you pull the trigger! Not bad for a $300 gun. -Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

And you can get them with factory laminated thumbhole stock and they will shoot easier yet. Those longer eye relief scopes helps to stop noggin knocking. Rob how much thicker rim was needed to get proper primer contact on big primers? That brake idea is neat in original barrel. And if they wanted to add on for extra speed in end of the extension..Ed MZEE WA SIKU | |||

|

| one of us |

ED- I'm a lefty remember so the thumbhole wont work for me unfortunately. My rims are .040 but I bevel the rims so that you can screw the cases into them so that the .50BMG case just touches the back of the NEF receiver for zero headspace. Same principal as I used to do for competition encore guns. The rims are virtually flush with the barrel face when seated. of course , I can make rims with any thickness you want. You measure the protrusion then simply blue locktight the rims to the cases with that protrusion as measured with a dial caliper. Its usually .002-.005. I arm the primers with .002 depth for a good flatening and so far zero misfires with no alterations to the NEF firing pin or spring. After firing you can remove the rims as blue locktight can easily be twisted off by hand. Then reload using a .50BMG threaded rim so that I can use std .50BMG shellholders. Works like a charm! Guys just remember this is a little unlike std guns, as the muzzel pressure is actually quite high due to the inefficiency of the case and powder. Thats why ba 32-34 inch tube is ideal! iALUMINUM WILL WORK BUT I'D DOUBLE THE NORMAL MUZZEL THICKNESS FOR SAFETY. AT LEAST .250-.300 SHOULD BE USED IMHO maybe even .500. RIPS tube sounds oK and should work. Personally, I'd use steel though. I would not want to be on the receiving end of a blown aluminum muzzel brake.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| Moderator |

Rob - PM me your new cellie number, brother, please opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

Jeffe- check PM.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

Great work Rob. My 1.5"x3" anodized-black-knurled-aluminum cylinder will become only a thread protector for the muzzle when the 1.5"x4" stainless steel Vais brake comes off. I don't need no stinking muzzle brake for loads that use shot cups, wads, or sabots. I do want a brake that will vent the 200-ish-grain H50BMG loads used with my 3.20 Foster-Factor Darwin Lead Beer Kegs, and Rob's 2.48 Foster-Factor Darwin Brass Beer Kegs, maybe even S&H 2.29 Foster-Factor Brass FN. I'll post a pic of the Stainless Steel Vais Brake and the aluminum thread cap. A 1.5"x4" silver cylinder muzzle add-on may suggest to the devil that I have a silver slug coming his way. Now a spelling lesson: V-A-I-S Hoping for a Care Package from Nevada with some good brass for H50BMG loads. I'll get some interesting chrono data with that. | |||

|

| One of Us |

I give you the .729 Express! The red insert is a teflon tip (tight pressure fit) for expansion of the hollow tip and aids the aerodynamics' of the bullet. The hollow base is for weight reduction and the body idealy is made from copper. Side channeling is for minimul frinction on rifeling and helps in flight aerodynamics'. If this comes out to around 300-350Grns at full bore size, then I think the sabot round can be droped.  Rob, could you see if this is possible to make if an when you have time. I sadly dont have the means to do so. Thx.  | |||

|

| one of us |

Beautiful Gibs! Whatever it weighs it will work in any 12GaFH varmint or plains game gun, or any brake type ... or any 12-gauge slug gun like the Savage, Mossy, Benelli, Remington, etc. etc., right off the shelf. This is progress. Highly evolved compared to the Darwin slug. Now if you can get them stocked up for sale by whom? | |||

|

| one of us |

I bought one of the Zabala 10Ga sxs doubles from John Wall Mercantile in 1985. That Gun Warehouse was out in the sticks of Blairstown, MO about 40 miles from Kansas City, MO, where TRISTAR is now. Seems like I only paid about 450 bucks brand new back then. Richland Arms was importing them back then. I chopped the barrels to 24" and put rifle sights on the rib and used to play at Foster slug shooting with it. I even took it dove hunting with 3.5" No.6 birdshot loads, in the millet and sunflower fields of Missouri. Worked O.K for dove. I did shoot a couple of geese with it before I chopped the 32" barrels. Thanks for the TRISTAR link. Didn't see any E213's on the web site but have emailed them about availability and price of the E213. | |||

|

One of Us |

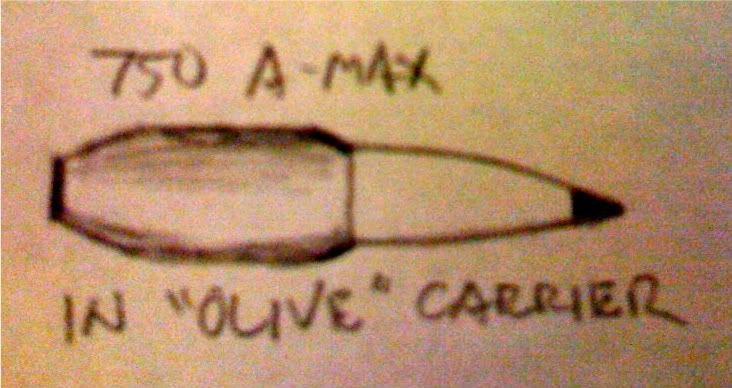

Rob... Have you done an aluminum carrier for the 50 bmg bullets? heat, press fit and cool any 50 cal 300 to 600 grains and 50 bmg 750 to 1000+ it would look like a bullet in an olive but versatile! 12 gfh shooting 50 cal or 50 bmg bullets at 50 bmg velocities! turn a 12 gauge into a 50 Alaskan, 50-110, 500 nitro or 50 BMG!!! Maybe a minimum engraving design or a wasp waist. I will draw pics tomorrow. The expanded mushroom will be greater than 729 so the terminal performance should be about the same + the weight of the carrier of about 150 grains. 600 grain woodleigh turns into a 750 ect...  577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

Boom, not trying to sound mean or anything, but that design might be a tad arse end heavy for stable flight. Just an observation is all.  | |||

|

| one of us |

Gibs- Nice looking bullet, but my guess is in copper it will be very hard to get to 350grs. The Al bullet I posted is very similar in shape and is exactly 356grs. It has a hollow base that goes way up into the nose of the bullet and was intended for a Tungsten carbide insert. A later version has two grooves machined into the nose cavity so a lead insrt can be swaged into place for producing any weight you want up to 1000grs reproducibly. The copper hollow point will probably wind up much larger as will the hollow base. Not a big deal just my observation from actually making these things. I would also suggest that the center of the bullet be step drilled(i.e. larger to smaller diameters, so that the bullet can be made in one CNC lathe operation rather than two. You can then add a Teflon or polypropylene insert for the aerodynamics. Otherwise the bullet needs to be hollow pointed or base drilledsaparately which is a PIA. Boomstick- That is a very Yucky looking design. Remember, I posted a pic of a wasp waisted dart stabilized AL carrier with a 750Amax in it somewhere on this or the .45 subsonic thread. Looked rediculous. -Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

Rob, How about simply adjusting your beer keg program to give it a pointy nose (spitzer or small hollowpoint), and a deeper hollow base, to get some dart stability, but do it in aluminum for really light-weight-high-velocity, with charges of 200-plus grains of "fast" powder, no wads, any brake. That would keep it simple, and interesting over the chronograph, and at 300-yard targets with 12gaFH "shotgun" slugs. Maybe a simple solid-base, aluminum, semi-bore-rider, .729-cal "Harlow" for plinking fun? | |||

|

| one of us |

Karl, TriStar responded that they do not carry the 10-guage. They say they think it is not in production anymore, replaced by 3.5" 12-gauge. Little do they know that it is being replaced by 3.85" 12-gauge. | |||

|

| One of Us |

Hey...that is a take-off on the Herters "Wasp-waist" bullet of yesteryear isn't it.... I don't think I would want an AL MB in this application either unless it was one of the "Quick Dump" styles, and the other parameters were scaled to the mechanical attributes of the different metals. Trying to dump the gas generated by 200 plus grains of powder in a short distance, 2 - 4" is a daunting task. A slug traveling at 1400 f/s...16800 in/s...takes approx 0.00011 sec to travel 2" and gas has a small amount of intertia so getting it to turn 90° then move through the vent area takes some amount of time and my calculation ability starts falling off at a geometric rate when getting into Thermodynamics and limited empirical experimentation starts taking over. I would suspect that a vent area on the order of 2 plus times the bore area would make for a more efficient MB. Re-directing and dumping the maximum amount of gas while the slug is still in the barrel is a basic tenent of MB design. Once the "obstruction to the gas flow" is gone so is the braking effect...and we are still talking about the function of time in this equation...0.0001 seconds of "restriction" time. A 2" long vent area and a 2" long "restriction" area in front of the vent area before the muzzle end seems logical for the 12ga bore and I've seen several vented shotgun barrels following a similar vein. The bore area of a 12ga is .4185 sq/in rounded up to .42 for easy calculations. Harrall's Precision uses a 3/16" x 6 hole x 6 row, rotated slightly...36 - 3/16" holes would give you .9936 sq/in...just over 2X bore area...I've used 3 of his on my larger calibers. The higher velocity of the larger calibers and the amount of gas production probably negates a need for a restriction area in front of the vent area in rifles as the gas pressure is sufficiently bled off before the bullet leaves the muzzle and also the bore area is much smaller compared to the 12ga, so the bore/vent ratio is much higher. The ratio for a Harrall's brake on a 416 cal is slightly over 7X. Stepping up to 7/32" holes will give you a 3X vent area in the 12ga...and 1/4" is 4X...etc. Just some ramblings while I have breakfast. | |||

|

| one of us |

Did they mention a price Rip? Also a general question for the floor is what is the low down on Briley rifled chokes? I seem to remember a big deal being made about them at one stage. A.do they actually stabilise slugs? B.Could they handle the velocities/pressures we are into? | |||

|

One of Us |

How about a 1/2" long .510" ID 729 OD copper tube of somewhat aerodynamic design and driving bands/crimp grooves to be heated and slipped on any 510 bullet shank? maybe aluminium for lighter weight and cost? All we need is a caliber bumper. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

Rob Not being a machinest nor even the ability to tinker hands on with a lathe (use to years an years ago) I'm not to familar with the term "step drilled" but if I take it to mean a gradual increase of the hole at the front of the bullet, I cant see how that be an issue. A straight forward plain drilled hole to the appropreate size will do. IIRC thats rather simple to do on any lathe. The reason is again for weight reduction, and simplicity of constrution. The only down side I can see is the fact that the bullet would need to be turned in the chuck for the base hole to be drilled. Me, I'd do it something like this. Put copper stock in a lathe, center it and then drill nose hole. Insert Teflon Rod, cut it off at right length. Now machine bullet shape. Cut off bullet turn in chuck, dress base, drill base hole. As I said been a few years since I fiddeled with a lathe an back in my day no puter pluged in, all done by hand Also the Banding helps reduce bullet weight (not by much but every bit helps). The ideal as I said would be around the 350grn mk, but since I cant try this i have no idea as to how close I could get the bullet to the target weight. If it came out at around the 400grn mk, it still be a winner in a full load 3.85 Brass case using the 4227 powder in a mod savage 210F (I think). Still i'd be interested to see how it turned out. Thanks for your input, I just luv the way this 12G thread has grown.  | |||

|

| one of us |

Well fireforming cases was a interesting session today. My old method of 55gr of Bulleseye and annealed neck case and filled to the top with cream of wheat basically resulted in 50% of the cases blowing off the last .5 inches. Now I used to just use .50BMG cases as is and this time I opened the case mouths with a expanding die thinking it should result in a higher full length case success rate. Rest of the case blew out beautifully. Tried a whole lot of things but basically found that 30 grs of Bulleseye and the rest of the case filled with cream of wheat and slightly compressed using a wood dowel gave the best results with at least 80% of cases blowing out nicely and the other 20 blowing off only .2 inches of case. Sounded like cannon fire and got lotsa attention at the range. I now have 15 fully formed cases and 5 that had to be cut down to 3.23-3.5 inches for the 210 gr loads. Also had a few misfires if I didnt screw the bases all the way down on the case. Mr NEF has very generous headspace apparantly. I'm gonna do some more Full power shooting tomorrow and then deceide if I need to elongate the firing pin. Seems like its not due to a light hammer strike but thats next if the longer firing pin doesnt cure the problem. Gibs- I was talking CNC bullet making, where every bullet has to be nearly the same weight and dimensions. Having to take the bullet out and turn it around for a separate op is something I'd like to avoid just because it would require a separate set up for me. That adds a lot of cost and takes time to get right. Maybe Macifej can do it with his better machines but it would be difficult for me. RIP, did you see the AL bullet in the pictures I posted? WE COULD SIMPLY PUT SOME DRIVING BANDS ON IT AND IT ALREADY WEIGHS 350GRS. I'M BETTING THAT WILL BE DEVASTATING OUT TO 300M or more if we dart stabilize it WITH A LITTLE LEAD IN IT. It has a near full length cavity that we could swage some lead into. Very cheap and easy to make too. Putting some driving bands on is the first thing I'm not really convinced that for 200m shooting it even needs more. It should hit 4000fps as is! Could be made from Copper but would probably weigh 500gr. and go 2700fps. 460 wby ME with a .729 hole from a NEF!-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

One of Us |

What about 50 cal bullet shank driving band caliber bumper tubes? turn bmg bullets into 729 bmg-12GFH bullets  577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| one of us |

Boomstick- Youd have to bond it to the bullet somehow and my guess is it might come off unless that bonding was pretty good.. At the price of A- max and whatever it would take to make a driving band liner, I'd think you'd be money ahead with a CNC turned bullet.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

One of Us |

If there is a minimal engraving driving bands design I think it would work. Aluminium? Kinda like an aerodynamic sabot that stays on. I get you on the cost. A neet idea imho. you could crimp the sleeve on the canalure to ensure it not going anywhere. buy 1/2" ID aluminium tube and make the driving bands/ogive/boat tail on the lathe. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| one of us |

Rob, Yes, your bullet like the above aluminum job would be all the world needs to shoot plains varmints with the 12GaFH, no? Smoothsided or banded, whichever shoots better, and a tiny little hollowpoint to make it an "expanding bullet" to be legal everywhere for edible game and whatnot. The lead filling and dart-stabilizing ploys are really not needed, and could lead to concentricity and accuracy problems. More trouble than they are worth for a varmint popper. Just a good monometal aluminum bullet for varmints. Yours does look perfect for such. Send me some samples and I'll do the accuracy testing, load development/chronographing and Iron WaterBoard Buffalo penetration testing for you, just to free up your time for fabricating brass and satanic single shots. | |||

|

| one of us |

Rob, You need to get a boxcar full of this brass delivered to Nevada. Ask Ed where he got it. There will be zero case loss with forming this stuff into 12GaFH: Before annealing:     After annealing:   | |||

|

One of Us |

Rip... them some nice 18.5x73 cases 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

Those would more correctly be called 11.78 x 99.82 mm "Straight" loaded as annealed... | |||

|

| one of us |

I had best luck fireforming using larger amounts of 7383 surplus and a little filler. It burns slower and I only had cracked mouths on about 10 cases out of 150 And those worked for 3.5". Then I run in expander to finish so that they were ready to load. The bmg straight primer cases I have are the only ones we have found in 3 months of looking and they'd save fireforming work. Put on rim and run into sizer and load them up. Any one needing new 12ga FH rifled Pacnor barrels contact me. I have two new blanks I won't need.Sell for 2/3 original costs. Work for Savage bolts, mossberg bolt actions, etc. One is 1.5" dia and other is 1.36" dia, both 30" plus long.Ed MZEE WA SIKU | |||

|

| one of us |

RIP- Yup I'll make a run of them for us to experiment with. I was initially and maybe still am a bit skeptical about aluminum bullets and so thought the more engraving area the better. The more I see though the more I'm starting to believe though. I'll design a version with driving bands and see how it works. Bands/ no-bands is trivial as its just another tool change for the machine. Putting a Hollow point on meand remounting the bullet in another machine and drilling. Sounds simple, but takes time and adds cost. I'm trying for a cost of $1.50/bullet so the more time the less likely that will happen. If folks want a HP and will pay more, then no probememo! Boomie- Yes you could do it, but I still ask WHY? It would be cost prohibitive, and I doubt a crimp on the cannelure would be strong enough. I was thinking solder type bonding. If that sleeve ever came off the bullet and stuck in the barrel the next shot would be a Kaboom. The most reliable and low cost approach is a machined monometal or swaged cup type bullet. Cost and quality are king in my mind. ED- I was really surprised at the results I had yesterday as I had great results fire forming before. What charge and filler did you use?-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

I use 180gr of 7383 surplus. I have lots of it and rest is farina up past shoulder to neck. Then I use a playdough plug packed tight, filling the neck. I use same on my 700 cases too. Then run in expander to finish and ready for first bullet.The expander isn't a mouth belling type, but straightens and forms the mouth perfectly to the top half of the case.Ed MZEE WA SIKU | |||

|

| Powered by Social Strata | Page 1 ... 29 30 31 32 33 34 35 ... 75 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  12 Ga From Hell -WOW

12 Ga From Hell -WOW

Visit our on-line store for AR Memorabilia