The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  African Big Game Hunting

African Big Game Hunting  The ULTIMATE solid design

The ULTIMATE solid designGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

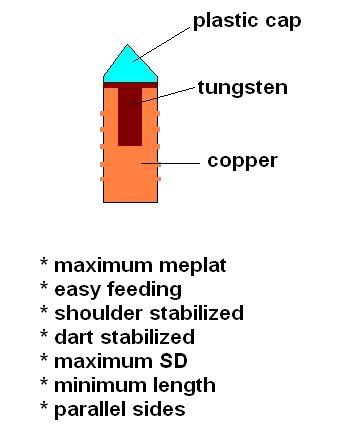

A new design for the ULTIMATE solid; perhaps Saeed, Robgunbuilder or Macifej can take a look? Design 1 is slightly complex, but has all the attributes of an ideal solid: maximum meplat with sharp edges for supercavitation and shoulder stabilization, very high SD, short parrallel sides for increased stability, dart stabilization, and ease of feeding, which requires some compromises in todays flat meplat solids. Note also drive bands, for lower pressures. The conical plastic or silicone cap is epoxied onto the slight cup to improve feeding; this allows a wadcutter type meplat. It is shed upon contact. The tungsten insert is epoxied into the annealed copper bullet, providing a sharp, flat, undeforming meplat and shifting the center of gravity forward for dart stabilization. A new design for the ULTIMATE solid; perhaps Robgunbuilder or Macifej can take a look? Design 1 is slightly complex, but has all the attributes of an ideal solid: maximum meplat with sharp edges for supercavitation and shoulder stabilization, very high SD, short parrallel sides for increased stability, dart stabilization, and ease of feeding, which requires some compromises in todays flat meplat solids. Note also drive bands, for lower pressures. The conical plastic or silicone cap is epoxied onto the slight cup to improve feeding; this allows a wadcutter type meplat. It is shed upon contact. The tungsten insert is epoxied into the annealed copper bullet, providing a sharp, flat, undeforming meplat and shifting the center of gravity forward for dart stabilization.  So what do you say, Saeed, Robgunbulder, Maacifej? can it be done? is it practical? if so, i have naming rights! | ||

|

| One of Us |

I'm no expert, but would not the forward facing tungsten core tend to separate from the lighter copper on impact? Steve "He wins the most, who honour saves. Success is not the test." Ryan "Those who vote decide nothing. Those who count the vote decide everything." Stalin Tanzania 06 Argentina08 Argentina Australia06 Argentina 07 Namibia Arnhemland10 Belize2011 Moz04 Moz 09 | |||

|

| one of us |

Ur right SGraves. Tungsten core needs to be tapered all the way to the rear and then riveted at the base to prevent inertia seperation created by the different mass of the two components. Pancho LTC, USA, RET "Participating in a gun buy-back program because you think that criminals have too many guns is like having yourself castrated because you think your neighbors have too many kids." Clint Eastwood Give me Liberty or give me Corona. | |||

|

| One of Us |

You may be right; although the resistance encountered by the tungsten cap is exerted in the same direction as the resitance encountered by the copper base, and the two can be epoxied together. Hows this?  | |||

|

| one of us |

How would the length vs. the weight ratio be ? I dont know tungsten except that it is very hard but what about weight heavier than copper or not ? Frederik Cocquyt I always try to use enough gun but then sometimes a brainshot works just as good. | |||

|

| One of Us |

Tungsten is more than twice as heavy as copper. Not easily machineable (unless you have the right equipment) and generally a PITA to work with. The benefits for a hunting projectile are few and the problems not to mention cost are many. This has ben done many times by firms with huge resources and they have chosen not to produce the product. It just isn't that hard to kill animals at close range and it's more practical to use a bigger bullet than a more complex one. | |||

|

One of Us |

the only carts that I think needs a tungsten bullet is the 458 win mag and the 45-70 to make up for case capacity. to make both happy make a multi canalure design to cycle in a lever action and make it 450 grains. it would look like this... 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| one of us |

Bullets, calibres and rifles etc are always a lot of fun to discuss, but I have to say I reckon the ultimate solid design has already been invented by GS Custom. - I love 'em to bits! I'm no expert but would have thought that any bullet with two types of metal in it would be inherently unstable and more prone to tumbling (than a monolithic solid), either inside or outside the body. Perhaps either Alf or Gerhard might care to comment. | |||

|

| One of Us |

Why not insert a radio transmiter then it is easier to find wounded animals "Buy land they have stopped making it"- Mark Twain | |||

|

One of Us |

the copper would only be there to engage the rifling say 30 thou thickness and only on the shank so no deforming stress on the copper part. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

One of Us |

lol... 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| one of us |

You don't need to make up for lacking case capacity in the .45-70. According to the numerous .45-70 DG hunting experts here on AR the slower the bullet the better it performs on thick skinned DG. In fact the best thing one could do with the 45-70 case is to use 15 grains of filler to further limit the case capacity. That way the hard cast loads will penetrate even better! | |||

|

| One of Us |

That's not so far fetched, there was a guy that tried to do that with arrows for bowhunters. | |||

|

one of us |

I see that Doctari has taken this on (actually the .450 Marlin) in the latest Sports Afield. Seems he had a different conclusion than the Guns and Ammo article... ------------------------------- Some Pictures from Namibia Some Pictures from Zimbabwe An Elephant Story | |||

|

| one of us |

As a matter of interest.  If the situation is much different in the USA or in Europe, please set me straight but, tungsten rod to use as raw material can be purchased in SA in these sizes only: 3mm, 6mm, 8mm, 10mm, 12mm and bigger. To do the insert as suggested above, assume a .458" bullet, one would need a piece of tungsten rod 12 x 30mm. It will cost around R124.00 ($17.71). To machine it to the shape shown, it will have to be ground or edm machined. Either way, it will not be done in less than 12 minutes and machining will cost around R40.00 ($5.72). Forget about riveting the base, tungsten rod cannot be riveted by mere mortals. Making the shaft of the bullet from copper will eat about R8.00 ($1.14) and the plastic tip will cost around R4.00 ($0.57). Plastic tips must be made individually as bulk manufacture is not an option at 5 bullets per hour. Then the pieces have to be assembled and epoxied individually - ad another R2.00 ($0.29). Total cost for such a bullet would be about R178.00 ($25.43). What profit margin will you allow the manufacturer? 20%? That would bring the bullet to R214.00 ($30.57) and it is not packed and shipped yet. It will be a special order item so minimum quantities would apply. Say 50 units per person. There is one technical problem I cannot figure out. What type of adhesive would one use to fix the plastic tip to the tungsten rod? It must resist the forces of feeding from a magazine and must not detach under any kind of unintended rough handling or lateral force. The adhesive must have magical properties too, because it must allow the plastic cap to detach and disappear on impact. So we are looking for an adhesive that will resist shear force but not compression force and will adhere to plastic as well as tungsten. Hmmm.....cost of assembly may go up. Any takers at R10 700.00 ($1528.57) per box of 50 plus shipping and handling? Bear in mind the bullet will have no track record or guarantee whatsoever until it has been proved to work (or fail) after some extended use and, if the plastic tip falls off in the magazine, you may have to re-cut the chamber to remove the gouge mark left by the tungsten insert. | |||

|

| one of us |

Now THAT'S what I call an informed opinion! Thanks Gerhard! | |||

|

| one of us |

I hoped Gerard would be able to comment. I have yet to see someone complain about the performance of a GS Custom bullet. _______________________________  | |||

|

| One of Us |

Although they were too expensive for good sales, Speer was able to market an excellent tungsten cored FN solid for around $4.00 US/bullet. 465H&H | |||

|

| One of Us |

.............Well we seem to have gone from [aircats ] to [air bullets] ....But at least people are thinking about what is coming out the barrel ............It appears to me that bullet makers who start their own business are major high energy over achievers..........Our un sung heros .......... .If it can,t be grown , its gotta be mined .... | |||

|

One of Us |

lol... My aircats just need some more time and money... all bullets and carts were "air" at one time 450 grain multi canalure 45-70/458 win mag bullet is a market that is ripe. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

I heard a rumour that the Speer AGS solid has been discontinued, although it seemed to be of excellent design, especially for the .458 Win Mag. Is this true, if so it would be rather unfortunate? I know that Speer's tungsten core-based bullets have always been on the expensive side, but it seems like a bit of a shame for a well designed bullet to go by the wayside! I can imagine that manufacturing costs and demand are probably the main constraints and possible downfall in this case. Indlovu, it all depends on how willing guys are to support you on the project. I think that the quotes for the total price of the bullets are going to be high, make no mistake, but as to the design, I think that there is nothing wrong in that department! You will never know how good it is unless it is tried out, but it is just getting to that point that can take a bit of blood, sweat and tears! | |||

|

| one of us |

Why do you need a new solid design? Where are the premium/custom designs failing for you specifically? _______________________________  | |||

|

One of Us |

Well guys here are my Bridger solids, that took my first elephant in Zim... I was the first to kill an elephant with John's bullets... First bullet a 450 gr X bullet full penetration on my first buf shoulder to just underskin on far side... Bridger solids, North Fork flat nosed solid, and my 375 H&H Hornady 300gr RN that took my leopard in Tanzania and into an ironwood tree... All are 450grs .458 diameter... BarnesX, 2 Bridger's from ele, North Fork, Hornady RN | |||

|

| One of Us |

Couldn't ask for better performance than that! 465H&H | |||

|

| one of us |

Kinda partial to the Northforks myself. Dave | |||

|

| One of Us |

Thanks for taking the time Gerard! I can't handle it anymore!! | |||

|

| Administrator |

A while back we had a discussion on whether bullets would go through a 1 inch steel plate. We tried several bullets, and the only one that managed to go through was the tungsten insert in the Speer. Everything else failed.          | |||

|

| one of us |

Yea...but it lost its petals. They may be the coolest pictures ever posted on AR! | |||

|

| One of Us |

Dont start with that petal stuff. Have we not been told by warrior (I do not like petals that fly off) at least twenty seven dozen times that when this happens the bullet is overstressed? It was shot into that steel plate much too fast and it would have penetrated better if it was shot at a lower speed. It would have retained more weight and made a bigger hole in the plate. | |||

|

| one of us |

Ehhh, who cares about performance on steel? Have the animals bought vests or are they hiding behind Bradley fighting vehicles? _______________________________  | |||

|

| One of Us |

Only in canned hunts "Buy land they have stopped making it"- Mark Twain | |||

|

| one of us |

Saeed, I too had similar failures on mild steel plate, just like with all your pictured bullet failures. With .416/400gr bullets at 2475 fps, the Speer AGS tungsten penetrator cores shed their jackets and pencilled through the steel, the jackets sometimes zinging back overhead (thankfully) of my 100 yard shooting position. I stopped doing that! The non-failures come from 50 BMG AP. | |||

|

| one of us |

Saeed, Can you tell what diameter the carbide core is in that .375 Speer AGS? | |||

|

| One of Us |

I have no complaints either, but - is it possible to build a better mousetrap? of course! in mmy opinion, the compromises in a monmetallic flat point solid are: 1)They are longer than tungsten or lead cored solids, hence theoretically less stable IN TISSUE, and ahve a lower SD 2) Meplat is not as wide as in my design, because of feeding limitations; also the edge of the meplat cannot be sharp as it wont feed easily 3) The monomettalic solids are shoulder stabilized, but not dart stabilized. Cost constraints aside, I think the design is complex but has advantages. Gerard, I am very fond of your bullets, they are my favorite solid; the adhesive used would probably be a form of epoxy, ie the stuff used by major manufacturers to bond lead cores to copper jackets; and the palstic caps would disintegrate o contact with tissue

| |||

|

| one of us |

And what about these. Barnes banded solid they look very good.  The 300gr in 375 as a SD of 307 and anything over 300 goes doesnt it? Frederik Cocquyt I always try to use enough gun but then sometimes a brainshot works just as good. | |||

|

| one of us |

/ | |||

|

| One of Us |

Last year, I called Speer about the AGS tungsten solid. They told me that cost of manufacture and low demand resulted in their being discontinued. However, they may be purchased here: http://www.gunaccessories.com/Speer/African%20GrandSlamRifleBullets.asp | |||

|

| One of Us |

Shooting into steel is very different to shooting into flesh. I guess it takes some experience to discover this. If I have ever seen someone confused, this is it !!! Warrior | |||

|

| one of us |

I have made some money on these bets. With 15 days to spare!!! Talking about confused - How is shooting into steel different from shooting into steel? I guess it takes much experience to tell the difference between shooting into this steel, as opposed to shooting into that steel. You really don't do well with this tongue in cheeck thing, do you? You fixed that error quicker than usual after it was pointed out to you. Only about half an hour but it was funny!!! | |||

|

| One of Us |

I have to say, i dont shoot hard brass solids in my rifles! With each shot, i imagine a cloud of rifling material disapearing downrange! Having said that, is an SD of .4 better than .3? Of course it is! Note that the brass banded solids dont have a maximally sized meplat (otherwise they would not feed reliably) and they are long for caliber compared to a denser solid; No daqrt stabilization. either. \

| |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  African Big Game Hunting

African Big Game Hunting  The ULTIMATE solid design

The ULTIMATE solid design

Visit our on-line store for AR Memorabilia