The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  African Big Game Hunting

African Big Game Hunting  The ULTIMATE solid design

The ULTIMATE solid designGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

And a TV camera so you can watch the path of flight and the hit......let's keep re-inventing the wheel..... "When you play, play hard; when you work, don't play at all." Theodore Roosevelt | |||

|

| One of Us |

Hey Gerard, Have you ever heard of a super abrasive machining center? I believe you can get the machining time on the tungsten down to around 15-25 seconds total. Also once the bullet proves itself one could build the tips in an injection mold with 32 cavities and run a 48 second cycle yielding 2400 parts per hour. I have often wondered if superabrasive machining can be applied to copper. Ridiculously tight tolerances can be maintained with these machines. Just a thought. Andy We Band of Bubbas N.R.A Life Member TDR Cummins Power All The Way Certified member of the Whompers Club | |||

|

| one of us |

SAM is the domain of extremely hard material machining. Mild steel and anything softer is best done with carbide tipped tooling and on CNC. Doing the carbide insert for the bullet above with SAM is viable but the very smallest machine available costs about 350 000 pounds UK (US$724 000)(R4.92m). Then there is cutting tool cost and so on. Even if there would be a savings over doing the carbide insert with EDM or conventional cnc grinding, it will only reduce the insert machining cost and not the insert and bullet raw material or assembly. Saving money on the cap, which is caliber specific, will not happen because the annual market for the bullet we are talking about is less than one day on an injection moulding machine, if we assume just six calibers. The cost of six 32 cavity dies will likely be higher than making the caps on a cnc lathe. We run tolerances of + - .005mm on our bullets. The effect of anything tighter than that can not be measured in group sizes, so there is little point in searching (and paying) for equipment that can deliver better than that. It will only drive the cost up again. | |||

|

| One of Us |

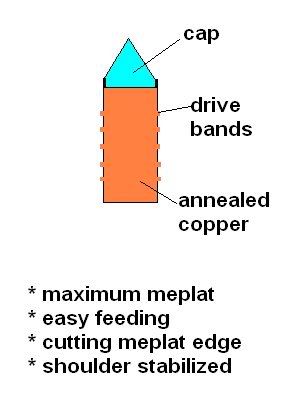

Gerard, you obviously know the costs much better than I do, but i do know that in the US you can buy Barnes MRX bullets (which have a tungsten insert) for a dollar and a half or so. For a hunting large caliber solid, the tolerances dont have to be as tight as those you have; would there be any cost savings there? Also, what about a simpler design, as below? Would feed better, have a larger meplat, would be shorter, and the plastic tip would disintegerate on impact.  | |||

|

| one of us |

The Bridger and the Northforks are pretty hard to beat on Buffalo and elephant..but then the old wore out Woodleigh suits me just fine. Lots of excellent bullet out there today, the day of bullet failure has "about" run its course. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

I tested some prototype full wadcutter driving band copper solids from the .375 on the heads of recently deceased elephant, and the performance was not good. Penetration was shallow. It seems that a frustoconical design gives the best penetration. | |||

|

| One of Us |

"The Bridger and the Northforks are pretty hard to beat on Buffalo and elephantard to beat on Buffalo and elephant" Ray, Im sure thats true for someone in his 109th year! | |||

|

| one of us |

A tungsten inisert like that shown will be about 2 1/2 times heavier and much harder than the copper HP it is inserted into. Result will be the hard, heavy insert splitting the copper HP in two. For those of you who are old enough to remember the Remington Bronze point you will know what I mean. The pointed bronze tip broke up the conventional cup and draw jeacketed HP into a million peices. Very explosive bullet and it was a lightweight peice of relatively hard bronze. Imagine what a tungsten insert will do! Best bet as Gerard has pointed out is to go with commerically available inserts that are close to full diameter. As 65 years of military AP ammo has proven all you need is about 1/2 mm of lead and an equal thickness of copper jacket to cushion hard core from the lands and grooves of rifeling. So subtract about 2mm from the diameter and you will have your core diameter. (i.e. a 7.62mm is 6mm core). Andy | |||

|

| one of us |

Indlovu,

The tungsten in an MRX is not the same as a solid carbide insert as is suggested in your first diagram. It is a fairly malleable compound and, if you have a go at it with a sharp object, it can be abraded and dislodged, much like a lead core. It is much cheaper than a solid machined tungsten carbide insert and serves a completely different purpose to that which is suggested in your first diagram. The only cost savings would be on reducing machine maintenance cost which would allow the machines to deteriorate to the point where tolerances can not be held at the level we require. One could also save cost by buying cheaply made machines not capable of the accuracy in the first place. I cannot really answer that question because we are not prepared to do either because results like this will then not be possible. 613 Yds on a steel plate.  | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  African Big Game Hunting

African Big Game Hunting  The ULTIMATE solid design

The ULTIMATE solid design

Visit our on-line store for AR Memorabilia