The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  .375/404 Jeffery Saeed of 2012: Adventures and Misadventures

.375/404 Jeffery Saeed of 2012: Adventures and MisadventuresGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

Jim, Nothing heavier than 300 grains needed for the .375/404 JS. Nothing lighter is needed either. 300-grain KISS principle. I'll experiment with the 320-grainer later, but for now, every turn I take is leading me right back to the GSC HV .375/300-grainer, you know, that bullet that Gerard says is inferior to the 265-grain HV? Well, I tried drawing the ideal bullet for my rifle and this is what I got: (drawn at 2X scale but ogive radius stated was life size so drawing should be corrected for that, x 1/2)  No way to significantly improve on the GSC HV which is ready-made, and shoots sub-0.5 MOA at short COL. Perfect for a 1" nose projection yet workable both in the CZ magazine and a .375-Weatherby-of-2001-style throat. Minimal compromising here. Maximal optimization here:   Pictured above is a circa 2010 Walterhog that has been doing so admirably to date. The Standard Walterhog will eat the dust of the GSC HV in the .375/404 Jeffery Saeed of 2012 with a Rigby-length box. Progress. Crimp the GSC HV with 4 bands outside and 4 bands inside of the case neck, COL 3.820". No crimp on the TSX, between cannelures at 3.820". Or just leave them both crimped and at 3.755" COL if the velocity and accuracy are right. A shorter cartridge may feed more reliably, so a sub-3.7" COL in an over-3.8" box might turn out to be the smartest way to go, like Saeed does. Will see with my rifle. No problems with .376" bands in my .3756" (+.001"/-.000") diameter free-bore, no problems noted so far. No throat slug done yet. Testing will determine what is the optimum COL, 3.755" or 3.820". 1:10" twist (instead of 1:12") barrel is in transit by UPS right now. Keep It Simply Smart: KISS 300-grain bullets only in the .375/404 JS | |||

|

One of Us |

Ron, I understand the 300gr issue. My comment regarding the 320gr CEB MTH L04 bullet was that it would be easy for Dan to basically reduce the nose length of this bullet, which would also reduce the bullet weight, to fit within the COAL for your CZ. But if the unmodified 320gr CEB MTH L04 bullet isn't accurate in your rifle it'd be a needless possibility. Looks like the 4-bands in/4-bands out should work well with your 300gr GSC HV bullets. Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

Jim, I see no way to improve the design of the GSC HV .375/300-grainer for my purposes. Each of the .376" GSC drive bands is a "seal-tite" band. The solitary CEB MTH seal-tite band is .377" and the remainder of the shank is .375" full bearing. The bore-riding space between the GSC HV bands is room enough for all displaced copper by the lands, and compression of the bands by .001" in the grooves. It fits my free-bore diameter which may be up to .3766" diameter by spec. If GSC can still supply this redheaded stepchild of a bullet, I want more. USA available? ... | |||

|

| <Mike McGuire> |

Ron, I think we can say you are king of the .375 bore size. You have left me way behind. BUT........to complete the deal you need either a 375/06 or 375/08. | ||

|

One of Us |

Ron, Yes you're good to go with the 300gr HVs - guess you'll need to contact Gina to determine they'll be available from their USA facility... And yes, the MTH bullets - except for our Y01 banded models - are full groove diameter from BT to STB and then from STB to Ogive except for the two waste grooves. I wonder how much total engravable shank the MTH has compared to the total engravable area of the TSX? Oh well...just one of many questions that arise. But - your .375/404 JS is coming along very nicely... Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

Aw shucks, Mike you are just being a comedian, what? If you can't beat 'em then join 'em, what? Don't need anymore .375s now. Got the ultimate here. Cheerio to Mike375: | |||

|

| one of us |

Jim, Edited: The max pressure allowed is 63,817 psi. Just to KISS, I am going to resume loading everything at 3.755" COL with 86 to 90 grains of H4350 Extreme. Will see how these three bullets shake out in relation to QuickLOAD predictions. I have found that guessing the start pressure for each bullet is very important in getting close to prediction, after the biggest variable of lot-to-lot powder variation for volume of fill and burn rate. Changing the bullet diameter from .375" to .376" in QuickLOAD made no difference. It did not compute any difference. Re: Guesstimation for start pressures, I did this based on the QuickLOAD recommendations for monometal copper, brass, lead and jacketed (cup&core) bullets as applicable, plus the moly correction where applicable (reduces start pressure by about 33%), and then I apply a factor of my own, based on proportion of bearing shank (sum of length of bearing surface) compared to total shank length (sum of bearing plus nonbearing length along the shank). Any brass bullets have very low start pressure baseline as recommended by QuickLOAD. My estimated start pressures for these three bullets: GSC HV 300-grainer: 1100 psi (estimated) Sierra GK 300-grainer: 3625 psi (standard jacketed bullet value per QuickLOAD) Barnes TSX 300-grainer: 4047 psi (estimated) {Load data being recalculated with further refinements.} Since it is a bit presumptuous to call the GSC HV .375/300gr bullet the "Super Walterhog," I have decided to call it the "WalterDog." The perfect dog with which to chase a wildcat. First three WalterDogs fired in the .375/404 JS of 2012:  | |||

|

| one of us |

More of the latest Walterhog in the .375/404J on 10-11-2012:      http://forums.accuratereloadin...1411043/m/2341013081 Ah! The old hand-foot-and-butt creep through the grass. Appears Roy bagged an Outer Circle buffalo: That lion bit off the tail is the only qualifying characteristic of the otherwise magnificent old dagga boy, hard bossed with worn tips. Appreciate the bullet photos of Walterhog tail first under the skin of the off side, petals lost in early internal explosion, then penetration like an FN solid until terminal tumbling aiding in wounding, and one dead buffalo with one bullet? Perfect. If only the "WalterDog" (GSC HV 300-grainer) will work as well in the ".375/404 Jeffery Saeed of 2012," it will be a resounding success. On September 29 of 2012 The Hunting Started ******************************************* Week 2, Day 13: 10-11-2012 ******************************************* A-Team: 1 Cape buffalo in the medium grass. 1 Crocodile 1 Waterbuck No doubt a lot of bait patrol going on. B-Team: Chaperoning for Z-Team, and kindly posting for Z-Team. Z-Team: Zee hunting continues, second day. 1 Wildebeest/Walterbeeste http://tanganyikagame.com/index.htm | |||

|

| One of Us |

RIP I would make the point that tumbling and ending up base first isn't an ideal performance profile--no matter who Walter is. | |||

|

| one of us |

Wrong. All bullets have a tendency to tumble at the end of their paths, when they are passing through variable medium resistances and velocity is approaching zero. Shoulder sabilization goes away, as cavitation collapses at low velocity in a variable resistance medium, spin stabilization is nil in denser than air medium, and spin stops completely from drag in tissue. Dart stabilization from tail slap and CG-forward is all that is left, at low velocity. A narrower cylinder shape has better tail slap, and a retained mushroom has better CG-forward, but neither is adequate to stabilize at low velocity in tissue. Even a perfectly mushroomed bullet that retains all petals may come to rest sideways or base first. All FN solids will have a tendency to flip at the end of their paths in soft tissue. If the petals of a soft point blow off and it becomes an FN solid after doing the work of a soft, that is just excellent NonCon performance, and a dead buffalo. Saeed's Walterhog did it all. It even has a slight mushroom and is CG-forward while long enough for tail slap effects, but still flipped at end of path.  A brass NonCon might give better wounding effect of petal shearing (secondary missiles), but the copper Walterhog has some other advantages over a brass NonCon. A copper "WalterDog" will too. | |||

|

| One of Us |

The BBW#13s don't seem to tumble-within a buffalo--or an elephant Even the Non con had straight line, point first penetration. there would seem to be to much destabilization to fast with the Walterhog bullet. You are going to have to go aways to show that tumbling is desirable in a big game bullet. | |||

|

| one of us |

PS-free-bore lengths thanks to Jim's tabulation: .375 Blazer = 0.1025” .375 Dakota = 0.1025” .375 Ruger = 0.1250” .375 RUM = 0.1753” add: .375 WBY = 0.3700" .375/404 JS of 2012 = 0.3700" .375 H&H = 0.0000" This is a "leade-only antique throat." But there is .007" of chamber neck chamfer length then a leade that starts at .390" wide and 2-degree slope down to bore diameter. The distance from .390" diameter to .375" (groove) diameter is 0.2148". Thus the Efeective Free-Bore of this zero-PS-free-bore throat is .007" + .2148" = .2155" plus the plus tolerance of the chamber beyond minimum brass length (.0300"). Thus the EFB of the .375 H&H is .2155" + .0300" = .2455" This is the distance jumped to begin engraving in a zero-PS-free-bore .375 H&H due to the sloppy wide leade of the antique-throat: EFB (Effective Free-Bore) Dave Kiff (PTG) makes a standard reamer like this, which I suspect is SAAMI, and CIP shows the same kind of Leade-only/Zero-PS-free-bore throat. Other reamers exist for the .375 H&H that have 0.1750" PS-free-bore length. I have a Clymer reamer drawing for such a .375 H&H, and the spec diameter of that PS-free-bore is 0.376", probably also with a +.001"/-.000" tolerance. My .375 RUM M700 factory rifle is outstandingly accurate with PS-free-bore of 0.1753" length. If the "WalterDog" bullet is seated to COL of 3.590" in a .3700" length PS-free-bore of .3756"(+0.001"/-0.000") diameter, it shoots accurately enough. If the "WalterDog" is seated to 3.755" COL, that effectively shortens the PS-free-bore to (0.3700") - (3.755" - 3.590") = .370" - .165" = 0.205" For COL of 3.820", the equivalent becomes (0.3700") - (3.820" - 3.590") = .370" - .230" = 0.140" So with seating length variation I have the chance for 3 different "Effective PS-free-bores": .3700" .2050" .1400" Call this the EPS as opposed to the EFB (Effective Free-Bore) discussed with Jim earlier. For one EFB, three different EPS values. All of these EPS lengths are adequate for pressure control. QuickLOAD makes no allowance for free-bore in its calculations, it just assumes free-bore is "adequate." What free-bore does in QuickLOAD, and real life, is to increase the effective case capacity. Pyzda ponted this out on another thread. Thus the longer throat allows extra velocity at same pressure as in the shorter throats with shorter COL Longer throat and longer COL takes more powder, and requries more magazine length than a shorter COL. As long as accuracy does not suffer in the longer throat, all is good. That requires that bullet shape and length be a good fit to throat and magazine box. And it has to feed well. Heck, if I have a .376" diameter bullet inside a .3756"(+.001"/-.000") diameter throat, then I have ZERO FREE-BORE. Rather, I have a smooth bore of bullet diameter to start the bullet into the rifling with minimal chance for mischief. | |||

|

| one of us |

Shoot enough CEB brass NonCons, or brass BBW solids, into live game and you are going to find terminal tumbling. That is not a bad thing. That is also inescapable, undeniable. However, I do have a 1:10" twist barrel on the way from Pac-Nor, for use with WalterDogs and such. The Walterhog copies (by Bridger) that I had tumble in mid air were faulty. Based on an old prototype sample of one, they had sub-caliber bands (very inconsistent diameters), and the bands were too skinny in width of bearing as well, compared to latest Walterhog used by Saeed. Mine might have been marginally stable at velocities over 2690 fps, whenever the bands grabbed enough to spin up to speed in the 1:12". The "WalterDog" is much better for my purposes.   | |||

|

One of Us |

Hey Ron, Finally had a chance to wade through the recent posts… I’ve had to adjust both the shot start pressure and the weighting factor to match many of Michael’s chronograph results with the CEB BBW#13 bullets – just some of the things we go through so we can run our ‘what ifs’ with somewhat accurate results. Speaking of QL ‘what ifs’ – unless you have better accuracy at 3.820” COAL you’re basically just spending additional powder to generate the same velocity you’re getting with 3.755” COAL… Go with your absolute best accuracy combined with flawless feeding and ignore whether or not you’re maximizing your CZ’s internal magazine length… Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

Yep. My thoughts precisely. Cartridge Overall Length (COL) can be over done. Then it becomes Cartridge Overall Aggrandized Length (COAL). BTW, I scratched the "max loads" and will recompute, still using the same start pressures for the other three bullets, but adding a North Fork CPS with start pressure of 1754 psi (estimation based on solid copper and fractional bearing surface, no moly), with more accurate case capacity (oops), and limited to H4350 and COL of 3.755" for everything except the NF CPS being 3.445", just as it should remain. More refined garbage in this time: All 300-grainers All H4350 Extreme KISS North Fork CPS: 86.0 grains >>> 2797 fps, 60131 psi, 100 % fill Sierra GK: 90.0 grains >>> 2804 fps, 59056 psi, 95% fill GSC HV: 90.0 grains >>> 2835 fps, 60647 psi, 99% fill Barnes TSX: 88.0 grains >>> 2800 fps, 60156 psi, 96% fill | |||

|

| one of us |

I am conserving bullets, not to be wasted, but learned a lot yesterday. First, I checked the water capacity of my brass, made from Norma 404 Jeffery. I had been assuming a capacity of 119 grains for Saeed's wildcat was same as for mine. External dimensions of my cartridge may be as close as humanly possible ... But, my brass may be newer, and heavier or smaller internally, than that used for old estimates gleaned from Saeed's posts here. My brass at 2.810" trim-to-length holds 115.1 grains of water. First 5 pieces of brass pulled for weighing and filling with water using a hypodermic syringe with needle for micro drips, on a digital scale: Filled weight minus empty weight equals gross water: 1. 411.4 - 296.3 = 115.1 gr 2. 411.7 - 296.6 = 115.1 gr 3. 411.0 - 295.7 = 115.3 gr 4. 411.6 - 296.5 = 115.1 gr 5. 410.3 - 295.4 = 114.9 gr average gross water capacity = 115.1 grains average brass weight = 296.1 grains +/- 0.7 grains. Very uniform. Secondly, I learned that I have a bedding problem with my rifle. Scope seems to behave, adjusts properly. But, I often get two shots touching at 100 yards, then the third shot is 1 or 2 inches higher. Or I might shoot a sub MOA 3-shot group at 100 yards and then the next group is scattered. Any bullet or COL is susceptible. I have no bedding of the action, just 3 inches of the breech end of the barrel is bedded. The action is resting directly on the aluminum bedding block. Not good enough, I guess, needs a complete bedding job re-do. I will switch scopes too, just as a hopefully unneccesary check of the scope. But the chronograph data is good. My goal is to get about 2750 fps with any and all 300-grainers, at pressures less than the .375 H&H and .375 Wby. This will be easy: 4 loads chronographed 10-13-2012: North Fork CPS 300-grainer COL 3.445" H4350 86.0 grains >>> 2749 fps ave, with 13 fps ES for 3 shots (15 feet from muzzle for all chronographing). This gave a 0.847" 3-shot group at 100 yards, the best I could do yesterday. Note that the QuickLOAD prediction for this load was 2797 fps, but the two loads I have shot are on the same slope as QuickLOAD plot of velocity versus charge, just 48 fps slower at the range, than in the computer.  GSC HV 300-grainer COL 3.755" H4350 90.0 grains >>> 2846 fps ave, with ES of 4 fps for 3 shots. Previously 85.0 grains with COL of 3.590" gave 2699 fps. These two chronographed loads plot velocity versus charge on the same slope of line as QuickLOAD, but about 15 fps faster at the range than in the computer. Might have something to do with bullet diameter being +0.001" over groove diameter, regarding why my velocity was faster than QuickLOAD predicted. I did notice some difficult in chambering of the long-loaded GSC HV, after the throat was fouled with soot ... The WalterDog bullet will be euthanized or re-sized to .375" diameter with a Lee bullet sizer. Adjusting to 87.0 grains should give about 2759 fps. It seems that maintaining the same % fill, by adjusting COL shorter as powder charge is decreased, keeps the loads plotting on the same line slope as QuickLOAD. Works in this throat with this bullet anyway. This is about 99% case fill with both 85 grains H4350 at 3.590" COL and 90 grains H4350 at 3.755" COL. This is how free-bore allows pressure let-off, through adjusting case capacity via COL.  Barnes TSX 300-grainer COL 3.755" H4350 88.0 grains >>> 2745 fps ave, with ES of 15 fps for 3 shots.  Sierra GameKing 300-grainer: COL 3.755" H4350 90 grains >>> 2809 fps ave, with ES of 15 fps for three shots. This one seems to very closely match the QuickLOAD plot. So close that I have to use the same line for both:  | |||

|

| one of us |

Great cartridge design, original from Saeed and Dwight Scott. Throat of theirs is unknown, though mine is known to within +.001"/-.000" diameter pending the slugging. Great brass from Norma. Great reloading dies from Hornady. My rifle has a great trigger that has a 2.5# crisp break. Timney. I have no reason to suspect the scope or rings, yet. The "partial bedding" experiment did not seem to work for this rifle in the CZ Kevlar "drop-in" stock. Almost, but no cigar. Needs to have the bedding redone. Will keep the free-float beyond the first 3 inches of barrel ahead of the receiver. As currently, it allows a 3x5 note card to be slid between barrel channel and barrel, from forend tip to 3" ahead of receiver. Bughole accuracy with chosen loads is next. | |||

|

| one of us |

I hear that recoil is very tolerable with 85 grains of H4350 and a 300-grain Walterhog bullet. Even Walter shoots it well:  More recovered bullets. Most are pass-throughs and not recovered, but there is a bunch of shooting going on in Tanzania right now:  Even though there is some skidding on the lands, Saeed does OK at 100 yards with his Walterhog design, this accuracy was with the 2005 version of his bullet:  | |||

|

One of Us |

Good stuff Ron! This’ll be all over the map so bear with me. Re-looking at Saeed’s lineup of 300gr Walterhogs – very nice engraving on all bands except for the very thin upper band which reinforces the perception that the very thin upper bands serves as a seating band rather than a driving band and something to not worry about with the throat specifications of Saeed’s .375/404 JS rifles. Now regarding the .375/404 JS of 2012 – This I find very interesting as I perceive it to be ‘end usable’ for determining the proper EPS and EFB for other calibers… I notice with your latest load workups that you accomplished a 0.847” grouping with the 300gr NF CPS – did you perchance note the groupings of the 300gr GSC HV, 3.755" COAL, using 90.0grs H4350 and 300gr Barnes TSX, 3.755” COAL, using 88grs H4350? And the bedding block in your synthetic CZ stock – I’ve heard that the upper bedding surface of the block may not be 100% flat due to manufacturing tolerances – then one has the manufacturing tolerances of the bottom of the action to deal with as well. Sounds like you need to apply some ‘inletting black’ (or inletting gold if everything is black) to check things out… Also, as I’m not that knowledgeable about how CZ delivers their rifles (I haven’t owned any) – do the CZ 550s stocks use stock ferrules similar to the M98 Mausers? And if so, does your stock have an embedded stock ferrule for the rear action screw? Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| One of Us |

To my eye at least half of the 16 bullets shown in the above photo show definite signs of skidding- | |||

|

One of Us |

As I’m not sure how soft Saeed’s copper construction Waltherhogs are – though at least soft enough for the petals to fold back upon themselves and for the shank to expand – I wasn’t sure if the band abrading was from skidding within the barrel or from the bullets perhaps passing through heavy bone. Perhaps someone in the know – or at least can find out the answer – can answer what caused the band abrading. Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

Jim, Maybe Saeed's first band on the Walterhog is just a quide for seating and starting it down the throat and into the leade. He has previously said that he does not crimp at all with his Walterhog loads. It is so tiny that it would be hard to see the engraving in these photos, and any skidding would make that even harder to see any defined engraving pattern on that tiny first band. The ugly truth on latest load testing:  There is a randomness here, two close shots and then the third flies wild. Or all three fly wild like with the Sierra GK. Just the randomness of it all, suggests that my rifle has play in the bedding and there is some rocking or slipping going on, hit or miss, shot to shot. Same scope setting for these 4 loads. I asked Rusty to just bed the first 3 inches of the breech end of the barrel, my fault, an experiment. I should have known better:  The CZ wood stock does have the "pseudo-pillar" spacers on the action screws like a Mauser. The CZ Kevlar stock has a full bedding block. I am going to get full bedding done, but the block serves as integral pillars.     No correlation between COL, throat, or even bullet make used from one session to the next. Getting worse as velocity and recoil increase, suggesting the rifle action is moving or even flexing more in the bedding, or the extra stresses bring out more of what is going on, whatever that is. It ain't me! I'll get the bedding job FINISHED and shoot the same loads again and see how the 3-shot groups shrink. Forend tip pressure is the last trick, that alone has cut group sizes in half with a formerly free-floated, skinny-barreled rifle, for me. But this is a heavy barreled rifle, No.6 fluted, and probably won't need that. If it's really good, I might even try more than 3 shots each, but some of them thar bullets can be mighty expensive. The bullet makers must be mighty proud of them. | |||

|

One of Us |

Ron, Good to know that the full bedding block has the action screw spacers (my BC stocks are still in Washington state so couldn’t quickly check them).

Before you re-bed the stock, couple of quick questions… Was either of the action screws loose? Or perhaps not as tight as they’re supposed to be torqued? Does the action tweak down in the rear as the rear action screw is torqued to specification? Reason I ask is I’m just wondering if the bedding under the breech end of the barrel is slightly to thick which is allowing one or both action screws to loosen during repeated full-load firings. Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

NO NO NO! No "spacers" with a B&C Medalist or CZ Kevlar. Throw away the spacers that come with the CZ or a Mauser in a wood stock, and get proper pillars epoxied into place in the wood. The action screw spacers are not pillars. The bedding block itself serves as pillars, integral. My action screws were torqued to 65 inch-pounds, but that alone will not make up for lack of proper bedding. Will sort it out. | |||

|

One of Us |

LOL... No problem Ron. I understand the Mauser action screw ferrules aren't pillars in the sense of modern pillars but they darn sure kept the action and bottom metal properly spaced going back to 1898! And in the only 3 military stocks that I have the rear action screw ferrule was a press fit in the stock… Anyway, I did believe the B&C Medalist bedding block had a rear action screw pillar but mine are out of state so I couldn’t quickly check them. Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

"Throw away the spacers that come with the CZ or a Mauser in a wood stock and get proper pillars epoxied into place in the wood." Added a phrase to the above, edit. OK, I meant the CZ Kevlar is built similar to a B&C Medalist, regarding full bedding block. I have a B&C Medalist stock for Mauser. I looked at it. It just has a great big ol'hole where the front action screw goes, and there is some epoxy/composite on either side of that big hole. That will need a pillar added IMHO. It is not a big, solid block like on the CZ front action hole. The rear action screw does have an integral pillar machined into it, it appears to me, but the bottom half of that pillar is hanging beyond flush with the bottom of the block, again with some composite material around the bottom of the integral rear pillar, similar to CZ, giving the appearance that it might be a screwed-in or glued-in pillar, but there is some paint around the edges of that pillar that hide any possible joint, and I have not scratched it off. It is nonmagnetic and looks like the same alloy as the bedding block. The CZ Kevlar has a small diameter hole through a thick block of metal for the front action screw. Just needs the metal roughed up and a skim of epoxy bedding top and bottom of that. The rear action screw hole in the CZ is flush with the rest of the bedding block on top and like the Mauser on the bottom of the rear integral pillar. Non magnetic metal throughout on both of these stocks. I hope that is titanium-aluminum alloy. BTW, I took the .375/404 JS out of the stock. The action and bottom metal just fall away when screws are loosened, really a loose fit. There are shiny spots on the left side of the bedding block where the action is not contacting uniformly. This should be easy to bed throughout with all that room in there. I will do the barrel channel again too, sand it out towards the tip as needed, start with full contact bedding everywhere. Will show it to Rusty McGee, and tell him I'm sorry I asked him not to do it like that to start with. Where is the "kicking self in butt" emoticon when you need one? | |||

|

One of Us |

I don't recollect the exact 'specified spacing' range between the metal of the magazine and the metal of the action magazine well - but I do know that there should not be any metal to metal contact in this area on a M98 Mauser. I believe one of the old permanent threads in the gunsmithing forum covered this spacing - so a search there may identify the correct spacing range. Pillar bedding a M98 Mauser action - Paul Mauser designed the action screw sleeve on the bottom of the front lug to be a 100% metal to metal male to female fit with the front action screw sleeve of the bottom metal. Once you get the correct spacing of magazine to action' magazine well along with the front action male/female junction 100% metal to metal fit then all that was needed to maintain the action to bottom metal spacing was a properly sized rear action screw steel ferrule which was then press imbedded in the stock. Modern day, the rear action screw steel ferrule can be replaced with a larger diameter aluminum pillar permanently epoxied in the rifle stock. But the modern aluminum pillar and Mauser's steel ferrule for the rear action screw are designed to accomplish exactly the same thing - that being to keep the exact action to bottom metal spacing when installed within a rifle stock and the action screws are torqued to their proper tension. To install a permanent pillar within the stock for the front action screw will require Rusty to machine away the fron action screw sleeves so that that 100% metal to metal fit designed by Mauser is replaced by a correctly sized pillar. An Internet search regarding pillar bedding a M98 Mauser action should identify a few articles that completely cover the modifications necessary to the front action screw sleeves. Your CZ action is different from the M98 Mauser action in that your CZ uses the separate magazine box and bottom metal, similar to the current M70, M 700, and M77 actions, whereas the M98 uses a one piece bottom metal with integral magazine. And CZ has eliminated the 100% metal to metal male to female fit of the front action screw sleeves of the M98 Mauser design. But at least CZ kept Mauser's original action C-ring! I believe the correct bedding methodology with the aluminum bedding block is to torque the action screws to their factory specification while allowing the barrel bedding compound to fully dry. I believe this is only way to assure 100% action to bedding block contact with 100% barrel to bedding compound contact in the full contact area when the action is removed and then installed. Please correct me if I've misunderstood the bedding process with a full bedding block within the stock. Time to go roost... Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

Jim, I dunno all the specifics on Mauser bedding, will pass on that for now, I am still learning about the CZ 550 Magnum and the Kevlar stock. I previously had good results by drop-in of both a .416 Rigby and a 404 Jeffery into CZ Kevlar stocks, with no bedding: Just discarded the action screw spacers needed for wood stock, discarded the F-block needed in the barrel channel of wood stock, and torqued the action screws to 65 inch-pounds. Might need to bed more than just 3 inches of barrel on this one. Variations in action and stock may be enough to add up to "decompensating" instead of "compensating errors" here. This action is one of the earliest ones to come into the country in the early 1990s, has no billboard on the side of it, blank left side, no roll stamping there. It has "AHR" prefix on the serial number: "AHR X0001" It puts a nicely centered indent on the primers. Full bedding. | |||

|

One of Us |

Ron, M98 Mausers are a study unto themselves. Unfortunately most folks don't understand the purpose behind the factory steel ferrule for the rear action screw and toss it along with the military stock when they restock the action - then they complain that they have action flex when they torque the action screws... Simply removing the factory steel ferrule from the military stock and reusing in the replacement stock would have eliminated the action flex - of course this assumes the serial number on the action matches the serial number of the stock. Regarding your early model CZ/AHR serial number action - could there be sufficient minor dimensional difference between the action screw lengths for your action and the current standard CZ 550 - or perhaps a better way to pose the question is a difference in screw length to maintain the proper spacing between the action and the bottom metal? Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

The Mauser spacers loose in the wood do prevent compression of wood, or expansion of some areas, but they do not prevent wood shrinkage. I think a pillar bedding can be done well with either Mauser or CZ 550 Magnum. The slide-into-stock spacers become a bottomed-out condition (metal on metal) in either of those actions. I want the torque of the screws to be acting on fixed pillars to maintain proper tension and mag box relation to bottom of the action, either action. I also do not want the instabilities of wood. So just color me uncouth: Any dimensional difference of early CZ action versus latest: Maybe, but proper bedding of action should take care of that. | |||

|

One of Us |

Yep I agree – synthetic stocks don’t shrink! Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

The adventure continues, fingers crossed, I take full blame:  | |||

|

One of Us |

Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

So far so good. It is all black and shiny, tight fitting, hardened ACRAGLAS for three inches of barrel and back to mag box well. The mag box well is bare aluminum bedding block. The barrel channel is sanded out to slide a crisp new $20 bill between it and the barrel, all the way down to the 3 inches of full contact near breach. The 3x5 note card is a bit tight now, it started sliding in a few inches then I was afraid I would tear the card in half if I slid it any farther. One dab of ACRAGLAS at the top of rear pillar. Did nothing to the bottom of the stock, as bottom metal fit well there.  A bit of gap where the side safety was removed for replacement with Lapour 3-pos safety on the bolt shroud, but that won't affect accuracy:    Now I will show it to Rusty and ask what he thinks about doing the next one like the above, only prettier. Photo below is of a 404 Jeffery that broke its wood stock and got dropped into a CZ Kevlar stock. This is a newer production action with the CZ billboard on the left side. I do indeed now detect some differences in it versus the older AHR action used on the other one.  | |||

|

One of Us |

Hey Ron, Looks like a pretty good job. One nice thing about the full-length bedding block is that you’ve zero need to be concerned with a small amount of relief between the stock and rear of the action. You could have used some of the bedding compound along the top-edge of the stock – along the sides of the action back to the rear of the action just to close up the gap between the metal and the stock to a minimum – but that’s more of a personal thing. I spoke to Steve a few days ago about the Brockman sling stud (also sent him an email you’re your photographs of it uninstalled and installed in the stock) – he liked the idea and believes it’s the perfect solution to potential hand-web pinch with the standard forward sling stud. A couple will be on their way shortly for him to install. We also discussed glass bedding my B&C Medalist stocks – we agreed as the stocks are rifle specific, and not going to be swapped amongst a number of rifles that my rifles, that they should be far more accurate with a full-glass bedding of the action and barrel – with barrel channel being free-floating for the barrel except for the 1st 3” of the chamber end – to assure that the stock to action fit is perfect. I’ll likely have CAS II do the glass bedding while he’s doing the Cerakote of my metalwork – that way when my rifle arrives there’ll be no additional work needed before range time. Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

Jim, Yep a Brockman forend tip sling stud is great. And yep, I can do the cosmetic top edge glassing on the rear sides of the action and at the tang and removed side-safety gap as a separate step, after I make sure it shoots. Will let it harden for a few days before I shoot it again. Rusty will do the next one with full bedding, no doubt will be prettier than the one above. PacNor 1:10" is in his shop now. | |||

|

One of Us |

looking good there! Passion of the purist on display. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| one of us |

Thanks, boom stick. We'll try to be even prettier on the next one, yet remain pure, until fouled by brass CEB Raptors. | |||

|

| one of us |

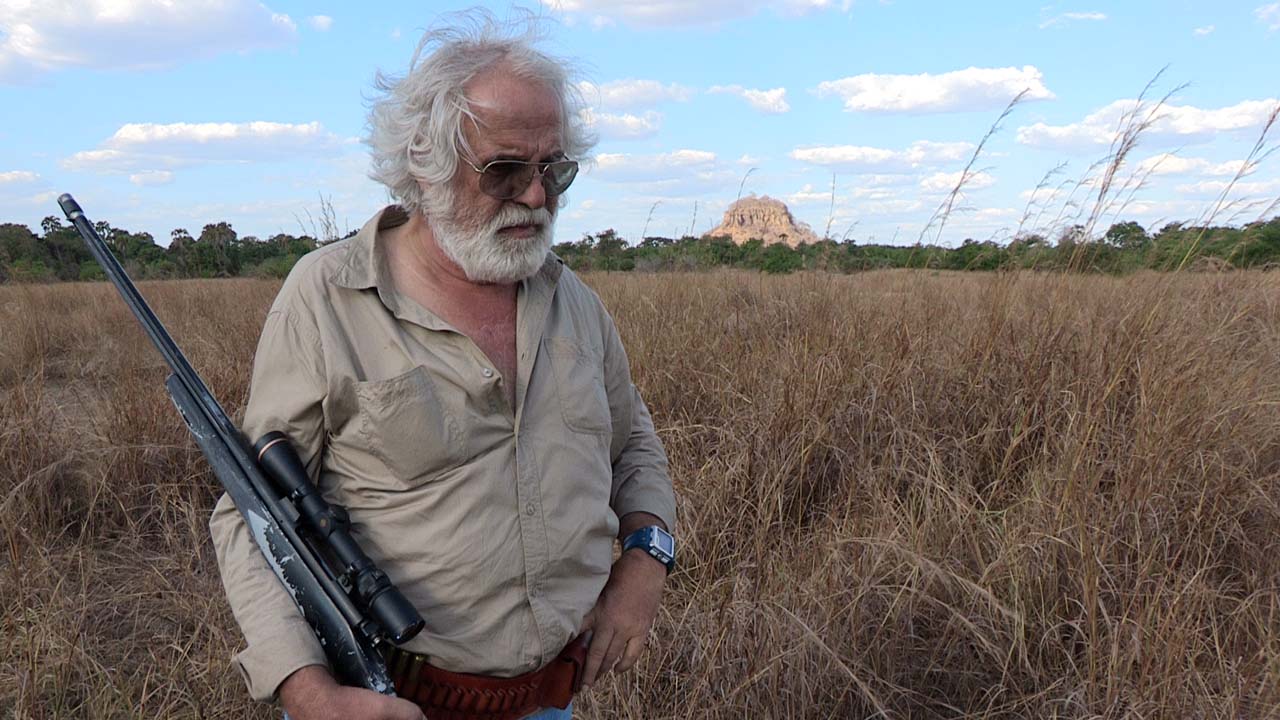

The latest borrowed picture of a .375/404 from Saeed's thread. Here we see Walter cradling the original, shocked (so sayeth Saeed) that he actually killed a cape buffalo. Obviously awed by the versatility of the .375/404: "Shock and Awe in the Selous"   | |||

|

| one of us |

Started over post bedding. First shot with fire-forming load at 100 yards was on paper. Adjusted scope and next 3 shots went into 0.291", near the bullseye, with fire forming load! Then I shot an 81 grain charge of Varget and CEB ESP 237-grainer. Knowing it would be way higher than the fire forming load, I held POA on the bottom of the 12" orange circle:  Adjusted scope with the next two 81-grain charges, then moved on to 82-85 grains of Varget.   The faster the velocity, the higher the bullets land, and though a sub-1.5" 3-shot group at 100 yards is acceptable for most big game hunting, I will not waste anymore of these long brass Raptors in .375 Caliber until I have a 1:10" twist to try them in ... The temperature was 52 degrees F. This was a different lot of Varget used today. For academic purposes the 85-grain charge clocked: 3105, 3103, 3100 fps, average 3103 fps. No pressure signs. QuickLOAD predicted 3077 fps and 63,496 psi for 85 grains of Varget. That's as far as I go with this 237-grainer. That's the best I can do with this CEB bullet, with COL = 3.695". The fire-forming load with Speer 235-grainer has COL = 3.550" and velocity is about 2736 fps, last check. | |||

|

| Powered by Social Strata | Page 1 2 3 4 5 6 7 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  .375/404 Jeffery Saeed of 2012: Adventures and Misadventures

.375/404 Jeffery Saeed of 2012: Adventures and Misadventures

Visit our on-line store for AR Memorabilia