The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Remington-Walker Explanation

Remington-Walker ExplanationGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

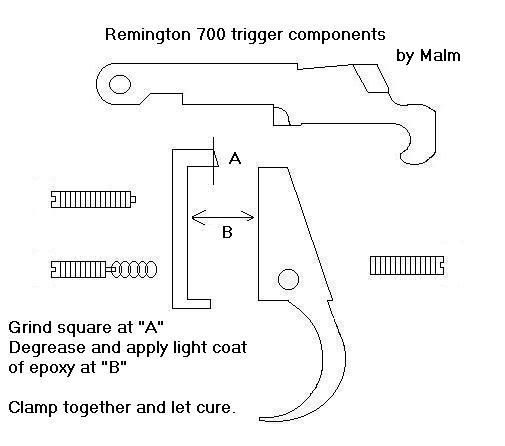

REMINGTON-WALKER TRIGGER EXPLANATION ©copyright 2010, H.J. Belk INTRODUCTION-- This paper is published as a public service aimed primarily at gunsmiths and advanced amateur gun enthusiasts that have a curiosity about the fascinating mechanics involved in modern firearms and are willing to look at very easy facts and features and figure out how it works. Remington-Walker triggers are more complicated than pliers, but not by much. Much of their mystery remains because the design is so like others in appearance, but totally different in operation. The author has a life-long love affair and intense interest in what makes guns do what they do and how to make them do it better by design instead of blind luck. For the past seventeen years, much of the gun study has been as a result of law suits involving firearms and their design. It has been an enlightening experience that needs to be talked about. I'm in no way picking on Remington, but they're in the spot light right now and actual facts are hard to come by on this subject. I've testified as an expert in Federal and other courts in civil and criminal matters in several states. My testimony has never been disallowed. There is a difference between studying design and function by taking things apart and comparing what is seen by a parts diagram and testifying to how the gun operates to a great degree of mechanical certainty. When testifying of how something happens, certainty is essential. The rule of 'follow the forces' in gunsmithing is a good one. Once forces and pivots are seen and understood, the entire trigger is no longer a mystery. Just because it looks like any other trigger is no cause to think it operates like any other. It does not. Attacks on the author by those that have not read this paper while actually examining a Remington-Walker trigger and the patent language pertaining to it will be happily ignored. Facts are facts and I'm trying to explain how to actually see those facts so you can come to your own conclusions based on mechanical knowledge instead of what was heard or said somewhere. Questions on this paper are gladly answered but preferably in the public forum. The purpose is, after all, the education of a subject out of normal vision and experience of the shooter. If you want to talk politics or personal appearance or what you think of me or something else, please move it to another thread. This discussion is about one particular family of triggers that are present on more than seven million rifles spread all over the world. Remington-Walker-Haskell trigger--- Please reference U.S.Pat. 2,514,981 That's the trigger we're talking about and it's different than all others. There are pdf download patents available without charge several places on the internet. To fully understand the operations and failures of the Remington-Walker trigger, the drawings and the text of the patent are MOST important. Print it out, if possible, for ready reference. It is the heart of the Remington 'problem' in 600 and 700 series triggers. This applies to all models but the M-788 which has a one piece trigger design in it. The patent drawings are probably different than the trigger you see in your rifle. Over the decades many changes have been made to the various parts. I'll explain the differences and what effect they have on operation and safety, later, but here's a rough test to see which 'generation' trigger is in your rifle. Remove the bolt and look down in the rear tang at the sear. If there is a stack of four parts, the outer housing and the two sears, it's an early gun and should be treated with special care. The more modern sears are chromed sintered metal and of one piece. The second test is to see if it has a bolt lock safety. Does the bolt open easily with safety ON? If so it was made after 1982. If you have a bolt lock gun, cut the lug off so it's defeated. Just grind off #32 Fig 1 of the patent. If the face of your trigger is smooth without the ridges commonly found on the face of triggers, it is a new X-MarkPro trigger that has a solid trigger and no connector. It was made after October of 2006. I have closely examined several X-Mark Pro triggers and their prototypes. It is as good as any trigger on the market and better than many. It's just 60 years late. With those comments I'll dive into a subject I extensively covered on this site and others ten years ago. The fact that the plane you're flying in has not crashed is no evidence that crashes don't occur. That pretty well sums up anecdotal evidence. Just because your rifle's trigger has never, ever done anything but what you directed it to do is no evidence of the lack of a defect. The defect is there and it's unpredictable and many times it won't repeat no matter what you do. The scientific method depends on masses of information when the occurrence is rare and non-repeatable. There are thousands of people that have written letters of complaints that describe the exact same failures time after time. The defect is in the trigger and just because it works now does not mean it won't fail in the future. Basics-- The Remington-Walker trigger is an “Over-ride” trigger system. That means it's not a “Direct-acting” trigger that pulls the sear out of position with the cocking piece (like M-98, 03, etc). An over-ride trigger props up the sear and is not attached to it. Winchester started the over-ride, or 'negative angle' trigger in hunting rifles in the M-70 in 1937. Sako made an override trigger contained in a housing that was then fastened to the action. Many custom trigger makers copied it just after the War. Timney, Dayton-Traister, Canjar, Jewel, Ruger M77, A-bolts, Tikka - just name a modern bolt action rifle and it'll have an over-ride trigger in it. They are crisp and allow very good trigger pulls. They are the 'standard' in modern bolt action rifles. The Remington-Walker is different than all those others and patent #2,514,981 tells us why that is. Figure 1 of the patent shows a jumble parts that usually makes people slightly ill to try to cipher it out. Here's a better representation with the parts labeled in common language and direction of movements given to hopefully, though crudely, better 'see' what's inside.  Notice the area inside the red circle. When the bolt closes, the cocking piece pushes the rear of the sear downward so that the sear rests on the rear corner of the connector. That overlap is the 'sear engagement'. Its usually .018 to .025 inches which means the rifle is prevented from firing by about .004 square inch of steel, at most. In this position, the cocking piece is held by the sear, which is pressing down on the top of the trigger-connector. When the trigger moves forward the sear falls and the firing pin rushes forward to fire the rifle. The safety cam lifts the sear off the top of the trigger-connector and locks the sear into the cocking piece so the gun can't fire, but the trigger and connector are free to move. When the safety is rotated to OFF, the sear comes back down on the trigger-connector. This is a simple 'Sako-style', modular, over-ride trigger. The fact that the sear is hinged at the front instead of the back makes no practical difference. It can be seen by this simple motion of the safety and sear that the trigger and connector HAVE to come back to the full rear position for there to be security in the sear / trigger engagement. In its simplest form, an over-ride trigger is two levers and two springs and two retaining pins. The M-70 is exactly that, plus an over-travel adjustment. The 'Sako style' over-ride triggers, contained in a housing having more parts, operate exactly the same---The trigger props up the sear and when the sear is allowed to fall, the gun fires. In the Remington-Walker trigger, the safety 'problem' is NOT in the safety. This is a common misconception but it's important to realize the Remington-Walker safety is not the cause of firing without a trigger pull. The safety could be called a 'victim of circumstance' in that it is converted to a trigger without the shooter's knowledge. How does it do that? Let's take a look at some patent language, shall we. Go to page 3, beginning on line 60 and read through to Page 4, line 61. This description has several parts and pieces that need examination. It starts by telling how the connector (you'll hear that word a lot) is not fastened inside the trigger housing, but 'flexibly mounted' in it. That means it's loose on the trigger but for the trigger return spring pushing against it. A lot of the verbiage describes nifty ways of making the housing out of a stamping, but that was discontinued many years ago. Page 4, line 22 through 40 is where it gets interesting to an experienced shooter. “This stop screw provides an adjustment to positively stop trigger movement just as the sear is released and makes possible the complete elimination of undesirable trigger slap or overtravel.” Page 4, line 40 starts a section that needs to be examined very closely: “ If we examine the functioning of the unit, we will observe that the trigger and connector move as a unit,...” and line 44, “At this point the trigger stops but the connector ….” Hold on, right there. Let's read that again and make SURE you know what that says, then try it on your UNLOADED rifle. Does the trigger stop it's motion as the sear drops off of it? If it does, the patent makes sense. The operation of the connector would shorten the overall travel of the trigger to only the amount of the sear engagement and nothing more. But, if the trigger is going to travel until it hits the stop screw anyway, why complicate the trigger with a part that has no benefits? The amount of motion in the trigger is as little as it can be made if the corners are square and the sear falls cleanly from the corner of the trigger. EXPERIMENT-- Take any unloaded, bolt action rifle with an over-ride trigger in it (anything bolt-action and civilian). With the rifle uncocked and bolt closed, carefully pull the trigger several times and note how much movement there is. It's usually about .020 inch or about two thirds the thickness of a credit card. What the patent is saying is that the trigger does not move that .020 after the sear trips. It says the trigger stops when the sear trips. That, of course is demonstrably not true. Try it on any rifle. The trigger 'follows through' as the gun fires. You can't stop it short of the stop if you wanted to. So, what are we left with? Using .020 inch as the sear-trigger engagement figure and assuming the pivot pin is near the center of the trigger, it can be said the trigger pull is .020”, plus a clearance after disengagement to allow the sear to fall without touching anything. Call the total trigger movement .030 inch when the trigger pull plus overtravel is figured. By actual experiment you can see that the movement of a Remington-Walker trigger is exactly the same as any other trigger having the same sear engagement and the nonsense on Page 4, line 30 does not apply. “...for it is not practicably possible to produce and maintain absolutely sharp square corners on the engaging surfaces of the sear and conventional trigger.” Nobody says that an absolutely sharp square corner is needed to make a good trigger, and everybody but Remington has done so. So, why the connector? If the connector really doesn't do anything, why have it? Is it cheaper than say a heat-treated trigger by any other maker? Possibly, but others have solid triggers. Does it, in ANY way, make the trigger a 'better' trigger? No, it's just different. It does not reduce the trigger movement at all, but it's different simply because it's more complicated. It seems to be the perfect example of a new design patent as the result of one little change to something invented prior. In this case, the improvements and attributes said to be present in the Remington-Walker don't perform the function claimed in the patent. The change in the trigger design was for the purposed of a patent and not for performance. Operation-- An over-ride trigger must, absolutely MUST, return to full position after every shot. The trigger return spring is there to do that job. That's the spring you feel in the trigger when the rifle is not cocked. A trigger that does not return to the proper position reliably under the sear is more likely to cause the gun to fire without the trigger being pulled. That is simple physics and easily set up in demonstration. “Return to battery” for internal trigger parts is part and parcel of over-ride trigger operations. The Remington-Walker's 'trigger' is not the piece you put your finger on. The part that acts as the trigger under the sear is actually the connector which is 'flexibly connected' to the trigger body. The trigger return spring pushes the connector which then pushes the trigger body into position under the sear. The connector offers a complication that is not needed in the trigger. The addition of the connector only adds to the complexity of what is a very simple and amazingly reliable mechanism when its parts are limited to only what's necessary to do the job. Is a mechanism that's called upon to return one lever with one spring more reliable than a spring pushing on an intermediary part and then the lever? Of course it is. The fewer parts, the simpler the mechanism, especially when dealing with simple levers. With the re-positioning of the trigger-connector required after each shot, in the presence of recoil and powder residue and debris, the answer becomes even more certain. More parts means more complications without benefits. HOW DO THEY FAIL? Remington-Walker triggers are subject to several failures all due to displacements of the connector inside the trigger housing. These failures are common enough to have acronyms for them: FSR-- Fire on Safety Release. How many people have pulled the trigger with the safety ON just to 'test' it out? I know of hunter safety instructors that teach it as a good thing to do every time the safety is applied. How many times is the trigger pulled while the safety is ON but not by the shooter? That's probably a rarer occurrence but it does happen, that's why manual safeties and trigger guards are put on guns. Should the trigger be pulled on a Remington-Walker, and the connector become displaced so that it does not return with the trigger, the shooter feels the trigger return not knowing the connector did not follow along with the trigger to its proper place under the sear. In that position, the safety lever is holding up the sear and the rifle fires when the safety is pushed to OFF. Prior to 1982, Remington rifles had a 'bolt lock' incorporated with the safety lever. (#32 Fig. 1) That bolt lock means the gun has to be taken off safe in order to unload it. FSR is one of the most common failures and the one that's caused the most damage, injury and deaths. In simple terms it's the improper displacement of the connector during the time the gun is ON safe. The 'trigger' is in the proper position, but the connector is not. JO—Jar Off When the gun fails due to impact it is said to have 'jarred off'. Precarious 'perching' of the sear on the very corner or edge of the connector causes a fragile connection that can fail with bumping or jarring. In all other over-ride triggers, this displacement is usually caused by improper adjustment of the sear engagement screw . A Remington-Walker can change that engagement dimension and drastically change the security of the system by simply capturing debris between two internal parts. It 'adjusts' itself to little engagement and just as quickly adjusts the other way as the debris is dislodged by the recoil of the shot. FBO and FBC-- These refer to firing without a pull of the trigger when the bolt is opened or closed. This is a variation of a common 'Jar Off' caused by vibration of the bolt closing (easy to reproduce by mal-adjusting the sear engagement.) or the change in alignment of parts as the bolt handle is touched to open it. In both instances the most common cause is a connector being held out of position by debris, dirt, powder flakes, dried grease on any number of things that trickle through the mechanism as it's fired and stored. Fire on bolt close many times happens on the first loading after long storage. By design, the connector is pushed away from the trigger body when the rifle is in the fired position. That gives a chance for lint and debris to collect in sufficient quantity to alter the sear engagement the first few times the gun is then 'exercised'. Can any of these failures occur in other triggers? Yes. The operation of over-ride triggers, whether Jewel, Timney, Canjar, or Remington-Walker is the same. The trigger is a prop for the sear. If it doesn't properly support the sear under knocks and bumps a hunting rifle takes in doing its job, a discharge without a trigger pull can happen. The point is that the Remington-Walker has an extra 'trigger' that does NOT do the job it was patented to do and it's much more subject to become displaced than competing 'solid' triggers. Why is that connector in there? Over-ride triggers, by design, are very fragile things and scary to think about when you also consider the risk involved. That they work well enough for a hunting rifle could have been disputed before the M-70 made it a fact in 1937. What had been known as a 'target' trigger became mainstream and a hunting trigger. The M-70 has two parts pinned in a milled recess in the bottom of the receiver which keeps side to side motion to a minimum so the two parts are held closely in alignment with each other and the cocking piece. The M-70 trigger scrapes the sear surface clean into a trash trench cut in the trigger on each shot. There is no housing to catch debris. The sear comes up through a port in the rear tang which allows very little contamination of the trigger parts. The sear spring is nearly sealed and debris is blocked from entry into critical areas. 'Bad' M-70 triggers are the result of bad gunsmithing and usually found on match rifles. Otherwise they're very reliable and after a period of 'break-in' are usually very 'good' triggers. Points to consider--- The Remington-Walker has an extra part that's free to move around inside the housing. That's the connector. The connector is displaced from the front of the trigger on every shot due to the angularity of the back edge of the connector which is impacted by the corner of the sear as it falls. That is by design. Page 4, lines 46-50. “...and, as the sear is cammed down, the radii existing on the points of the connector and the sear cause the connector to be cammed forwardly and completely clear of the sear step. ...” In a mechanism subject to environmental conditions as well as lubricants and powder residue, two parts that separate several times during recoil are subject to a wide variety of contamination between them. As can be seen by study of the mechanism and it's patent, the Remington-Walker trigger is not self cleaning and it is housed within steel walls, but the unit is open at the top where the greater amount of such contamination is present. The top of the Remington trigger housings are totally exposed in the rear tang of the rifle. At each operation of the sear, debris is 'pumped' into the housing. (Look at the top of the bolt release to see the stuff that comes all the way through the trigger.) Each operation of the bolt pushes more material into the vicinity of the sear opening. Remington-Walker triggers do get dirty and they can't be easily cleaned without dis assembly. Dis assembly of the trigger breaks the factory seals. The connector is, in reality, a separate flexibly mounted trigger. It cannot be felt by the shooter. The position of the connector can be different than the position of the trigger without the shooter knowing it. The shooter can not know the position of the connector, it's out of his control and out of his view. Practical gunsmith's test of the Remington-Walker trigger--- Over the decades, standardized tests of Remington-Walker triggers have been developed to show a trigger that is prone to repeatable failures. These tests are simple, non destructive and can be very useful in identifying triggers that are demonstrably bad. It must be kept in mind that just because a trigger passes these test does NOT mean it's safe. As seen by the design, the defect is inherently present in the trigger. It just doesn't always fail. The shooter has no way of knowing when that failure might occur. “Tricking” a trigger is done by carefully placing the safety lever in the 'null' position between fire and safe. Some guns won't perch there, some will. With the safety perched between detents, pull the trigger and release very slowly. Pay careful attention to a tiny 'click' as the trigger is pulled. If it's there, the gun will likely fire when the safe is pushed to OFF. Try that test several times and flip the safe off after each careful pull. Tricking is a way to determine if the lift of the safety cam is enough to clear the top of the connector in half-way position. “Screw driver Test” is done with the gun cocked and ON safe. Push against the bottom of the connector, seen just in front of the bolt release leaf, with a screwdriver or punch and then push the safety to OFF. If the connector is sloppy on the trigger it will over ride the front of the sear so that the sear has no support when the safety is released. Guns that fail this test can sometimes fire on safety release after suffering common vibrations in a vehicle or on horseback. “Sear lift test” assures the safety cam raises the sear high enough to not drag on the connector when on safe. Place the rifle safety ON and pull the trigger several times and release it slowly. If the connector drags on the bottom of the sear it can't get back under the sear to catch it as the safety is flipped OFF. Guns that have been dropped while on safe can develop this failure by denting the safety cam. Trigger adjustments-- Just be aware that the clear to cloudy-yellow sealer found on Remington-Walker screws is put there by assemblers as the trigger undergoes final adjustment at the factory. When that sealer is removed, the company has a certain amount of deniability and 'blame' is transferred to the one doing the adjusting. (I know, I know!!) I've adjusted Remington triggers for forty years because so many are useless without it. Just be aware of the liability involved and how it works so it's not made (much) worse by alterations of the surfaces or excessive adjustments. Trigger repair--- The Remington-Walker can be made into a solid trigger system without using the connector by replacing the trigger and connector by an aftermarket or shop-made trigger, OR, the connector can be epoxied to the body of the trigger as long as one thing is done very carefully; The rear of the connector has to be ground square after the epoxy sets, BUT the actual disengaging corner of the connector has to be left in its' original position relative to the center line of the trigger pivot pin. It takes a precision grinder and fixture to do it right. Do it wrong and the trigger is even more unpredictable and could become very dangerous. Without grinding the rear of the connector square, the sear hitting the angle will soon break the epoxy bond and the trigger is worse than before. In the coming weeks, the Remington-Walker trigger is going to be in the news. Those that know guns will be answering questions from those that don't. Please have the facts and please, please just look at the mechanism and the patent and understand how it all works and it’s then very easy to see how it also fails. Defeating legislation through education. There is no safe direction to point an unsafe gun. | ||

|

| one of us |

Fascinating reading. Wish I understood it better. Howard Moses Lake, Washington USA hwhomes@outlook.com | |||

|

| One of Us |

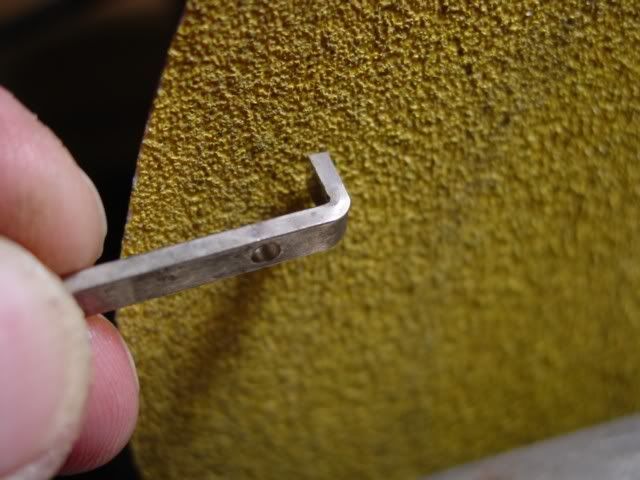

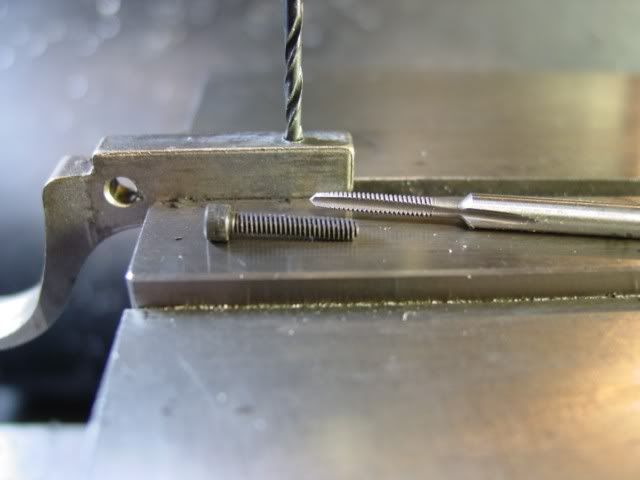

Here are a few pictures that show the various parts and their relationships. This trigger exhibited EXACTLY what Jack talks about and prior to my dis-assembly it had never been worked on.   | |||

|

| One of Us |

Great explanation. I have always preferred the two stage military triggers of Mauser, Springfield, M16, etc. I wish someone offered them for the Win 70, Rem 700, and other modern rifles. If they did, I'd convert every rifle I own to one. CAS II - Nice photos. It is amazing that the connector, which acts as the trigger, is just floating around with nothing to restrict it but a little spring pressure. . | |||

|

One of Us |

FWIW, this is how I originally dealt with the problem.  This is how I now deal with it.   Well, that and a thorough cleaning! _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

I had an aftermarket shroud/safety/trigger setup on a mauser in 264 that I have, it would do the first acronym above, if it were on safe (side safety) and you pulled the trigger, it often on taking off safety would "fire" thankfully I discovered this on an empty chamber. I ended up going back to a military shroud with a buehler safety, kept that trigger which actually is pretty nice. I think I understood the above, even without the pictures, thanks for the writeup. Red | |||

|

| one of us |

Actually, there is no Design Flaw with the Walker Trigger. If there was, every rifle manufactured with one would exhibit the problem. However, there are things that can make the Walker Trigger operate incorrectly: 1. Worn or Broken parts in the Trigger Assembly. 2. Trash, Dirt, Crud, Solidified WD-40, Gunk in Solidified Lube(s) - basically - Non-Existant or Improper Trigger Maintenance. 3. Mis-Adjusted Triggers which allow the Sear to Release when the rifle is Dropped, Bumped or Jostled. 4. Pulling the Trigger with the Safety OFF. Either by accident with a Finger, Twig, Button, etc. Now, here is the critical part that many people never seem to understand - the exact same thing can happen on ANY Firearm ever manufactured from Battleship Cannons to Saturday Night Specials. Here is one example of a M70 Firing when the Safety is Released. | |||

|

| one of us |

Very well written and easily understandable, Jack. HotBoor, you miss the point entirely. Yeah, we all know that a gun can fire when the safety is taken off if the trigger was pulled when the safety was on. And we all know about those other typical failures. The difference is (and Jack explains this very well if you had bothered to read the 'effin article) that the connector, which is not present in other designs, can get out of place without the handler being able to detect that it is out of place. I have guns that can be fired "FSR", but you can tell if they would have fired FSR by pushing the trigger forward. Pushing forward on one of these RW triggers won't necessarily tell you anything. | |||

|

| One of Us |

I've just received permission to use photos from a case this year.  This is slice of CT scan done at North Star Imaging in Rogers, Minnesota. Their website has video samples of what they do. it's near magic. In this view the muzzle is down and the bolt handle is to the right. The circle at top right is the safety detent ball. My reference lines terminate in the body of the trigger. Just below that is the connector with the nose of the over-travel screw leaning into the hole, off-center. This is a Model 660 Mohawk (gold trigger) that used a folded metal housing but a one-piece sear. The OT screw was tapped through two tabs bent from portions of the side plates. It's obvious the tap was run into a crooked hole which resulted in an FSR and a fatality. The gun would not repeat the failure and two visual inspections failed to see the fault. The gun was clean, rust free, wear from maybe 50 rounds, and had never been out of the stock. WHY is the connector in Remington-Walker triggers? Anyone? Defeating legislation through education. There is no safe direction to point an unsafe gun. | |||

|

| One of Us |

You should know this before post such a long thread hot air. If you don't know quit posting all of this junk. | |||

|

| One of Us |

Facts are facts and it's best to know them. Saeed said as much when I asked his permission. Defeating legislation through education. There is no safe direction to point an unsafe gun. | |||

|

| One of Us |

Facts according to who? I deal with these issues every day. Everyone has a different notion as to what constitutes facts. Dropping Saeed's name does not alter the facts. | |||

|

| One of Us |

Then I ask you to kindly print out the patent, grab a M-700 trigger and see for yourself. DON'T take my word for it. I wrote the instructions and others say they're plain and easy to follow. I'm working on getting you the PE version, if it makes you more comfortable. Defeating legislation through education. There is no safe direction to point an unsafe gun. | |||

|

One of Us |

And probably up until this point, hadn't been pointed at someone. I am a big personal responsibility advocate. I'm sorry to hear someone died because of careless gun handling practices, but I don't see where Remington can be blamed for bullet placement. The CT scan should have been of the individuals head, who was holding the gun when it went off, in an attempt to see what the hell they were thinking. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

I do not disagree with the contention that the connector may cause the FSR. However,on every trigger I saw which exhibited this tendency, the cause was unrelated to the connector and it's movement in the housing. Instead, in every case (and they were fairly numerous), the cause was a dimensional problem with the safety itself or the sear upon which the safety acted. The safety did not lift the sear up off the connector. On these triggers,the problem would have existed with or without the connector. It was a manufacturing problem rather than one of design. Indeed, the same problem has been evident on Model 70 Winchesters on which the safety was worn or improperly fitted. Any design which depends upon disconnection of the sear from the trigger, has the potential to fire when the safety is released if the trigger has benn pulled while the safety was on. This, providing the safety does not adequately lift the sear from contact with the trigger. This is the case whether the safety works upon the sear directly (Remington) or upon the striker (Winchester, Mauser, Weatherby. The trigger connector WAS a superfluous part and DID create the potential for FSR but it was not the only cause and quite possibly, not even the primary one. I still believe the cause was, and is, as much a problem of quality control as it was a design flaw. If Remington had eliminated the connector yet still produced safety levers which were too short, the FSR problem would still have existed. For instance, on a Remington 788 trigger with a worn safety or sear, the possibility of a FSR is existent and I have seen it; one piece trigger and all. In the end, the elimination of the connector by Remington might not have saved a single life but it would have made the lawyers find a different approach without the connector to pick on. It was about three years ago that fellow brought in a 700 with the new "safe" trigger because it had fired when the safety was released. The cause was a combination of misadjustment, gummed up lubricant in the trigger, and cold weather and the result was the same as if the trigger had been saddled with the Walker connector. In my view, the connector has become a convenient scapegoat and to give the impression that the elimination of the connector is a certain fix for the FSR problem is just plain wrong. Regards, Bill | |||

|

| one of us |

If the examiners were unable to repeat the failure how do we know just what failed? Howard Moses Lake, Washington USA hwhomes@outlook.com | |||

|

| One of Us |

We know there is a manufacturing defect that makes it likely the connector cannot re-attain the in battery position. Remember the connector slides up and down over that screw. It's not supposed to touch. Defeating legislation through education. There is no safe direction to point an unsafe gun. | |||

|

| One of Us |

Bill--- The difference is in what the shooter controls and can discern from feel in his rifle. I'm sure you can tell if your trigger is .030 out of position, I know I can. The RW doesn't have that. The trigger almost always is in the 'normal' position in the trigger guard when the connector is displaced. You can't manually replace the connector like you can a solid trigger. I'm sure any bad sear you've seen (of the new sintered type) was messed with by somebody not knowing what they were doing. I've never seen a bad one or heard of one that was unaltered and out of spec. except for the M600s that couldn't lift high enough because the sear hit the rear mounting pin. Good point on the sear lift from the safety cam. That happens from natural wear, too. That is what the 'trick test' is for. Defeating legislation through education. There is no safe direction to point an unsafe gun. | |||

|

| One of Us |

I have owned, adjusted and used M700s and 40X rifles since the late 1960s. I know how the trigger is designed and functions. I also have several loose triggers in my tool boxes. I have read nothing here that touches on the real issue with people blaming an inanimate object for their own stupidity. The Remington M700 trigger was considered the finest trigger on a production rifle in the US for decades. Then a local kid shot his dad in the back with one in a car. The dad happened to be a lawyer. So did the trigger suddenly get defective after 3 decades or did shooters suddenly get stupid? | |||

|

| One of Us |

Ouch! But accurate. Still, why design and sell something that can do this with some unfortunate regularity? Stupid is as stupid does, for manufacturers as well as users. Mike Wilderness is my cathedral, and hunting is my prayer. | |||

|

| One of Us |

I concur... i can show you a hole in a fence (and 100 yards away an air conditioner) in the back of what used to be Intermountain Outdoors in Idaho where a guy was 'diagnosing' a 700 that would fire on a closing bolt. He was standing less than 20 feet from the bullet trap that was used by the gunsmith to test guns but decided not to use it. You are right MR, stupid is an stupid does, all the way around. | |||

|

| One of Us |

Your arguments in your other posts seem legitimate. Your only mistake was to make the discussion personal by attacking the person on the other side. Personal ridicule doesn't win the argument. This whole issue could really be interesting so long as everyone sticks to advancing their evidence. There are no fact finders here. | |||

|

| One of Us |

If the rifle has an undue tendency toward accidental discharge then the product should be corrected or discontinued - even if no one was ever killed or injured in an accident.. To continue with such a product would just be begging for an accident. You are expected to drive your automobile safely but if you veer off the road and hit a tree you still expect the airbag to deploy. You should never depend on airbags or rifle safeties to prevent accidents but they exist for a reason. They add an additional margin of safety to proper and careful operation of the machine. . | |||

|

| one of us |

Nicely stated. Howard Moses Lake, Washington USA hwhomes@outlook.com | |||

|

| One of Us |

I would be interested in further opinions as to the reasons for the connector - I recall reading (a long time ago)that the additional piece of metal gave the trigger a "better" feel. I don't recall the exact word that was used now but maybe "resonance" or another similar concept applies ?? Cheers - Foster | |||

|

| one of us |

By your Definition(and howard's agreement) - ALL Trigger Designs - should be removed from the market. Needless to say, I disagree. ----- I completely agree. I remember a thread on HuntAmerica where he was telling people how to "Grease" Hunting Trigger Assemblies and what type of "Grease" to use. As the thread developed, he mentioned "Cycling". Would any of you care to say why that was a Red Flag. In fact, I'd love to hear the explaination from howard. | |||

|

| One of Us |

I believe you will find Belk is a shill for folks that want to sue the firearms industry. I bet he makes more money doing that then taking folks money for gunsmithing that didn't get done. Butch | |||

|

| One of Us |

Jack, I take no position here. I am curious though: 1. are you making money doing this? 2. or is it as a public service? The answer makes a tremendous difference in your position here and elsewhere. regards, Rich | |||

|

| One of Us |

This will end up like the suit over the shotgun barrels- the only people who will benefit will be the lawyers. All the damn safety's in the world won't help if you have it pointed in the wrong direction. I remember reading something about the connector being a separate piece so it could be hardened instead of the trigger | |||

|

| One of Us |

I took a hotel room in Boseman for the interview in March, otherwise I'm not making a dime and paid my own way. Working for lawyers is different. I charge them for the time they take up. My fees are all part of the sworn public record in every case. As stated in the Explanation document, this is information not found anywhere else and is written as a public service to gunsmiths. We were sold a bill of goods in the '80s and it shows yet today. Next Wednesday the body of evidence will change dramatically. I thought it would be a good idea to tell how it applies to us to prepare for the hard questions to come. It seems those that most need to know are the least likely to listen. It is a shame. Defeating legislation through education. There is no safe direction to point an unsafe gun. | |||

|

| One of Us |

The operative words you apparently skipped over were "undue tendency". Surely you are not suggesting that "ALL Trigger Designs" have an undue tendency toward accidental discharge. There is no such thing as a perfect mechanical system. Any mechanical system can fail. In spite of having some of the world's most talented engineers NASA burned one bunch of astronauts on the ground and another bunch on takeoff. All tires are subject to failure but if a particular brand and design has an unusually high number of blowouts then that indicates a problem. No crib is perfect but if a particular design is responsible for an unusually high number of infant deaths then you would expect the design to be pulled from the market. Every drug has side effects but if you find a significant and high number of people becoming blind or having heart attacks while using a certain drug then maybe it's time for a recall. The same goes for rifle safeties. Anything mechanical can fail, even triggers and safeties. An occasional report of failure of any manufacturer's guns should be expected. But thousands of reports of a particular design failing over and over again suggest something is definitely wrong. And a very compelling part of the picture is that the problem is reported in every firearm that uses this particular design. Other rifles by the same manufacturer that use a different design do not experience the same failure rates. One can bury their head in the sand, pooh-pooh the facts, or defend the design because of a mindless emotional affiliation with the brand but the problem will not just fade away. . | |||

|

| One of Us |

Question. What did/does the USMC, USA, and other military and civilian agencies do to the thousands of Remington sniper rifles out there to make the triggers "safe" ? Anything? | |||

|

One of Us |

They put them in the hands of folks who know what end of the tube the round comes out! Oooorah! _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

Jack Belk I have replaced a couple of triggers on Remingron 700's with Shilen triggers. Do they suffer from the same problems as the standard Remington units? DOUBLE RIFLE SHOOTERS SOCIETY | |||

|

| One of Us |

The Shilen trigger is solid and does not suffer the malfunctions of the Walker connector, but I've heard here that the thumb safety is prone to perching on the null position and will FSR should the trigger be pulled while in that position. Read the 'trick test' in the above document. All in all the Shilen is a fine trigger, but I'd prefer to mount one with a three position shroud safety. Defeating legislation through education. There is no safe direction to point an unsafe gun. | |||

|

| one of us |

Thanks for the info Jack. DOUBLE RIFLE SHOOTERS SOCIETY | |||

|

| one of us |

I suspect there were a couple of reasons for the inclusion of the connector in the original design. The primary reason was probably one of cost. By using the connector. Remington was able to make the trigger lever out of whatever they wanted. Any other perceived advantages to the design were, more than likely, advertising "spin". It sells the design much better to say it provides a better feel than to say it's cheaper to make. Jack, I know the connector has the potential to cause problems and in some cases, it has. I'm just saying, in every case I saw where the rifle FSR'd, it was NOT the fault of the connector but of the safety lever or sear. In those cases I saw where the connector was at fault, it was not a FSR situation but a total malfunction. The connector was at fault because it broke at the hole.I don't mean to belabor the point, but I think it is wrong to point at the connector as the cause of all the FSR related accidents when there is every possibility that it wasn't the cause in most if not all cases. Regards, Bill. | |||

|

| One of Us |

The question is a red herring. Anyone that really wants to know will know that the connector makes the mechanism a "flexible" trigger. The connector is able to jump out from under the sear. I believe the M52 Winchester also has a flexible trigger. I have to ask again. The Remington M700 trigger was considered the finest in a factory rifle for more than 3 decades. Why did that perception suddenly change? Opportunistic lawyers? | |||

|

| One of Us |

For starters it is great to see Jack posting here again, I have read lots of his old posts but he left prior to me joining here. Secondly I will never under estimate peoples ability to make bad decisions by polluting their decisions with emotions and not facts. For many that fact that the military uses 700s is emotional proof that it is a great rifle. | |||

|

| Powered by Social Strata | Page 1 2 3 4 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia