The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  The Silver-Lining Scholarship Rifle

The Silver-Lining Scholarship RifleGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I think that says it all! You were a blessed man Glen Butch | |||

|

| One of Us |

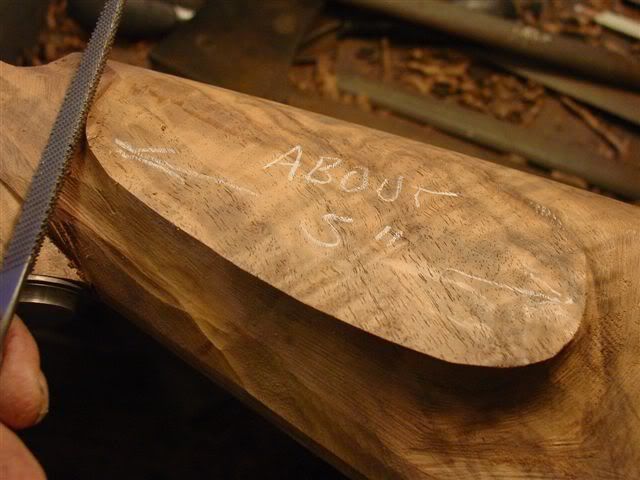

Glen, thank you for sharing that letter with us. Thinking about the aspiring teacher we’ll be helping is my inspiration to keep this project on track. I’ve had to take a couple of days off to finish a rifle for a great fellow who posts here as “CAS IIâ€. Now I’m back on the Scholarship Rifle project… First band saw off the butt to desired length.  After laying out cast off, locate and drill holes for screws...here I use a drill motor to "tap" the wood, forming threads.  The horn buttplate is now completely fitted. We decided to use horn, since it's not only very classic, but the future owner will have lots of leeway to fit to length  We've laid outlines for bandsawing. For clarity, I've highlighted the scribed lines.  Just getting rid of unwanted wood…  This will drive OSHA crazy! I use a milling cutter on the polishing head (3450 rpm).  The wood just kind of melts away (I'm making a disclaimer here -- try this at your own risk!)  As you can see, it's starting to look like a stock....an old stockmaker once said "Just remove the wood that doesn't look like a stock".  | |||

|

| one of us |

Duane, this is an expensive blank and we don't have a spare. Can't you just use a rasp and draw knife? ______________________________ "Truth is the daughter of time." Francis Bacon | |||

|

| one of us |

Duane, hope you do not sneeze while doing this.  Keith IGNORE YOUR RIGHTS AND THEY'LL GO AWAY!!! ------------------------------------ We Band of Bubbas & STC Hunting Club, The Whomper Club | |||

|

| One of Us |

I have been perusing this forum almost every day for the last few years or so and have to apologize by saying I have passed over this thread until today. I cannot offer a valid reason but feel compelled to comment on the gathering of greatness. As a late comer, as Trez has explained, I would like to contribute in some way to this project. I simply was not aware of what was going on but will pay closer attention in the future. Please contact me if anything additional is needed. Jim Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Former Professional member American Custom Gunmakers Guild | |||

|

| one of us |

Mr.Wiebe When I hear, (Master Gun Maker) your name is one of the first I associate with this statement. I have followed and studied your work for some time. You are truly a master in all aspects of rifle building. As great as your stock work is I am fascinated with your takedowns. I would like to thank you for the time and effort of taking pictures and posting them here. It takes a lot of time to do as you have done. I know your dedication to this project is greatly appreciated. Thanks Now a question on the rifle. The barrel you inletted was round. About mid December Mark posted pictures and a progress report that the octagon barrel was finished and chambered. At that time he was finishing the quarter rib. I know Mark had some health issues after this date. My computer has been up and down for some time so, did I miss something? James | |||

|

| One of Us |

Good catch James regarding the barrel. There were a couple of issues with the octagon barrel that needed to be addressed before I could install and inlet. In the interest of time (we’re way behind schedule) we decided to use a round Krieger barrel that was on hand so that I could get on with the stockwork. We’ll let Mark work his magic on the quarter rib and sights for this barrel now that he’s back on his feet. On with the woodwork…A very sharp plane will remove a lot of wood, and if VERY sharp it will cut against the grain  Spoke shave works well in tighter areas  Tom Burgess thoughtfully left the tang at full height...shaping this should be left to stockmaker  Generally, this area will end up with same thickness as grip cap is wide  Credit for this gadget belongs to the late Alvin Linden...the purpose is to develop a straight line as if cheek piece did not exist.  Yep! I'm using a body grinder to quickly remove wood…  As I get about close as I dare with the body grinder, I switch to this very fine wood rasp (This one is made in France, costs about $100.00)  Again, using rasps to develop lines  This measurement will come out a little less than an inch  Here, we're developing a straight line from grip to toe  Using that straight portion as a guide, we can't go wrong in blending the other lines  In spite of a seeming obsession with straight lines, I like to leave the comb line with a SLIGHT convex. It always seems to me that if this line is perfectly straight, it ends up looking concave to the naked eye....maybe it's just my eyes?  Ah....F....ooey! Guess I'll end up doing a little re-designing to the grip cap.  See the inletting black smudge? I like to leave the sides just a tiny bit convex.  Well...what do you think so far?  | |||

|

| new member |

wonderfull sir...wonderfull...thanks | |||

|

one of us |

Truly amazing work. Thank you for showing us how it's done. Ever think about putting all this in a book and selling it? After I win this rifle I will send you a personal thank you note Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Please no more pictures of that finger remover. I looked at it three times and I still get chills. That thing made the 4 foot cross cut saw that my dad used for fire wood look safe. John | |||

|

| one of us |

As a person not usually much interested in bolt rifles, this is suddenly a lot more interesting and has even enticed me enough to want to buy into this raffle. Is there a target date for ticket sales? Brent When there is lead in the air, there is hope in my heart -- MWH ~1996 | |||

|

| One of Us |

Appreciate your misgivings, but the fact is that the wood does actually "melt" even acoss or against the grain. Of course, one needs to use common sense...as with a buffer, work "below center" There is no "grabbing" tendency at all. Mind you, for legaleeze I can't condone anyone use this method. I sill have all fingers after using this since 1968...Thank you for your post | |||

|

| One of Us |

Actually, there seems to be enough interest that we're contemplating a CD | |||

|

One of Us |

I would buy that CD | |||

|

| Moderator |

Well, I think you are amazing.. and I need to just put my tools out in the rain.. i'd buy the DVD jeffe opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

Yep makes this poor hobby guy feel like I never knew a thing. I'm like a kid waiting for Christmas looking to see if new pictures are there. Put me down for a DVD. As usual just my $.02 Paul K | |||

|

| One of Us |

Duane, I'm shocked to see electric tools and grinders and such. After talking to Forrest I thought you only used flintstones and wooden mallets. _________________________________ AR, where the hopeless, hysterical hypochondriacs of history become the nattering nabobs of negativisim. | |||

|

| One of Us |

As for that little "ding" in the grip cap, how about a little judicious tig weld? Jim Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Former Professional member American Custom Gunmakers Guild | |||

|

| One of Us |

Jim: I'll give that some thought..on the other hand, this is the perfect oppurunity to see how a radiussed edge might look...if all else fails, I do have another cap | |||

|

| One of Us |

They were seized as historical artifacts... | |||

|

| One of Us |

TC1, After careful consideration, we regret to inform you that you are not going to be the winner of the raffle for this rifle. We have agonized over this and have decided that the Hensley's would benifit a great deal by owning this one. If you would like, you could look into buying one from Duane and the rest of the crew. We are sorry for any pain this may have caused you and wish you well in the future. | |||

|

one of us |

HA! It doesn't surprize me. If there were 100 of us in a room and 99 door prizes, I would walk out of the room empty handed. The only way I'll ever own that rifle is to take it while nobody is looking Duane say's there might be a CD for sale. I'll buy one and be happy. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

One of Us |

Duane: As a person who helped get the blank for this project, I would be curious to know what your overall impressions are of it (grain structure, mineral lines, layout, etc) now that you have started carving. And thank you so very much for all of your photos and descriptions. 577NitroExpress Double Rifle Shooters Society Francotte .470 Nitro Express  If stupidity hurt, a lot of people would be walking around screaming... | |||

|

| One of Us |

The Jerry Fisher designed bottom metal has this curved floorplate which is a but troublesome to fit to a stock contour, but carries nicely  Be careful here! Once the metal is in the stock though, this detail is well protected  A small cabinet scraper is ideal for taking out rasp marks  Utility rolls are widely used during the "shoe shine" method  Here, I'm making a new guard screw from 01 tool steel, because I need a thicker than normal head so.....  I can do this!  Have plenty of various sized dowels, sandpaper wrapped for detailing  Grip will end up a little less than 4 3/4" circumference...should fit most hands well  Same flush screw treatment...left a few degrees off for future wear  Adds visual appeal to have he bottom line of the fore end slightly convcave  Again, visual appeal is enhanced with shadow detailing  | |||

|

| One of Us |

Mr. Wiebe, As one who thinks of himself as a pretty good driver, but who is not much of a mechanic, I love to see how a fine machine is made. It's a real eye-opener. Tools, technique and lots of talent, as well as lots of hard-earned experience, are needed to be able to perform this kind of hand work. You sure do have those bases covered. I sparked a debate around here one time by referring to the best gunmakers as artists, but at the risk of doing so again, I have to say it: You, sir, are an artist. This series of posts reminds me of the excellent Holland & Holland DVD on fine gunmaking. I own that one, and I would buy your DVD in a minute. I don't know what it would cost you to produce, or if you could make any money from it, but if it will help, put me down for one. Thanks for taking the time to record this and share it with us. Mike Wilderness is my cathedral, and hunting is my prayer. | |||

|

| One of Us |

You did well...one of the best I've ever worked on...about perfect in every way. | |||

|

| One of Us |

The alcohol evaporates so fast, it was difficult to get this preview...such as it is   | |||

|

| one of us |

| |||

|

| One of Us |

http://img.photobucket.com/albums/v705/Burford/Searcy%2...sfinalshaping017.jpg Mr Weibe As I viewed this area of the grip cap I wondered if the metal was just pushed over and could be reformed cold and dressed. If it was hit by your power tool, it will likely be missing. If it was just pushed over, you may have success tapping it back and dressing the area. Please let us know how you deal with this, and again, thanks for the effort to show us your talents. That is a very beautiful stock, and if the metal work is equal (it sure looks to be at this point), it will truely be a "best gun" in every sense. Roger | |||

|

| One of Us |

Forrest B How are we sitting for money? Are we Okay yet on the funds? | |||

|

| One of Us |

FANTASIC in every way.....Thank you Mr. Wiebe, your skills, talent, art and donation are much to be admired....bless you! | |||

|

| one of us |

jjs, It sure looks like all your haggling with Denli really paid off for us. This is a beautiful stick of wood. Right now, I'm in admiration of all you've done for this project. 22WRF, I think we're OK on funds for right now. We have knives that we will auction shortly and hopefully that will bring in enough money to get the guncases and some other items built. To everyone, with regard to the raffle, our hope is to be in a position to start selling raffle tickets in late October. The rifle will make the rounds at SCI, the Custom Gun Guild show, Dallas Safari Club and then the NRA convention. If we get the ok, we'll have the raffle drawing at the NRA convention in early 2008. I just can't get over how good the layout is on this stock. I don't think I've ever seen a blank with the grain so well matched to the finished stock. It almost looks fake. Maybe Duane is embellishing things with his magic marker. ______________________________ "Truth is the daughter of time." Francis Bacon | |||

|

| One of Us |

What a spectacular rifle! Well done by all of the great artisans working on this project. I can't even say how tempted I am to just ask how much is expected to be raised form the ticket sales, and just cut the check and put the thing in my safe. I rarely lust over rifles, but this one is just incredible. | |||

|

One of Us |

Yowza! Beautiful! | |||

|

| One of Us |

The grain through the wrist is amazingly angled to match the sweep of the pistol grip. How wonderful to see such a communion of style. _________________________________ AR, where the hopeless, hysterical hypochondriacs of history become the nattering nabobs of negativisim. | |||

|

| one of us |

Give us a check for $40,000 and it'll save us the hassle of the raffle. This rifle would just love to go to Africa along with with your 416 Rigby. ______________________________ "Truth is the daughter of time." Francis Bacon | |||

|

| One of Us |

Duane, That is superb work, with a good looking piece of wood to work with. Don | |||

|

| One of Us |

Roger R: Wish it were so... | |||

|

| One of Us |

While you weren't paying attention, I installed be rear swivel base...truth...I didn't notice I ran out of memory space!  Raising the grain by wiping with alcohol, then use a heat gun on "low"  After final sanding, scub with "Sctchbrite" to uncover areas needing more attention  Here are the actual sanding blocks and Porter Cable sander I used on this stock. Usually final sanding up to 320 is sufficient, then raise grain one final time and start the sealing process...these slight "wiskeers" will aid in filling grain while wet sanding.  This blank was pretty dense and a bit heavier than usual, so, we're drilling a couple holes to get rid of weight.  Using the mill, cut a few interrupted channels...between this and the buttstock treatment, we lost 3 ounces....I was pretty conservative, another oz. or two would have been possible.  For sealer, I use "Ship n' Shore" by Daly's in Seattle....REALLY slop it on all over…to the point of run off  I'll keep applying sealer for the next couple hours, let it dry for two days and repeat once more....we'll start the finishing next time  | |||

|

| one of us |

Duane, Thanks for posting the pictures and your process. Very Cool! I was fasinated with Forests rifle stocks that you did that he posted here over the years. I have a couple patterns I made out of old stocks, cutting up and used bondo fiberglass gel on. I spent many hours redoing the grips, cap and butt lines, lookin at photos and Alvin Lindens prints. Very nice to see how you do it and get some of your measurements as reference and comparison. Rick | |||

|

| Powered by Social Strata | Page 1 ... 10 11 12 13 14 15 16 ... 23 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  The Silver-Lining Scholarship Rifle

The Silver-Lining Scholarship Rifle

Visit our on-line store for AR Memorabilia