The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  The Silver-Lining Scholarship Rifle

The Silver-Lining Scholarship RifleGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Glen How was Ms. Raney chosen? What criteria did she have to meet to beat out all of the other applicants? What did she have to say when she found out she had won a scholarship? | |||

|

| one of us |

22WRF - The applicants had to meet a minimum GPA, have had significant participation in extracurricular activites/groups including community service, submit recommendation letters from at least two of their teachers, and plan to become a classroom teacher. If they met those requirements, then they had to write an essay about a teacher that had impacted their life and how they would apply that as a teacher. The essays were then judged by a selection committee. The essays were identified only with a number. Each committee member read and ranked each essay. Points were assigned according to rank and when totaled gave us a winner. We notified the school counselor that applicant #13 was the winner. We did not learn the name until a few days before the award ceremony. After reading some of the essays and given the large number of applicants, I suspect that not all were planning to be teachers. They probably wrote an essay for another scholarship application and just used it to apply for this one also. The school will need to do a better job of screening those out in the future. Danielle was very excited, and I suspect her parents were as well. | |||

|

| One of Us |

Pleasant surprise! The blank was perfectly flat on both sides and parallel. After the determining top stock line and bandsawing close, I true up on the jointer. I first determine pitch (I'll use 3 degrees in this case), then establish length of pull (using 14" rough) and finally determine exact center of front guard screw. From that point, using dividers and calipers, transfer measurements from bottom metal and action. Comb line is established by making nose barely clear cocking piece...in this case I'm dropping at the heel plus 1/2". Finding the exact center of the trigger, I set divider at 3-3/4" and scribe an arc...somewhere on this arc line will be the front of the grip cap... I'll make the rear of the cap hit a line 2-9/16" below the comb line. Now, measuring the length of the cap, I "fit" within my personal; preferences the line of the cap (extended, it will meet the comb about 1=3/8" ahead of the buttplate. I allowed 5 -1/4" for buttplate and simply "connected the dots" We now have a profile of the butt that I can band saw. and start inletting. Please keep in mind that all these measurements are sort of "average" for a light weight rifle...I'm going with "average" since we have don't have a specific owner to build to suit...more to follow               | |||

|

| One of Us |

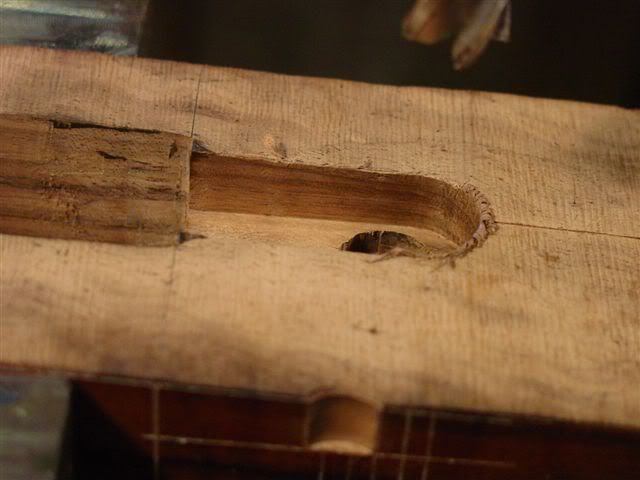

After establishing a center line all around the blank, we lay out the magazine opening at it's smallest point (since the sides are tapered), then hog out with a forstner bit, then to the milling machine to get as close as you dare to the scribed layout. From here, chisels, gouges and....yes, a pocket knife are used to gradually let the magazine box until you hit the front pillar. Using the bottom metal as a guide, drill the front guard screw hole through, then, using a piloted countersink, make room for the pillar to proper depth. Using a sharp scribe, and the layout lines you made on the side, hog out the front tang. Once that starts to enter the wood, the trigger guard portion will begin to hit, and again, hog out to depth. During this time, the magazine box will get tighter because of it's taper, so you have to keep on relieving. Never get "ahead" of your cut...only take out the wood that interferes, easily seen with inletting black. On that note, I have no use for the commercial inletting blacks...too thick! For years, I've used lampblack and oil...after a time, this will settle into a cake…adding just a little oil from time to time, but not mixing the compound, you can brush on a VERY thin coat of black. Next time we'll start inletting the action.          | |||

|

| One of Us |

I was asked about the center line...this is not the center line of the blank, but of the finished stock, offset to make room for cheekpiece...anyway, using calipers and dividers, we lay out the action and all it's peculiarities very carefully. I make a note to myself how far up I have to move the quill to remove wood where there won't be any when done, so why fool with it if we don't have to. Note that I make a shallow cut on each side that will act as a "return to zero" if I take the blank out of the vise. Using a home made radius cutter, we might as well rough out the barrel shank so it won't be in our way during action inletting. We check to make sure the magazine box is not going to press against the bottom of the action.....030" shy of touching is just about right...should you inlet the box too deep file off a bit. The inletting black shows that the bottom of the recoil lug is touching...I'll remove suitable wood with a 1/4" end mill, but not all the way to rear...we want a compressed fit here        | |||

|

| one of us |

Watching this with great interest Duane, thank you. A question if you'll allow. You said that the top of the magazine box should not touch the bottom of the action. With the action out of the stock but assembled to the magazine I assume the front pillar and it's recess should be in full contact as should the rear pillar between the tangs. With the works set up this way there should be verticle play in the magazine box (very slight, .030")? Thanks, Rob | |||

|

| one of us |

Duane, Those step by step photos are amazing! Thanks for taking the time to show us how it should be done!!! Best Regrds, Dave | |||

|

| one of us |

I hope that someone starts a scrap book (of as many steps as possible) of the craftmanship needed to produce this work of art. Keith IGNORE YOUR RIGHTS AND THEY'LL GO AWAY!!! ------------------------------------ We Band of Bubbas & STC Hunting Club, The Whomper Club | |||

|

One of Us |

Duane, Those have to be three of the best posts/photos I have seen on this forum. Can't wait for the next update. Well Done! | |||

|

| One of Us |

This may be somewhat of an understatement. _________________________________ AR, where the hopeless, hysterical hypochondriacs of history become the nattering nabobs of negativisim. | |||

|

| one of us |

Duane, Thank you for taking the time to talk us through your process. The photos are great; what model camera are you using? John Farner If you haven't, please join the NRA! | |||

|

| One of Us |

In theory, you're absolutely right, but I've not seen bottom metal for Mauser's that are machined as you describe. If you want to carry this to the Nth degree, saw off the front pillar and make a seperate one to fit exactly. Should you try to take off enough metal from the top of the box, you might end up with a solution in search of a problem... mmaybe a shim on the top of the pillar would work..My own scientific solution is to pretend the problem doesn't exist, just bed tightly | |||

|

| One of Us |

A Canon EOS 400D and an older Sony DSC S75..most of these were traken with the Sony because the memory card down loads faster then flash card | |||

|

| one of us |

Wow, what a thread and I have read every bit of it very carefully, am going to print it out.. One thing I would suggest with the G33-40 action is a straight bolt handle and the Holland and Holland type 4 inch long and very petite quarter rib off the front ring..Also perhaps a half round and half octogon barrel..All needs to be small to frame that nice small ring action... Most American quarter ribs are very long and large, some you could land a jet plane on them me thinks. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| one of us |

What a GREAT thread. That is such a beautiful piece of wood that I would oil it and hang it on the wall as art. No way I would have the guts to start enlaying the metal! Don't limit your challenges . . . Challenge your limits | |||

|

| one of us |

This is absolutly great stuff!  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

| One of Us |

While he may be a bit late, Ray is spot on as pertains to the quarter rib and barrel contour. Smaller is better otherwise you should use a standard 98 action. Duane, that series of photos is super! Thanks. | |||

|

One of Us |

Bill Soverns, I know you will do my son's gun's the same justice the as Duane is doing to this rifle. OUT-fucking-standing! (And I don't apologize for using the F-word.) 577NitroExpress Double Rifle Shooters Society Francotte .470 Nitro Express  If stupidity hurt, a lot of people would be walking around screaming... | |||

|

| One of Us |

577, I will go ahead and apologize for you...however I do understand your excitement...I share, with you and all the group, the experience and excitement of seeing something come together and do look forward to seeing Bill's stock work on Ewan's rife. I held this blank in my hands and had a hard time parting with it!...but you guys should know the story.... Mr. Wiebe, I am a fan of your work and through ForrestB have gained some experience and appreciation for you art. I am having a couple of rifles built and I just may have to speak with you about doing the stock work and a few of the finer details. Above all else, like everyone here, we all appreciate you taking on this project, as well as all the outstanding craftsmen who have contributed their skill, and the special meaning behind all the decication. Glen, thanks for keeping all of us informed about the scholarship, it has a special meaning and we all share in the tribute.... I am sure the finsihed product will be beyond expectations. I can only hope I have the winning ticket Been a long month+ so please excuse my rambleings.... ForrestB, when the time is right, please let us know what we can assist you with as the project progesses. All my best, jjs | |||

|

| one of us |

Mark- I am sorry to hear that you had TN and I sure do hope the surgery has been a total success For those of you not familiar with the neurological condition trigeminal neuralgia, it is considered THE MOST SEVERE pain known to medical practice. As a neurologist or neurosurgeon what is the "suicide disease" and they will quickly tell you it is TN. Mark has been through hell and I hope he is quickly back on his feet. Mr Wiebe- than you very much for posting those pictures! I would love to see you write a book helping us lesser skilled guys get some insight into how the true Masters do it. | |||

|

| One of Us |

ForrestB and the many others involved, I have been thinking a lot about what I could do to work with you all. I thought about another rifle as ForrestB and I talked about before but don't know if this is too much for now with the project that is going on. There is such a good project going on now that I don't want to detract/distract from it in anyway. What IS best for us late comers to do? I don't simply want to wait on the side lines but would like to be involved. If another gun project would be good to do, count me in. I have several mauser actions Argentine mausers, a couple of mexicans, and a peruvian mauser. Any of which I would donate to start up the next one. I would also be willing to work on the stock in part or in whole. I am not your guy for barrel/metal work however and would defer this to...... What say ye?? | |||

|

| One of Us |

I think its kind of interesting to compare the styles of two extemely skilled gunmakers, such as Mr. Wiebe and Mr. Hensley. I notice that Mr. Wiebe has less of an angle on his grip cap, and that the radius for the grip is more closed that that of Mr. Hensley's. Both are extremely beautiful work, and its just fun to compare. Here is a photo of some of Mr. Hensley's work (stolen from another web site I might add).  | |||

|

| One of Us |

To give credit where it is due, though I work in my dad's shop and build rifles in the same style as trained by the "master", dad (Darwin) built these two. These two were in my hands many times and they are both exquisite examples of his master craftmanship/artistic abilities. Thanks for the kind words, I'll pass them along to my father. If you would be praying for my father, I'd appreciate it. He has retired from the trade and only dabbles in it now. Parkinson's disease has taken away his passion or at least his ability to perform it as an ongoing trade. He has a great attitude however and that goes a very long way. It's hard to see him this way at 65, seems way to early for this. I've admired Duane Wiebe's work many times. It is indeed first rate. I'd be proud to own one of his stocks...rifles. There is so much talent represented here. Hats off to you all. With any luck and as many raffle tickets as I can afford, maybe I will. Either way, it will be money well spent. Thanks again guys for setting up and doing such a fine thing. As an aside, check out the Pair of Gibbs Farquharson Rifles that I get the pleasure of building with Clay Barker over at Luxus walnut. http://www.luxusgunstock.com/ The first stock he is showing is still unfinished but as a wood importer his pick of wood was awesome. | |||

|

| One of Us |

So...to continue: Look carefully, you'll see where the action "cheeks" are starting to hit the wood...these areas should be shaped and inletted carefully, since recoil can also be absorbed here. Just imagine this is a 500 Jeffery and treat the inletting as such...take up recoil wherever you can.    Note the use of a rawhide mallet...helps to define the mark! The rear guard scew boss is simply countersunk with an 11MM tool and 1/4" pilot.    At about this point, start using "T" handle guard screws to mimic actual draw into the stock, scrape and chisel where needed. When bottomed out, inlet the bolt stop. I've chamfered the corner so there will be a little more wood to reinforce this fragile looking area. No particular gaps here, but the stop must move freely.  The trigger is next, we'll hog out with a 3/8" end mill and clean up to not only look nice, but with minimal wood removal...but...the housing must not touch anywhere.   Someone will ask "how about a rear guard screw pillar?" Fair question, but while working with this blank, I kept thinking I had forgotten how to sharpen tools! This is one tough, dense blank and I don't think a pillar is needed. The last photo...action is fully inletted. We've spent a great deal of time on the action inletting, but this is about the most important part of the job. Taking each portion at a time, we can be pretty sure the entire action is inletted to the best of the stockmaker’s ability. The barrel is next, then the fore end tip, followed by grip cap and buttplate.  | |||

|

| One of Us |

Mr. Wiebe: Absolutely exquisite work and exquisite photos. Thank you so much for sharing all of this information with us. | |||

|

| One of Us |

Amen!!! Don | |||

|

| One of Us |

Mr. Wiebe, When are you writing a book? I know that I for one would buy it. Great pictures and details. Your layout methods and especially the "return to zero" idea are very well thought out. Thank you for sharing. That "return to zero" technique will save me some alignment challenges in the future. Thanks again, | |||

|

| One of Us |

Hi Trez: Write a book? that would be a mighty short book! Thanks...by the way, the return to zero is an idea from Pete Grisel | |||

|

| One of Us |

Short story, pamphlet???? As a recap from the 2nd page. BARREL TEAM Mark Stratton elcaballero lawndart rick0311 butchlambert ACTION TEAM Tom Burgess jeffeosso ramrod 340 22 WRF STOCK TEAM Duane Wiebe 54JNoll tiggertate ENGRAVING TEAM Roger Kehr loud-n-boomer and the real skill players... THE MONEY TEAM TC1 fla3006 577 Nitro Express Digital Dan jjs DPhillips mufasa Harry Hunter Several anonymous donors and others that joined in later. Thanks and blessings to you all. I'd be proud to get to know each of you. May not get that opportunity this side of heaven, but it is great to see such generosity. As my daughter would say.........YOU ROCK | |||

|

| One of Us |

Trez Maybe we could get him to star in a DVD entitled Professional Stockmaking from the Blank. What the heck, maybe we could get you to star in it as well!!!! I know for sure I would buy a copy, or maybe two, or maybe even three. | |||

|

| one of us |

The quality of a book is not determined by the number of its pages. So far, you have two readers in waiting.... Brent When there is lead in the air, there is hope in my heart -- MWH ~1996 | |||

|

| One of Us |

The fore end is going to be approx. 8", so we cut off at about 6-1/2" (room for tip).  On the side of blank, layout the taper of the barrel, same process as on other parts.  This depth is one half barrel diameter at straight taper portion.  Set up and rough out with 1/2" ball end mill.  Generally, use chisels across grain and scrapers with grain.  Part of an old barrel can make a nice scraper.  Bench rest shooter Harvey Miller taught me that equal pressure on each end of the guard screw is desirable.  Fore end pressure...had to get to that sometime! I use very little and make the pressure points as a "V" block.  Once barrel is bedded to satisfaction, I like to use a miter saw with carbide blade to square off the fore end...ditto with the ebony.  Don't know if the Stanley No. 59 dowel jig is still available, but I find it invaluable.  Both parts accurately drilled, using two 1/4" dowels with epoxy glue.  Suck ‘em up with a pipe clamp and set aside for overnight...Tip: slightly round off the ebony where clamp bears, and you'll eliminate any canting tendency.  | |||

|

| one of us |

Well then, you might want to pick up this one as a spare because it looks like Stanley doesn't make them any more. Stanley Dowel Jig on ebay Duane, we can't thank you enough for taking on this project and especially for taking the time to share your photos and tips with us. ______________________________ "Truth is the daughter of time." Francis Bacon | |||

|

| one of us |

Amen! | |||

|

| one of us |

Double that Amen! Seeing real craftsmen bring this rifle to life piece by piece is amazing! Best Regards, Dave | |||

|

| One of Us |

Commonly, the tip material is left JUST free floating.  Before the next step, make sure the cocking piece clears the comb.  Here, we set up to make the cap area absolutely flat.  We find the exact center with a wriggler.  Lock the table and drill for the cavity.  Can't help but fit perfectly! Many thanks to Jerry Fisher for donating this cap. That about does it for milling machine work. I'm first to admit this is not the ONLY way to make a rifle stock, but I'm real comfortable with the precision inherit with this method...rather than have a $15000.00 machine dedicated to only stock carving, we still can use the machine for hundreds of other operations...The milling machine is widely used by many stockmakers for these same reasons.  | |||

|

| One of Us |

Hello Duane, Why do you put the tip on after you inlet the stock. Thanks John | |||

|

| One of Us |

You might have noticed that throughout the the process, I like to devote all my attention to one small part at a time ...easier for me! | |||

|

| One of Us |

Why have I been wasting my time reading the rest of the "Gunsmithing" forum? flaco | |||

|

| one of us |

Some new folks have recently "found" this thread, and there has been increased interest in the project due in no small part to Mr. Wiebe's contributions. To perhaps give the newcomers some insight and also to remind us all why we are doing this, I am posting part of a letter I received today. It is from one of Sheryl's ex-students and it speaks for itself. June 18, 2007 Glen Searcy & Family, I am writing this…to express my thoughts and feelings about the late Sheryl Searcy. I was one of her B.E.S.T.T. students for the school year of 2001-02. I’ve been wanting to share my thoughts and memories on how Mrs. Searcy… influenced me to become a teacher. Mrs. Searcy was the best teacher I have ever had, and she helped me become the person I am today. She not only loved and accepted me as one of her own children, but she taught me how to become a successful teacher. She not only told us all that she loved us every day, but she proved it through her kindness and hard work to make learning exciting. Every time you would walk into her classroom, you would be greeted with a smile…that would light up the room. She always had crazy ideas up her sleeve to grab our attention, and you could never expect what could happen. …I hope this letter brings you joy as a remembrance of Mrs. Searcy brings a smile to my face. I am proud to mention that I will be graduating in December 2007 from the University of Houston to become a teacher. I know that if I did not have the faith and encouragement of Mrs. Searcy, I probably would not have been able to finish (my degree). …She is the reason I am going to be a teacher, and I hope that I can one day make a difference in a child’s life as she did (in) mine. I wanted her family to know that even after her death, she is still changing lives. I remember her everyday that I am in a classroom. Sincerely, Julie Guyton | |||

|

| Powered by Social Strata | Page 1 ... 9 10 11 12 13 14 15 ... 23 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  The Silver-Lining Scholarship Rifle

The Silver-Lining Scholarship Rifle

Visit our on-line store for AR Memorabilia