The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  Integral Sling Swivel Band

Integral Sling Swivel BandGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

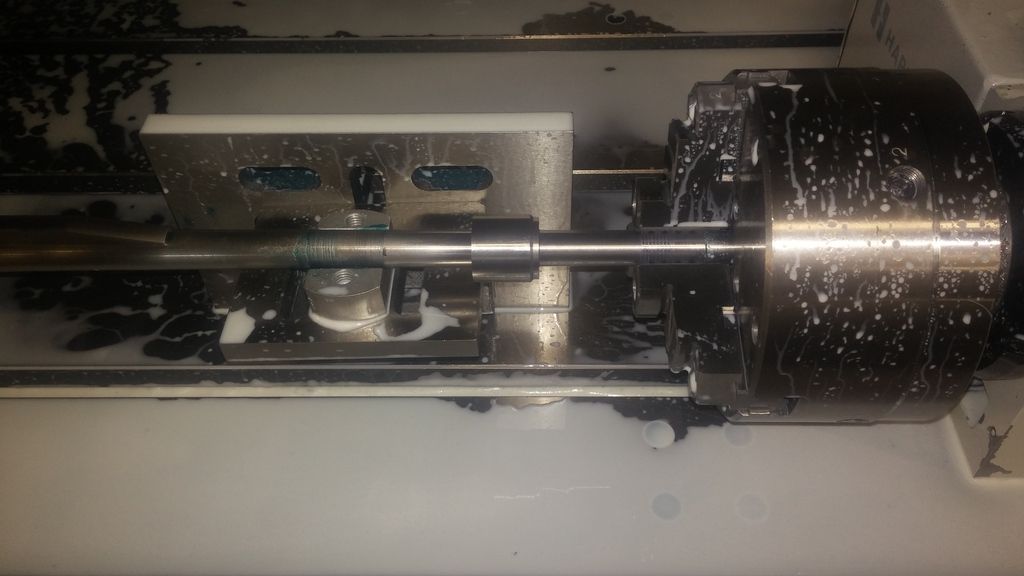

I thought we would start a new thread for this feature, but if you missed the first part you can go to This thread to get up to speed on this project. Today we machined the integral barrel band swivel on the barrel for the Dubiel stocked Mex Mauser. First we made up a sleeve to go on the barrel so we could clamp on the tapered section to allow access to the area to be machined. Here it is all set up and ready to go.  Next a couple roughing passes were ran to get rid of the bulk of the material. That left it looking something like this.  Once the finishing cut was made on the band part, the lug was profiled.  The little counter bore was then machined, and the hole drilled and reamed.  A few minutes with the emery and scotch bright, and we have this.  After looking at it I wish I would have made it about .2" shorter. It could also probably use about 10 minutes with a file to soften some of the edges on the bottom a little. Other than those small items, I felt that the process went very well for the first time. The guys in the shop had a lot of fun doing this. Hope you enjoy, John | ||

|

| One of Us |

Very nice! | |||

|

| One of Us |

20 years ago I wouldn't have given a plug nickel for a barrel band sling swivel. 20 years later after owning several German rifles with barrel or barrel band sling swivels I wouldn't give a plug nickel for a swivel stud on the forearm. Nice work! DRSS: E. M. Reilley 500 BPE E. Goldmann in Erfurt, 11.15 X 60R Those who fail to study history are condemned to repeat it | |||

|

| One of Us |

I like it! | |||

|

| One of Us |

Thank you for sharing...this has been a neat project, and it does look like fun. Has the front sight already been done? _____________________ Steve Traxson | |||

|

| one of us |

Very cool- thanks for sharing with us. | |||

|

| One of Us |

Nice work, looks fantastic. Just curious though, if you are going to go to the trouble to make one integral, why would you make it look like a slip-on banded one? | |||

|

| One of Us |

Gasgunner/John, Great work. It's great to see your progress photos. Don't be bashfull with the camera......I'd be happy to see more photos. srtrax mirrors my thoughts........have we got the front sight machining to look forward too ??? Perhaps on barrel #2 you'll leave a parallel section on the front section of the barrel until you've machined the sling swivel and the front sight band/base so that you can grip it. Not trying to tell you how to "suck eggs". Are you still using the one type of end mill ??? I love the simplicity of the setup and the fact that you can start the machine and go off and do something else while it all happens. Great work. Thanks for sharing. Looking forward to seeing the work on the front sight and a picture of the completed barrel sitting in the stock. | |||

|

| one of us |

On the front sight. As this was kind of an experiment, and I was not really sure if it was going to work out or not, I just used an existing blank that I had on hand. The largest blank I had was 1.250, and according to my calculations that would just not be quite big enough. I had an old Lyman around that I was planning on using, but I may upgrade to a NECG. If we do it again, we will get a larger blank and try to incorporate the front sight. Yep, still using the same 5/16 carbide end mill with .020 outside radius for finishing. Why make it look like a band? No good reason, other than to make people go HMMMM when they look at it. Due to the nose radius on the turning tool in the lather you can tell if you look at it very close that it is not a separate piece. It does actually reduce the amount of polishing needed by doing it this was as you do not have to blend the part that was milled with the part that was turned. The step at the end of the band eliminates that need. But mostly I just thought it would be cool. I guess if you did have an integral front sight, it would be hard to get the band onto the barrel. The barrel is a 6.5mm in 1-8 twist and is going on a Mex mauser in a John Dubiel stock. I am open to suggestions on caliber. The only requirement is that since John Dubiel died in 1937, it needs to be a caliber that would have been around at that time. Don't hold your breath on seeing the finished rifle, Ben is 8 now, and I figure this rifle will make a good birthday present for his 12th birthday, so we got some time. Still a lot of action work for someone to do. (not me, I know my limitations) John | |||

|

| One of Us |

Gasgunner, I'm "chuffed" by the simplicity of your setup. Perhaps,..........just this once.....if you wanted to persist with this barrel and finish up this experiment, you could silver solder a larger diameter peice of material on the front end and test your processes by machining it. Thereby testing your programs and procedures and ending up with a barrel band front sight for your boy's rifle.......and you'd have it all prooved in case a flood of orders came in.....and Ben's rifle would be closer to "hand over" stage. Am I attemption to goad you into action in order that we can continue to watch this "technogeewizery" to completion ............. yes !!!! I have the selfish need to see your curiousity rewarded..... and then you'd also be able to tell us an accurate machining/completion time and it would also help you price the completed product. Please consider. Please stay curious. | |||

|

| One of Us |

I did mean attempting | |||

|

| One of Us |

John, How are you doing ?? Have you got enough bills paid to get curious about the barrel band front sight for your boy's rifle yet ?? He's getting bigger you know.........might need that rifle shortly. | |||

|

| one of us |

I'm doing well. We decided to stick a .25 caliber barrel on this action for now. I figure the little 80-95 gr bullets out of a 257 Roberts would be mild recoiling for him. He has been helping me finish it up. Got the bolt handle done, Lyman 48 added, trigger guard reshaped and polished. Out for finishing now.  Yes, he is getting bigger. We just got back from the Tulsa gun show with Grandpa.  John | |||

|

| One of Us |

Looks very nice... love it all together with that stock! "If the women don't find you handsome, they should at least find you handy." | |||

|

| One of Us |

That is just marvelous!! Ten years ago I thought I was looking pretty cool when my gunsmith taught me how to make barrel band sling swivels, and ramp front sights. Just marvelous... Rich | |||

|

| One of Us |

John, You cheated !!! I was hoping to see the process involved of you machining the barrel band front sight. Pleased to see that your boy has something to shoot with though. He'll be borrowing your car next !!!!! | |||

|

| One of Us |

John, I'm shamelessly bumping this post in order that you may have progressed further with this project. Seemed like there was interest in these barrels and they may pay some bills too. | |||

|

One of Us |

First off, awesome job. Isn't the band portion superfluous? 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

bump | |||

|

| one of us |

I also question the use of a integral band, wouldn't it be cleaner to just ave the swivel stud integral to the barrel itself as boomstick mentioned..I have an old brno with integral full rib, rear sight, front sight and swivel sans a band...Not criticizing just a question and seems it would be easier to do..Both are better than weld for sure or IMO anyway. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Ray, That's the beauty of "custom". Go to the right builder, lay your money down and get what you want. As we say here "beauty is in the eye of the beerholder". If you're shelling out the money you get it the way you want …………. and it doesn't have to suit anyone else. | |||

|

| One of Us |

Yes Sir! You are correct. | |||

|

| One of Us |

BTT | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  Integral Sling Swivel Band

Integral Sling Swivel Band

Visit our on-line store for AR Memorabilia