The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  Integral Rib Barrel

Integral Rib BarrelGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

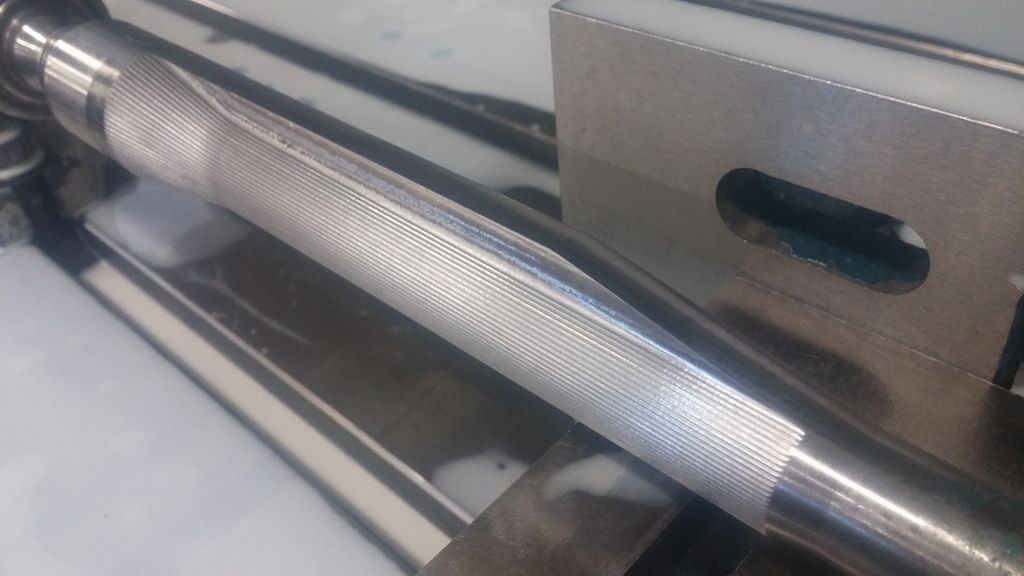

There was quite a discussion on here a while back about integral barrel features and the feasibility of machining them on CNC equipment on a short run or one off basis. There was a lot of posturing and opinions, but very little facts in the discussion as I recall. It did get me to thinking and I kind of worked out a plan in my head that I felt would allow a person to machine one economically, and also be able to easily alter the program to make whatever contour you wanted on the round part of the barrel with very little fuss and no additional tooling. A little disclaimer first. I am not a gunsmith, nor am I an engineer or master machinist. We build AR-15's, and make barrels for the same. (you know, those ugly black plastic things that do not require any gunsmithing skills to build) As such we have a CNC lathe and a CNC Vertical Machining center. We do a lot of AR barrels. Contouring is done on the CNC lathe, and secondary operations like drilling gas ports and fluting on the vertical. This being said, I love custom rifles, particularly pre-war American customs, and have done a little bit of work on traditional steel and walnut rifles. The primary goal of this project was to prove out the process. I did not worry to much about dressing up the rib and fitting the rear sight to it at this time, those details can easily be added later. I had a 1.250 diameter SS .264 blank on hand, so the only investment made in this project was a 5/16 end mill with a .020 corner radius. Now on with the project. I had a Dubiel stock on hand that I bought on the net a few years ago. I am sure that at one time it had a Eric Johnson barrel on it, likely in 7mm and likely with an integral rib. I thought this would be an ideal time to make a barrel for this stock. The barrel channel was measured at several points and a solid model was made of the barrel. We also added a integral sling swivel which will be machined later. Once this was done the barrel went on the Okuma lathe and the barrel was contoured and threaded with the exception of the area where the rib and sling attachment would be. The barrel was left full diameter at these points. Now onto the rib. The short section of barrel that was left full diameter for the sling attachment was clamped in the chuck mounted to the rotary. The tailstock then supported the breach end of the barrel. The plan was to run the end mill down the side of the barrel while the barrel was held at 90 degrees and the end mill was half the width of the rib above center. The barrel would then be rotated slightly and another pass made until 180 degrees of the barrel was machined. The barrel would then be rotated to 270 degrees and the process repeated on the other side. The first roughing pass the barrel was rotated 25 degrees per pass. As we got closer to finished size, this was reduced. First pass.  Third pass I believe.  About half way through finishing pass.  Here we are sitting in the inletting after the final pass, but before any polishing has been done.  After about 20 minutes with some 180 and 240 grit.  While this barrel took a significant amount of time due to all the putsing around with the program and experimenting with feeds and speeds, I am very happy with how it went as a whole. We were very conservative with depth of cut and speeds on this first barrel, but I really feel the rib could be machined in 3 passes and about 2-3 hours of machine time, and have a much better finish that required much less hand work than you would get off a Bridgeport. The best part, it is a very simple matter to alter the program to get any barrel contour or rib width that you desire. The dovetail for your rear sight, and matting of the top of the rib and makers engraving or caliber designation could also be done at the same time with minimal fuss. I did not have the rear sight at the time we made the barrel so I could not cut the dovetail for it, but it would be a very simple matter to machine it as well while the barrel was in the machine. I just machined a small flat surface on the top of the rib so I could level it back up when I am ready to fit the sight. Stay tuned, if there would be a demand for this type of work, we may decide to offer it sometime in the future. Hope you found this interesting. We sure had fun doing it, and am very happy with how it turned out. I'll get the integral sling attachment finished up sometime in the next few weeks and post it. John Holliger | ||

|

| One of Us |

Nice Job John! Can you please quote how many hours you will have invested into this barrel (planning,modeling,programing,setup,tooling,runtime,inspection,finishing)? That was kind of the point! A Smith gets an order for that type of custom feature seldom, he works to be efficent & therefore can probally be done faster for a one off prototype conventionaly vs CNC. That being said, should you prototype & develop programs for several Barrel& Rib programs such as Octagon to round with full length intregal rib & front ramp & intregal sling swivel, that you could advertise you would probally get lots of orders and be far better off with quality & hours & cost. Again Nice work!, And I still accert that it can't be done for $500 with wizardry as was suggested! m4220 | |||

|

| One of Us |

Well done and written. | |||

|

| One of Us |

Outstanding, John! A very worthy combo of CNC and hand work. Any evidence of warpage due to stresses being relieved during the contouring operation? Doug Wilhelmi NRA Life Member | |||

|

| one of us |

Well, the planning, modeling, inspection, and finishing are going to be the same whether it is ran on a manual machine or a CNC machine. The way this barrel was machined, it would be a very simple matter to alter the program for any contour desired. Heck, it could even be done with variables in the program so that one program could run many different barrel contours. Just take 5 minutes to plug in the correct value in the variable. This is the same way we contour our AR barrels, one program can do many different barrel contours and lengths, just plug in the correct variable and run. As mentioned the actual run time on this barrel was quite long as we were learning as we went along, but I really think that you could do the machining of the rib area of the barrel in under 3 hours once you got the program tuned. The finishing pass took the longest of course, but even that could be done in less than 1.5 hrs. Of course the barrel when done still needs chambered, installed on the action, and crowned as would any other barrel. So, can you buy a Krieger blank, turn it, machine the rib, chamber and fit and finish it for under $500, no, but you can't do that with a round Krieger barrel either. However, do I think you could add an integral rib for less than a $500 upcharge over a regular round barrels? Yes I think that would be possible at a shop rate of somewhere in the $100/ hr range. John Almost forgot. We machined this barrel without ever changing the fixturing or set-up. What this means is that during the 3 hours of run time, the machinist can be chambering other barrels, running another machine, or building rifles. | |||

|

| One of Us |

John, If a guy could get enough orders/work of this type I still think a CNC Lathe with live tooling Mill/Drill/Tap capability would be the most effecient machine tool for this type of work, as was shown in last discussion.http://www.youtube.com/watch?v=8VMzs1Mqxzg It could all be done on 1 machine in 1 setup, especially with other variables available such as tuliped octaginal to round with full rib & front site ramp & integral sling swivel to duplicate some of the early German Mausers. Not meaning to diminish your fine effort, KUDO'S! I know, we all have to work with the tools we have as with the Smith who only has a conventional mill & lathe m4220 | |||

|

| One of Us |

This is very interesting and it worked out well, nice finished barrel. That is not a lot of hours altho it does seem so when doing it from cnc compared to doing it manually. Are you flooding the cutting with coolant while machining the barrel? If you could speed it up without heating up or getting chatter that would add to the profit but I'm thinking that's NOT very many hours to finish a barrel of this contour as is. Manually I have had anywhere's of 60 to 90 hours on a Bridgeport mill on a couple I have done. Hell if you could do quarter ribs, barrel slings and front sights integral at even $700.00 I'd damn near give up and buy semi finished. I do cnc work for a top fortune 500 company five days a week...I've always thought it could be done and your proving that, anyways keep playing and see how far you can take it. I'll just have to go slow on my manuals and if I ever done it from a business stand point I'll make $7.00 dollars an hour and get on government health care. _____________________ Steve Traxson | |||

|

| One of Us |

Great work John! I know a little about your shop and abilities. Don't sell yourself short. I think a Kreiger barrel chambered, rib, frt. sight base and sling ring could sell at about $1500. | |||

|

| one of us |

Last I priced them was $1800 an not polished..I usually buy old MAUSER custom barrels and have them rebored. At $700, we need to talk..I think I can keep you busy. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| one of us |

srtrax, It is a lot of time for the amount of material removed. The limiting factor is just the rigidity. The machine could hog the material much faster, but the barrel would need affixed much more solidly which would require that you likely unclamp some of the fixturing for each pass. For me, it just makes more sense to do it this way and you can let the machine run unattended for a couple hours while you make money doing other things. We did not take the time on this barrel to fine tune the program to remove unneeded movement and air time as you would if you were doing production. This can easily reduce the machine time by 30% or more. The work is done under flood coolant. The blank was a good quality button rifled blank that had been stress relieved after buttoning and I detected no movement while machining. Butch, congratulations to your Texas service rifle team, they kicked ours and everyone else s butt's this year at Perry. NTT and the NTIT, great job! And TX is building a GREAT junior team. I shot with a little cowgirl from TX in the NTI, she was working on her last leg points. She had a rough day, but she will get there soon enough. They are going to be challenging the CA juniors in no time at all. Sell short, deliver long, and let the work speak for itself I always say. John | |||

|

| One of Us |

Gasgunner, CNC is marvelous stuff. Any chance of posting a video of the machining......suitably fast forwarded in the repetitious stuff? Once you sort out your model for an Octagonal to round, integral quarter rib, sling swivel and front sight ramp barrel I think you'll see some orders. If the machining was done pre boring/drilling/rifling and then cut rifled the warpage issue should be minimised. Well done. Great post. | |||

|

| One of Us |

Ain't gonna see it machined predrilled, reamed, and rifled. John,Nez Rongero was really pleased with them. He was beside himself. | |||

|

| one of us |

We actually made a short video, but it is pretty boring. Not much to see with all the coolant all over the place. I guess you could do a time laps, but that would take much more filming (is it still called filming) and editing than I want to spend time doing. Warping is just really not an issue with a properly stress relived barrel. To machine it prior to rifling it would have to be cut rifled. No way to button it after. John John | |||

|

| One of Us |

Watching a video of a cnc mill turning a 1.250" blank into a svelt sporter barrel with an integral rib boring !!!!???? Perhaps I've got less of a life than I suspected as I find it - what CNC will do - intriguing. John I'll be pleased to see any video you get around to doing. Yes I was thinking of cut rifling as then you'd have the "deluxe" package - fancy profile and best accuracy. Fascinating project. Pleased you got curious enough to attempt it. | |||

|

| One of Us |

[QUOTE]Originally posted by twobobbwana: Watching a video of a cnc mill turning a 1.250" blank into a svelt sporter barrel with an integral rib boring !!!!???? Perhaps I've got less of a life than I suspected as I find it - what CNC will do - intriguing. John I'll be pleased to see any video you get around to doing. Yes I was thinking of cut rifling as then you'd have the "deluxe" package - fancy profile and best accuracy. Fascinating project. Pleased you got curious enough to attempt it.[/QUOTE Twobob, Have you crossed paths with Stuart or Annie Elliott in Springwood? They have BRT Shooters Supply. | |||

|

| One of Us |

I just threw the 700.00 out there for shits and grins from a post awhile back. I wouldnt even do it if my shop was set up for cnc at $700.00. Like I said, I thought it could be done...for something like this to happen you have to have someone who does something close to this to begin with and then a little (I could do that) and then throw in some programming and a cnc machinist and wall'a, the devil is in the details. 30% would be quite an improvement really and still cut without putting to much pressure (heat related stretch/stress) on the tailstock. Anyway, thanks for posting, It's a good post and I enjoyed seeing it. Hope to see more! _____________________ Steve Traxson | |||

|

| One of Us |

Butch, I understand (?) that Stuart sells precision shooting gear and is a long range accuracy rifle nut. I think he's an agent for Berger and alot of accuracy related stuff (?). I haven't run into him but have seen some of his articles in "Diesel and Dust" magazine. Having spoken with a mate of mine - who shoots F class matches - about what extent/accuracy they go into to build their rifles, reloading etc for F class Stuart would certainly be an interesting gent to talk to. Springwood is south of Brisbane and I am about three hours north of Brisbane.........but I'll run into him eventually. | |||

|

| One of Us |

Stuart and Annie have been friends for a lot of years. They are both in the BR Hall of Fame. They teach shooting lessons around the World. They are rimfire, FClass, long range, short range BR, and fly shooting. I think they are Texans that happen to live in Oz. Only trouble is they like the nasty Wild Turkey and Vegemite. Great friends! | |||

|

| One of Us |

I understand you use Wild Turkey to "cut" Coca Cola in order that "Coke" is safe to drink. Vegemite I can tolerate. Make it known if you're going to be down this way I'm sure that, between a Queenslander and a Texican, we can find more suitable fare. Might even be an excuse to visit Stuart and Annie. | |||

|

| One of Us |

John, How'd you go with the sling swivel and front sight ramp ?? Anything you can share with us ?? | |||

|

| one of us |

Been busy with AR-15 barrels. (it pays the bills)Hope to get it on in the next couple week, but no promises. John | |||

|

| One of Us |

only a couple weeks, and already my inexpensive McGowan tapered octagon barrel with FL rib for under $500 is forgotten. You guys must like to spend too much money for stuff... | |||

|

| one of us |

| |||

|

| One of Us |

Rich, Is this the $500 barrel that took 3 tries to make & a little over a years wait & a price increase to $850 range for what is pictured below? We are still waiting to see your finished product & hear what the actual price you have into your 2 year project when finished. Those facts alone don't make it seem as attractive as described. m4220

"This will be the third barrel. I ordered it in December of 2013. May the first barrel came, all to my specs, but with a quarter-rib. Sent it back with a note. Second barrel arrived in mid-November, tapered octagon, but with NO rib. Called, and sent it back. Then via phone the week between Christmas and New Year's the conversation was that they were a bit unsure of just what I wanted, and would I make a drawing. My drawing skills are even less technically advanced than my penmanship. I draw a circle using a 3lb coffee can lid (Folgers for those of you who care) and draw a square inside it. Then I measure and draw flats to make an octagon. Then, I turn the paper over and outline the octagon on the opposite side and make a copy. I leave the top flat with an 8/th circle above that flat. I called to check Friday, and they told me two months. It will be interesting to see just how many $$$ it ends up costing me." | |||

|

| One of Us |

gasgunner, Oooooowwwww !!!! Aaaaaaaahhhhhh !!!! Looks great. Can't wait to see the "in progress" photos. No pressure though !!!????? For our information, forgetting about the manual mill versus cnc p*ssing competition - $500 thing, can you let us know the actual machining time/setup details when it's done ??? Again great work. Pleased you got curious enough about this to give it a go. Thanks for sharing. | |||

|

| One of Us |

m4220, the barrel only took so long because McGowan had trouble envisioning the profile. Once I made them a drawing and an explanation of the process and sent the letter, it got done in six weeks. They know how to do it now. As far as price, it was a bit under $400, including shipping to my home. That included the barrel blank, along with the profiling. This is great machine work, just a different approach and perhaps a bit more costly. You call McGowan this afternoon, and you will have it before Halloween I expect. But, thanks for asking and allowing me to clear up your confusion. Rich | |||

|

| one of us |

I challenge you to look over our web site and tell me if we are charging people to much for our stuff. This thread had little to do with selling stuff, and a lot to do with sharing information. If this is something that we decide to offer at some date, you can bet it will be at a very fair price as is everything we do. You can also bet that we will have a process figured out BEFORE we take a single penny from a customer for the work, or make a single promise. Yea, I know, a radical idea in this industry where you promise first, take the money second, tell bunch of lies third, and then maybe deliver well after the promised delivery date, and at a higher price. If you would like to talk more about your barrel and the enjoyable process by which you acquired it, feel free to start a thread about it. John | |||

|

| One of Us |

Remember John, He drives a jag a were. | |||

|

| One of Us |

little colicky are we today? You post something, and imply that is going to be rather expensive. I have no issue with that. I even explained the process wherein you might save time and $$$. To avoid comparisons post your thread and then lock it. Of course you run the risk that no one will line up to ooooooooooooooh and aaaaaaaaaaah and tell you how wonderful you are. My post simply tells the membership that there is a viable option to your "might be someday, but we don't know how much, but it might be a lot...". I guess coming from the same state that gave us obama, the notion of competition gives you gas. Might be the "If" and "May"in your post... butchlambert, yes, I do. It starts and runs every time out, and when I bought it eight years ago, it was sitting right there at the dealership; and I could even test drive it and negotiate a mutually agreeable price. I took it home that Saturday afternoon for a weekend test drive, came back on Monday and bought it. Here's a deal on this barrel VS mine: can't handle this one, can't tell how much money it might cost me, and don't know if I will have it before the next presidential election, if ever. But the pictures sure are pretty and it can fuel your fantasy like Playboy did when you were in HS. This resembles the flack I took over the guy in Australia that was going to build those gorgeous single shot rifles a couple years back, remember? I questioned him about cost, delivery schedule, etc. Several simple minded members here castigated me for weeks. But then, the story sort-of faded away. Why don't you take on the quest to see how many members here ordered one, paid up front for it, got it, and are shooting the rifles today. This is a beautiful machining exercise. Took a lot of skill, creativity and application of machine tool technology. I applaud that. For poor, pragmatic me, however, I want to see a rack of twenty or thirty finished barrels sitting in inventory, ready to be shipped to customers, and a price list. As Dirty Harry said, "Go ahead, make my day..." He could, simply by posting pictures of that rack full of customer orders, and prove me wrong before SCI. So, all you yappers, send this man orders, and get him to make them for you. It is that simple. Absolutely that easy! And, to boot, think of all the fun you could have telling me how wrong I was. However, I not only have my barrel sitting about four feet away, installed on my Wesson #1 LR action, but the wood is pantagraphed and ready to be sent off to be stocked. The difference beween talking and having is that close. I am sitting in my house enjoying the rain come down; and the rest of the posters here are standing out in the rain wondering why you are getting wet. Dream on kids... Uncle Rich | |||

|

| One of Us |

Rich, please tell me you can see a difference in the two barrels. A straight barrel with no taper is an easy job. It has at least half the machine time as gasgunners barrel | |||

|

| One of Us |

Even with a taper, is just an offset of the center in the dividing head at the muzzle end. That barrel could be cut on a conventional machine in several hours with no change to the setup other than indexing. No programing or CNC time required! But if it's what Rich wanted & with somemore machine time to fit it & the additional $$'s to finish it, he got what he paid for! I honestly am looking forward to see how your vision turns out when completed Rich. Curious to see completion of the Rib contour (sighting plain & sights) & please keep track of hours & $$'s so we know the total $$'s into that barrel upon completion. Now, let's get this back to gasgunners thread because it is obvious that He gets it! Fit,Form & Function! & artistic expression only works if a guy doesn't lose $$$ everytime he does it! Process must be efficient!! m4220 | |||

|

| One of Us |

Rich doesn't get it. | |||

|

one of us |

IMO, it's a pretty sharp looking barrel, John. I would love to see a 1/2 octagon 1/2 round with a full rib in a nice trim contour. -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Meticulously shaped and the end result shows it. Very nice barrel, Gasgunner. . | |||

|

| One of Us |

Rich lives in the real world. This is a fantasy one-off thing none of you can have... I get it, I just refuse to waste much time on things that are not available. It is a fantastic piece of workmanship, just like the $5,000.000 LA Ferrari Ferrari made five of last year. I admire the pictures I see, then I get into my old Jaguar convertible, put the top down, and go places. The man has created a wonderful thing, what's not to like? Just that one little issue you are all pointedly ignoring: YOU CAN'T HAVE ONE!! No matter what you say, YOU CAN'T HAVE ONE!! I'm like the messenger of bad news. You can't dispute the message, you just want to hammer me about it to compensate for that fact. I have a tapered octagon barrel, with a full length non-tapered integral rib. None of you do. Deal with it. And right now, I am sitting here, and my barrel is on my lap, fit to an action, and I am thinking about all of you wishing you could make it so at your house. Talk to me when yours arrives on the USPS truck. regards to all, Rich | |||

|

one of us |

We all know better. -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Nice work on a very complex contour John. You may be on to something. Steve | |||

|

| One of Us |

TC1, "we know better". Actually, none of you know jack... The unassailable truth is that Rich has a barrel. That's the real world I live in. That's reality. And, none of your childish prattle and posturing, by any or all of you, can change that. Sticks in your craw, doesn't it? I think that is the root of the problem in regard to this whole barrel thing, isn't it? Most of you talk about wonderful things, and I just go ahead and buy them. regards, Rich | |||

|

one of us |

And you think you're the only person here with a barrel? It's funny but sad all at the same time.

So,,,you're the only one here that's ever had a custom rifle built too? Wow, just wow. I guess the medicine runs low at the end of the month. -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

TC1, okay, show us a picture of yours... Oh, that's right, YOU DON'T HAVE ONE. If nobody shows me up by posting a picture of their, aside from the one Duane Wiebe built; it must mean I am the only one. Here at least. I think it is pathetic that neither you or any of the posters can show me up with yours. Talk is cheap. Owning one isn't. That is the difference on this thread. regards, Rich | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia