The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Subsonic 45ACP rifle shooters?

Subsonic 45ACP rifle shooters?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

A interesting aspect of the aluminum or brass carrier design is that by reaming the cup precisely to .001 or .002 ( needs to be empirically determined) under the diameter of the donor Boolit then heating the carrier sufficiently to expand its diameter and inserting the boolit, and letting it cool, you will have created a tight interference fit that will be extremely concentric. I'm going to make a few in the next few days and see how they work. If aluminum can be made to work that would be a extremely low cost alternative to brass. I'm going to order some of the alloy Gerard suggested and play with it.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

Sounds like an excellent approach Rob, which might even lead to production-scale manufacturing. Aluminum, as you know, has quite a bit larger expansion with temperature than steel or tungsten. Possibly offsetting this is the low melting temp of aluminum. Maybe Corbin has some tungsten bullets which closely match one of your OVERKILL calibers, which would work as you describe. This could be a really simple assembly process: heat up the premachined aluminum shell, slip a tungsten perform into it, and let it cool. | |||

|

| One of Us |

An old machinist once told me, “First, try to find what you need already manufactured for some other purpose…â€. These are manufactured for “Worm Weightsâ€, for use in fishing. They are 97% tungsten, and each have a hole drilled along the axis so that the line can be passed through. They come in many “colorsâ€, but also are offered in plain, unpainted. So far I have no diameters on the eight different sizes they offer. I’ll bet they are purchased from some bullet manufacturer, then repackaged for sale as weights. Tru-Tungsten | |||

|

| One of Us |

I’ve communicated with Bob Bosse at Tru-Tungsten by email, requesting diameters and lengths of their eight “Worm Weightsâ€. Typically, Bob wanted to be sure we weren’t looking to steal their propriety information. Bob is an “avid fishermanâ€, and I admitted to be an avid Shooter who wants to assess their weights as bullet components. I always have a little hesitancy doing this, because these days you never know when you will run up on a rabid gun-hater. We can always buy a small number of Tru-Tungsten weights from Midway et al, and do our own measurements. Just trying to save a few bucks… | |||

|

| one of us |

Henry22LR-Thats a neat discovery. Id be very interested to know to what tolerences they manufacture these fishing weights too and if they can sort by weight.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

I just received this email from Bob Bosse at Tru-Tungsten: “Henry, Thanks for your explanation. I have forwarded your requested to our development group but it will be their call to send the info. I do know that they have discussed the hunting market before so there may or may not be interest. As another option you could order one pack of each (at our website or another online dealer like www.tacklewarehouse.com) or go to a local bait shop/Bass Pro Shops/Cabelas and have a look at the store…..which may be quicker. Thanks again, Bob “ Rob, I guess the best part of this “discovery†is that SOMEONE is manufacturing these, and that they can claim 97% tungsten. I really think Corbin will turn out to be a better source for our rather specific needs, and that Corbin will be more likely to understand our specific needs like sorting by mass to fairly high tolerances. | |||

|

| One of Us |

| |||

|

| One of Us |

That's cool! How much for a dummy round firmly crimped? Love shooting precision and long range. Big bores too! Recent college grad, started a company called MK Machining where I'm developing a bullpup rifle chassis system.  | |||

|

| One of Us |

It is! Be like driving a spike. Any plans for a huge .620? | |||

|

| One of Us |

Rob, I’ve been running some atmospheric drag calculations on the .45 OVERKILL shapes. As it turns out, their Cd (drag coefficients) are a minimum of about 0.2 at subsonic speeds but peak at about 0.55 at about Mach 1.4. I’m using Aerolab software, which comes from the amateur rocketry bunch. Among other things, I will be calculating “terminal velocity†or the maximum velocity a dart-stabilized (tungsten/aluminum) bullet will achieve when dropped from a great altitude. Have you run any drag calculations on the heavy OVERKILL bullets? | |||

|

| One of Us |

Turns out, there is an optimal bullet weight for dart stability. This graph is for non-wasp-waist bullets constructed with an aluminum back end and tungsten tip end. As you can see, bullet weights around 650 grains total weight have the highest dart stability. All these bullets were 2.39 inches in overall length. | |||

|

| One of Us |

| |||

|

| One of Us |

Looks like the higher density tip materials yield a higher dart stability. But surprisingly, for 45 cal bullets with projectile length 2.39 inches, highest dart stability happens at about 500 grains of total projectile mass, independent of tip material. This is not something I would have expected. Looks like I better run some 600 OK bullets. Rob, what length bullets for the 600 OK’s? | |||

|

| one of us |

I made some 700gr wasp waist bore riders and will post some pics later. They look cool and center perfectly in a .451 bore. Having some trouble with the aluminum carriers but hope to have that resolved this afternoon. I made one with a 300gr .375 bullet insert and the aluminum doesnt add much weight. To get to 500 grs in a .451 will require a long tungsten insert I'm afraid. Hope they can be obtained. Interesting calculations. I would not have predicted that either.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

Here are the pics of the 700gr wasp waist borerider and an aluminum carrier for a 300gr .375 bullet. The aluminum carrier and bullet weigh 465 grs and by making the cup a little longer I should hit 500grs very easily. Same bore rider approach. OAL of both bullets is 3.0 inches. Boy is the aluminum carrier ever dart stabilized. -Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

one more pic-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

One of Us |

Freaking cool! Any word on what we talked about? 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| one of us |

Boomstick- PM me. I think I forgot. remind me.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

One of Us |

pm sent 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

Beautiful, Rob! Now we can see if this “dart stability†thing holds any water. I’m sure it would make a big difference with smoothbore or 30 inches per turn leisurely twist. But whatever else it does, we won’t know until you get a group at the range. HERE’S HOPING!!!!! | |||

|

| One of Us |

Rob, just one quick try at duplicating what you built, without trying hard. This pretty well matches what I see... The surprise for me is the combined effect of the wasp-waist with the alum/lead combo. This one has a dart stability of about 4.0, which is almost as good as alum/tungsten, and quite a bit better than the alum/lead without wasp treatment. Try throwing one up into the air, and see if it lands point-down every time. If so, that illustrates the dangerous nature of these "finless darts". If you fire one of these for max range, at about a 45 degree up-angle, when it reaches max altitude the spin will try to keep the bullet axis still pointed up at the same 45 degree angle. In a spin-only stabilized bullet, it will start falling broadside to the air, so loses velocity fast because of increased drag. But these dart-stabilized things will point downward, and probably fall tip-first in a very streamlined manner. Bad luck if you happen to get hit by one! | |||

|

| One of Us |

Boy, did you hit it SPOT ON! Don't know whether you have the fabeled "magic eye" or "magic hands", but you hit the sweet spot first time out! Don't change a thing! | |||

|

| one of us |

Henry- When thrown like a dart, they fly point foreward like a dart then the nose tips up as it falls and lands tail downwards. When held by the tail and flipped if thrown high enough it lands point downwards but presessing around the axis. IT wont self align like a true dart. It flies much better than the 700gr brass borerider though.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

Rob, it is almost impossible to get a good drop. One way I’ve seen done is to tape a very light thread to the flat back end, so that when held by the string it points directly downward like a plum-bob on a transit. Stick the whole thing out a fourth-floor window, and once all motion as settled out, burn the thread off with a torch. . This imparts no torque, so there is nothing to precess around. But this is a minor test, and will be replaced by firing it smoothbore, with no torque from rifling. I expect that, soon enough, someone will try this, and we’ll hear. Of course the important test is paper punching at the range, or penetration. I think we might need even more dart stability. Tungsten is one way, and I’ll get serious about getting you some worm-weights. Another way is maybe to replace as much as possible of the solid aluminum back-end with a hollow aluminum tube. This effectively reduces the average density of the aluminum section, and nudges the CG forward. Pain in the ass to build, though… Of course, firing them at higher velocities will also help exhibit the true nature of their dart stability. | |||

|

| one of us |

When dropped it goes straight down point first from any height. I'm still waiting for my barrel to arrive. It would require a secondary op to drill out the base. As it is, the code I wrote requires 5 tools to make the body in just about 1.5 minutes. I could make a million of them and cheaply too. I plan to test this out as soon as my barrel arrives.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

And it will accept lots of different 0375 bullets, right? Maybe its time for a production run of 100 or so. Material is pretty cheap, too. Let others try out some of those other bullets, while you sell the carriers and listen for success stories… | |||

|

| one of us |

I reamed the cup to .374 and heat it then drop in the .375 bullet. On cooling the aluminum contracts to a interference fit. You can put any bullet you want in the cup. The wall thickness of the borerider section was just too thin for a .429 bullet and I didnt have any anyways near 300 grs. I might try that again with a better aluminum alloy like 6061 and if I can swage a heavier .429 bullet.-I'm going to see if I can find some 3/8 tungsten carbide rod blanks that I can sharpen. Now there is a nasty idea. Penetration from Hell!-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

The heaviest bullet-like weights offered by Tru-Tungsten is the “Flipin Weight†at 1.5 ounces, or 656 grains at about $8.00 each. Unless I have done something wrong, these are 0.519 inch max in diameter. Maybe Corbin would turn us on to a tungsten bullet-maker. I think the tungsten carbide might be more available, and should penetrate better. | |||

|

| One of Us |

Rob, I don’t know how deeply you can drill 6061 on your CNC, but here is one to keep in the back of your mind for a while. Without the wasp waist it doesn’t look as sexy, but the very light weight of the aluminum carrier will make up for the lack of wasp waist, and giver higher dart stability. Glad to hear you are planning a 600 OK version. If you want, I’ll run some cases. And you are right, this whole thing may still be a banana, so some range testing must happen before we break out the beer. I know your upcoming barrel will have a 1/7 twist. Could you also fire some of these more dart-stabilized things with your current lower-twist barrel? | |||

|

| one of us |

Some advice if I may,

One Million parts at 90sec each. 90 x 1 000 000 = 90 000 000 sec 90 000 000 / 60 = 1 500 000 minutes 1 500 000 minutes / 60 = 25 000 hours 25 000 hours / 24 = 1 041.6 days 1 041.6 days / 7 = 148.8 weeks 148.8 weeks / 52 = 2 years and 10 months. No spoils, no stopping for tool changes or machine service, running 24 hours around the clock, seven days a week. Figure 1 out of two hundred spoils and 1 hour out of 24 for tool changes and service. 2 years and 10 months becomes 3 years. Figure 8 hours off and 16 hours of machine time per day, 3 years becomes 4.5 years. Take Sundays off and 4.5 years becomes 5 years and 4 months. Life is a bitch with just one machine and too much work. | |||

|

| One of Us |

OR About 9 weeks on an 8 spindle multi with two or three guys working shifts... Where ya gonna sell a million of one shooting related item regardless of the price?? | |||

|

| one of us |

Just a figure of speech. If there was a market for a million of them Macifej is right just buy more machines and guys to run them. Lets see I had 1300 people working for me once upon a time( Only 12 directly though!. Dont think I want a repeat in my old age.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

You only need one machine to make any of this stuff...but you also need a couple guys who can operate and maintain it and of course someone who has the $,$$$,$$$ to own it. | |||

|

| one of us |

Well I do my own operation and maintenence as best I can. Its lotsa fun and a great learning experience. Basically if I can think it up and I'm good at that, then I can make it without having to wait for years. all in good fun!-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

Having spent most of my adult life doing “researchâ€, let me tell everyone that what we have been doing on this Thread lately feels very much like “research†to me. The natural, inescapable enemy of successful research is the “suck-outâ€. Suck-outs come in many flavors and from the least-expected sources. Maybe the overall design was just plain flawed: a banana. Or maybe materials cost or machining costs are just too high. Or maybe the shop went unionized just in time to miss a critical delivery. Most anything can go wrong at any time. But just one burst from the nose-cannon of a Warthog aircraft would keep Rob and all his friends busy for quite a while. Or just a very few thousand riflemen lobbing darts against advancing troops. So until we find good, hard reasons not to continue what smells, to me, like successful research, I expect to stick it out. Too much fun not to. | |||

|

One of Us |

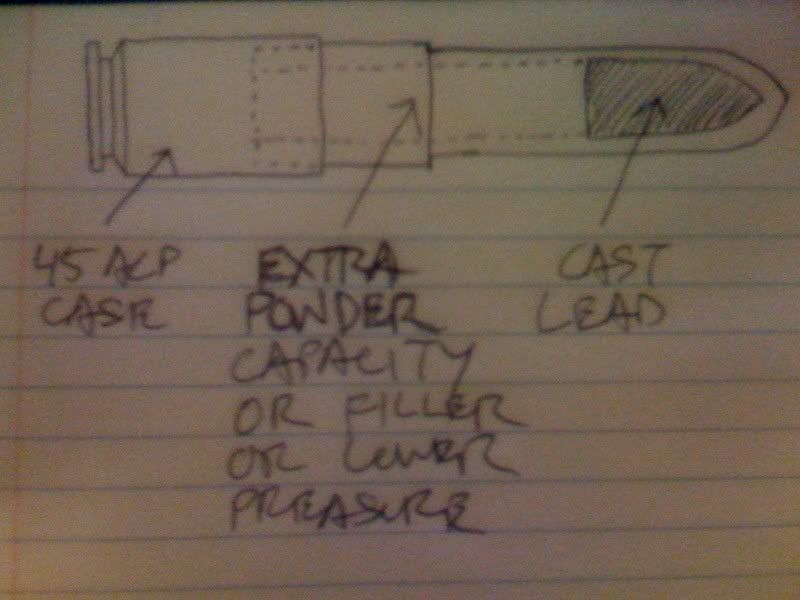

hmmmmmm... OK sorry for the crude drawing but how about either using the machined aluminium as either a mold for cast lead or inserting a cast bullet tungsten weight or regular bullet inside the machined aluminium piece and the left over space could be used for more powder room or lower preasure.  577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

Boom Stick, I’m afraid the thin aluminum would swell up inside the barrel, and jam. In the carrier I showed, there is a thickish aluminum bulkhead at the back end of the carrier to keep the high chamber pressure out of the carrier. | |||

|

One of Us |

Yes, I thought about that and thought it might need to be made of thick brass. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| one of us |

boomstick-I can forsee a number of problems with the hollow carrier design. The most serious are keeping concentricity and uniform weight density. You'd have to swage lead into the carrier and hollow point it as well as internally groove it to let lead out and hold it in place to have any chance of maintaining concentricity and uniform weight. I also don't like the hollow tube as I do agree it could result in very high wall pressures on the aluminum. I also like as little air space between the base of the bullet and the powder as possible.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

One of Us |

Ok well my only other idea is to turn the rims down on 220 swift cases kinda like a boat tail maybe, put whatever bullet you want in it like a high BC 338 bullet or a heavy 375, load it in the 45 acp case and fire away. Use Norma cases for best concentricity  577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| Powered by Social Strata | Page 1 2 3 4 5 6 7 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Subsonic 45ACP rifle shooters?

Subsonic 45ACP rifle shooters?

Visit our on-line store for AR Memorabilia