The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  460 Bauer - a new big bore cartridge

460 Bauer - a new big bore cartridgeGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Here is another citation .... (a reference to a published or unpublished source - a citation is an abbreviated alphanumeric expression embedded in the body of an intellectual work that denotes an entry in the bibliographic references section of the work for the purpose of acknowledging the relevance of the works of others to the topic of discussion at the spot where the citation appears.) .... points number 2 & 3, where this question of shoulder angle to neck length is discussed by target shooters seeking ultimate accuracy, and strangely enough they do mention this phenomenon as well of a turbulence point or convergent point if you will. Again not a theory of my own. I am sure this point has been mentioned by others as well, both before and after P.O. Ackley whether in terms of accuracy or throat erosion, who would really exactly know the origin of this thought or observation. What is for sure is that all these guys came up with this idea long before I spotted it. Anyway here it is - 6 tips are given and points no. 2 & 3 are the important ones here - and this is what benchrest shooters believe and recommend. Here is the link for the full context ... http://262neck.webs.com/theriflescartridges.htm ... but I am quouting the relevant section: (also look carefully what shoulders angles & neck lengths these benschrest cartridges exhibit) "We could include dozens of cartridges in this section but here are a few of the most significant accuracy cartridges in use in the UK. What makes an accurate cartridge? To be honest no one seems to know for sure, but there are a few accepted rules we need to adhere to if we are looking for something new. 1. Short, fat powder-columns seem to offer more consistent powder-burning characteristics. 2. A steep shoulder-angle of 30 to 40 degrees appears to work best. 3. A long case-neck is desirable - not just to hold the bullet in alignment but also to keep the 'turbulence-point' within the case neck. The turbulence-point is the point where the shoulder angles would intersect if extended. Most accurate cartridges exhibit this characteristic. 4. Quality brass. You won't load an accurate round using poor quality brass. Stick to European brass - like Lapua, RWS or Norma. 5. The same goes for bullets. All the major manufacturers make pretty good bullets but 'pretty good' is not what we are looking for. We seek perfection! This will only come from the custom bullet makers who, in the main are American. Look for names like Fowler, Barts, Watson, Euber, Starke, Carteruccio. Benchrest Central has full details. 6. Meticulous assembly of your chosen components. Prepare your cases, seat your primers properly, weigh every powder-charge to one-tenth of a grain or better. Seat your bullet with a good quality straight-line seater die like the Forster Ultra Seater. The Sinclair catalogue contains all the accurate reloading gear." Warrior | |||

|

| One of Us |

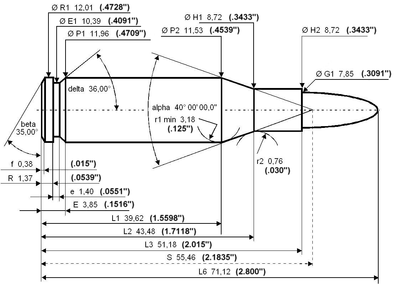

Now relate the above to what P.O. Ackely is saying ... Let me quote ..... "Exponents of the sharp shoulder ideas feel that the sharp shoulder creates greater resistance to the burning powder thus holding more of it in the case during the burning process, which prevents such a high percentage of unburned powder being blown out into the throat of the barrel to create a sand blasting effect at which point erosion quickly destroys accuracy." - Handbook for Shooters and Reloaders, Vol. I, Parker O. Ackley, page 158 (1962). So, anyone is free to interpret this his own way as to what it means, true or not, and if it relates to accuracy at all or not and throat erosion or not. However, the last 4 words in the quote does refer to accuracy and that more powder is burned more completely inside the case. And it is one of the reasons why Ackley decided to design all is cartridges with a shoulder angle of 40% !!! So did Ackley believe this or not? Or did he just do it for love and charity? Warrior | |||

|

| One of Us |

With regard to propellant combustion in a cartridge case and chamber, here is an explantion put forward by some scientists. It goes basically like this: The propellant and trapped air not ignited by the primer-blast is compressed into a solid mass having the characteristics of a very viscous fluid. Straight-walled and bottlenecked cases are distinct in shape and function and so have distinctly different combustion characteristics and efficiencies. In the straight-walled case, propellant that was not initially ignited by the primer burns from the flashhole end forward with most of the propellant following the projectile into the bore of the barrel. The bottlenecked or shouldered case is somewhat more efficient. As propellant is ignited at the primer flash hole or holes, a shock wave moves through the propellant that compresses and heats the propellant. The shock wave is partially reflected off the case shoulder toward a central interior portion of the case. As pressure behind the shock wave begins to move the projectile, the propellant plug approximately the diameter of the projectile is sheared away from the body of the charge. Ignition along the resulting shear surface is rapid because only an infinitesimal gas path out of the shear layer exists causing a rapid pressure and temperature build up. The portion of the propellant plug which is exposed to the case neck can only burn from the aft end forward due to the quenching effect of the case neck and later the barrel bore. The sharper shoulder (30% to 40%) of a cartridge case provides for more burning of the propellant in the case interior and the neck rather than within the barrel. Reduced propellant burning in the barrel reduces erosive damage to the throat and rifling. The shorter powder column with the longer neck causes a more complete burn and support bullet retention in the neck for a longer period of time. Cartridges which are longer but have a shoulder angle less than 35 degrees (Jamison U.S. Pat. Nos. 5,970,879, 6,550,174, and 6,595,138) or double radiused shoulders (Weatherby) do not have a well defined shear line, as the shoulder angle is insufficient to trap the propellant in the cartridge case. A substantial portion of the sheared propellant follows the propellant plug down the barrel. In longer cases with mild shoulder angles, all propellant not initially ignited may follow the bullet down the barrel, as is the case with straight walled cases. As the cartridge becomes fatter and the shoulder angle is made steeper, greater than approximately 40 degrees, the shear line acting at the bullet diameter becomes more pronounced between the propellant plug pushing the bullet and the propellant trapped by the shoulder. This sheared surface ignites more quickly than the normal propellant burn rate as previously described. The double burning surface area of the sheared surface adds greatly to the pressure being generated and can be added to the semispherical burning surface originally ignited by the primer to determine peak pressure. Peak pressure is achieved when total area reaches a maximum, early in bullet movement into the barrel. The use of this additional surface area to explain the pressure-time curve in gun cartridges has not previously been postulated or disclosed. Warrior | |||

|

| One of Us |

Warrior... V Varrior, beech peace. Oscar. I am Spanish My forum:www.armaslargasdecaza.com | |||

|

| One of Us |

Do you believe those sharp shoulders might cause feeding issues? | |||

|

| One of Us |

eezrider, that would be my opinion, based on having designed and had built, half a dozen over the years. The 22-378 I had was the worst offender. Rich DRSS | |||

|

| One of Us |

eezridr, Yes, getting 40 degree shoulders to work is a bitch. Winchester opted for 35 degrees on their 300 WSM. Ruger opted for 30 degrees on their RCM for better feeding. Winchester battled it out on their WSSM by changing the bolt face till they got it right. Sharper shoulders go invariably hand in hand with blown out cases to increase case capacity. These two factors together makes feeding more difficult. In wildcats your gunsmith will always have to do some work for you to ensure slick feeding. Here are some statistics for you: 308 Win -------> 20 degrees 30-06 Spr -----> 17.5 degrees 300 H&H -------> 8.5 degrees 300 Win Mag --> 25 degrees 300 WSM ------> 35 degrees 375 Ruger -----> 30 degrees 375 H&H -------> 14.96 degrees The .223 WSSM like the 243 WSSM, was problematic even with a 28 degree shoulder and very short case length. Their short and fat cases, sharp shoulders, and rebated rims make it a nightmare to feed from the magazine - a jam might just happen, when you have to chamber quickly and so loose your buck. Browning has been forced to delay the release of their super short action rifles due to feeding problems (the A-Bolt II is a push feed action) and the extremely rapid barrel erosion. Winchester have now solved their feeding problem with their new hybrid "controlled round push feed" action. I am of the opinion that both the 243 and 223 WSSM, just like the 6 mm PPC and 22 PPC, will serve better at the bench than as hunting cartridges. Custom building them, require that special action and adapted magazine to avoid any feeding problems. These shorter cartridges require an action that is half an inch shorter than the WSM. That said, steep shoulder angles are not for DG cartridges. That is why Holland & Holland designed the 375 H&H and its derivative the 300 H&H with a small angle - to feed easily and more omportantly, to extract more easily after firing in hot climates such as India and Africa that can easily go over 40 degrees C. Also remember these 2 cartridge cases do not have parralel sides, but sloping towards the mouth of the case and that is as important. Even though hunting rifles have more loose chambers than than the tight tolerances of benchrest rifles, most hunters still prefer to full length size their cartridge cases; reliable feeding is paramount in DG rifles. For benschrest shooting where one can takes one's time, single feeding a round is not as critical as with a hunting rifle that must be able to feed quickly under time constraints from a magazine. So it is all horses for courses. Warrior | |||

|

| One of Us |

eezridr, If I may ask which cartridges do you shoot with? What type of hunting do you do? Do you also come to Africa for DG? Trusting that I have answered you question about the feeding issue with sharp shoulders and blown out cases. Ackley Improved cartridges with their 40 degree shoulders have not gained a following in the hunting arena since the early sixties and it is not likely to do so now, but the idea has spawned a lot of experimentation with benchrest calibers. I will post one such example of a shooter that set out to show the value thereof by designing his own cartridge and he went on to set a phenominal record at 1,000 yds. Warrior | |||

|

| One of Us |

Rich, Please tell us a bit more about this 22-378 WBY Magnum. What sort of an animal is this? a .223 bullet that is being chased by a tornado or something? Is this a new cartridge? Tell us about the feeding issues as well. I do know about the .224 WBY Magnum. though. It features a 41.7 degree shoulder with almost no body taper. It competes with the 22-250 Rem with a 28 degree shoulder and more body taper. And the 22-250 is arguably the most popular varmint cartridge ever. From Wikipedia --- 22-250 Rem and I quote: "Sharpe credited the steep 28-degree shoulder for this performance. He insisted that it kept the powder burning in the case rather than in the throat of the rifle, as well as prevented case stretching and neck thickening. "Shoulder angle ranks along with primer, powders, bullets, neck length, body taper, loading density and all those other features," he wrote. "The .22 Varminter seems to have a perfectly balanced combination of all desirable features and is not just an old cartridge pepped up with new powders." In 1937 Phil Sharpe was one of the first gunsmiths to build a rifle for the .22-250. in 1965 Remington Arms adopted the .22-250, added "Remington" to the name and chambered their Model 700 and 40 XB match rifles for the cartridge along with a line of commercial ammunition. Just curious to know. Warrior | |||

|

| One of Us |

Warrior, Let me see if I can answer your question on what I shoot or own first. 22, 22 mag, 222, 223, 22-250, 243, 257 Rob, 25-06, 257 Wea, 270 win, 270 Wea, 7-08, 7X57, 7mm Rem Mag, 308, 30-06, 300 Wea, 338WM, 340 Wea, 375H&H, 375 Wea., 416 Rem, 416 Rigby, 45-70 458WM, 458 Lott, 470 NE. + a bunch of pistol stuff I seldom shoot. Love archery as well. With that said historically I shoot a 22LR, 243, 270 Win and 338WM most often. Just in the past 3-4 years have I become interested in big bores. For most of my hunting tenure a 340 Wea was the largest gun I owned. As far as hunting; Primarly deer and Elk (Archery). I have shot numerous moose and caribou in Alaska. A lot of bird hunting. I do not call shooting pigs hunting (exterminating and big bore testing). I am looking to Africa for my first trip in 2012, maybe 11 if I can find a good deal and will most likely go to Zim or Moz and focus on Buffalo and Sable with some other stuff as well. I was raised hunting from a very young age and still 53 years young. I have picked up a lot from these big bore forums. Been shooting the heck out of my Lott recently. Dialing in loads. Probably shot 20 test rounds this weekend at my farm in E Texas with A 2520 and 450 swifts as well as 500 Hor across my chrono. Also took out some left over pumpkins from Halloween and did a little long range target practice (400 yards) with a 7MM mag. Did pretty good! Really looking forward to Africa; Planning on taking my 470, 416 Rem and a 338.(First trip EZ | |||

|

| One of Us |

I read an article about the 22 / 378 Wby decades ago. They referred to it as the 22 ear gen splittin loundenboomer; SERIOUSLY! EZ | |||

|

| one of us |

| |||

|

| One of Us |

The 308 Win is sitting at an ideal position - chosen by the military for various reasons, one of which is reliability of feeding. The exterior shape of the case was designed to promote reliable case feeding and extraction in bolt action rifles and machine guns alike, under extreme conditions. It is not exaggerated in any way - it has a 20 degree shoulder and some body taper. Barrel life is very good and estimated between 6,000 and 8,000 rounds depending on how it is used which is a great advantage over the smaller bore cartridges (The .243 Win, on the same case only gives about 2,000 to 2,500 rounds).  The .308 is still the most popular sniping round, and for good reason. It is not punishing to shoot, not to much barrel raise in automatic fire, and has no peculiarities. While there are quite a few rounds that outperform the .308 Win, has been consistent, accurate and a great performer. Little wonder that the .308 Winchester has also become the most popular short-action for hunting antelope worldwide. It is not your "ulimate" 1,000-yard cartridge or short-range paper-puncher, the .308 remains one of the best cartridges in the modern arsenal, with versatility that few other calibers can match. Warrior | |||

|

| One of Us |

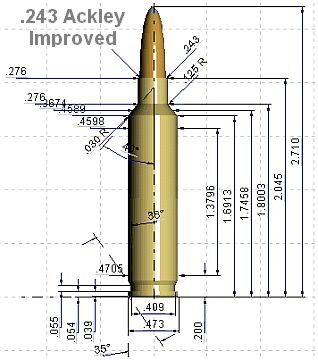

JUNE 2006 - RICHARD'S DASHER  Richard (foreground) waits for his relay to start Here is an account of Richard Dasher who set out to have a rifle built for him based on principles on which present day competition rifles are built. However, Richard’s rifle wasn’t built with 1,000 yard benchrest competitions in mind – this is first and foremost a ‘working’ rifle and spends its time in the field rather than on the bench. Then one day he attended a shoot in the UK during June 2006 at Diggle Ranges, and what a surprise it was for the benchrest shooters to have a field rifle competing with them. Richard stunned them with his spectacular 5 inch group – the best of the day. At the time the 6 mm Dasher was not even in common use in the UK, and that added to the curiosity of its design aspects. So here are the basic details of what a 6 mm Dasher is and I quote some extracts from various articles. "The 6 Dasher is an "improved" 6mm BR, so performance is a bit faster than the standard 6mm BR. It offers about 4 grain more case capacity than the standard 6mm BR case. It has a 40 degree shoulder, and the shoulder is moved forward .100. The 6 mm Br has a 35 degree shoulder with a longer neck, whilst the 6 mm Dasher has a 40 degree shoulder with a shorter neck, but the turbulence point remains inside the neck of the case. One can usually get an extra 125 fps with a 105 -115 gr bullets over the 6 mm Br. The 6mm Dasher has the capability to easily push the 105-108 gr. 6mm bullets up in the 3,000 fps range (2950 - 3050 fps)." "This is the standard Ackley-isng process made famous by the late, great Parker Ackley. But of course, you knew that. All this work usefully increases case-capacity by about 10% and the steeper shoulder is thought to give a better powder ‘burn’ by keeping the ‘turbulence-point’ well inside the neck area. Of course, these are all theories but they seem to work in practice and the short, fat powder column and steep shoulder-angle are features displayed by most of the ‘inherently’ accurate cartridges currently claiming the accuracy records."  Left, the 6BR, centre the 6mm Dasher and right, for comparison, the 308Win Richard prefers Reloader 15 powder, CCI 450 Small Magnum primers and of course, Lapua brass. For target-work, Richard prefers the 105 grain Lapua Scenar bullet but uses the Hornady 105 grain A-Max for vermin. So, whether we buy into this theory of the 'shorter powder column with steep shoulder angles' or not, it seems to have been proven yet again. As I stated before in the article that I wrote, I still believe it is a combination of factors that contribute to the overall accuracy equation, but with all the evidence mounting it cannot be totally ignored. It begs the question ... why are we not seeing cartridges with long sloping shoulders (small degree angles) such as the 270 Win and the 360 Spr dominating benchrest competitions? Hope y'all enjoyed the ride. Warrior | |||

|

| One of Us |

Warrior! Thank's a lot for the interesting information! Is this why my 243 AI is far more accurate than my friends 243 Win. ? The only thing I envy him is smoother chambering... m | |||

|

| One of Us |

Metric, Now here is another report from Bob Blaine, from Sinclair International: "Parker Ackley reluctantly developed the .243 Ackley Improved ("AI"). Ackley finally gave in to his customers' requests to develop the .243 AI. He had always felt that the .243 Winchester was already an improved configuration, but he did say that the best thing to be gained by improving the .243 Winchester was to substantially reduce the case-stretching problems. The .243 Winchester parent case has always stretched brass, almost as bad as the Swift. Even though you get more velocity with the improved .243, I've also found that the improved version gives a bit more throat life than the parent case does." Again this report seems to confirm 2 aspects: 1) The 20 degree sloping shoulder of the .243 is known for case stretching and the formation of doughnuts at the junction of the neck and shoulder. 2) The faster 243 AI, by virtue of a bigger case capacity, and thus more powder to burn actually gives a bit longer barrel life, and that seems to be at odds with the general theory that more powder will burn longer and expose the rifling to heat longer. The only thing then is to notice that the so called 'turbulence' or convergent point is well inside the case neck, by virtue of its 40 degree shoulder, and the 243 Win is well oustide the neck. Unless Mr. Bob Blaine is telling us a lie here ... a sweet little lie.  Warrior | |||

|

| One of Us |

Experimentation with cartridges that are better suited to a particular range carries on unabated - 300, 600 & 1,000 yds). We have seen so much of this in the last 10 years, and the quest is still on to shift the boundaries. Hornady has launched its own cartridge an added another alternative to the already most popular cartridges that are dominating the benchrest scene. Long-range shooters gravitate towards calibers which provide great ballistics and accuracy along with relatively low recoil. Because these loads are highly specialized, it's almost impossible to find factory ammunition that provides match-winning long-range performance. It's just a fact of life that to get match-winning performance, you need to reload. This presents a barrier for entry into the sport for would-be new shooters. Competition shooters do have some other excellent choices in the 6.5 mm caliber as well such as the 6.5-284 Norma, .260 Remington and 6.5x47 Lapua, but Hornady had an idea to offer something that they felt was unique. The 6.5 Creedmoor was developed for the express purpose to provide a cartridge with the accuracy and ballistics to be competitive at the top level long-range competition using factory ammunition, while also being easy on the novice reloader. The components used in the factory ammunition would all be available to the reloader in plentiful supply, and the factory loads would use readily-available commercial components. The recipe to exactly duplicate the factory loads would be printed on every box of ammunition from Hornady. The powder used in the factory loads is H4350 and the primer is the Federal 210M Match. Dave Emary and the Hornady engineers went to work and by early 2007 had come up with a cartridge roughly based on the .308 body size, shooting a 6.5 mm bullet. The case has a 30-degree shoulder and a 0.370-inch neck. The case head is identical to .308 Winchester which makes it a shoe-in to any .308 action, and the body is tapered 0.004-inch per side for extraction reliability. While some reloaders will try to hotrod the cartridge, factory ammunition is limited to 58,000 psi and shoots the 140-gr A-MAX (BC 0.585) at 2,810 fps from a 26-inch barrel. Compared to some long-range ammunition which runs at a maximum pressure over 60,000 psi, being able to achieve a respectable 2,800 fps with the high-BC 6.5 mm bullets will increase safety, aid reliability, and provide long brass life. For reduced recoil or short-course matches, the factory 120-gr A-MAX (BC 0.465) loads run at 2,980 fps. It is also expected that the 6.5 Creedmoor should give more than twice the barrel life of the popular 6.5-284 Norma. http://www.hornady.com/store/6.5-Creedmoor Now we are just waiting for results to come in to see how it does in top competition - there may be some already. Long-range shooter Ray "RayDog" Sanchez summarized the Tubb rifle in 6.5 Creedmoor as "boringly accurate" at 1000 yards. Warrior | |||

|

| One of Us |

Hornady makes the above issue a major selling point of the 6.5 Creedmoor cartridge. Whilst the 6.5-284 Norma is still the most popular 1,000 yard competition cartridge, it is hard on barrels being so over-bore and running at at the highest pressure, despite its 35 degree shoulder angle. Barrel life is a key issue for 6.5-284 shooters, because barrels can loose their accuracy edge in as little as 800 rounds, though 1,000 rounds is more typical, and I have seen postings on other forums of 1,250 rounds. If the rifle is set back at around 900 to 1,000 rounds it can last another 700 to 800 rounds. That is still not a lot at 1800 rounds. Let us site a few other 'barrel burners' ....  Left to right: .22-250 Rem; .223 WSSM; .220 Swift; 7 mm Ultra Mag; and the .30-378 Wby. Mag. Cartridges like the fastest .22's (left three) that approach or exceed 4,000 fps are going to wear out barrels more quickly than slower cartridges. Cartridges that are over-bore and require prodigious charges of powder, like the fastest 7mm's and .300's, are also going to erode throats faster than more efficient cartridges. The higher the pressure the higher the flame temperature the more erosion it causes. Put another way, erosion is accelerated when there is more hot gas than the bore can efficiently convert to kinetic energy of the bullet. Warrior | |||

|

| One of Us |

In 2003, Winchester Ammunition, Browning and Winchester Firearms introduced the 223 and 243 Winchester Super Short Magnum (WSSM) cartridges. Even before the first Browning firearm chambered in WSSM calibers hit the dealer’s shelves, speculation had it that barrel life would be terrible. Test results show that in non-chromed barrels, the wear performance of WSSM calibers was equal to the 22-250 Rem. In chromed barrels, the wear resistance was doubled - see chart. It should also be noted that Browning has never sold a rifle in 223 or 243 WSSM without a chromed barrel, and as an added benefit the smooth surface of chromed barrels makes cleaning them significantly easier. So now we are looking at 2,000 instead of 1,000 rounds. This is interesting to know.  Warrior | |||

|

| One of Us |

Certain overbore cartridges are even worse - they generally don't let a barrel last much past 700 shots. An actual DOCUMENTED case of a .300 Remington Ultra Magnum had the barrel last only 580 rounds. The 7MM STW is a cartridge is in the same category. The .30-.378 Weatherby, is another notorious barrel burner. They deserve the title as barrel burners. The .30-378 Mby case holds as much as 120 grains of powder without requiring a compressed load. Now compare this with a 308 Win that has the same bore size and consider the ratio of the powder charge to the bore volume. The .30-378 WBY is possibly the worst one out there at around 300 rounds of barrel life (some sources say that throat erosion was already evident after 125 rounds) and I consider this cartridge similar to a Mona Lisa with a moustache. Warrior | |||

|

| Moderator |

Chris, This is big bores, not 308 or 22wssm. If it doesn't start with .375 or bigger, stop posting about it. Take the rhetoric to the correct forum. Thanks opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

True but a generalization. Lighter bullet and slower burning powder yields lower pressure. Soft crappy barrels will wear out faster than other. Extreme applications call for innovation in materials. Entering your checker cab in an F1 race produces substandard results eh? | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  460 Bauer - a new big bore cartridge

460 Bauer - a new big bore cartridge

Visit our on-line store for AR Memorabilia