The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Medium Bore Rifles

Medium Bore Rifles  30-06 dancing like a 300 h&h

30-06 dancing like a 300 h&hGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Ah, yes. Reading too fast again. Senior moment... thanks. | |||

|

| one of us |

if you get case head expansion you will get loosened primer pockets, if your load is in the vicinity of expanding the case head your case head will expand with each consequative shot, and so will your primer pocket, and within 6 or seven firings you will have very loose primer pockets before you do your test remember to fire the case with two mild loads like 57 gns of hunter to case harden the head of the case ..... im only suggestion would be to use lapua brass its so much better then winchester/remingtom brass also remember not to mistake loosened primer pockets with high pressure only.....after 10 or 15 firings there is wear and tear on the primer pocket Regards | |||

|

| one of us |

I wanted a 06 to be like a magnum so I went out brought a 300WM. | |||

|

| one of us |

The suggestions by Ackley Improved User above are good ones. Watching for the loosening of primer pockets earlier than the fourth or fifth loading is the most practical way to assess whether your load is reasonably sustainable. | |||

|

| one of us |

If you shoot about any load 5 to 6 times you can look forward to some loose primers popping up..toss them....better yet anneal your brass every time you shoot it and it'll last damn near forever.. When loading the 300 H&H forget the belt, headspace on the shoulder like any other beltless round and brass will last longer. With the 30-06 use a case full of H4831 and get your best velocity and cases last a long time, but again annealing is the secret to long life. Most all my caliber will shoot about 10 to 14 times without any problem other than I'll toss a few loose primers out..No sinch in annealing if they do that, after a dozen reloads toss them and buy new brass, 06 brass is cheap.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

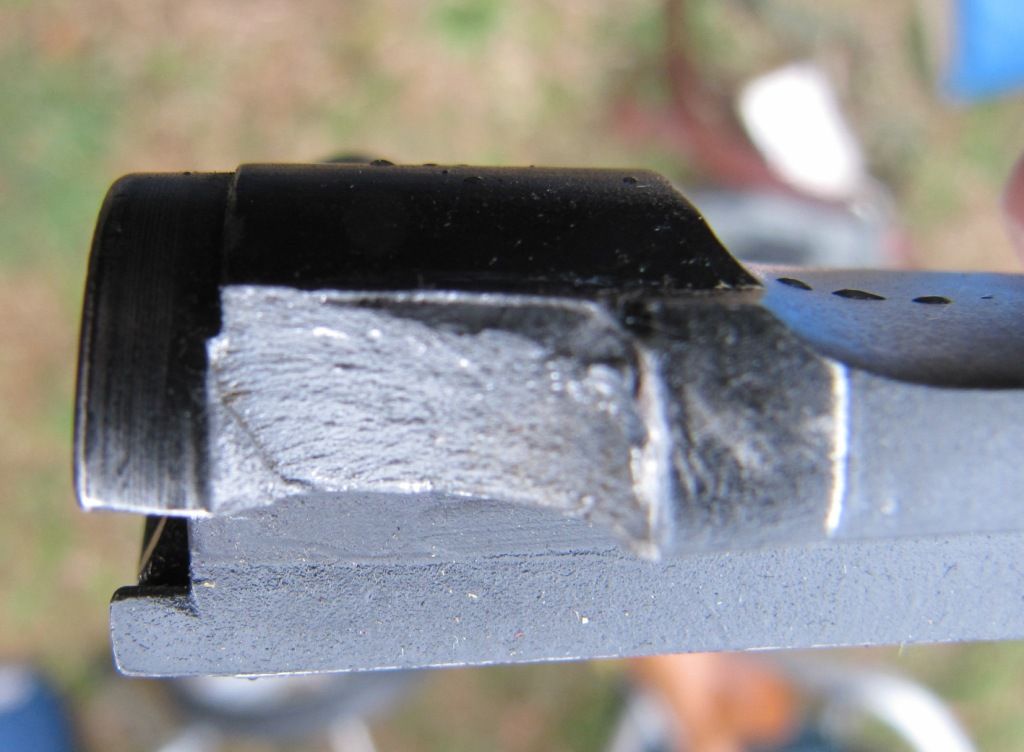

I am going to pee in the punch bowl of this hot ammunition love fest. I don’t believe that nature provides shooters a free lunch. The faster the bullet moves, the higher the pressure. If your bullets are moving extra special fast, it is because your pressures are extra special higher. While some rifles exhibit standard signs of over pressure, others don’t, and I don’t know why. We have all been taught that blown primers, leaking primers, sticking extraction, expanded primer pockets are all signs of excessive pressure, and I believe that these signs are 100% evidence of excessive pressure. However, it has not been proved that absence of these signs means that pressures are OK. I do believe, believe because I don’t have pressure data to prove it, that you can have overpressure conditions and not have these classic signs. Phillip Sharpe had a section in his book “Complete Guide to Reloading” on the pressure problem and I remember in “Important Loading Notes” he had cartridges that appeared to be fine after firing, but when pressure tested the loads averaged 66,660 psia with a max over 68,000 psia. Mr Sharpe is very adamant that you cannot estimate cartridge pressure by a physical examination of the cartridge case, or by extraction indications. So, does that mean overpressure loads are dangerous? Well it certainly will be dangerous if the cartridge case ruptures, if the chamber bursts, and if the action breaks while under high pressure. Up until those events, nothing eventful is likely to happen. Sort of like falling 10,000 feet without a parachute; you are perfectly safe till you hit the ground. From a designer’s viewpoint, your thunderstick was designed to carry a load. Lets say the load is one, and that requires a certain amount of steel. "Standard" safety factors are applied to the calculations to increase the material thickness. Let us say the designer uses a safety factor of two in yield and four in ultimate. Yield is the most important consideration, hopefully the intelligent person will stop using the firearm once parts deform. A safety factor of two does not mean the firearm is twice as strong as it needs to be. Rather, with a safety factor of two, the designer truly hopes it will complete a normal service life with a loading of one, given all the uncertainty in strength of materials (steel varies by lot) , variability of heat treatments, and part tolerances. I have probably lost you, but overpressure means that the load imparted on the locking mechanism and the barrel are in excess of the design load. The next issue is fatigue life which is based directly on service life. By the way, there is an interesting article in this month’s American Rifleman (March 2015) titled “Are your guns Tired and Stressed?”, “Fatigue Failures”. Shooters just assume the lifetime of their favorite thunderstick must be infinite. I don’t think that is reasonable at all, unless you happen to have bought a 50 pound single shot 30-06. You can have a firearm where the locking mechanism has an infinite service life if you are willing to buy something so massively heavy that it is a crew served weapon, with wheels so your crew can roll the thing to your firing point. In terms of fatigue life, extra weight increases the number of cycles a structure can endure before breaking. However, if you want a seven pound 30-06, a weight which includes stock, magazine, sights, barrel, etc, then you are going to have to make compromises. One of which, the locking mechanism is designed to a finite lifetime, a finite service life based on the design load. A good question is what is the reasonable service life of a typical hunting rifle?; and I am going to say that a reasonable service life is in terms of thousands, to tens of thousands of rounds, but certainly not hundreds of thousands of rounds. These light, hand held weapons are light duty items. I found out from a cannon designer, that the 155mm used on the Stryker, the barrel, locking mechanism, recoil mechanism, and mount, are all thrown away at 15,000 rounds. The military is willing to trade off weight for reduced lifetime. If you ever go through the DoDiss specifications, you find that rifles such as the M1 Garand, M14, and the M16, all they really have to do is fire 6,000 rounds without breaking. This definition has gotten more complicated in time, but the military decided 6,000 trouble free rounds was a good service life for a battle rifle. (for a rifle to shoot 6,000 rounds without failure, parts obviously have to last on the average, longer than 6,000 rounds, but make the weapon too heavy, and the military buys someone else’s gun) When a service rifle is returned to depot for rebuild, anything, and I mean anything, can be scrapped or replaced, and this is acceptable. So, I am going to say that that is reasonable that your rifle receiver was designed as a light duty part, and that its service life is likely to be in the tens of thousands of cycles, given a standard load. As you reach the maximum number of load cycles, at some point in the future, you can expect the locking mechanism to fail through fatigue. If you over load the structure, it will fail sooner. I have bud’s who are shooting cartridges such as the 6.5 Grendel, 6.5 Turbo, in AR15 actions. These cartridges have a wider radius than the 223 cartridge and as such, deliver more bolt thrust. One bud, with his rifle, he got an extra bolt. When the lugs crack on the first bolt, he is to remove the first bolt and put in the new bolt. He has stories of lugs cracking, The second bolt should last through the accuracy lifetime of the barrel. When the barrel is shot out, and I am talking about less than 6,000 rounds, the whole rifle goes back for one new barrel, and two new bolts. Target shooters consider their rifles as consumable items, and if they use up their rifle, but win a National Championship, all is fine and good. I have researched fatigue lifetime, in the book “Atlas of Fatigue Curves”, and in that book there are all sorts of interesting materials and loadings. I did find one example of periodic overloading, and let me assure all, periodic overloading drastically reduces fatigue lifetime. So, if you are getting extra special fast velocities, it is because you have extra special high pressures. If you are willing to trade off part longevity for speed, then, do it understanding what you are actually doing. With overpressure loads you have eaten into the safety margins designed into the structure. You are exceeding design loads, the lifetime of everything carrying load will be reduced, and fatigue failure of your rifle parts will occur sooner than later. Fatigue failures may or may not come with a warning, usually, they don’t. If you ever see the tiny tiniest crack in anything, stop shooting. These are examples of modern mechanisms that cracked, obviously with over pressure loads. If gas has spilled back into the action, because of cartridge rupture, the shooter could have been hurt. All I know is that these pictures were posted on the web, and I assume the shooter walked away unhurt. Commercial Mauser FN 264 Win Mag    M70 FNSPR 300 WSM     | |||

|

| One of Us |

IIRC, that FN mauser you have pictured, failed due to way excessive hardness in the lug region. D'Arcy Echols has commented that he has seen the same thing in FN masers that were excessively hard in the bolt lugs. If you look at the newly exposed metal surfaces after failure, it appears that the bolt is through-hardened. Depending on ones HT method even when properly done, some methods will set up boundaries in the steel, where as another HT method can have a more graduated transition to the core. Depending which HT method is used, the action can react differently to the same load. | |||

|

| One of Us |

If this is true, then that shows how part quality can vary in firearms considered high quality and from a reputable firm. It would be dismaying to find that “standard” loads caused part failure in a rifle that underwent proof. I have made a small study on metallurgy. Older guns, such as the military Mausers, M1903’s, and even the FN Mauser actions, were all made of plain carbon steels , which are erratic in hardening depth, have low fatigue lifetimes, and marginal impact strength in cold weather. Caution should be applied in reloading for the things, given the age, the number of service lives the things have gone through, and the inferior metals and process controls under which they were built. | |||

|

| One of Us |

Mr.Echols posted that the guy who cracked an excessively hard FN bolt was trying to run 140s at 3300 from his .264win and naively developed his max. load in winter. with factory ammunition or std book loads, he might never have managed to crack his lugs. I remember from 1980s, loading my 7x57 M70 featherweight in 'chasing 7mmMag vel- ala Ray Atkinson style', then I very soon realised its wiser to more safely use my .270WBY with book loads if velocity is what I want... with .300H&H , id be more than satisfied with factory ammunition 180gn/2880mv, without trying to do extreme handloads simply to try and 'beat' the .300win or 'tailgate' the .300WBY. | |||

|

| Moderator |

there are several 2800+ loads for 30-06 with slow powders, in the books - the "beyond max" OAL is NOT a sure safeguard for your loads in a "normal" rifle .. anything with throat erosion (1903 or garand come to mind) will allow long 30-06 in the chamber win 780, or MRP are pretty slow powders.. 780 being around norma mrp and rel22 .. no magic there, ammoguide shows 7 powders with 180gr bullets over 2800 ... even with 22" barrels opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

But do they do that in real life book velocities are just that. It depends on the book and a lot of the older book velocities were just estimates. | |||

|

| One of Us |

Absolutely they were estimates. Most of the older manuals used the same system we use: physical and visual indications of excessive pressures. In P.O. Ackley's handbook, there is a quote from Mr Speer, Speer stopped using the pressure gages of the era to develop loads. Ackley certainly was not using pressure gages when he was making his fallacious claims that "Improved" (straightened) cases increased velocities without increasing bolt thrust. All he was doing was driving pressures high but not seeing the physical indications of pressure. Savants on other forums give out a rule of thumb that a 40% increase in case volume provides a 10% velocity increase, implicit is the assumption that this is isobaric. This may be a crude rule of thumb, and I have done nothing to verify this. Below are comparisons of Ackley's published data compared to pressure tested data. 49th edition of Lyman Handbook, the max load of a standard 30-30 with a 150 grain bullet and using 28 grs IMR 3031, the velocity is 2145 with a pressure of 38,000 cup. In Ackley’s own handbook, the maximum load for a 30-30 AI for a 150 grain bullet using IMR 3031 is 38 grains for a velocity of 2700 fps. From web data, the case capacity of the 30-30 Ackley vs the unImproved Winchester parent differ by 5% http://www.gmdr.com/lever/3030atext.htm yet here you have Ackley stuffing in 10 additional grains of powder and claiming a velocity increase of 125% over the standard 30-30. The only way to get those sort of velocities through incredibly high pressures. If you go to your 1957 Gun Digest, factory ballistics for the Winchester 180 grain Super Speed 30-06 is 2700 fps. Modern reloading data shows you can push a 180 Barnes with 55.7 grs IMR 4350 to 2685 fps, in close agreement with older factory data. Ackley’s handbook gives reloading data of 61 grains IMR 4350 with a 180 grain bullet for a velocity of 3053 fps. Noslers shows a max load for the 30-06AI of 56.5 grs IMR 4350 with a 180 gr bullet at 2835. For the 30-06AI Ackley is putting 5.3 additional grains of powder in the case and claiming a velocity increase of 113% over the parent cartridge. His data is pushing bullets 218 fps faster than modern pressure tested ammunition of the same case. The only way to do this is through incredibly high pressures. If you compare loading data from today from those older manuals, there are very good reasons why maximum loads have decreased: modern data uses piezo electric pressure gages. In fact, piezo electrical pressure gages are why you don't see certain powder/primer/bullet combinations. Now that the pressure curve can be examined real time, testers can see pressure wave fluctuations and some combinations, like Blue Dot in rifle cases, the spikes in the pressure curve are so sharp with small component changes, loading companies know it is irresponsible to recommend these combinations because someone will blow up their rifle. And guess what, it does not take much searching to find examples of rifles blown up using Blue Dot. http://forums.accuratereloadin...2511043/m/8131029301 | |||

|

| One of Us |

The links posted above show Piezo PSI data vs. velocity for the 30-06 for a variety of bullet snd powders. It looks good to me. | |||

|

| new member |

One does not need to dig back into old manuals to find 2800+ loads listed for the 06 with 180gr projectiles. Ramshot list a handful. While I tend to agree with Slam Shot in principle regarding "chasing super velocity loads," I must say he seems to be ignoring certain principles of physics in order to affirm his black-n-white pressure proclamation. Of course increased speed only results from increased pressure, but "more pressure" doesn't necessarily mean a taller pressure spike (a higher PSI). Simple physics. "Pressure problems" are not merely a matter of the height of the pressure curve, but also (and perhaps more importantly) it's slope. How rapidly does the pressure climb, and how long is the slope? Both max height and slope are force dynamics that determine load safety. Hence the advantage of slow burning powders. More slow powder in a case may not lead to higher max pressure (higher psi), but a more sustained or longer pressure curve. Savvy archers well know this principle of physics. Set two compound bows at 70lbs of draw weight, one for an archer with a 28inch draw, the other with a 32 inch draw. If both bows shot a 28 inch arrow (something guys with long draws used to do in the 80s using a contraption we called an overdraw), the long-armed guy with the 32 inch draw would shoot that arrow at MUCH faster speeds than the fella with a 28 inch draw. Why? Simple physics--a 28 inch force curve vs a 32 inch force curve. The increased velocity was achieved despite both bows having the same max draw weight of 70lbs. Think about it folks...this is why barrel length matters--longer pressure curve, not higher. Rifles with 24 inch tubes will generally shoot a load a bit faster than those with 22 inch tubes. To apply Slam Shot's black-n-white pressure theory, the only plausible explanation for this would be that longer barrels result in higher pressures (more psi). Nope. They simply sustain pressure for a longer period of time by allowing you to use more powder. This transfers more kinetic energy to the projectile by allowing it to further overcome its initial inertia. The same principle can be inferred to slow burning powders. Simply put, physics would not let me get away with stuffing 61 grains of a fast burning powder behind a 180gr projectile. That would be a dead-man-walkin' load. But again...think about it folks, as a bullet travels further down the barrel, more space is created for the expanding gas to fill behind it. A slow burning powder allows for more space to get created before the pressure curve reaches its max. The velocity advantage comes from having the extra powder (fuel) to burn and keep the lengthening space behind the bullet filled with high (but not necessarily dangerous) pressure. I'll say it again...in principle I agree with Slam Shot regarding chasing unrealistic velocities. Fools' folly for sure. But I will counter his piss with the assertion that the reasonable/safe zone has probably stretched a bit with advanced powder chemistry and geometry. In the final analysis, I will probably eventually morph my long-range rig into a 300magnum simply because I don't like "max loads." Nevertheless, a final bit of perspective is certainly in order here. Even if we all were to agree upon the old tried and true gold standard for the 30-06 (2800fps w/180gr projectile), the subject of this thread that has caused so much fervor was a load achieving 2875. We are talking about spitting 75fps over the old standard. Now if I had somehow throttled this baby up to 3000fps, man can you imagine the data space this conversation would gobble up? | |||

|

| new member |

P.S. sorry. By Slam Shot, I meant Slamfire. And regarding longer barrels, I didn't mean to write "they allow you to burn more powder." I go ahead of myself there. I meant to write that they allow the powder to sustain pressure for a longer period of time. D'oh! | |||

|

| Moderator |

the area under the pressure over time curve is called work -- and that makes velocity ... peak pressure is both a safety concern and a byproduct... NOT a determination of max vel .. bluedot makes a higher pressure than rel 25 ... opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

There are certainly factors which contribute to more velocity than "more pressure". The size of the pressure vessel, the diameter and finish of the barrel, the length of the barrel, the burning characteristics of the powder, the metallurgy and bearing surface of the projectile, etc., etc., can all work together to achieve more velocity without increased pressure. Slamfire is correct that ordnance steel, when subjected to repeated stress, will "fatigue" (this is actually work hardening as the metal stretches and contracts under the force.) It's just like bending a piece of wire which will eventually break. He is also correct that gun actions which move as a result of the discharge of the round have a somewhat predictable and finite life. But this is due to wear and fatigue of ancillary moving parts, not the breech locking mechanism itself. It is also not due to the effects of chamber pressure, but due to the movement of the parts irrespective of chamber pressure. Of course, excessive chamber pressure, especially excessive port pressure in gas autoloader, can speed up the process. However, he is wrong that a modern bolt rifle of acceptable metallurgy somehow has a finite life due to work hardening of the locking lugs -- at least not with loads which do not destroy the brass case. The only time a modern, front-locking turnbolt fails is when there is an overload which exceeds the tensile strength of the steel (in which case it is typically not the action which fails, but rather the barrel/chamber which blows open. With such catastrophic pressure excursions the bolt is usually found completely intact, although the receiver ring into which it mated may be in several pieces.) The cracked lugs illustrated in Slamfire's post would have occurred regardless of whether chamber pressures were "modest" or "maximum", because the metallurgy of the bolts in question was defective to begin with. The same failures would have occurred even if firing nothing but factory loads of modest pressure. Bottom line: You're not going to "wear out" or "fatigue" your Remington 700 or Sako L61R action with loads which do not exceed the pressure capacity of the brass case -- that is, pressures which do not expand the case head such that a primer is too loose to dependably stay seated. Not in 10,000 rounds. Not in 100,000 rounds. You'll suffer more wear from simply opening and closing the bolt on an empty chamber. | |||

|

| One of Us |

Right on, Stonecreek!!!!!... Most shooters/reloaders have NO CLUE when it comes to metallurgy or a stress analysis in a firearm, or WHAT ACTUALLY happens when you pull the trigger, how/where/what the pressure is actually expanding to/doing, the actual psi ratings of the steel/brass of the various components and only get a very tiny, incomplete and extremely incorrect view of what is happening from the 'net. No diss intended as most never get that far in their educational process and only have a limited knowledge base to use or limited resource's in the form of computer software/desire to know or understand, this complicated subject. For those that want a primer from an engineering analysis perspective, goto Varmint Al's...http://www.varmintal.com/..."Rifle Action stress and Bat Action analysis" and read up on his rifle action stress analysis. Excellent reading along with excellent pictures. Every time I start to get a bit on the wrong side of "Magnumitis" I re-read those analyses and re-examine just where I'm at with a particular recent cartridge/rifle build. The problem with this subject is the need to "PROVE" something by pulling up tons of "out of context" and "extraneous, incomplete and erroneously used" garbage from various sources, and tossing it out as "from an expert source"...no different than the media and politicians do moment by moment. Misinformation, disinformation and down right lying...Nixon would be proud. There is no stopping it either as this long thread proves. Be careful out there, dragons and daemons are hungry. | |||

|

| One of Us |

Modern first-rate bolt-action rifles - e.g., R700, W70, and the like - should be able to withstand at least ~150,000 PSI. Weatherby wanted his rifles to withstand ~200,000 PSI, but I don't know if he achieved this. The main risk of loading HOT with modern bolt-action rifles is that you may experience a pressure excursion and get a stuck case, after which you need to reload but instead you watch that trophy of a lifetime disappear over the hill. Stuck cases at the range are also a pain in ass, but the consequences are usually not so serious as missing out on that trophy. Finally, gases escaping from a blown primer - although such gases shoul be be vented to the side - could potentially cause eye damage, if you're not wearing eye protection. I always wear eye protection. For HOT hunting loads, I use new cases and work to stay at or below 65,000 PSI. I stop when I see the slightest excessive pressure signs, which is usually "loose" primer pockets within 4 to 5 reloadings. | |||

|

| One of Us |

I disagree with this. Of course anything is going to break if the load exceeds tensile (or ultimate), that is the definition of ultimate. But fatigue occurs with loads below yield. And, do you understand this, with standard loads the lugs are stressed below yield, the receiver seats are stressed below yield? Perhaps you don’t understand fatigue or fatigue life. There is plenty of college course material on this, uploaded to the web. Just because you have not seen or experienced fatigue failure in one of your rifles does not mean it cannot occur. You have not shot your rifle enough, put it through enough load cycles, to experience cracks. Instead, what I am reading from your post, is denial, your expectations are that your rifle will last forever, you can fire it an infinite amount of times. But you have not provided an analysis to back up your desires. Nor, have any of your supporters. I have calculated shear, calculated load, and examined the S/N curve for the Mauser action for various materials, it is quite easy. Why not do it for the M700? Instead of stating “it cannot happen”, get your calipers, calculate a load, look up material data, find an S/N curve, and come up with a cycles to failure. You do this your argument will have credibility.

You don’t know that. I don’t know that either. Just how many rounds had been fired in that rifle, and what were the loads? Do you have that information?, please share if you do. Now I have seen a bolt that shed a lug, and I am certain it was a defective bolt. I was on the firing line and got to talk to the shooter. This was a new rifle, had around 200 rounds through it. The shooter had squirreled away thousands of LC match rounds in his career and that was all he had shot through it. The lug sheared while firing LC 79 Match. Based on this information, I am highly confident that what we had was a defective bolt. This is an aftermarket bolt, but made of 8620. If you search the history, the original manufacturer’s of the M14 had bolt lugs breakage, because the quench times for 8620 are not forgiving. I suspect the maker of this aftermarket bolt did not know this, but, it could have been something else that caused the breakage.       | |||

|

| One of Us |

This thread is like the vast majority of threads on this forum - people enter with their strong opinions, express their opinions strongly, and leave with the same strong opinions unchanged.......I often think, why bother? | |||

|

| One of Us |

I am really curious about the people who contribute to such threads as this. When I shot frequently I rarely shot anything larger than a 22LR for pleasure. I shot them for hunting and to develop a load for hunting. My load development was strictly to develop an accurate load in the rifle I was going to use. I always loaded by the book and have never in my life had nor used or even seen a chronograph. I figure the book values are good enough for me and I never loaded them much over midrange and rarely if ever to maximum. I used a 30-06 with excellent results in Africa on everything up to Wildebeest. I always used a 220gr Nosler Partition which my rifle shoots with great accuracy. I always used the ballistic charts from the manual and shot one Wildebeest at over 325yds measured. He dropped at the shot. The amusing thing about this is the fact that both my Wildebeests were shot at over 300yds with 2 basic differences. The first was shot with a 375H&H with 260gr Nosler Partition. The PH estimated the range at 200yds and I held accordingly ( I always know the trajectory of all the loads I use and sight the rifle in acordingly) and it turned out the distance was over 300yds and rather than take the animal out it merely broke a front leg and I can assure you a wildebeest can cover a lot of ground on 3 legs. The second one was estimated at 350 yds and I held accordingly and it went down at the hit. That's why I ask are these people hunters or shooters? It worked for me my way for over 50 years. SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

I'm glad I got through that stage of life without destroying any of my Mod 70's! | |||

|

| One of Us |

Not only the burn rate effects the shape and duration of the pressure curve, but also whether powder used is 'single base'..or 'double base'. A popular cartridge like the .270win which will usually be fueled with US powders, can reach well beyond 90 kpsi in the pressure curve, but can show a uniform 58kpsi from round-to-round in the copper-crush pressure test/reading method. | |||

|

| One of Us |

Pacific Standard Dec 2014, We are all Confident Idiots – David Dunning http://www.psmag.com/navigatio...fident-idiots-92793/ An ignorant mind is precisely not a spotless, empty vessel, but one that’s filled the clutter of irrelevant or misleading life experiences, theories, facts, intuitions, strategies, algorithms, heuristics, metaphors, and hunches that regrettably have the look and feel of useful and accurate knowledge...... In many cases, incompetence does not leave people disoriented, perplexed, or cautious. Instead, the incompetent are often blessed with an inappropriate confidence, buoyed by something that feels to them like knowledge.” Another point the David Dunning makes is the more ignorant the idiot, the more confident the idiot. | |||

|

| one of us |

Oh man!! Isn't that the truth! | |||

|

| one of us |

Slamfire: You contend that the locking lugs (of proper metallurgy) of a bolt rifle can fail due to "fatigue" (work hardening). Perhaps this can happen, but I know of no example of this nor have I seen anyone prepare a mathematical estimate of when such failure could be expected to occur after X rounds at Y pressure, etc. I recognize that "never" is a very long time, and that even steel has a halflife, so I know that left to its own devices a bolt's lugs will eventually fail because the metal has suffered atomic decay. I'm not at all sure how many thousands of years this process takes to play out, but as I recall the halflife of carbon-14 is about 15,000 years (or is that the limit of carbon-14 dating?) But assuming that we are talking in terms of a few decades, or at most a couple of centuries, I doubt seeing any bolt failures due to atomic decay, wouldn't you agree? While the subject at hand is work hardening in a fixed action, the example you cite as evidence of your position is of the failure of a nearly new bolt in an autoloading action shooting loads of known safe pressure. What, pray tell, does this have to do with work-hardening failure of a fixed action rifle due to overstress from high pressure loads? Does your example involve excessive pressure? NO. Does your example involve work-hardening? NO. Is your example of the same type of action? NO. Your defense of your position is like telling me that my tire is going to blow out if I drive too fast, then showing me a tire which ran over a railroad spike at 5 mph as proof. | |||

|

| One of Us |

GREAT POST! Thanks for the link. AIU | |||

|

| One of Us |

I tend to agree with Stonecreek on the issue of "metal fatique" of a modern first-rate bolt-action rifle. I don't shoot hot hunting loads often enough - likely less than 100 per gun per lifetime - to induce "metal fatique". I only use the hot hunting loads for - you guessed it - hunting. Only one or two animals per season. | |||

|

| One of Us |

I am not going to provide you an analysis, if that is what you are looking for. As the M1a bolt, I thought it would be interesting, even if it did not fail through fatigue. As for finding bolts that have cracked their lugs, with the slightest of effort, I did a Google Search. It turns out some AR shooters shoot a lot more ammunition than your average bolt gunner. So reports and pictures of cracked lugs are not difficult to find. Who has broken a bolt with a mid-length gas system? http://www.m4carbine.net/showt...e6c3f20c00bccc0d39fc Sheared lugs on Colt bolts http://www.ar15.com/archive/to...l?b=3&f=118&t=590251 I broke the unbreakable Sharps Reliabolt - TWO BROKEN NOW! Update Pg. 5 (Page 1 of 8) http://www.ar15.com/forums/t_3_118/658805_.html The Burned Out Barrel Problem http://weaponsman.com/?p=20064 My Mini 14 Bolt Broke....Now What?***UPDATE*** http://www.perfectunion.com/vb...-broke-now-what.html Auto Mag Buyer’s Guide http://www.amtguns.net/article...to-mag-buyers-guide/ Sheared bolt lugs http://www.65grendel.com/forum...f90d0495239c5732f1dc Socom II broken bolt http://www.ar15.com/archive/to...tml?b=6&f=6&t=300423 Broken AK http://glocktalk.com/forums/showthread.php?t=1178380 Broken flat carbine bolt http://forums.thecmp.org/showthread.php?t=28644 Weekend Inland Mishap http://www.milsurps.com/showth...highlight=Bolt+Break This article from the American Rifleman is worth reading: http://www.americanrifleman.or...-tired-and-stressed/ Broken bolt reports are primarily from gas gunners. This does make sense, many of these shooters are practicing combat type shooting, lots of rounds. And it is very easy to have a high round count with a magazine fed rifle. These guys are also shooting, whereas some of the fossils in this thread are petrifying behind their keyboards . You can move the goal posts again, in any direction you want, but at least you will have seen pictures of broken bolts. | |||

|

| One of Us |

Perhaps your assertion that participants in a discussion won't change their mind is correct. But I'd bet that there are a lot of us who do not participate in such technical discussions as this is who greatly value the discussion itself. That is the importance of these debates. Parenthetically . . . I've commented many times on a variety of leftist fora (like NPR) never with the idea of changing anyone's mind, but with informing lurkers of a rational approach that may or not be right, but is contra to their received wisdom. Personally, I sincerely thank all participants in this discussion. I find it fascinating, even though I don't know enough to participate. In the end, and for better or worse, I'll make my own decision wrt the technical aspects of posts like this, but I love being able to read and think about issues that are raised in this kind of debate. | |||

|

| one of us |

So Slamfire shows us a dozen tires with railroad spikes through them to convince us that driving too fast will ruin our tires? His intellect is too profound for me. I give. | |||

|

| One of Us |

If you are addressing me, I'm genuinely sorry that you have so much contempt for me. | |||

|

| One of Us |

One cannot load the 06 to keep up with any of the .300 magnums. But, it is easy enough to get past 2800 with a 180 grain - even with a 22 inch barrel. | |||

|

| one of us |

And what more do you need really? | |||

|

| one of us |

Wow! this thread is a run away train, bouncing all over the place.. HOmetown Doc, Nice thread, good conversation and all points were covered, sorry if you felt threatened, just protecting my child! all in good fun however. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Medium Bore Rifles

Medium Bore Rifles  30-06 dancing like a 300 h&h

30-06 dancing like a 300 h&h

Visit our on-line store for AR Memorabilia