The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  African Big Game Hunting

African Big Game Hunting  Mlele 2022 Live Report! Videos Have Been Added on First Post

Mlele 2022 Live Report! Videos Have Been Added on First PostGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| Administrator |

This is going to post my live hunting report on this thread, as all information posted here is relevant to our safari. Last year, I made our usual NO MISS hunting bullets. They never failed. Trouble was everyone took that seriously, and all my stock has gone!! Been doing a bit of traveling, and now back home to make some more. Our safari is just over a month away. We are hunting Mlele again this year. A fantastic area for buffalo and sable. Plains game is rather scarce. But for me at least, buffalo hunting every day is just the ticket. I have been asked to post details of our NO MISS bullets. Well, I buy the cheapest 100% copper rods I can find. Our current stock is made in India. It is sold at construction material stores. Nothing special at all, as some bullet manufacturers would have you believe. Bullets are made one at a time. Every single one is checked for diameter and weight. I then wash them in acetone to remove the lube. After that I spray them with TUNGSTEN DISULPHIDE. That is it. Ready to shoot. I will post pictures of this process. I will be adding videos from our safari this year here for easier access. One Two Three Four Five Six Seven Eight Nine Ten Eleven Twelve Thirteen Fourteen Fifteen Sixteen Seventeen Eighteen Nineteen Twenty Twent_one Twenty_two Twenty_three Twenty_four Twenty_five Twenty_six Twenty_seven Twenty_eight Twent_nine Thirty Thirty_one Thirty_two Thirty_three Thirty_four Thirty_five Thirty_six Thirty_seven Thirty_eight Thirty_nine Forty Forty_one Forty_two Forty_three Forty_four Forty_five Forty_six Forty_seven Forty_eight Forty_nine Fifty Fifty_one Fifty_two Fifty_three Fifty_four Fifty_five Fifty_six Fifty_seven Fifty_eight | ||

|

| One of Us |

i doubt even a no miss bullet will help biebs | |||

|

| One of Us |

Great! I’d be very interested to see the process and some of your machine pics. We are starting to do more machining at our school here. I ordered a Haas mill back in May. It arrives this fall! A lathe is next on my list! Preparing for a hunt is a big part of the experience, enjoy! | |||

|

| One of Us |

Wow, already! I look forward to the photos of the process,Saeed. "Early in the morning, at break of day, in all the freshness and dawn of one's strength, to read a book - I call that vicious!"- Friedrich Nietzsche | |||

|

| Administrator |

Funny you mention this. I presume you mean a Blaser? A friend has one, in 375H&H. It has an extremely tight barrel. I make him 0.372 caliber bullets to use in it!!?? He is happy, and that is what counts. | |||

|

| One of Us |

It is a well engineered and machined German firearm !!!!! Better get out the calipers and manufacture exact SAAMI spec bullets for it Mike | |||

|

| One of Us |

Can you make them in heat seekers? | |||

|

| Administrator |

I designed these to seek the heat of a buffalo bull. | |||

|

| One of Us |

Mike Wilderness is my cathedral, and hunting is my prayer. | |||

|

| Administrator |

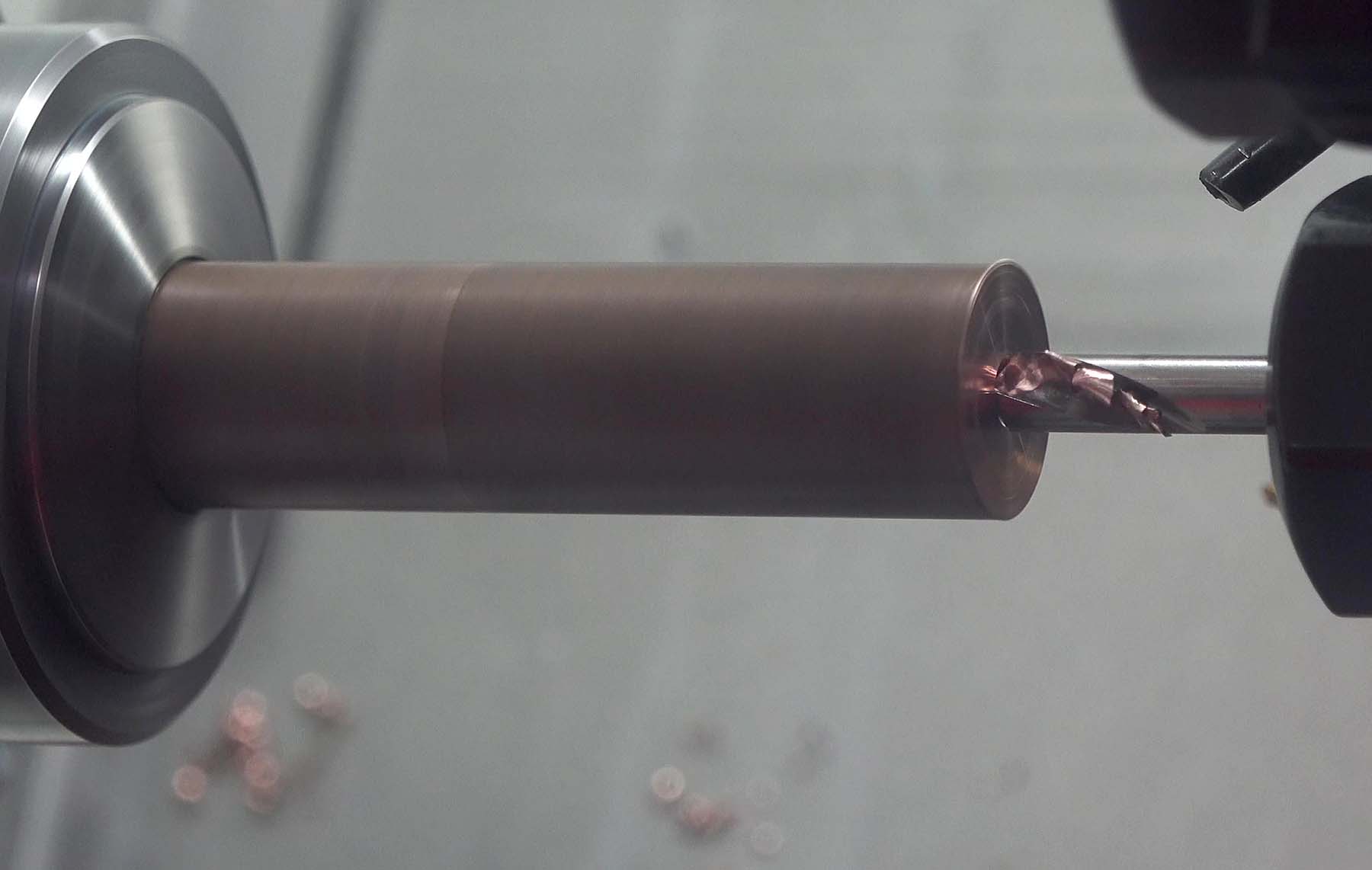

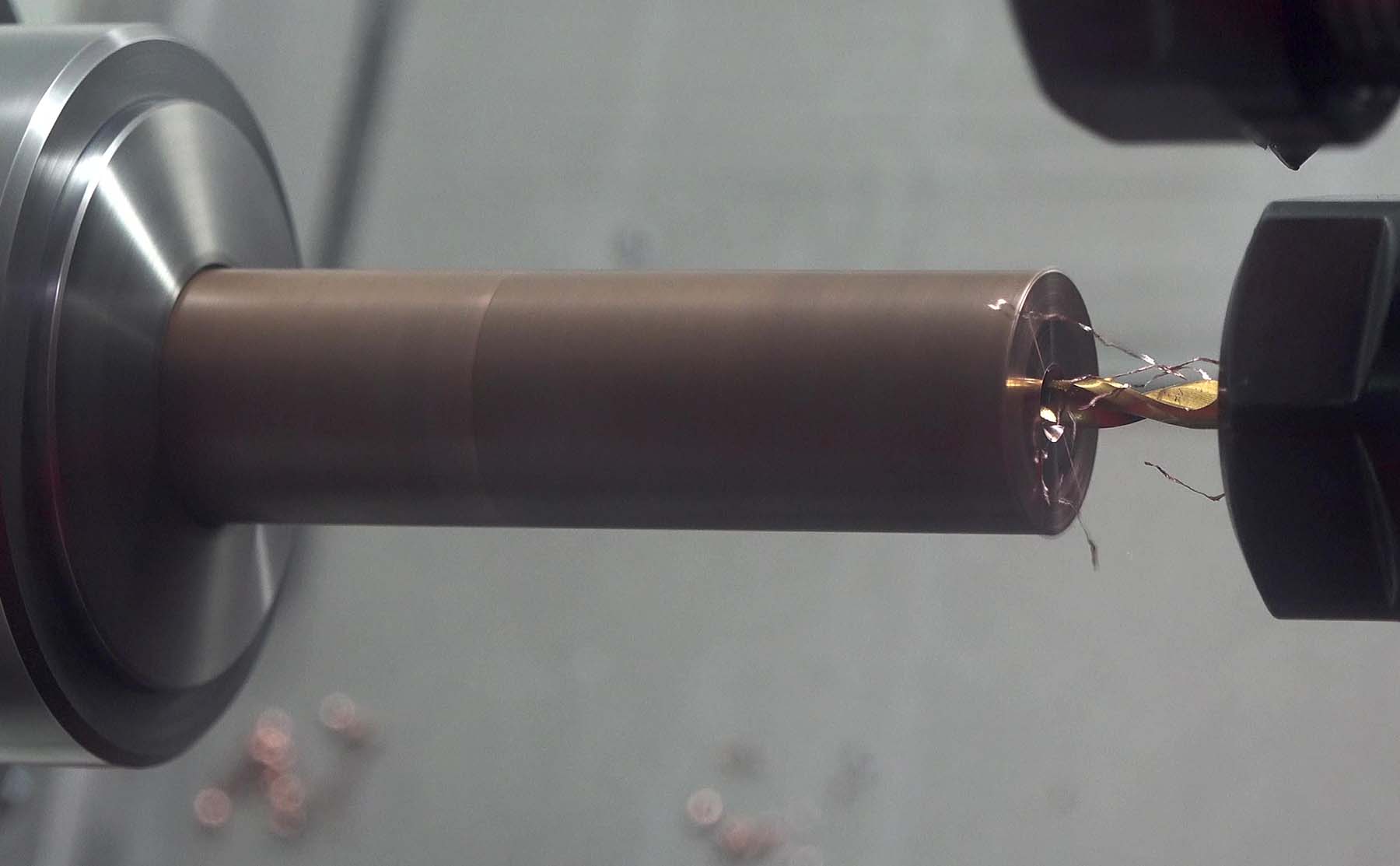

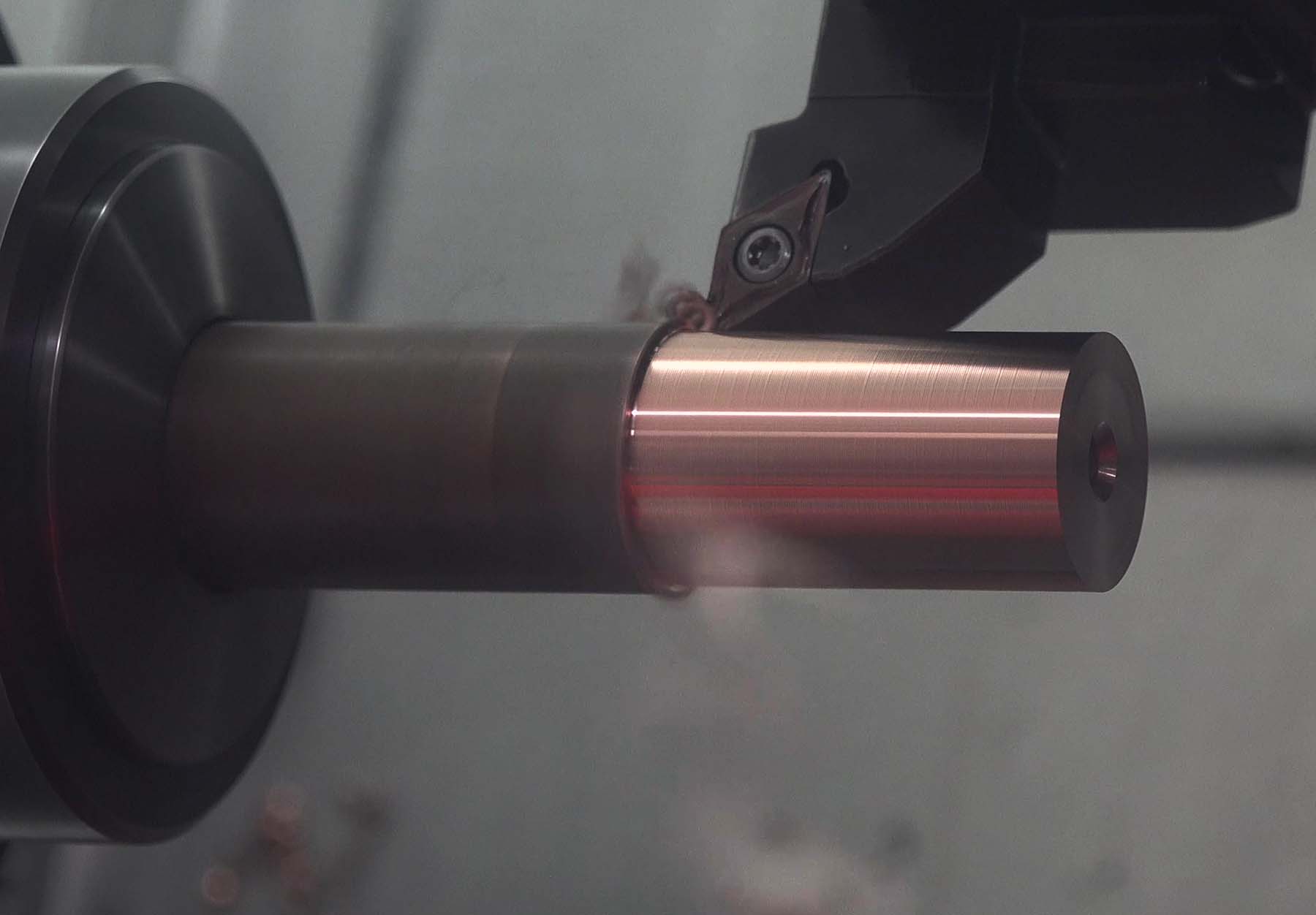

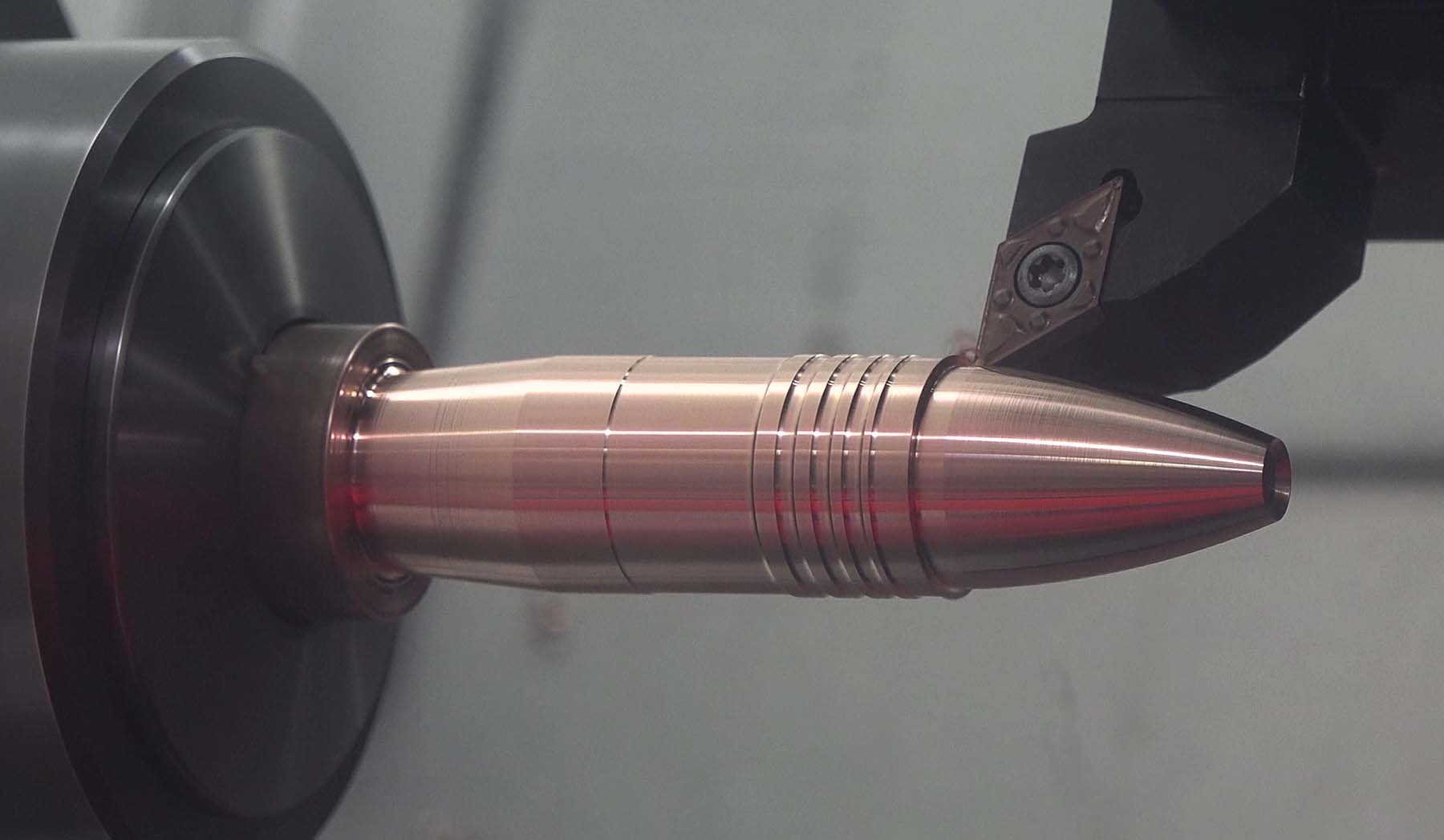

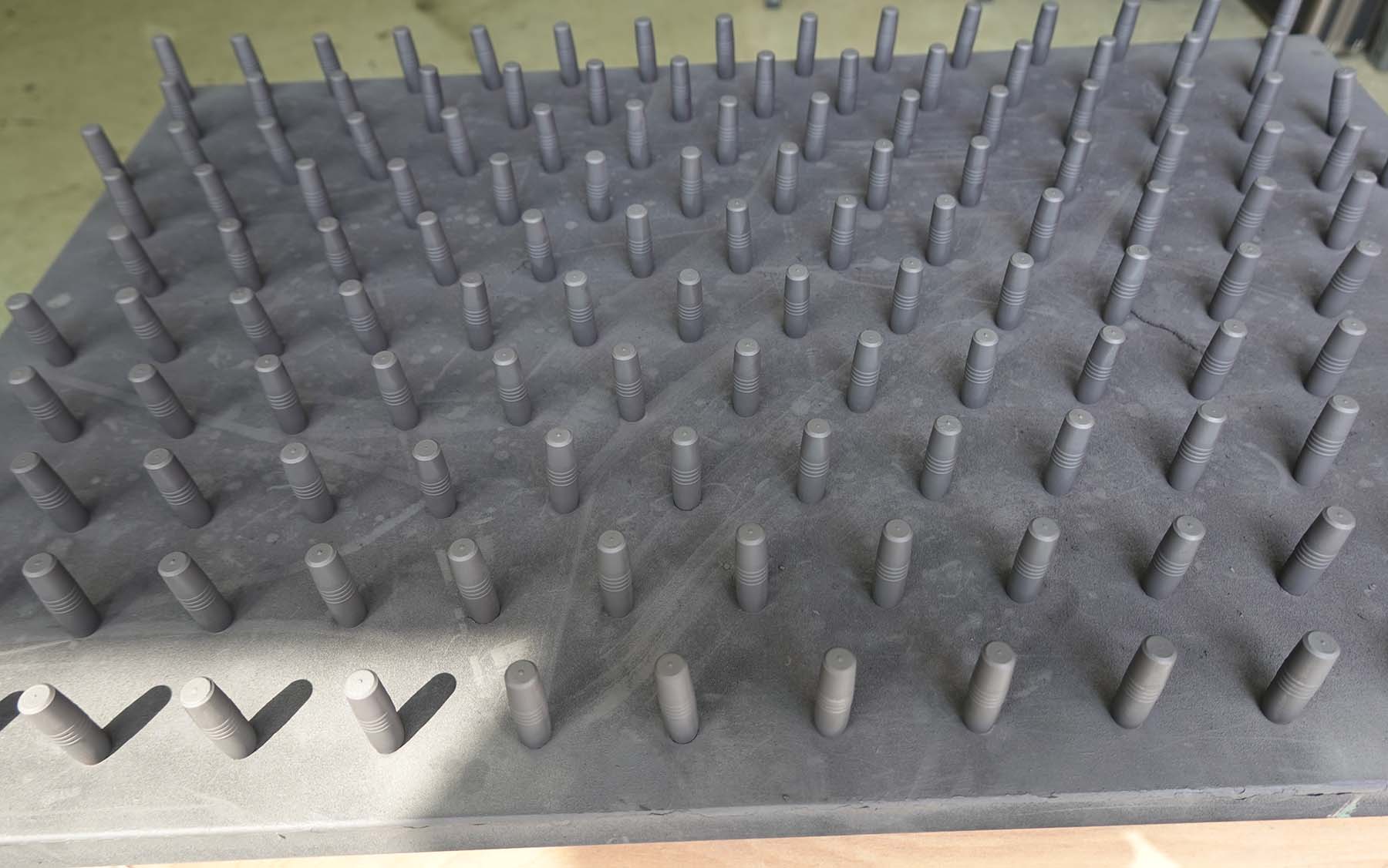

Here are the processes involved. The trays I make from commercial kitchen chopping boards. I made several, with different diameter holes to fit different caliber bullets. The copper rods come in 4 meter lengths, and we cut them to 60cm size to fit in our CNC machine. Any questions you might have I will be very happy to answer.               | |||

|

| One of Us |

Thanks for posting the pictures of your CNC machining a bullet. Very neat to see in the various stages. ______________________________________________ The power of accurate observation is frequently called cynicism by those who are bereft of that gift. | |||

|

| Administrator |

Got asked how true the NO MISS bit. Many of us shoot these bullets. And I honestly cannot remember when the last time I missed. But, Walter makes up for me. He believes I give him different bullets??!! Last year he shot a bull in his rear leg toes! He was standing broadside. I asked him how he managed that shot. His answer was “because it happened!” | |||

|

| One of Us |

Very good looking bullets Saeed. Thanks for posting the pics of making them. Is that a moly coating sprayed on them? Obviously you think there is a benefit for that or you wouldn't be doing it. NRA Endowment Life Member Life Member Wild Sheep Foundation | |||

|

| Administrator |

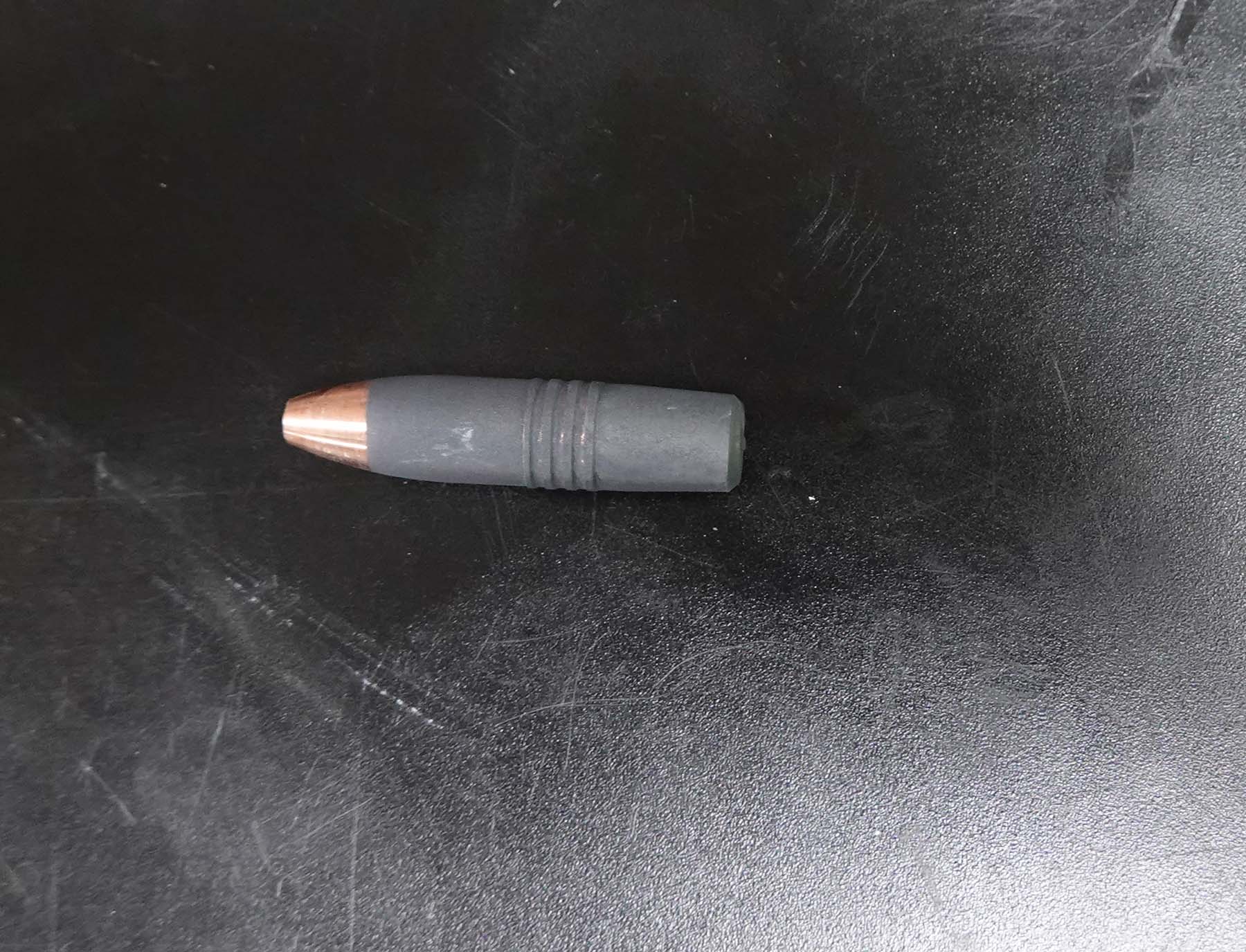

Now I am using Tungsten. Same results. Mainly preventing copper fouling. Both work very well. I will post a picture of the ones I am using. Due to the density of the copper rods we get, there is always a slight difference in weight. So I sort all bullets into lots to be within 0.5 grain weight. Funny enough, I think the original rods I used to design and make these bullets, to be at 300 grains, must have been less dense than others we have been getting ever since. Current lot is running around 303 grains. I have had some that went up to 307 grains. | |||

|

| One of Us |

Saeed, if you could post links to some of the YouTube videos you’ve posted of making these bullets, I think the members would find them of interest. I looked but couldn’t find them. | |||

|

| Administrator |

I have never posted anything on youtube. But, I will post one or two right here., thank you for suggesting. | |||

|

| Administrator |

Here are a few videos of the process. various calibers, and I have to turn the lubricant off to be able to take the videos. The finish on these is not as good as when the lube is on. Nomiss bullets in the making 1 Nomiss bullets in the making 2 Nomiss bullets in the making 3 Nomiss bullets in the making 4 | |||

|

| One of Us |

No need for those bullets if one shoot a Blaser. Amazing and fascinating process that workshop of yours. I envy the skill of the cnc lathe. Being a goldsmith of trade I know our human hands can never surpass that cnc. | |||

|

| One of Us |

Saeed, How long does it take you to make a batch of 100? Have you noticed a difference in the performance of the bullet (mushrooming, fragmenting, penetration etc) with different sourcing of the copper? | |||

|

| One of Us |

Still not a fan of mono bullets for softs. Solids, of course. I know they work, you've proved it. But I don't have access to your bullets and I don't like Barnes. Maybe you should gear up and start marketing them? | |||

|

| Administrator |

Bullets recovered from animals look different. All depends on the distance, and what they encounter in the animals. No way I can tell the difference because of different batches of copper. I am in the workshop right now, and the cycle time for each 300 grain 375 caliber bullet shows 2 minutes 51 seconds. I can alter this by several factors. Feed for instance which will alter the finish of the bullet. Or I can increase the speed. This is at a 100% feed setting both rotational and forward movement. The machine has a setting that can be increased up to 120% on both. But I use the normal 100% setting. This setting give me a very smooth finish. After each bullet is made, I measure it for diameter on a digital micrometer that goes 5 places of decimal. I do have to continuously adjust the finishing tool for almost every new rod I put in the machine. The FANUC software I have, MANUAL GUIDE Oi-TF, allows wear tool adjustment to 4 places of decimal. When I started this batch, the wear was set at 0.0000 . Currently the machine is set on -0.0022. Some of this is due to the wear on the finish cutting tool. It also seems to need changing up or down depending on the rod being used. These are just some of the funny things one learns as one goes along. I have designed bullets for all the calibers I use, in several bullet weights. Sometimes, if I need a few for testing, I only adjust the wear tool to get a specific diameter. If I am making 308 caliber bullets, and I need a few 311 caliber bullets, I make them from the 308 program, by just adjusting the wear tool. Same goes for 277 and 284 for instance too. Running a CNC lathe is fascinating. One can make practically anything within the physical capabilities of the machine. With this one I can work with rods of up to 30 mm. Here is an example of something I made for show.  | |||

|

| one of us |

Thank you Saeed for sharing the small video clips was interesting to see. Maybe you should consider to give Walter other ammo so that you can really call your No Miss bullets - No Miss! Frederik Cocquyt I always try to use enough gun but then sometimes a brainshot works just as good. | |||

|

| Administrator |

Walter and hunting don't really mix very well. He gives his professional hunters mini heart attacks. Hunting with Pierre von Tonder, he set specific distance for different animals. Not sure about the exact ones, but I think kongoni, warthog and impala were about 80 yards. They found a really stupid warthog, who was looking at them from a short distance. It took Walter a while to get on the shooting stick, the wart hog started walking. Pierre was counting the distance "50 yards. 60 yards. Hurry up Walter he will be out of range. 70 yards. 80 yards. STOP! DON'T SHOOT! He is too far now" Both of us were using the same rifle, same ammo. He kept missing, and blaming my ammo. One day I shot a warthog running at full speed, and killed him. Pierre "See Walter. That is how to shoot!" Walter "It was a freak shot!" I said "He is right. I wasn't aiming at the warthog" Walter laughs, "You see Pierre. I was right!" | |||

|

| One of Us |

Very interesting videos, Saeed. Thanks for sharing them. "Early in the morning, at break of day, in all the freshness and dawn of one's strength, to read a book - I call that vicious!"- Friedrich Nietzsche | |||

|

| One of Us |

Great videos Saeed, It was very interesting to see that in person. Joyce really liked seeing how a mono bullet was made. ______________________ DRSS ______________________ Hunt Reports 2015 His & Her Leopards with Derek Littleton of Luwire Safaris - http://forums.accuratereloadin...6321043/m/2971090112 2015 Trophy Bull Elephant with CMS http://forums.accuratereloadin...6321043/m/1651069012 DIY Brooks Range Sheep Hunt 2013 - http://forums.accuratereloadin...901038191#9901038191 Zambia June/July 2012 with Andrew Baldry - Royal Kafue http://forums.accuratereloadin...6321043/m/7971064771 Zambia Sept 2010- Muchinga Safaris http://forums.accuratereloadin...6321043/m/4211096141 Namibia Sept 2010 - ARUB Safaris http://forums.accuratereloadin...6321043/m/6781076141 | |||

|

| Administrator |

That was a long time ago my friend. Walter was fascinated by how the machine works. He liked to watch the process through the glass screen. He seemed to be mesmerized by it. He was NOT allowed to touch it. One day, he got himself a cup of coffee, and decided to enjoy it while watching the machine make bullets. We had the previous machine to this one, which had a slanting keyboard. While the machine was running, he was trying to put the cup up to his mouth to drink, and his elbow touched the keyboard! Disaster struck! The tool head, which normally would cut the finished bullet short of the chuck as programmed, and go back and stop ready for the new cycle, curried on forward. It hit the chuck! Destroying the chuck, and part of the tool head. There was an almighty crunch! Cost us over $6,000 to fix. | |||

|

| One of Us |

Ouch! | |||

|

| Administrator |

This is the spray I use. And how we sort and store our bullets.   | |||

|

| Administrator |

Got a message asking when we started making our own bullets. I started by buying a table top CNC lathe about 30 odd years ago. It was awful. Although it said on its specs it would cut metal, it was hopeless. It would have taken a whole day to make one! I then gave it back, and the dealer suggested another table top model, bigger. He assured me it would cut copper, and he would take it back if it did not. Apparently those were bought by technical colleges for students to learn on. We got ours, and it did work with copper. But, it was very slow, and no two bullets were ever the same size!!?? Best groups I could get with those were 1.5 inches! I made a few and took them on safari. Worked great, hit everything I fired at. Shot several buffalo as well as other plains game animals. When I got back home, I decided to get a proper CNC lathe, and bought an EMCO. Worked great for many years, used floppy disks. We had to do several modifications on it to bring it up to date. Then spares started getting scarce. Then I got our present one. The difference between this one and our original one is like comparing a moon rocket to the square wheeled jalopy Fred Flintstone used at Bedrock! | |||

|

| one of us |

How meticulous do you have to be when spraying and do you do it in the open or do you have a booth you do it in? "In the worship of security we fling ourselves beneath the wheels of routine, and before we know it our lives are gone"--Sterling Hayden-- David Tenney US Operations Manager Trophy Game Safaris Southern Africa Tino and Amanda Erasmus www.tgsafari.co.za | |||

|

| Administrator |

I just open the doors in my workshop and spray them. Visually I make sure they are covered. Not that important really, as long as the copper is covered. | |||

|

| One of Us |

Does the tungstan disulfide build up in the barrel like moly coating does? | |||

|

| Administrator |

This is something I have not seen myself. Molly building up in a barre. I have used Molly for many years, and have never seen any negative effect from it. I do clean my barrels regularly, but not as often as if they are shot with uncoated bullets. | |||

|

| One of Us |

The target shooting guys in the US had problems with moly building up in barrels and causing issues. It was hard to remove among other things. | |||

|

| Administrator |

I have read that. Not in my experience. I have an unlimited 6mm PPC bench rifle, built by my friend Dwight Scott. All the bullets I shoot in it are Molly coated. When I do my part I cannot measure a 5 shot group. I have rifles with several thousands rounds through them, all Molly coated. No problems at all. | |||

|

| One of Us |

Ok then, not to belabor the point, why the use of tungstan rather the moly as a solid lubricant? Just interested in your logic as to choice. | |||

|

| Administrator |

My supply of Molly was finished. The new ones I found was not very good quality. Too many reject cans. I decided to use Tungsten. Seems to work just as well. Everything we do here is try to find what is best for our purpose. If it works, we stick with it. If it does not we try something else. In my experience, far too many options on the Internet that make absolutely no sense at all. | |||

|

| Administrator |

Bullet making process over. I will start loading our ammo tomorrow. Tanzania visa already done. Spoke to Alan yesterday. Last minute bits and pieces to gather. Walter has left on holiday! Should be back in 3 weeks time. This man leads a charmed life! | |||

|

| Administrator |

| |||

|

| One of Us |

Nice one Saeed. Good times just around the corner. Pre hunt anticipation is a delicious feeling. I'm sure Walter took some time off now to suitably prepare himself mentally for all the fun ! Hunting.... it's not everything, it's the only thing. | |||

|

| Powered by Social Strata | Page 1 2 3 4 5 6 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  African Big Game Hunting

African Big Game Hunting  Mlele 2022 Live Report! Videos Have Been Added on First Post

Mlele 2022 Live Report! Videos Have Been Added on First Post

Visit our on-line store for AR Memorabilia