The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Barrel on Montana not in center!

Barrel on Montana not in center!Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I have a customer with a rifle made on a Mntana Rifleman action, with a off-center barrel! Highly visible on the primers, but even easily seen on the outside, were the distance from the barrel to the reciever on the left side is notably larger than on the right! Is this very uncommon for Montana Rifleman actions? Bent Fossdal Reiso 5685 Uggdal Norway | ||

|

| One of Us |

Rumors abound of QC problems with that maker. | |||

|

| one of us |

I have two of these actions, left-handed, and my brother has a right-handed one and none of them are as you describe John Farner If you haven't, please join the NRA! | |||

|

| Moderator |

dan spreads rumors like flies spread sh... er fertilizer. .... sory of like his "rumor" that an empire rifle wounldn't feed a 500 jeffe... and the second one asks for details the "rumor" goes away... but his "opinion" remains. Bent, email them, telll them what you see, and ask for suggestion. they are fairly easy to deal with. opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

You say it was built on the Montana Action, but was it actually barrelled by them? I'd pull the barrel and check to see if the barrel were the problem. | |||

|

| one of us |

Malm

Yep remove the barrel from the action & spin it between centers in a lathe & see if the OD is turning true or not. If you really want to tell if the firing pin is striking center do this. Turn a piece of nylon, delron or simular soft material to about 1.200 OD for 6 inches & then thread it to fit the receiver. make a little extension on the face to simulate the case head protruding from the chamber (headspace). Cut the turned section off & screw it into the action. You see where i am going with this? Dry fire the gun. Unscrew the nylon blank from the receiver. Set it in a four jaw chuck & indicate the OD true. You will easily see how true or out of true the firing pin strike was.  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

One of Us |

BTW...when ya do this please let us know if the barrel actually is the trouble.....MRC don't need any more bad press than it earns itself.....I'm pulling for them. /////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

| One of Us |

The barrel might be drilled off-center. How does it shoot? The only easy day is yesterday! | |||

|

| One of Us |

The barrel is pulled at found flawless. The action is so bored off center it is seen with one eye closed. Amazing. I think I'll have to send them a mail to hear their responce. Thanks, guys! Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| one of us |

This is not unheard of. I have one which was also way off center. I have not seen the setup used in the machining of the receiver ring so can't say how this error is introduced. Some show significant misalignment due to warpage from heat treating but this one was definitely a machining error. Opening the threads to 1 1/16x16 fixed it right up. I have to say, this was the only action of those I've handled which had this problem. Just my luck it happened to be mine! Regards, Bill. | |||

|

| One of Us |

I find it remarkeable that the person who fit the barrel didn't do anything about the out of whack action at the time. | |||

|

| One of Us |

Isn’t checking, and if necessary, truing the receiver a standard part of a barreling job? If the guy that installed the barrel skipped that basic procedure I would be wondering what else he decided to skip. | |||

|

| One of Us |

The man that installed the barrel was an old military gunsmith, as far as I understand. Since the barrel is quite new, I will have to make a sleeve to screw into the actions threads, and drill and cut new threads. But to set this up properly requires special tooling, me thinks. Suggestions? Like this: http://www.gtrtooling.com/prod05.htm ? I just talked to the people at Montana. Super service, very nice people, offered to replace the actions at once. I am going to think about that, but the paperworks involved is not tempting. Shipping gunparts between USA and Europe is a bitch - and that is a gross understatement! Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| one of us |

Well, apparently Dan's (500grains) statement in this case isn't rumor, but fact, according to at least two first person sources on this thread alone. xxxxxxxxxx When considering US based operations of guides/outfitters, check and see if they are NRA members. If not, why support someone who doesn't support us? Consider spending your money elsewhere. NEVER, EVER book a hunt with BLAIR WORLDWIDE HUNTING or JEFF BLAIR. I have come to understand that in hunting, the goal is not the goal but the process. | |||

|

| One of Us |

I’ve never worked on a Montana action, but I know you can ream out and cut new oversized (and straight) threads on a pre-64 Winchester 7O and on Remington 700’s. I would assume that the Montana probably has enough thickness in the front ring to do the same. Might be allot easier and sturdier than what you mentioned. | |||

|

| One of Us |

I kknow that the Colorado school of trades was buying these actiions and barrels for student projects,and because of many problems with them ect. The discontined using this product. van | |||

|

| One of Us |

If a gunsmithing school won't take them because they are too out of whack for even their students, what's that saying? | |||

|

| One of Us |

The first thing I would do with that action is determine if it is just the threads that are crooked. If the bolt ways are also off its gonna be really difficult to true any of the other surfaces since you won’t really have anything to index from. At some point you have to decide if you’re just chasing your tail trying to fix something that is beyond fixing. | |||

|

| One of Us |

I had dealings with Those people a few years back over a .50 barrel ! Thier so called Gunsmiths can't read a Mic ! or READ a Print or use a Lathe ! NEVER AGAIN ! | |||

|

| one of us |

So did you contact MRC and heard what they had to say?? They usually stand behind their product. Get in touch with them, I'm sure you would prefer that if somebody had doubts about work you had shipped. In fact, this is what one could have expected you to do before you posted this on the Internet. - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

one of us |

I noticed an off center primer strike on my Lilja barreled MRC. Shoots very well. I'll have to take a closer look now. Probably won't worry too much about it though. ______________________ Always remember you're unique, just like everyone else. | |||

|

| One of Us |

So it turns out that Dan's "rumor" weren't rumors at all. Everything is fact including his signature line. Jeffe is the one that is spewing the bs .......... again. A suggestion jeffe, the next time someone posts something that you know nothing about, don't guess what an answer would be, just don't type anything. Your post count will go waaaaay down but it will be a better place. | |||

|

| One of Us |

If Jeffe were resigned to posting only about subjects he actually knew about, he might never post. | |||

|

| one of us |

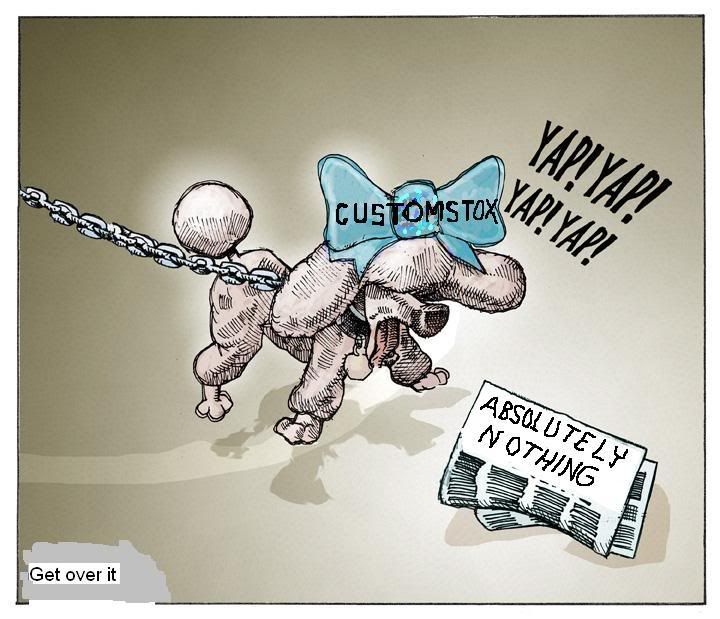

Why are you so worried about Jeff's post count? No one needs you to tell us who knows stuff here and who don't. Once again you earn the coveted yapper award.  | |||

|

| One of Us |

Concerning the Empire Rifles .500 Jeffery that would not feed, that is exactly what the owner of the rifle told me. Jeffe says that Empire reports that it would feed 535 grain bullets ok but jammed with 570 grain bullets (Woodleigh round nose). So in my book it still does not feed since a rifle that feeds only one of the several bullets it can reasonably expect to see still needs more work. _____________

Exactly! I hope that MRC can turn things around, but there is much work to be done. Sadly, Winchester's quality also went out the window the few years before the Connecticut plant closed. | |||

|

| One of Us |

I think what the deal is with that Montana is, when the receiver is cast it's cast with no threads in it. The machinist must dial in the bore of the action and thread the receiver. Being the part is a casting the outside surfaces are going vari some so the dial in process must be done on every receiver to ensure concentricity of the barrel threads to the bolt bore. Dialing in each part on a large run of parts takes the patience and understanding of the importance of concetricity of the barrel threads in relation to the bolt bore. If the barrel threads are concentric and the outside of the action is concentirc to the bolt bore then it will all look and work right. Timan | |||

|

| One of Us |

A quick test to see if the bore and receiver are aligned is to make a short bushing with a .125 or smaller hole through the center and insert it in the bolt tunnel at the very rear of the receiver. While looking down the bore from the muzzle end, examine the diffraction rings in the bore. The appearance of the rings should quickly tell you if something is out of whack with the alignment. Of course, you might want to drop an unprimed, snug fitting case in the chamber and check the barrel's straightness first. | |||

|

| One of Us |

This is the crap that one has to live with on this forum. A lot of yapping, and a little reading. Mike, read my conribution above yours. I am not a novice, and it is a fact that the barrel is off centre. I referred to a link above, and asked if anybody has any experience with a tool like that? Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

Brent, I have one of those Jigs, but don’t use it too often. The problem I found with it is that the holding power is pretty fragile depending on the receiver your working on. Round receivers like Remingtons seem to hold the best, Mausers the worst. You might, however, be able to drill and tap some new holes to place the holding screws in a better position for a particular receiver. It works just like a lathe spider for holding a barrel only it has holding screws fore and aft so you can move the front and rear of the receiver to center it in the fixture. The instructions even warn you to take VERY light cuts so you don’t push the receiver off the holding screw pads. To set up and center the receiver in the jig you must have a very tight fitting mandrel inserted through the bolt ways to indicate off of, so a receiver with crooked bolt ways is going to cause you problems unless you ream them out and true them first and then use the reamer body (you leave it in the receiver) to indicate from. The jigs are basically designed to be used along with the bolt way reamers they also sell. Hope this helps. | |||

|

| One of Us |

Duikerman

You show a total lack of comprehension on what is written on here. It seems to go along with your writing skills or lack of. I will not go through the bother of trying to explain to you (splane if that makes it any clearer) the intent of the comments. It is good that Jeffe has another idiot to defend him. You must be a poster child for The Mind Is a Terrible Thing to Waste. | |||

|

| One of Us |

Fyj, Thanks man! I had my suspissions. Think I'll make a jigg of two halves which I can srew on, and then cut the outer diameter with it installed on a tight fitting mandrel that fits the bolt-way exactly. Then clamp the jigg in the chuck. Thanks again - advices appretiated, yapping ignored. Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

I must apologize sir, I just noticed I called you “Brent“ in that post. Sometimes the old brain, eyes and fingers don’t sync real well. | |||

|

| one of us |

I mentioned this topic to another 'smith in the shop today. He says, "Oh, like this", walks to the back bench, and comes back with a barreled Montana action. Definitely off center on the reciever ring. But, the rifle shoots fine. Mainly a pain in the butt, on the inletting end. As long as they shoot good, I wouldn't get too excited. And, i would also have to start looking at a lot of production rifles, to see if the same thing is present. Granted, on a custom action, you wouldn't expect it. Shooters Cast Bullet Alumnus Ric Carter | |||

|

| One of Us |

Bent, Maybe I am missing something, but no matter what you do to the action. You will still get the off center primer strikes because the firing pin is not centered in the bolt. Just a thought, it sounds like that is what caught the customers attention to begin with. I'd hate to see you do a lot of work to center the barrel in the action and the customer still not be happy with the primer strikes. Les | |||

|

One of Us |

This thread seems to be damaging badly to MRC. Notice my post and the reply. /////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

| One of Us |

What you are missing is that the bolt and fiering pin is not aligned with the bore as it is today, and therefore the primer is hit off-centre. It is the barrel that needs to be relocated. Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| one of us |

I have a good deal of experience in truing all kinds of actions; including the MRC. One thing has to be understood about the MRC receiver; most especially if one intends to set one up and try to true it. Only the bridge is reamed and only the bridge aligns the bolt. The entire front end of the receiver, with the exception of the threads, face, and inner barrel seat, are left "as cast". This includes the locking lug seats and the opening which would normally be considered to be part of the "bore" of the receiver. This is left considerably oversized to accomodate the expected warpage which WILL occur during heat treating. What this means is this: It is entirely possible that the entire receiver ring is misaligned in relation to the bridge. The fixtures which have to be made up to check this are simple enough as long as one gives some thought as to what he is trying to check ahead of time. As I said before, I have not witnessed the procedure used by the machine shop in the machining of these receivers. When working with a casting, the machinist will first make a cut or series of cuts which will produce the reference surface for all subsequent operations. Now, that initial operation could be the reaming of the receiver bridge; it could be the machining of the threads and barrel seats; or it could be the machining of the flat on the bottom of the ring, along with the rear of the recoil lug, the magazine well, and trigger mounting surfaces. Whatever the intial machined portion is, it is the surface which will determine the type of fixturing which is used to perform the rest of the machining on the receiver. Knowing what came first is really only of acedemic interest since it doesn't change the fact of the receiver's misalignment. As I mentioned before, only the receiver bridge is a machined surface which affects bolt alignment. The bolt fits fairly loosely in the bridge which allows it some latitude to fit into a misaligned front end. Now, if one wants to make sure the front end lines up with the bridge, he has to be prepared to remachine the whole darn thing. This includes the threads, face, internal barrel seat, locking lug seats, and possibly, the outside of the receiver ring. One other aspect of the MRC action which makes this a bit of a challenge is that the locking lug recess is eccentric as cast. So when you have finished facing the lower locking lug seat; you still have about .025" to go on the top one. I have my method for dealing with this, you might think of a better one. I do use a fixture which is similar to the Gretan in principle but which I use a little differently. Mine is of steel and has a total of 16 different screw (3/8 coarse) locations to accomodate different actions. I set up with the receiver on a mandrel and set between centers. The fixture is then set to run true to the mandrel. The mandrel is then removed and the fixture set up in the four jaw chuck and steady rest. On my MRC, the reamed bore of the receiver bridge was actually quite well aligned with the outside of the receiver ring. This was good. I didn't want to have to re-machine the outside of the ring. The threads, and everything else in the front, were offset by close to .030". As I said, rethreading to 1 1/16 x16tpi, fixed things right up. At the same time, I recut the locking lug seats, modified and recut the internal barrel seat, and the face. I also modified the bolt nose and fitted the barrel with a counterbore into which the bolt fit (no more coned breech which is a poor breeching system anyway). So, check carefully to find out exactly where the misalignment is and it's extent. From there you can figure out the right approach to fix it. It is fixable but it might require considerable desire to do so on your part. By the way, very few gunsmiths are likely to go through the considerable trouble of making up pieces to check alignment on any aftermarket action. This certainly would not be considered part of a standard barreling job. Hell, it's probably a good half day's work. The MRC's design and manufacture makes this considerably more difficult than with most other actions. Regards, Bill. | |||

|

| One of Us |

Just one question to all involved in this thread. MAN,is this once reciever worth all this??? Send it back to wereever | |||

|

| One of Us |

Or toss it in the North Sea and start with a military M98. | |||

|

| one of us |

Grains, there was a lot more value in this thread than the many pages of BS you engaged in discussing twist rates | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Barrel on Montana not in center!

Barrel on Montana not in center!

Visit our on-line store for AR Memorabilia