The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Making it Feed

Making it FeedGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

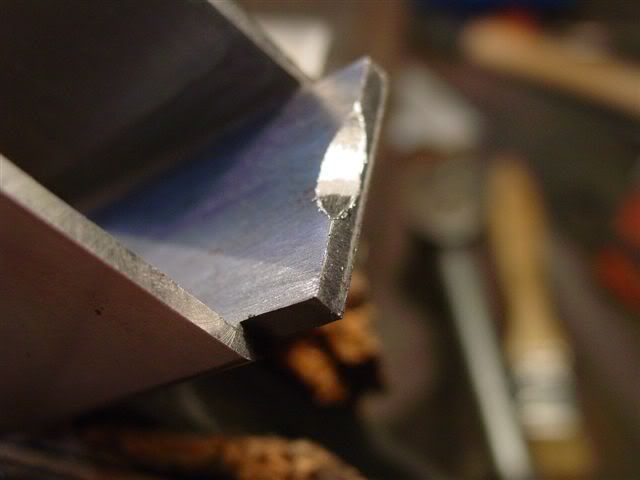

First step is to open the lower quadrant so a round will slip under the extractor…   The extractor as received is WAY too tight. Relieve until the extractor flexes abut .005...use your judgment here, but the extractor must hold a loaded round to the bolt face.   File or grind a "moon†shape at the upper rear magazine wall to pretty well match up the same plane as the bolt face.   Might as well, grind away a relief on the inside of the bridge to give more room for these fat cases to eject.   Part of the reason rounds will not feed is the vertical wall the bullet noses bump into.  I like to use carbide burrs rather than grinding wheels...less dust and burr keeps it's shape. Note that we're staring to remove some of the upper rail to give rounds room to climb the modified ramp...go slowly here, try and try again to make sure you don’t remove too much metal.     Don't forget the left side. but you'll probably devote most time to the right side...I like to make the top round feel well before trying out the stacked rounds.  Sure enough! The right side of the ring extractor slot is too tight to allow single feeding. In this case, I took a little material off the side of the extractor, but had to end up removing material from the receiver...not an easy spot to work in! Here I spot welded a piece of coarse file to a rod that I can drive with a reciprocating air tool   Here's what things look like afterwards...feeds smoothly fast, slow and in any position (upside down too). Someone send along the round shown...didn't even bother to try and make this feed since the blunt end will not enter the lead anyway. I try to urge dangerous game hunters to use round nose ammo, since this is a part of the whole reliability picture.    Even without ammo, this bolt was pretty cranky and wanted to hang up...about 15 minutes with lapping compound, runs very smooth  I'd like to mention that if any of you guys have more ideas, please join in! | ||

|

| One of Us |

That was really fascinating Duane. Thanks for sharing those pics. Will this rifle have timed screws? | |||

|

| one of us |

Bullet makers are going the opposite direction by offering an ever greater assortment of bullets with flat meplats. ______________________________ "Truth is the daughter of time." Francis Bacon | |||

|

| One of Us |

Is this amount of work typically needed to get a GMA to feed? Thanks | |||

|

| one of us |

Very informing post. | |||

|

| one of us |

Great topic ... and WONDERFUL post! Thank you very much. I notice that then I look at a Mark X action done for a standard magnum caliber that they have used a ball mill to open up the rear end of the rails on both sides ... pretty evenly. Duane, is it your recommendation to start on the right side a fair amount then open the left side to finish it? How do I know then the right side is deep enough? (Going to doing an Argie to the Steyr .376 case soon.) Thanks again!!! Mike -------------- DRSS, Womper's Club, NRA Life Member/Charter Member NRA Golden Eagles ... Knifemaker, http://www.mstarling.com | |||

|

| One of Us |

Mr. Wiebe; Thank you for your time and photos and for shareing your knowledge on these subjects. Like I have said before, "thats why I'm here" and it's great to see these kinds of posts. Another way to skin a cat, a photos makes it all that much easier to follow along...For this ol bas$#*! anyway. And we get to see how a millionair Smith goes about doing his thing! Again Thanks! _____________________ Steve Traxson | |||

|

| One of Us |

I know...believe me I know! | |||

|

| One of Us |

Yep! I have a Satterlee action here set up for the 416 Rigby...feeds like ball bearings! right out of the box. This is not to condemn GMA actions...you just gotta be prepared to do some work | |||

|

| One of Us |

| |||

|

| One of Us |

I recently received a follower from Sunny Hills. Instead of a sharp division (in the middle), the high part was more like the rounded shape of a cartridge. I think this is a great idea and makes a lot of sense | |||

|

| one of us |

Duane Excellent and very informative post but you must be a gluten for punishment for opening a can of worms like this. But -- don't listen to me just keep doing it. I love your willingness to share and you have the knowledge and talent to back it up. Thanks James | |||

|

| One of Us |

James: I'm not into self punishment, but obviously there's a lot of questions and problems with feeding that we can have an in depth seminar. As the topic starter, it's not for me to say "do it this way", but share information so we all can learn | |||

|

| one of us |

Can't wait to see how this one turns out! | |||

|

| one of us |

Duane I meant no disrespect by my statement. I hope it did not come across that way. Your wealth of knowledge and willingness to share is greatly appreciated by me and many others on this forum. Thanks again for the post and pictures. James | |||

|

| One of Us |

Duane, In regards to the flat nose bullets. I am under the impression that the rails need a little step underneath at the neck shoulder junction so when the shoulder contacts it, it pushes the nose out toward center and thereby out of the rails and helps the case up the ramp. Am I wrong in thinking this? | |||

|

one of us |

Duane I am sure there is something simple that I am missing, but what is the purpose of that moon shaped relief? Jason Jason "You're not hard-core, unless you live hard-core." _______________________ Hunting in Africa is an adventure. The number of variables involved preclude the possibility of a perfect hunt. Some problems will arise. How you decide to handle them will determine how much you enjoy your hunt. Just tell yourself, "it's all part of the adventure." Remember, if Robert Ruark had gotten upset every time problems with Harry Selby's flat bed truck delayed the safari, Horn of the Hunter would have read like an indictment of Selby. But Ruark rolled with the punches, poured some gin, and enjoyed the adventure. -Jason Brown | |||

|

| one of us |

I read that you adjusted the right rail first. Did you periodically check the feeding from the left side as you adjusted the right rail? Opening the rails is a balancing act as one affects the other. How do you determine wheather follower adjustment is needed or just the rails or both?  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

| one of us |

Great photos and wonderful discussion topic! I also start with the extractor because often times that's all that needs to be adjusted to get a rifle to feed. On ex-military Mausers I then work a little on the follower, usually just putting a slight radius on the top of the divider, and then I start from the bottom up, getting the rifle to feed that last cartridge smoothly first, then the second and on up until a full magazine works. John Farner If you haven't, please join the NRA! | |||

|

| One of Us |

A trick I learned from David Miller and I think was done on some of the last Model 70's was to remove part of the ridge on the follower to allow the LAST round to come up under the extractor quicker. I remove it the same amount basically as I remove from the right rail. SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

Hmmm...I understand the sugestion...envision the follower having to be depressed rather abruptly...but I'll sure give it a try...thanks! | |||

|

| One of Us |

| |||

|

| One of Us |

| |||

|

| One of Us |

Yes...it's a good idea to do so. | |||

|

| One of Us |

D Humbarger: Sorry I overlooked one question...maybe because I don't have the easy answer. Someimes it helps to smear a little spotting compound on the case and run it through. You often can see where maerial needs to be removed. Remember I mentioned that the Satterlee action fed those 416 Rigby's so well? Customer changed his prioriies and decided to go with a 450 Rigby instead. A first glance, they look the same, but the shoulder is a little larger in diameter on the 450's...know what? It doesn't feed those at all! My point is that each cartridge presents it's own special set of problems. | |||

|

| One of Us |

Daune, how many hours to you usually need to put in a GMA action to get it right? Also concerning the right rail. If the cartridge has more taper to the case do you need to remove less of the rail opposed to a straight wall case? Thanks for taking the time to write about this topic. | |||

|

| One of Us |

Time...well, had to get to this eventually...maybe I'm just slow, but I have eight hours even on the 500, did a 404 right afterwards, also a GMA and had 4 1/2 hrs Now; there's also the "puckerfactor" Screw up a $3500.00 action and there's a big problem...Screw up a 98...well, you CAN replace it with some degree of certainty.....at least until Jan 20th! | |||

|

| One of Us |

The rail..Well, that's pretty accurate...a lot depends on getting that groove under the exractor lip just after the cartridge nose enters the chamber...this is "controlled round feeding" | |||

|

| One of Us |

Looking at the rail on this action I can see the "puckerfactor". I just looked at my Dakota and the rails appears straight for a 30/06 so a little easier on the heart. | |||

|

| One of Us |

I really hate to see this topic fade away. It is very hard to find this kind of info anywhere. How about someone sharing how they open up a standard 98 to feed some of the larger cartridges? Thanks Duane for sharing your work. It is always first rate. Steve | |||

|

| One of Us |

I am with DUane on this, not to imply I do it as well but, I received some phone instruction from Herman Waldron a few years ago on this very thing. I do pretty much the same as Duane but when it comes to the follwer that is the last thing I do. I usually run three rounds in the magazine and work on the right rail until it is fairly smooth then move to the left rail. When this one is done, Iwork on the last round. If this won't feed, it is the follower that needs some work. I know some would disagree with me but it works for me. When doing a conversion to a magnum, at least on a Mauser and model 70, the underside of the action, under the feedrails, needs to be "straightened out for the fatter shoulder at about a 8 degree angle with a ball end mill in the mill. Do this before the rail work. Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Professional member American Custom Gunmakers Guild | |||

|

| One of Us |

Jim: Wonder if you'd mind showing us the fixture you use to open the rails? | |||

|

One of Us |

You don't need a fixture. All you need is a milling machine, a milling vise with a swivel base and the appropriate cutter. I can provide pictures. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

| |||

|

| One of Us |

. OK maybe I overcomplicate things...pics would be welcome...thanks Duane | |||

|

| one of us |

I'm sure Duane's client was an Aggie. If it's a .500 Jeffery I would probably want Duane to bless the feeding, extraction and ejection before I faced a buffalo or elephant. It is amazing to begin to appreciate the intricacy of bolt actions, in particular dangerous game or stopping rifles. Duane, was anything special done to accomodate the feeding etc of the .404 Jeffery? | |||

|

| One of Us |

Guess it's up to me to answer this one...The action)s) were ordered for specific cartridge. They came with proper bolt face, proper magazine length. Anything after that is left to the customer or gunsmith...call them "semi set up" I've personally used a number of GMA actions...just the way what it is! A to the M-70, I think most gunsmiths do just that. | |||

|

| one of us |

Duane,after you do the feeding work on the actions and they are ready,do you feel there is any action that is better in any way.In other words, do you feel the Cz 550 will work better than the Dakota or the mod 70 or the GMA etc...Do you think there is any advantage in one over the other aside from magazine capacity? | |||

|

| One of Us |

Don't mean to step on your toes Malm, I think it would be difficult to hold the action in the vise without a fixture of some type. This is what I use to get at the underside of the action.    Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Professional member American Custom Gunmakers Guild | |||

|

| One of Us |

Jim: I agree....that fixture you made up is about the same as mine...I've made an elongated hole at the rear guard screw location so I can set the taper...I'd post a photo, but don;t have the help of an 11 year old at the moment | |||

|

| Powered by Social Strata | Page 1 2 3 4 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia