The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  New Stock Duplicator

New Stock DuplicatorGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

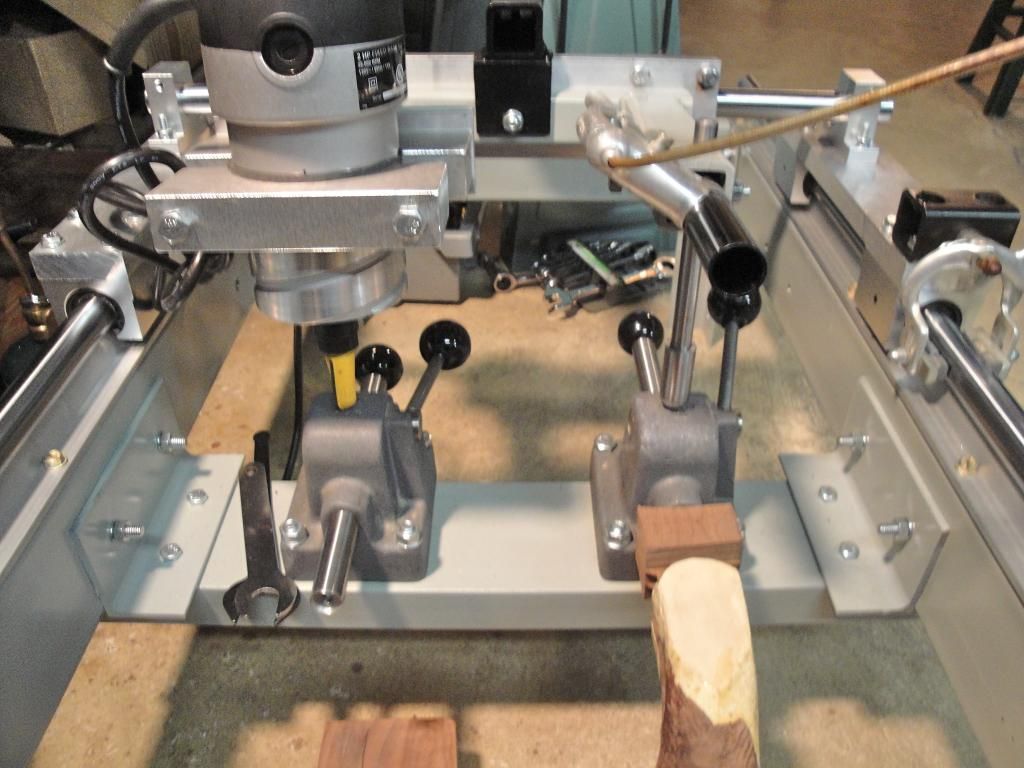

I got bored last week so decided to build a stock duplicator, which I did. Just to show you guys what you can do with some scrap steel and a Harbor Freight router. I do not know if it works or not but those linear bearings are tight. That counterweight is 17.5 pounds of lead I cast in a bowl. I got the brake from my wife's bike, which she is too fat to ride any more so she won't miss it. Don't worry, she never reads AR.     | ||

|

| One of Us |

Excellent job. I wish I could throw things together and have look that good. When are you going to duplicate your first stock? Eric NRA Benefactor TSRA Life DRSS Brno ZP-149 45-120 NE | |||

|

| One of Us |

Thanks, This week. That's a Baikal stock pattern. and that will be the first one. | |||

|

| one of us |

Absolutely too cool for school.  | |||

|

| one of us |

I would like to see a video of it working | |||

|

| one of us |

I like it what are you tails made from? I had a brake on the side rails. Found that most of my cutting was length wise and took it off. May need to try it on my cross piece. As usual just my $.02 Paul K | |||

|

| Moderator |

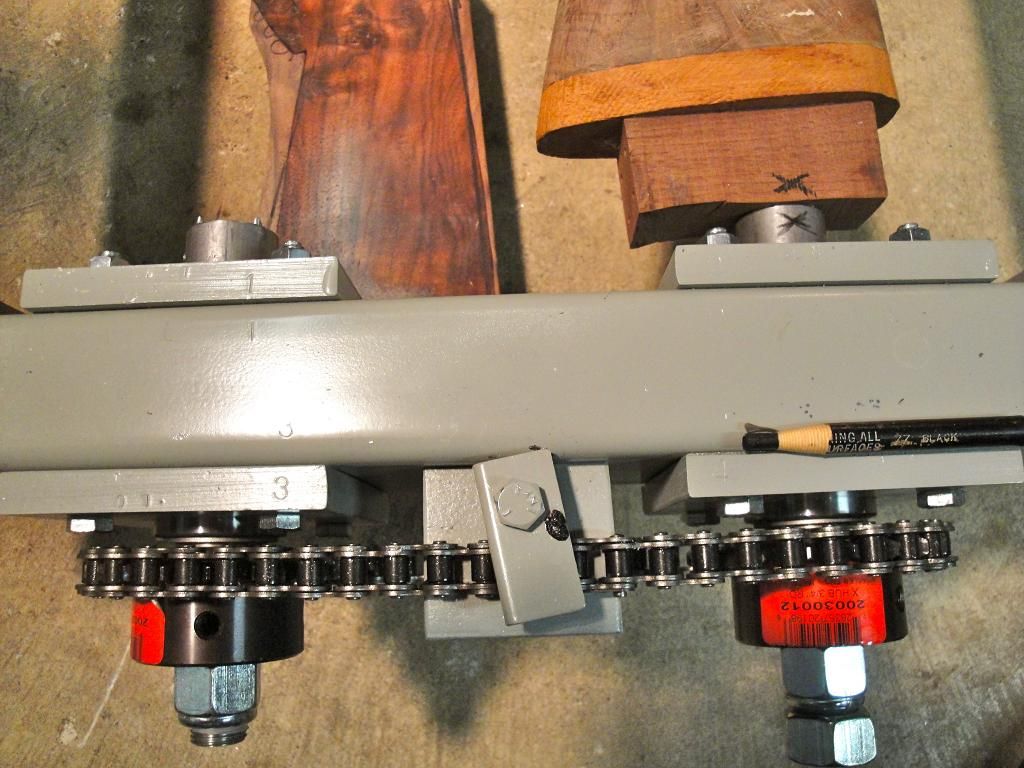

great! i used a spring loaded roller on an arm to tension my chain .. opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

I like it too, but again those tail stocks are something else. What are they and where did you get them. Adam ______________________ Ammo, you always need more. | |||

|

| One of Us |

Well one maker is Heinrich, they call theirs a Grip-Master fixture. here is one or here they work great if you don't have excessive vibration, otherwise they loosen, which would be a bummer. | |||

|

| One of Us |

Looks great! Never seen one in use before...what's the brake for? | |||

|

| one of us |

Removing a lot of wood requires a larger dia bit. That bit can dig in and want to throw the router (kickback) . The brake simply locks the cross piece to try and eliminate kickback. If you have used a router you know one direction is easy the other the bit wants to be in control. As usual just my $.02 Paul K | |||

|

| One of Us |

Yes, they are Heinrich clamps. Don't need no chain tensioner as it is drawn up tightly in tension by the tapered bearings in the headstock. I do have a chain lock, shown in the second pic. The brake will fit on either the cross slide or the longitudinal slide. It's bracket is just bolted on with 2 of the bearing bolts. | |||

|

| One of Us |

Gotcha! Thanks for the explanation.

| |||

|

| One of Us |

If you are going to take a lot of wood off of a blank, it is better to use a band saw. In order to get some accurate guides to how deep to cut, try the following. Mount the blank on the duplicator with the model. Set a 1/4" or less bit in the router and mount it about 1/4" high. Then make annular rings around the blank about every inch or so from butt to tip. Make cuts all around shaped items like a cheek piece. Now take the blank off the duplicator and use those cut rings as a guide on your band saw. | |||

|

| One of Us |

If you are taking off large depths of wood on the duplicator, you would be better served by using a band saw for that. First make guide line annular ring cuts around the blank about every inch from butt to tip. Make cuts all around objects like a cheek piece to aid in cutting. Then use those rings and depths as a guide on the band saw to remove bulk wood. It will save you a lot of time. | |||

|

| One of Us |

How has this machine been working out for you now that you have had it for a few years? | |||

|

| One of Us |

It works great but I don't use it much; my time is better spent on metal machines and I usually farm out the stock turning to those who do like it. | |||

|

| One of Us |

love it!! | |||

|

| one of us |

Son, you might as well get ready for it. Someone who knows someone who knows someone will recognize your new toy on AR who just happens to know your wife. "Experience" is the only class you take where the exam comes before the lesson. | |||

|

| One of Us |

Nope, no chance; she does not talk nor listen to anyone who knows me. In fact, she does not even talk to me. | |||

|

| one of us |

Lucky bastard! | |||

|

| one of us |

The PERFECT woman... "Experience" is the only class you take where the exam comes before the lesson. | |||

|

| One of Us |

I thought the same thing! By the by, that is so interesting to me yet so far over my little pea-head. Thanks for sharing your work with us, Zeke | |||

|

| One of Us |

Problem is that, occasionally, I actually need to talk to her. She gives me a dirty look and says, "Why are you talking to me". (As I have interrupted her Korean soap opera (sorry, they are dramas)). | |||

|

| one of us |

dpcd, On my original duplicator each headstock spindle is adjustable so a blank can be set after you check when the blank is placed into the machine. On some thin blanks you can shift slightly and see if the cheek piece will be cut with enough to shape after it is routed. These were some of the things that I thought about when I designed the first one back in '81. | |||

|

| One of Us |

I have your CDs; I know how to make adjustable centers. I was too busy to make the moveable centers. As I said, I do not use the machine much as I am quite busy with metal working; I usually farm out the stock duplicating work. | |||

|

| One of Us |

I'll bet your scrap pile is more pretty than mine. Your machine is a thing of beauty. You can always add some things each time You redo it. It would take me more than a week to set it up. Old age is a rip. Kenny | |||

|

| One of Us |

Trust me, I have no scrap pile; and it is not hard to set up at all. Just measure a little before setting the center. | |||

|

| One of Us |

dpcd I meant me being slow and lack of ability not about your machine. Kenny | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia