The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Wildcats And Their Development

Wildcats And Their Development  404-303 vs 375-303 (or 303-404 vs 303-375)

404-303 vs 375-303 (or 303-404 vs 303-375)Go  | New  | Find  | Notify  | Tools  | Reply  |  |

One of Us |

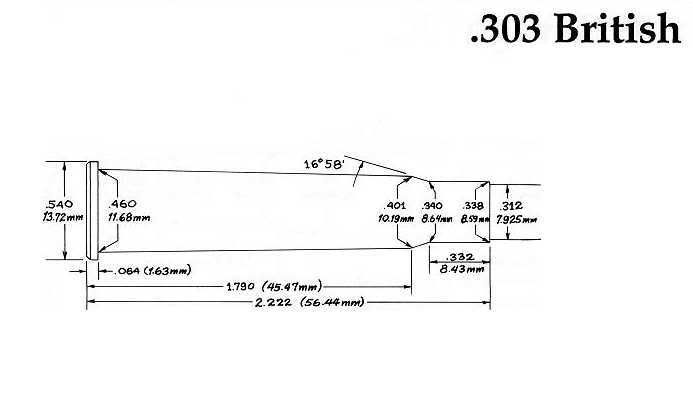

I have been 'creating' cases with .411 necks and .375 necks using expanders I made. Both up-sizings are a breeze except that the cases need to be sized again to squeeze the 'shoulder bulge' out (or in). Both up-sizings leave a little doughnut which I think is good to have as a seating stop. The .411 up-sizing reduces body taper and shortens the case to 54mm while the .375 up-sizing does not reduce body taper and reduces case length to 55.5mm. Max cartridge length is 76mm so bullet length would be 28mm for the 375 and about the same for the 411. There is no-way I would want to shoot bullets as heavy as that would make them, to velocities over 2000fps (target velocity is closer to 1800fps for cast). So, the question is, would there be any material difference between the two choices? Bullet availability, bullet BC, recoil and so on. I am thinking of driving a bullet of 300gr or so to between 1800fps and 2000fps. The 375 choice would have less case capacity, so would that push the pressure too high? And then, what twist rate would be ideal for either choice, considering that cast bullets are the objective but would like to be able to use jacketed bullets as well. Regards 303Guy | ||

|

One of Us |

Them 300 grain 405 bullets are ideal imho 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

303guy, as you said going to the 411 neck size reducesthe body taper and this in turn reduces case capacity. However the 375/303 if you will design it so you have astraight parallel section of the neck exactly one caliber long will allow you to seat 375 dia cast bullets with the gas check still inside the case neck itself. As far as twist in the 375/303 I'm going with a 1x14 twist. still allows cast and jacketed bullets up to and including 300 grains.Course you would need a throating reamer to lengthen the throat out aways when shooting the 300grain bullets. I'm guessing here, but assume you are toying with the idea of either a 411/303 or 375/303. of the two i'd say its easier to get the 375/303 to feed through a smle magazine using either cast bullets with smaller meplats than larger 411 dia bullets with larger ones. I have such a rifle in the works.Using the dimensions from a takeoff rem 700 vs barrel in 308 winchester. Will have to have the breech area bigger to mate up with the enfield receiver, maybe make the bbl slightly thicker and a maximum length of 22 inches.This way I will have a 375 tube that should be reasonably in terms of weight and stiffness. Why 22"?. I don't hunt any more so most of my shooting takes place at the range. There I can easily place it in a rest and even with let's say the speer 235 grain spitzer get good accuracy with a medium weight rifle and enjoy the benefits of shooting cast bullets. Nothing fancy regarding the wood. Nice long branch buttstock, cut down $4 MKI lower forearm maybe with ebony tip. I've cut down the charger bridge, so this will give me a lower ling of sight. Instead of having to sight over the charger bridge.By this time you could reasonably guess that I'm fond of the 375 bore. And you'd be right. There are plenty of 375 bullet moulds available and they use less bullet metal than the .411 size. Frank | |||

|

One of Us |

Thanks for that Singleshotlover. It's just that, well how can I put it? Aah.... boom stick expresses it very simply;

But use of the standard L E magazine, less lead, easier up-sizing, less recoil (maybe) and a very handsome cartridge to boot, does lean heavily in the 375 direction. The 444/303 would have been great for the availablity of store supplied cast bullets but really not going to work in the Lee enfield with 303 parent brass (unless I went to '57 Rimmed brass). Now, next question, Hah! I have been overlooking something - the 38-55 Wnchester/Ballard! This thing is almost identical to 'my' 375-303. It has a slightly smaller case and reloading data is available for it! ADI give a 250gr cast bullet at 1740fps. Hodgdon give a 255gr bullet at 1830fps @ 28,200 CUP and Speer lists it too. So, the 375-303 should be able to do a 250gr at 1800fps (maybe a little more). Regards 303Guy | |||

|

One of Us |

I have now tried the '375-303' cases in the magazine and simply put, it won't work. Not without modifications anyway but I suspect a complete rebuild will be required. On the dough-nut - should I decide I need to seat deeper or want to load with a lube wad under the bullet, I am thinking of ironing out the dough-nut using a die and punch. The punch would be a close fit in the guide to force the ironing evenly. Rolling over a mandrel might work too. This is a 'punch die' I made for the hornet. It was for seating an over-powder wad and neck sizing simultaneously so as to hold the wad at the 'sized' step. I ended up using it to repair damaged ie crinkled necks. In this one, the punch is fixed in the die. Regards 303Guy | |||

|

| One of Us |

Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

One of Us |

That sounds plenty good for me! Thanks. Now what to do with that dough-nut? It sits 8mm into the new neck - a little short of one bullet diameter. But even with the bullet seated that far out, the cartridge would still fit the magazine. I see no reason why I couldn't roll it out. And if I did, I would be lengthening the case at the same time. This can only be good - I think. Regards 303Guy | |||

|

One of Us |

There was supposed to be a picture with that post!  I cannot remember who sent me this picture - nor what caliber it is.  Regards 303Guy | |||

|

| One of Us |

Why not just convert to 405 win | |||

|

One of Us |

I looked at the 405 Win but it is too long for the Lee Enfield. It could be shortened but I'm not sure I can get the brass for it. It has a rather non-standard rim thickness. But thanks for the thought! I didn't realize till now that the 40-65 Win used the same case as the 45-70 - almost (but with more body taper and a thicker rim). Now there's a possibility! But actually, I don't want too much recoil so I am kinda settling on a 375/303. This would be a lower pressure 375 Win. (Since the 375 Win has plenty power as it is!) Regards 303Guy | |||

|

| One of Us |

I know a couple of sambar hunters that would disagree with you about the 375 win.lol.Could you use the 405 idea but on 303 brass,was under the opinion the 405 was only the 30/40 Krag blown out | |||

|

One of Us |

The easiest would be to put the three cases on the same page. By necking the 303 Brit case to take 375 bullets, the neck OD meets the body just about right. Another factor I have considered is that the 35 Remington gives enough power for my needs at a rather low pressure, as does the 375 Win so 375/303 sounds about right. Also, I am not sure about availability of 405 bullets although the idea is to make them. Also, if I stuff up the attempt at making that 375 bore, I can still try again for the 405 or 41! Regards 303Guy | |||

|

| One of Us |

303Guy You could give Nelson Collie at Status Guns in Invercargill a ring. He showed me a 303 conversion last time I was there and I think it may have been either 375 or 358 and he has the reamers(drawers full of them) for lots of one off's. Von Gruff. | |||

|

One of Us |

Thanks. I might just do that! Regards 303Guy | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Wildcats And Their Development

Wildcats And Their Development  404-303 vs 375-303 (or 303-404 vs 303-375)

404-303 vs 375-303 (or 303-404 vs 303-375)

Visit our on-line store for AR Memorabilia