The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  .425 Westley Richards Range Report - Reloaded

.425 Westley Richards Range Report - ReloadedGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

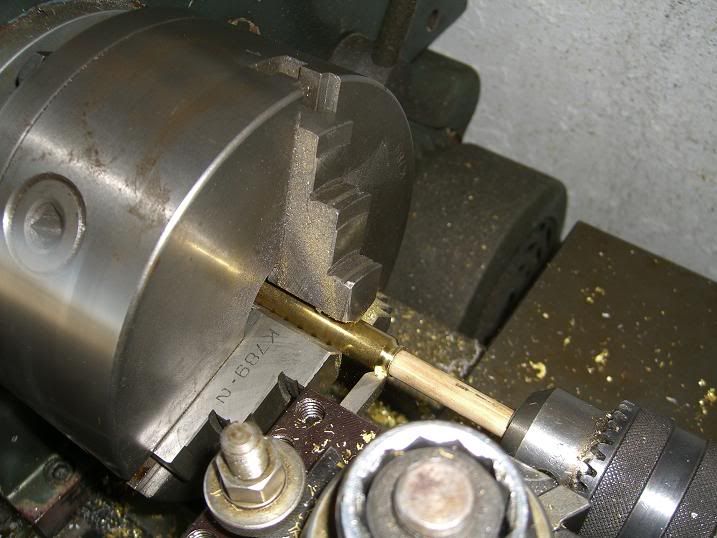

Last week I posted some findings that I gathered while trying to develop a load with Hogdon's extreme powders for the .425 Westley Richards. Several responders requested photos of the rifle and information on the process that I went through to make 425 brass out of commercially available .375 RUM cases. Thanks to the suggestions of several members, I have now mastered the technology to include pictures as part of a post (www.photobucket.com). This is a picture of the gun that was used in the test. It is an original .425 WR built on a Mauser 98 action. The barrel is 24 inches long and as can be seen from the pictures includes a drop box magazine that holds 4 rounds. The gun weighs 8.5 lbs (unloaded) and is more of a pleasure to shoot at 2,300 fps than at 2,475fps:  All of the load tests were conducted at 5,100 feet MSL, 88 degree F and 25% humidity. Bullet - Woodleigh 410 gr softpoint (I also tried some duplicate loads with 410gr woodleigh solids with no difference) Primer - Federal 215M Cases - Masterifleman's gourmet Remington .375 RUM converted to .425 WR Chronograph - Chrony C Test results: 75.0 gr H4895 produced an average velocity of 2,468 fps with a slight feel to the bolt on extraction ... I never did bother to try 80 grs of 4895 that was a recommendation I found on the web! 74.0 gr of VARGET - produced an average velocity of 2,342 fps 75.0 gr of VARGET - produced an average velocity of 2,408 fps. (note the first shot was 2,369 fps and the rest were 2,402 - 2,414 fps - could this be due the tempurature of the gun and the ammo? At the start of the 75.0gr test, the both the gun and the ammo were hot to the touch from being shot and from sitting in the sun. Although this might simulate actual hunting conditions in the African bush it was not an intended part of the test, just an observation. I found that there were no extraction problems whatsoever with any of the VARGET loads even after the rifle and ammo got hot. Several persons inquired as to the process to make the cases from commercially available .375 RUM brass. A good friend, "masterrifleman" is a NRA master long range shooter, gun nut and gun smith should get the credit for the the following process that was used to make .425 cases: Masterrifle man created a cutting tool to turned down the bases of the .375 to match the rebated head size of the 425 WR. The follwing is an action shot of this operation:  We then ran the cases through a .404 Jefferies die and belled the mouths. The following is a picture of the case after it was run through 404 resizing die and after the case mouth was belled in preparation for run the case through the .425 die:  The following is a photo of the case after successfully exiting the .425 resizing die:  The cases were about 1/4 inch to .300 inches too long so we rigged a cordless drill to a Forester case trimmer to trim to proper length which worked like a champ!  The following is a picture of what happens when you try to run a .375 RUM case directly through a .425 die skipping the intermediate .404 resizing step. Note, to masterrifleman's credit, these are the only cases that we lost in the process:  This final picture is a photo of the rounds that were developed for the test. No, I did not try Reloader 15 but it would be a good candidate powder for this cartridge:  I found that the cases that we made from the Remington brass to be superior to the cases from specialty manufactures that still make brass for this cartridge. Hope the pictures make it this time ... - Induna Jr. | ||

|

| One of Us |

Nice work on the case forming. That rifle looks like a Westley Richards Ranger model. Good hunting | |||

|

| one of us |

Thanks! That was a tour de force in stimulating reading and viewing for rifle and handloading loonies. It is no surprise that your Remington brass for the .425 WR is better than Bertram's, eh? BTW, when you say ".404 Jefferies" I know you mean ".404 Jeffery" or "Jeffery's .404 Rimless Nitro Express." Thanks again for endeavoring to persevere in this reloading, writing and photo-posting project. Welcome to the "Rifle and Handloading Looney Bin," as you surely qualify. | |||

|

| One of Us |

I should have cleaned my bench before you took the pictures. "I ask, sir, what is the Militia? It is the whole people. To disarm the people is the best and most effective way to enslave them" - George Mason, co-author of the Second Amendment during the Virginia convention to ratify the Constitution | |||

|

| one of us |

Masterifleman, So you are Sancho Panza to Don Quixote? Congratulations on your immediate successes. | |||

|

| one of us |

Wonderful thread. There is hope, even when your brain tells you there isn’t. – John Green, author | |||

|

| One of Us |

sounds like work. I simply run BELL 404J brass from my stash thru my RCBS 425 WR form dies and trim them to .265" in a cheapie $30 Lee trimmer hooked to my Dremel tool. | |||

|

| One of Us |

I commend you on your attention to detail and willingness to do whatever it takes to get it right. Great job! Mike Wilderness is my cathedral, and hunting is my prayer. | |||

|

| Moderator |

awesome work and great pics

and if he left his bolt face over sized, he could do the same -- except he has and uses a spec 425 case ... just saying opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

what is this "special 425 case..." you speak of? | |||

|

| One of Us |

I think he means spec as in "to specifications" That brass looks amazing. well done. | |||

|

| One of Us |

It does, and it is, but just seems like a bit of extra work, especially considering that you will have to repeat all of these machining operations every time you want brass. I have more than 450 new BELL 404J cases in a box out in my shop. Takes two minutes to run one thru my 425WR form and then trim die, and load and shoot them. | |||

|

| One of Us |

When I was loading the 425 20 years ago, had trouble with Bell cases. Primer pockets expanded and cases were very difficult to extract for 400 grain loads going 2400 fps. Had 20 Bertram cases sent up and they were great. Finally switched over to 416 Rigby before a trip to Africa. Loved my 425 Westly Richards rifle but never took it to Africa because brass case problems. The RUM case conversation although a bit preparation intensive, produces very reliable and strong cases for this great caliber. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  .425 Westley Richards Range Report - Reloaded

.425 Westley Richards Range Report - Reloaded

Visit our on-line store for AR Memorabilia