The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Another REALLY BIG, Big-bore added to my collection

Another REALLY BIG, Big-bore added to my collectionGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

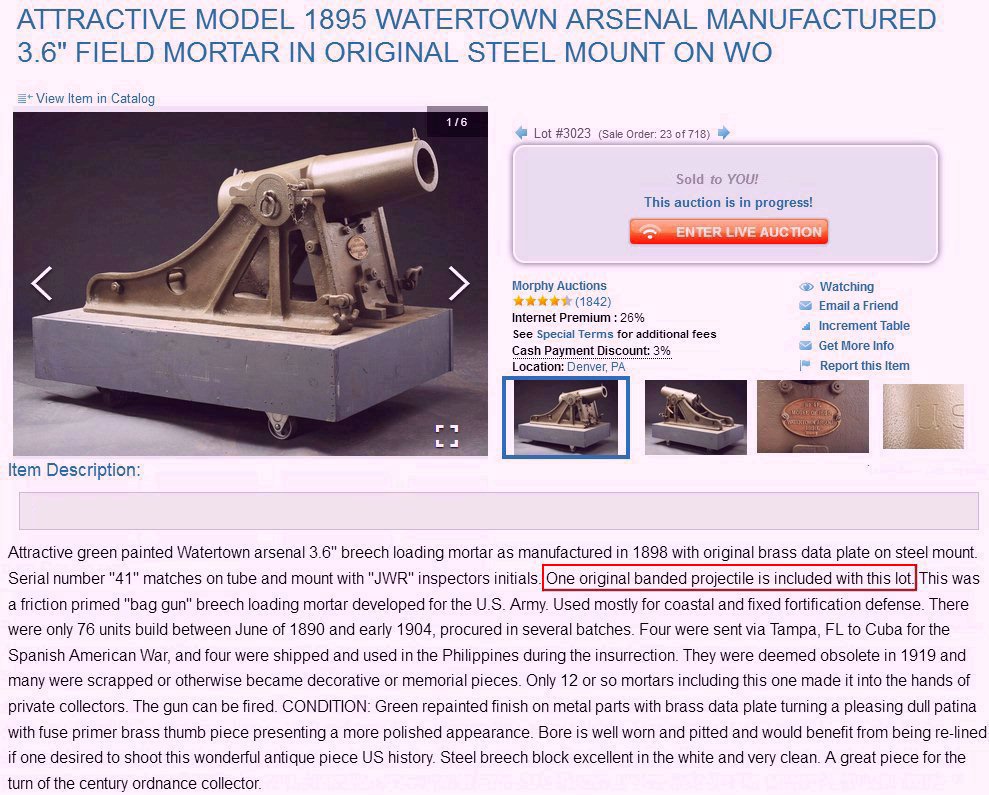

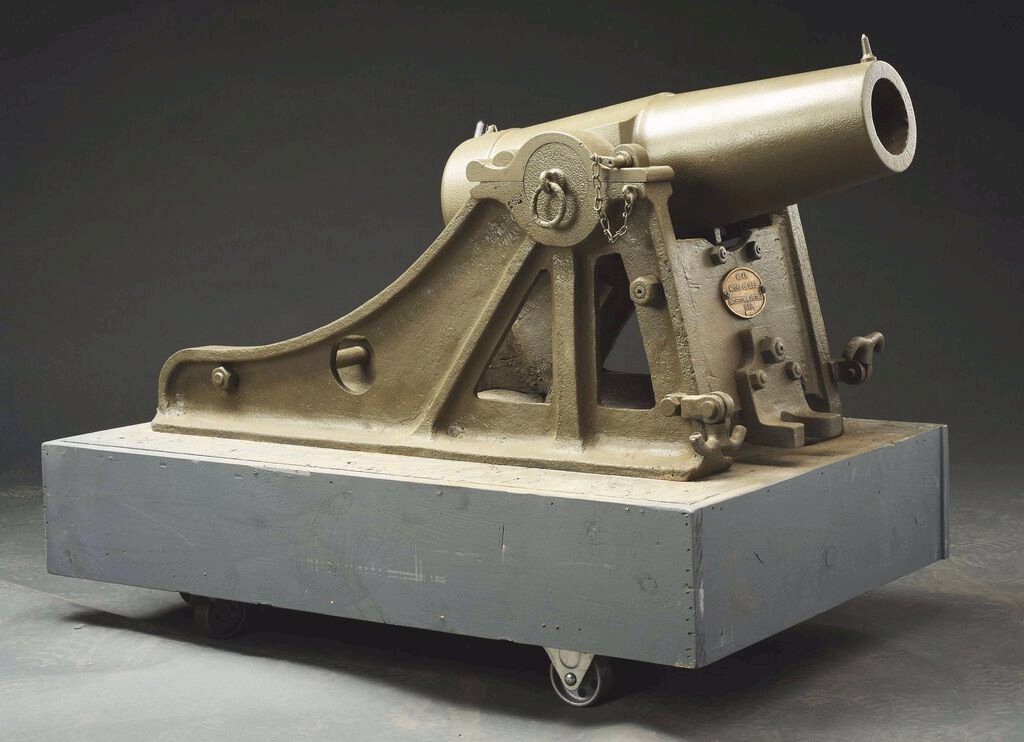

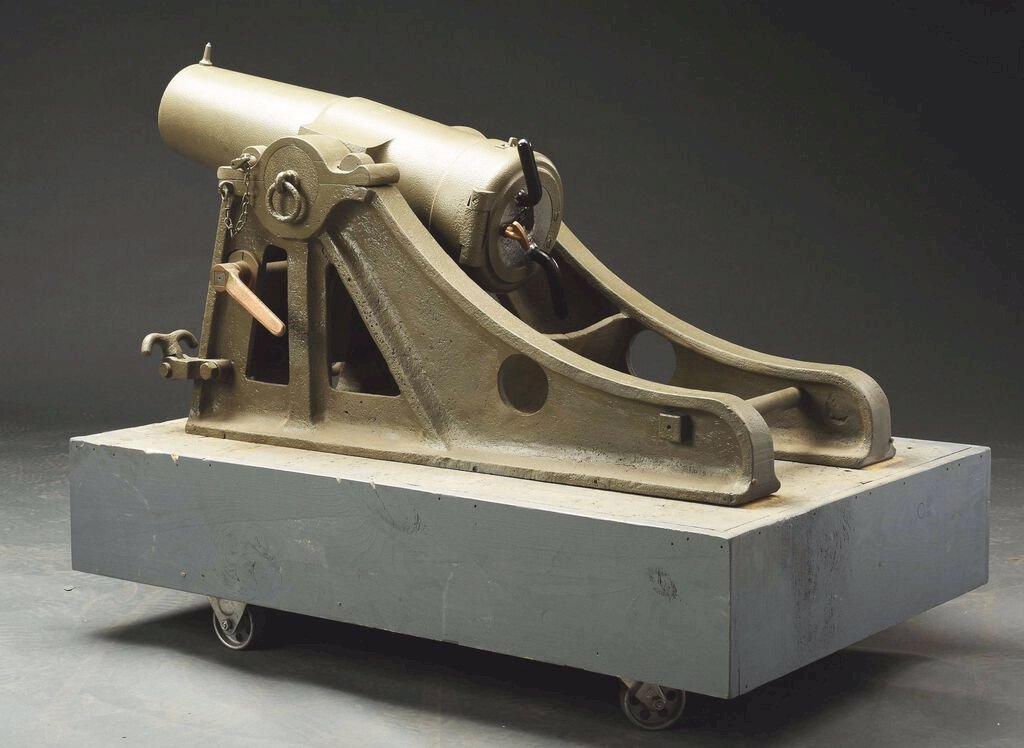

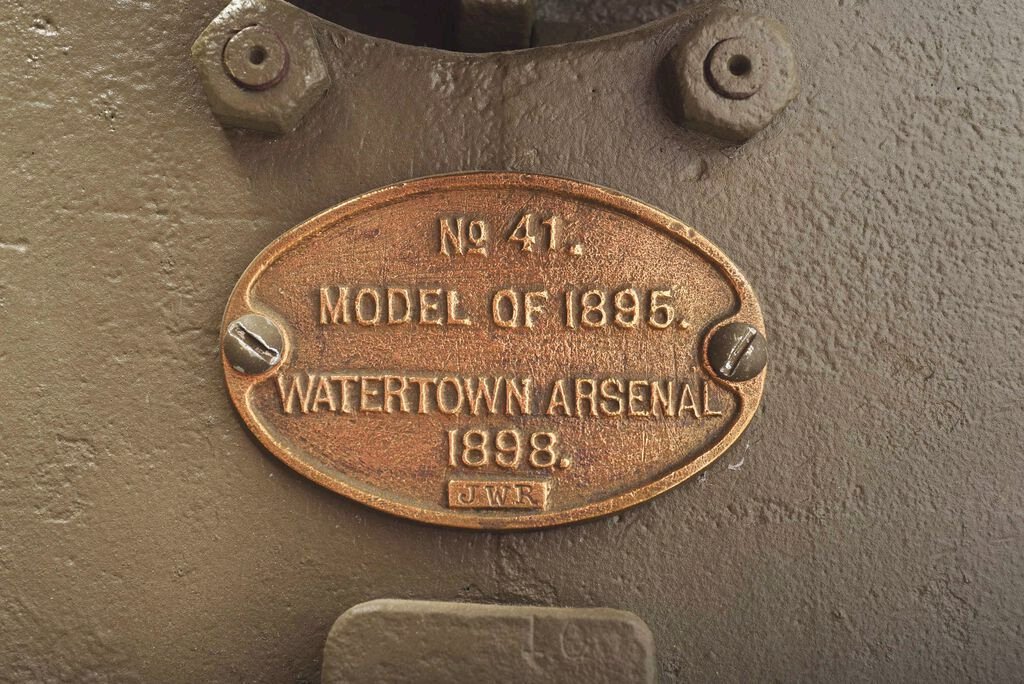

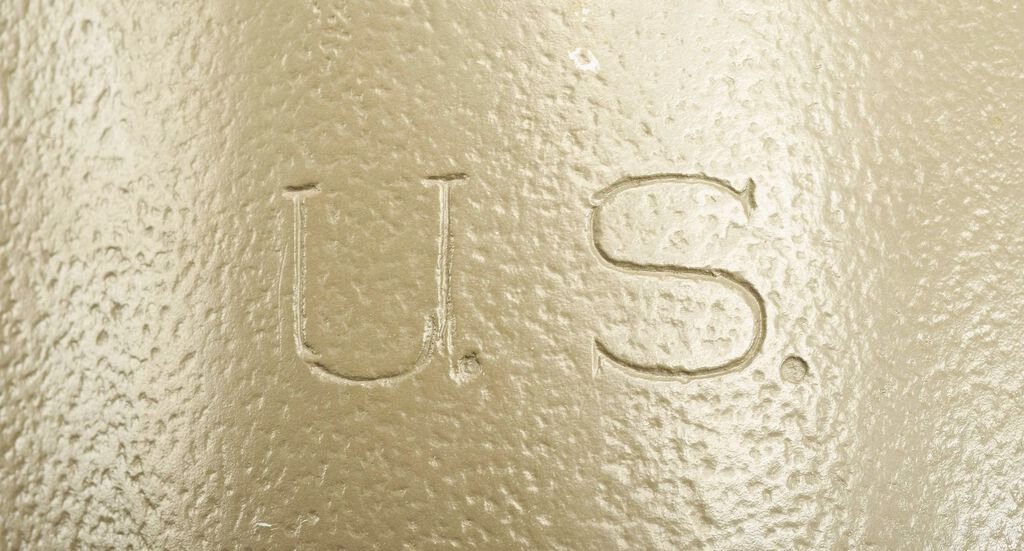

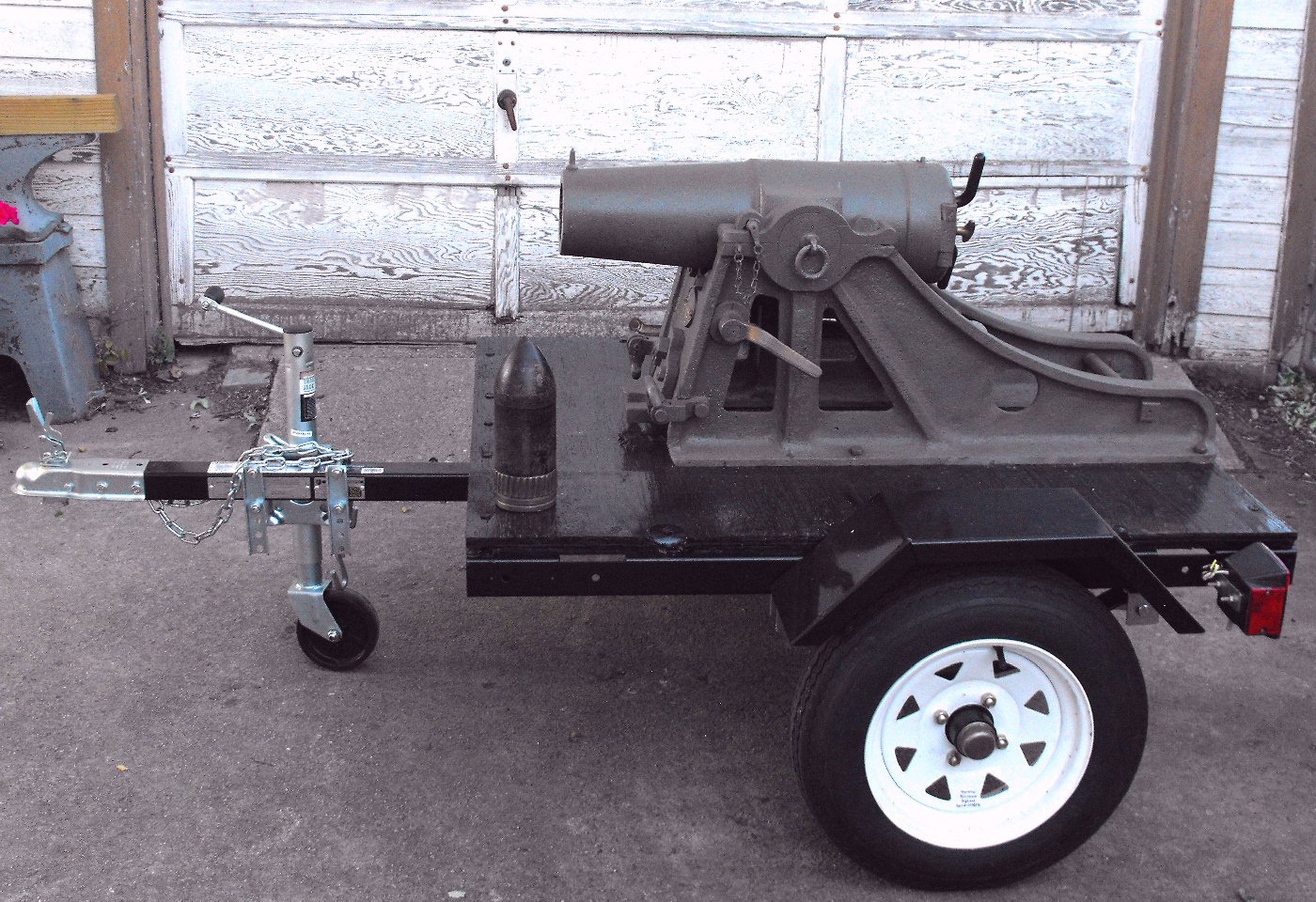

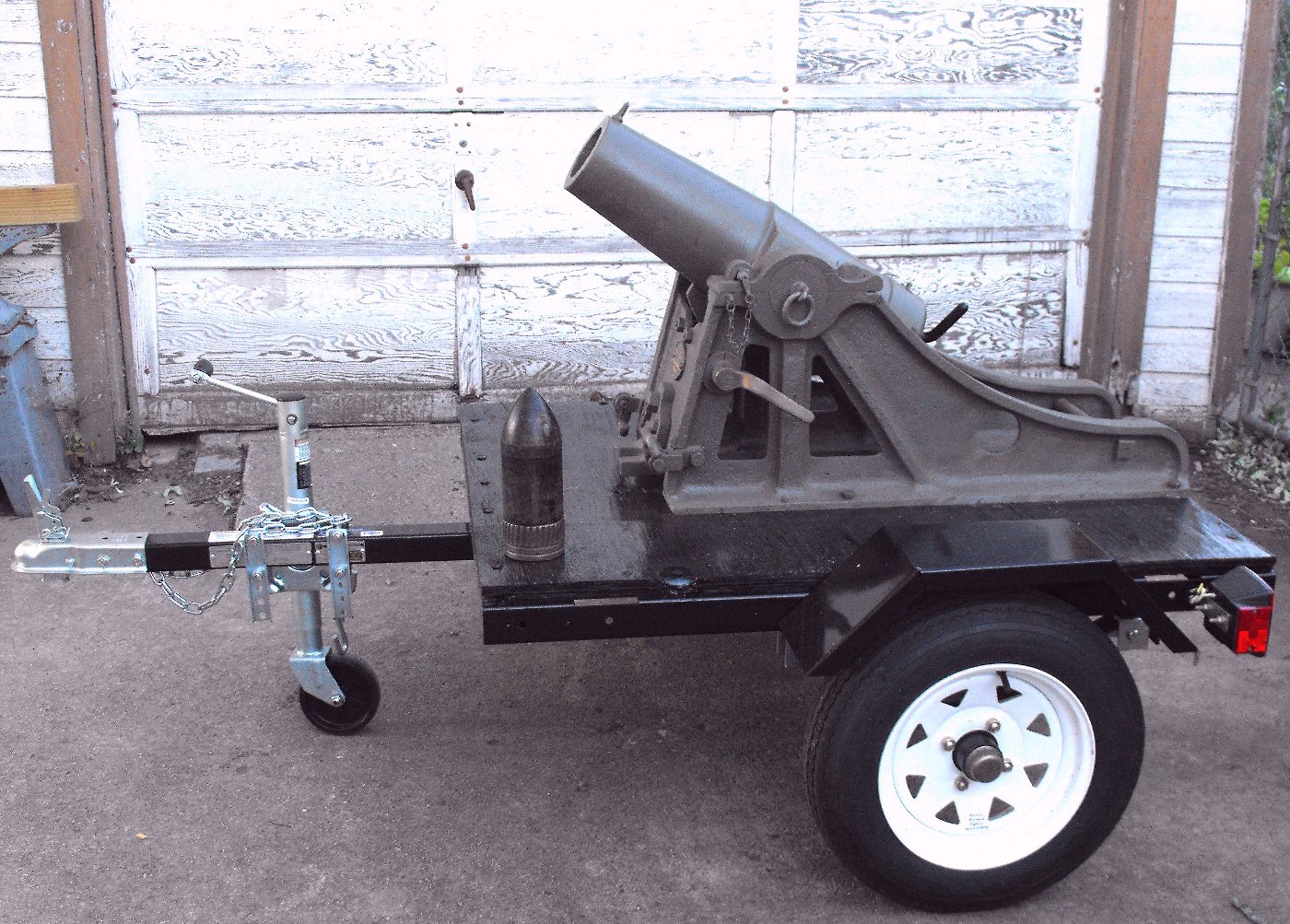

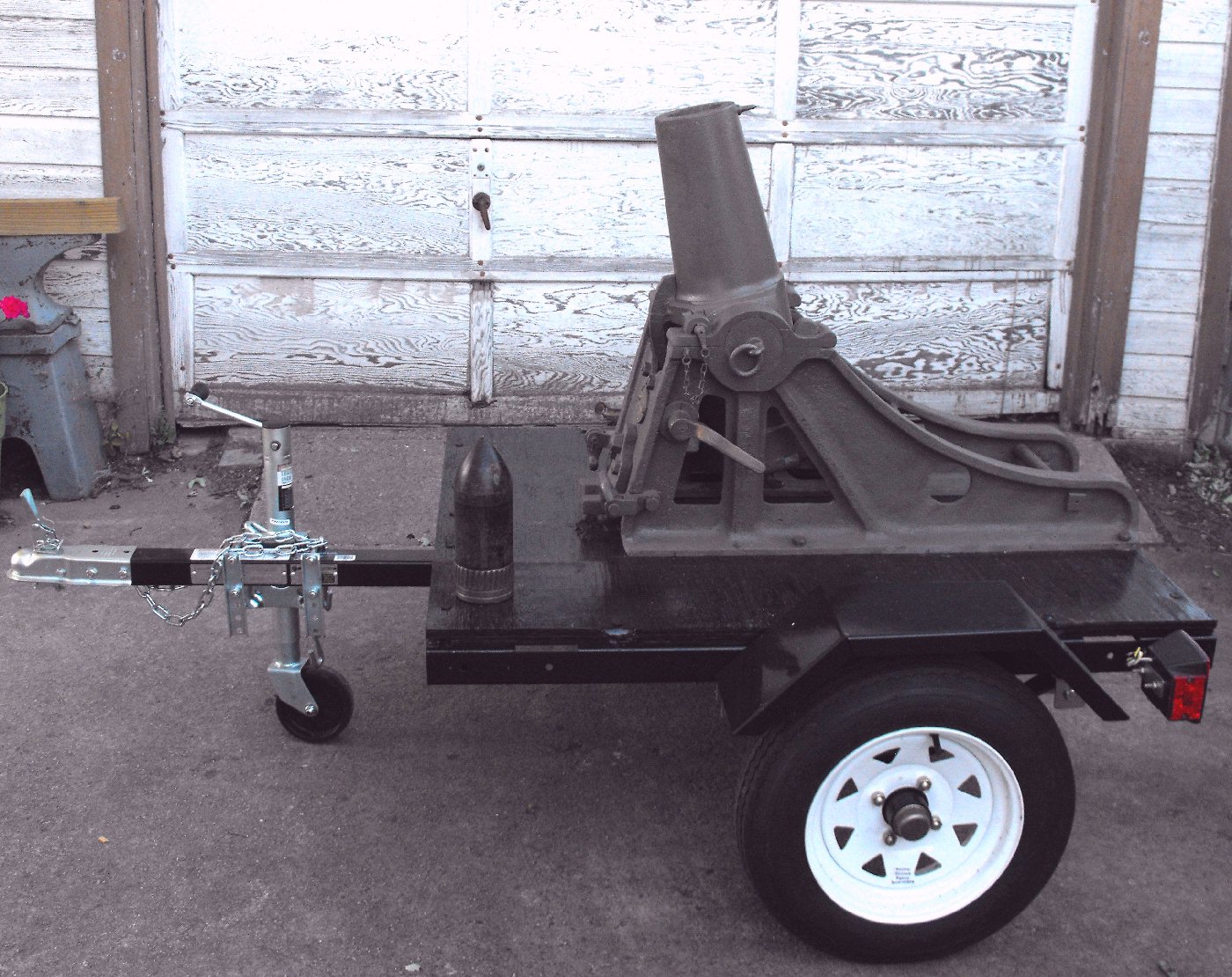

Hello All, You may remember this post from a couple years ago, about my really BIG - Big Bore ... http://forums.accuratereloadin...341045342#4341045342 Well, .... I added another really BIG, BIG-BORE to my collection. An 1895 model 3.6" Field Mortar. I had to build a custom trailer to transport the 545 pound rig, and its permanently mounted thereon. Take a look at that "bullet" ... - WEIGHS 20 pounds ... 750 fps velocity ... 4,000 yard range .... THAT'S 2-1/4 MILES .... No one is going to have a bigger gun than I.           . ORIGINAL LOADING DATA is listed as ... "HOWITZER" from 0 degrees to 40 degrees ... and as ... "MORTAR" from 45 degrees to 85 degrees .    . . " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | ||

|

| One of Us |

Might work for elk, a little small for Buffalo. Just kidding of course. I love seeing your wares. | |||

|

| One of Us |

My father was a machinest at the Waterveliet Arsenal for 30+ years. He rifled the 1st atomic cannon and made numerous trips to the proving grounds in New Jersey. | |||

|

| One of Us |

You sure are the man. A fair bit smaller but I love your Winslow 378. | |||

|

One of Us |

That would be fun with aluminum projectiles! Try to get to 2,700 FPS and put a scope on it! 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| one of us |

Nice trailer carriage. How far backwards does the trailer roll when you shoot it ? | |||

|

| One of Us |

hi, helmut..that's a very impressive new find!!!......i'd recommend a 6-24 nightforce scope in griffin and howe mounts for those long shots.!!!!!! very cool to see for an old artillery man!...best regards...JOHN | |||

|

One of Us |

I wonder what the Taylor KO factor is on that one! | |||

|

| One of Us |

From which end? | |||

|

| One of Us |

You have to take that one out after coyotes. | |||

|

| one of us |

I enjoy artillery and that is a pretty nifty find. I've only got replicas but they range from BB at .177" bore up to BB at 8.75" bore. My current favorite is a full scale 3lb breech loading swivel gun. It's been enough firepower to keep the pirates off the lake! | |||

|

| One of Us |

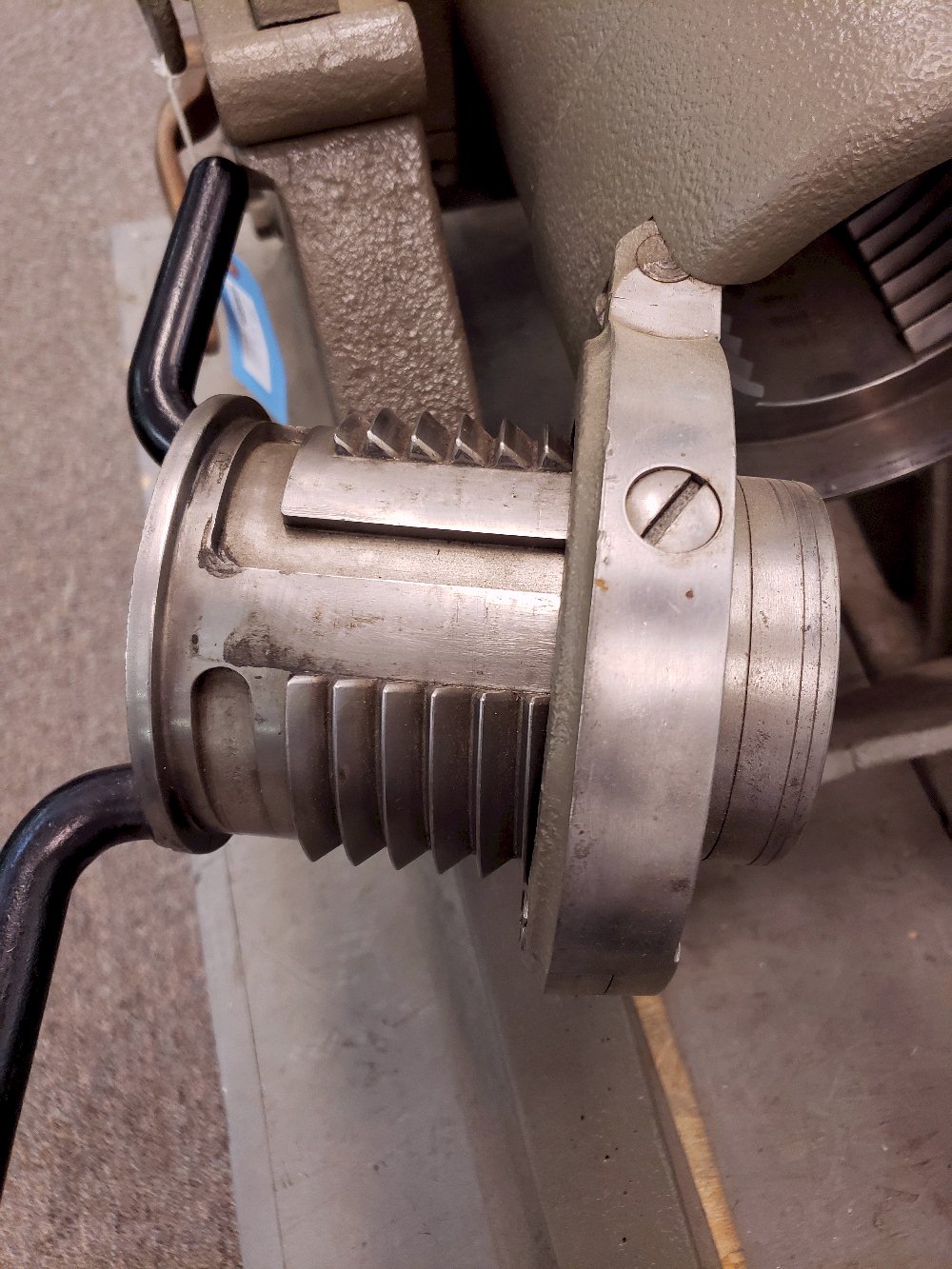

Maybe that is where WEATHERBY got the idea for many locking lugs ? Hip | |||

|

| one of us |

Now you have to start looking for a bigger gun. Dave | |||

|

| One of Us |

Weatherby got it from Newton, who got it from Ross, who got it from artillery. More than a few other makers have tried the same interrupted screw-thread principle. It works, but it was more difficult to machine until CNC took over. | |||

|

| one of us |

Now buckstix will find a suitable pipe with 3.6" OD, some crazy filler material and start making projos and lobbing them about the countryside! | |||

|

| one of us |

He will be selling blank firings to attendees at the local annual festival, to anyone who will pay for the BP used for the shot. Paper wad thrown in gratis. | |||

|

| One of Us |

A friend has a Rem. 788 in .30-30 he has made into a BENCH REST RIFLE (new bbl, stock, etc,). He told me that most of the locking lugs have no contact ! But that is mass produced before CNC (I think) machines Hip | |||

|

| One of Us |

That's sad. I'm certainly no Remington authority, but I believe the 788 was a budget model. Just because something is harder to do without CNC doesn't mean it can't be done; it just takes more human skill and time (and therefore more money) to do it. The 788 was built to a price, so not every last ounce of care and craftsmanship went into it. That's why they chose a rear-locking bolt; it's easier to machine the recesses in that location. Years ago I toured the Pratt and Whitney plant for which we performed all the metallurgical testing and lab work. Automated inventory, robot carts whirring around the plant, a sea of CNC machines, it looked like the Blade Runner set. I came across a small group of non-CNC, old-fashioned (but brand new) manual machines. I stopped and talked to the man running an immaculate SIP jig borer, identical to one I had used back in school. I said it was not at all the sort of machine I expected to see there, and asked what type of work they did. He pointed to a cart with a few extremely sophisticated titanium castings and told me, "We fix up the CNC f***-ups." If one of the machining centres went a millionth of a frog hair out of tolerance, it was up to them to try to save the casting. CNC is awesome; it's not infallible. | |||

|

| One of Us |

that is pretty cool even the garage door and trailer are to scale. :-) | |||

|

| one of us |

buckstix, Have you tried out our modern BP to see how it compares to the most excellent powders of the 19th century ? I wonder how the range of impact varies for those elevation angles, with a 20-pounder ? What elevation gives the 4000-yard range of the original loadings, 40 degrees ? I am pretty sure 90 degrees elevation might be too friendly a firing angle. Friendly to the enemy. | |||

|

| one of us |

I think I saw an identical item on a Morphy site. Helmut, you better bid to keep somebody from challenging you in the big bore race. I can see it now, a matched pair and a bigger trailer. Dave | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Another REALLY BIG, Big-bore added to my collection

Another REALLY BIG, Big-bore added to my collection

Visit our on-line store for AR Memorabilia