The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  404 Jeffery

404 JefferyGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

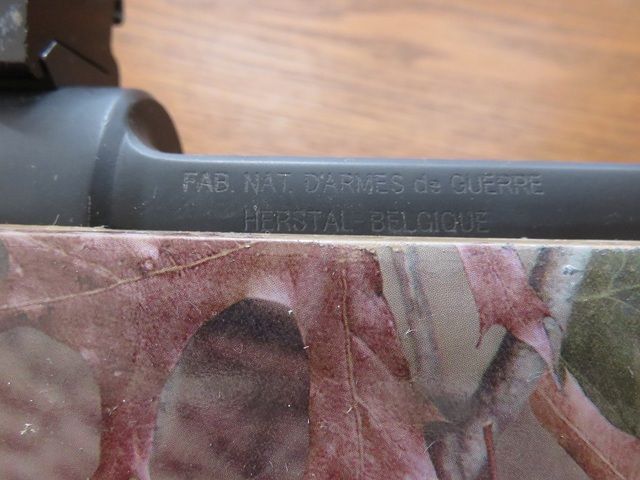

I just purchased an FN Mauser chambered for 404 Jeffery from an individual on another forum. The seller bought the barreled action in England. There are English proofmarks on the right side of the barrel. The action has a 4 digit serial number located on the bottom of the action plus there is a "W.J.Jeffery & Co." serial number on the bottom of the barrel. It looks like the barrel was shortened to 24 1/2" and crowned eliminating the front sight. It has been stocked with a synthetic stock. Can someone explain the English proofmarks? 'MLF' is stamped on the bottom upper right corner of the action. Anybody know what that means? I assume the four digit number on the bottom of the action is the FN serial number? Am I correct? Did W.J.Jeffery & Co. use FN Mauser actions for their rifles?       Jim | ||

|

| one of us |

I have owned one and seen a number of FN in Tanzania in 404 Jefferys..I am pretty sure yours is a converted FN, not factory..The opening of the magazine and the workmanship isn't that of FN from the others Ive seen... The FN in .404 is and issue gun to the game scouts in Tanzania in many cases, They get the gun but no ammo. No ammo to them saves a lot of elephants that would normally be poached by the game scouts..just a bit of historical worthless info. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

In several cases in the last decade the game scout that went with us had no rifle at all. But in 2012 we had a scout with a 404 and he did have ammo with him. He was very happy when our buffalo dropped at the shot. He told me that he didn't like shooting the 404 himself.  The buffalo was shot was thru the face and along the neck to chest at 70 yards, using a 416 Rigby (sort of a sister to the 404). Bullet recovered showed secondary expansion AFTER shedding its petals. (Muzzle velocity of TSX was probably about 2850fps):  A monolithic in the 404 could probably be handloaded almost as fast the Rigby, though there is no high-BC bullet yet that would take advantage of that speed. The newer 350gnTTSX in .416 is my idea of a true all-around Africa load, anywhere from 2650 to 2850fps. It will drop little antelope at distance or buffalo up close. (Of course, I would recommend solids for ele and hippo.) Final picture is an oribi at 200 yards with the 416 that same year:  +-+-+-+-+-+-+ "A well-rounded hunting battery might include: 500 AccRel Nyati, 416 Rigby or 416 Ruger, 375Ruger or 338WM, 308 or 270, 243, 223" -- Conserving creation, hunting the harvest. | |||

|

| one of us |

Game scouts from time to time get lucky and a client with good intentions gives them ammo!! usually without mention to the PH..in which case he just furnished a poacher with ammo to kill elephants..The road to hell is paved with good intentions.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

So what you're saying is we should all load some 404 Jeffery ammo up at 1200 fps and give it to the game scout to kill poachers. | |||

|

| one of us |

| |||

|

one of us |

| |||

|

| One of Us |

The proof mark on the barrel is definitely from the London proof house. So the barrel wasn't proofed in Belgium. Normally there would be no reason to "re-proof" a barrel already proofed in Belgium, so the re-barrel to 404J seems the obvious conclusion. _________________________________ AR, where the hopeless, hysterical hypochondriacs of history become the nattering nabobs of negativisim. | |||

|

| one of us |

1200 might not be slow enough lots of things are killed with that kind of velocity. | |||

|

| One of Us |

Just sub in a volumetrically equivalent amount of cream of wheat for powder! | |||

|

| one of us |

RyanB, Fact is I know some PHs that have loaded 404 full of Bullseye and left them laying around in certain places to be picked up by game scouts or so they claimed I better add. A correct post above in that the 404 and 416 Rigby have about the same powder capacity and can be loaded to some very high velocity, the 404 to 2700 FPS and the 416 Rigby to 2900 FPS with some African friends of mine..Consider the 416 WBY is actally a 416 Rigby with a belt added for all practical purposes and Ive loaded a 404 to within 100 FPS or a 416 Rigby max load..That said, its was experimental, I shoot my 404 at 2350 to 2400, as well as the others. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

I like the stock but the African purest will hate it. | |||

|

| One of Us |

I'll give you my opinion, for what it is worth. I believe someone got hold of a takeoff barrel that was from a Jeffery rifle and modified a FN action to fit. The amateur level of work on opening the front of the action would never come from Jeffery. The four digit number on the barrel was stamped freehand and not dressed down, so it was added . The proofmark with the sword indicates London Nitro Proof, cannot identify the lp over 13 in my book of proofmarks. It was probably done after 1955 when they changed some of the Rules of Proof and it cut back on the number of stamps placed on guns. If it shoots good, enjoy it, but I don't believe it could be sold as a Jeffery rifle, just a rifle with a Jeffery barrel. Not trying to be rude. I checked three of my FN commercial actions and all had ML stamped on the lug in the same place and in the same font, I have no idea what that means or why yours has an F on it, but it may be an inspector mark. All my FN's have the serial number stamped on the right side of the receiver and they are not the same as the numbers stamped on the receiver flat, those numbers could be production numbers, but that is purely speculation on my part. DRSS(We Band of Bubba's Div.) N.R.A (Life) T.S.R.A (Life) D.S.C. | |||

|

| One of Us |

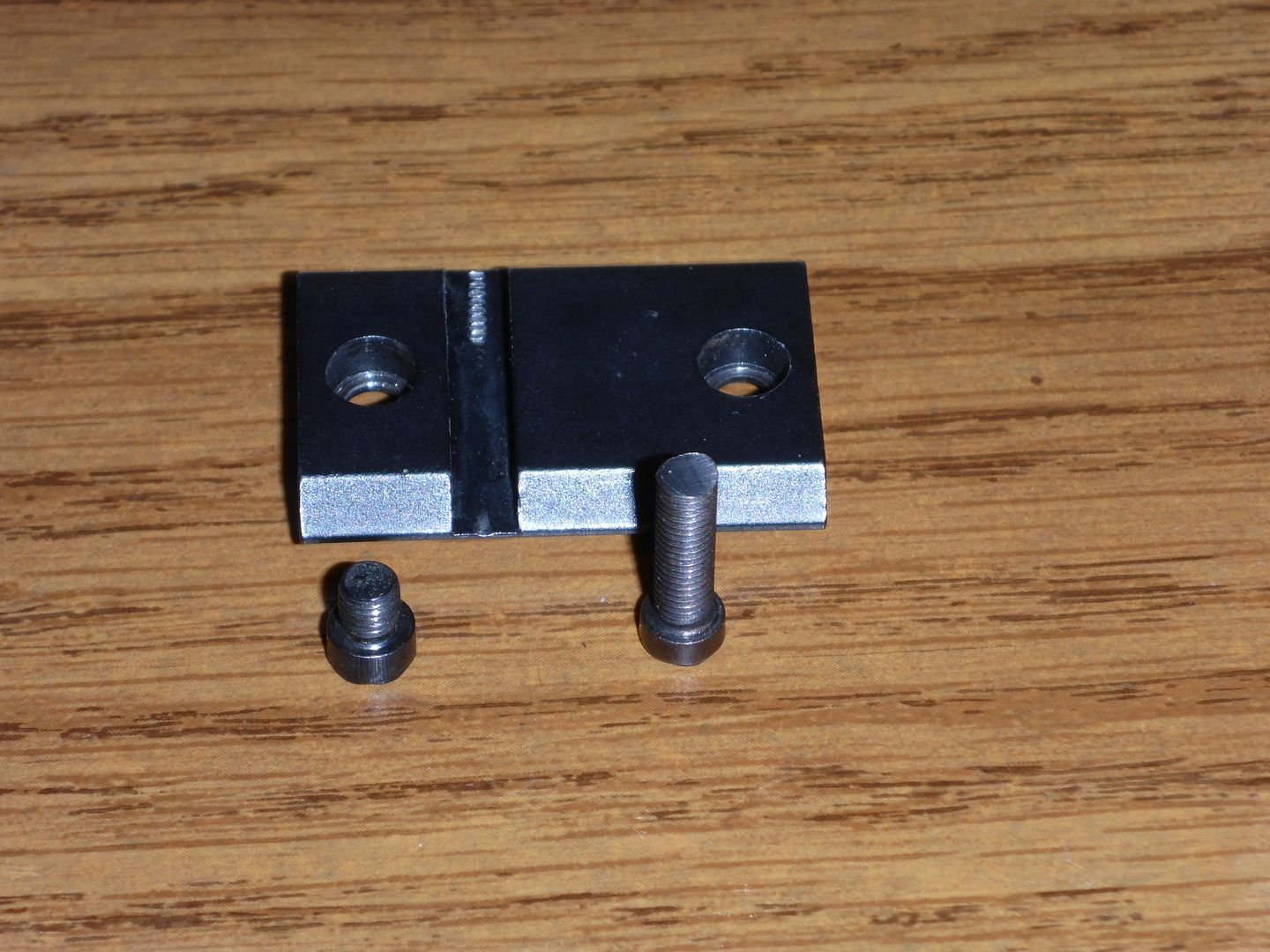

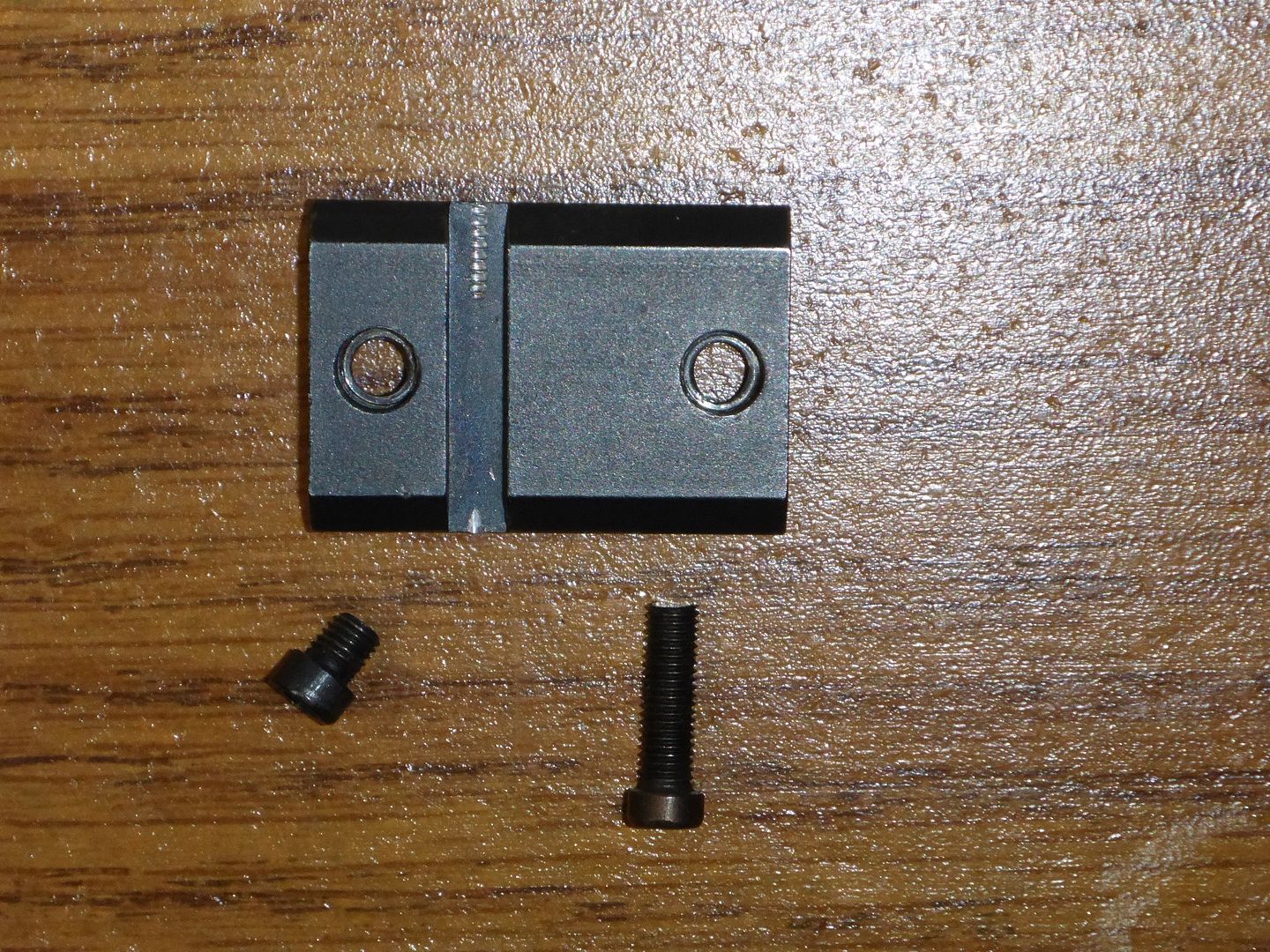

Thanks for all the replies. I agree with Lee440. I had some feeding issues corrected by my gunsmith. When I picked up the rifle I had him remove the scope bases. To our surprise the front screw was screwed through the barrel chamber, see pictures. Is there any reason for drilling through the chamber other than oops? Is this rifle safe to shoot?    Jim | |||

|

| One of Us |

I presume you mean drilling through the receiver ring into the bolt locking lug recess, if so not a problem and is common enough from what I have seen. There is no pressure in that area. However drilling through the receiver and barrel tenion into the cartridge chamber is a huge no no. One of the scope base screws looks awfully long and would protrude somewhere, hopefully NOT the chamber although maybe just an illusion in the photo. PS I think I see the answer, when looking closer I can see that shiny screw thingy through the receiver ring hole in the bolt lug recess? | |||

|

| Moderator |

this sure looks like dremel tool feedwork  opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

The receiver is generally drilled and tapped with the barrel removed. Your receiver looks to have been done so, because the front hole shows the threads of the barrel. the back hole generally lines up with the locking lug of the bolt, so you need to make sure that the screw is the correct length because if it too long, the bolt will not be able to open if closed or close if opened. | |||

|

| One of Us |

Ray B, What you see is the bore light I inserted into the chamber. The camera flash overpowered that light. The front hole is drilled through the barrel into the chamber and the long screw was tightened and the screw was shaped to conform to the chamber acting as a plug. If you look closely at the middle photo you can see the end of the long screw has been reshaped. Jim | |||

|

| One of Us |

That's not how it would have been taught at Trinidad; but then, if you find a copper screw that would match up, you might be able to develop a system of measuring pressure with it via Copper Units by measuring the amount of compression on the screw after firing. probably more trouble than it's worth since you'd have to remove the screw after each firing for measurement, and if the pressure was too great it would blow the copper screw right out of the action- best forget that idea. | |||

|

| One of Us |

Jezzus I noticed the long screw had been contoured on the end and wondered why but never imagined that the front hole had been drilled clear through into the chamber. The dremel work and now this, sorry to point out the obvious but that rifle has been worked on by a butcher. What's done is done I suppose but I wouldn't regard it as a good find, then again morally I couldn't flog it to another unsuspecting buyer either. | |||

|

| one of us |

As I said in my above post, its a parts gun Im about 99.9% sure..The lengthening of the bottom metal in the feed is not the work of Fabrique nationale for sure. The FN has been ground along with other markings..The barrel is probably an original 404 Jefferys barrel, but even that would have to be verified IMO..Lots of fake guns out there today, so I would have to take a close look at the inscriptions on the barrel, and there are a few smiths out there that have some original or well copied stamps for old custom Mauser such as Jefferys, WR, Rigby and even Holland and Holland. Probably a single C ring action and that's a plus if it feeds and shoots. Hopefully it,s single C ring action and it could be a 1935 comm. FN as some of them were military with the thumb cut. Anyway if all is in specs it should be a shooter. I would have a gunsmith with some knowledge check it out, and cast the chamber and bore size... The front base front screw looks like it just touched the threads on the barrel, not good, but still safe..The rear screw looks to be too long and if so it will lock the bolt?? but hard to tell in a photo..Also are the slots in the screws flush on top with the mounts when tightened. ONe more thing, the serial number appears to be an add on, but probably not a problem. Good luck with the rifle. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

That is my question. Jim | |||

|

| One of Us |

I and a few others have had a few discussions on here about our predilection for epoxy gluing and screwing scope bases on. I forgot to add in those discussions that that is one of the reasons I use epoxy glue so if I drill through into the chamber I still have a perfectly safe gun to shoot I can't answer your question with any authority Jim but but seriously if the front screw is loctited in place it is probably quite safe to use the rifle in this condition without any harm being done. 404 Jeffery ammo is not normally loaded to high pressure anyway. The worst that could happen is the screw is popped and gas escapes. The scope ring base will stop the screw being ejected (maybe). Can't think what the smith was thinking when he did that little piece of handiwork. | |||

|

| Moderator |

I'll be brutally honest - as this seems to be what you are looking for i'd tie it to a tire, fire remotely, and inspect cases and action for leaks and damage --- see below i expect that the "smith" knew the screw as into the chamber, and recut the chamber with the screw locked in -- though not staked - and with the base epoxied on, it was a pretty certain return to zero -- this is a mess in all honesty, this looks like an assemblage of parts, and is most certainly not the better or later work of any "known" smith - especially the dremel tool front ramp work. this isn't the work of jeffrey, FN, or even jeffe - facts are there are likely tens of thousands of mausers with the front base screw drilled all the way through -- i know i've seen many "truck guns" made exactly like that at the gunshows.... if it was mine, and I was stuck with it, i'd load up a pretty stiff load (not one of ray's mentioned case-full of pistol powder loads, though), tie it to a tire, and test fire ... then wipe a tissue or cleaning pad around the screws to look for gas escape - and check the cases -- i'd likely fire 5 to 10 of these, as I am always concerned about gas escaping and things working loose .... can you fix it? yeah ... but it would never be "right" .. take the barrel out, put the screw back in, cut it off, tig it into the threads, "recut" chamber to be certain (to clean up screw stub, not to change headspace), chase the threads back clean, remount the barrel, and go .. but finding a licenses and insured gunsmith to do that might be tricky -- good luck, sorry this one turned into such a quagmire opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| Moderator |

the good news is that, if it feeds decently, you would have little trouble installing another 404 barrel or 375 ultra -- opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

The front screw is just touching the threads, sloppy work but safe and not a problem..The rear screw regardless of its shape does not exit in the chamber, that screw is in the locking lugs drive way and most all bolt action are as such, the screw just cannot be too long or it will not allow the bolt to open or close so it must be cut flush.. A screw hole in the chamber of a rifle is a ruined barrel, end of story, you may get away with it to various degrees and various repairs with glass or whatever, but with 55,000 PSI working it may eventually blow the screw or glass or whatever is in that hole, along with scope and mounts right off or out of the hole or worse..if nothing else it will fireform brass into the screw hole and lock everything up..I would recommend you rebarrel the gun if it has a hole in the chamber. I personally would take it back to the seller, demand my money back and pull a knife on him if I had to!! Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Ray, read the OP answer back a few posts, the long screw with the contoured end is the front screw for the base and goes right through into the chamber. Your second paragraph above is the correct answer for this gunsmithing stuff up. | |||

|

| Moderator |

Ray, i think you have the length of screws backwards -- the long one is IN the chamber, the short one the rear -- look at picture 3 in the first series of photos -- and that the long screw is cut in a radius .. sort of like it was in the chamber and then shaped with a reamer .... opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| Moderator |

and? opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

Jeffe, and Eagle, OK, I see where you two are coming from but: 1. The pictures of the bases alone show the short screw is the front screw, Im assuming the poster put them in that order on purpose. 2. In the front ring photo carefully Look at the screw holes, the front screw hole is not a total hole, it shows two silver marks right and left and a black mark in the center ( front screw ) that is the threads of the barrel and the drill and tap bits only cut partially into those threads..If it were in the chamber then you could not see any thing but a hole! This graciouly leads me with all respect to both of you, to believe that you two guys have it backwards,  I wish we had the gun in hand, and Jeffe your brutality come across to me as pretty good advise. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| Moderator |

ray READ THIS POST BY THE owneR

he set the screws next to the corresponding part of the base -- see pic three in the first post opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

FWLIW, I would: Replace the .423" barrel. Have it rechambered with a proper reamer like I will have used for my upcoming project. Reaffix the scope mount base, but do not drill through the receiver, and into the the chamber. Just don't do that. Get out the dremel, and a fixx a medium size grinding stone. Carefully clean up the chopped apart bottom metal. Make sure you are using 404 bottom metal from Duane Wiebe. Clean up your stock until it accommodates the above referenced bottom metal (top metal also). Mount a low power scope and Ed Lapour winged model 70 style safety. Shoot, after you put on a recoil pad. Save up for Africa. Go, and have much fun. Your rifle is about 1/2 way to here is needs to be. Finish it up correctly, and you will have a true companion for the rest of your life.  | |||

|

| One of Us |

Good advice lawndart. We're all so shell shocked with the 'smithing' we are not helping the OP sort out that rifle. One thing for sure, at least it is in a great cartridge. | |||

|

| One of Us |

Almost as good/voluminous as the 416 Rigby. With re-barreling a probability , I would reconsider a Rigby upgrade, only needing the bolt-face enlarged from .537" to .590". The bottom of the action might need slight rail enlargement, which would allow a partial covering of the previous dremel work. Excellent brass is easy to get with Hornady. Then, if 404 is chosen, it is chosen on a fresh basis, rather than forced by the original barrel. +-+-+-+-+-+-+ "A well-rounded hunting battery might include: 500 AccRel Nyati, 416 Rigby or 416 Ruger, 375Ruger or 338WM, 308 or 270, 243, 223" -- Conserving creation, hunting the harvest. | |||

|

| one of us |

Jeffe,' That post got past me, I bow to your observance, and stand corrected..Guess I should read all the post as opposed to a single picture. Gun in hand is a must! Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

I would be curious to see the bottom locking lug from the top. Did they lengthen by taking ALL the metal from the front, or did they take as much as possible from the rear? Without some additional looking, I am not sure it is a good action anymore. Hate to be a downer, but safety is important. Take too much from the front and you do ruin the action. A proper job take just enough and no more. I really hope it just needs a barrel and a little cleanup work. A trip to a good gunsmith is in order. Jeremy | |||

|

| one of us |

Judging from the amount of metal removed surely they just worked in the front..although the Mark 10 including their safari rifle has front end removal..I agree properly done you releave mostly in the rear and as little as you can in the front.Bottom line is the gun appears to be a disaster. I know that WR produced .404 Jefferys and even 416 Rigbys on std. Mauser actions, and they certainly work well enough. I prefer to use a true magnum action with either one.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Disaster may be a premature judgement, but certainly it warrants caution. Not knowing the metal used, it is hard to say if it is safe. The Mark X folks used a 4XXX alloy steel, FN may have, I don't know. Post war, I would imagine they used something in the 4XXX alloy series was used, which would be great. My comments are for caution, and a suggestion to seek professional guidance. Jeremy | |||

|

| One of Us |

In terms of lost strength in the front end of an opened up front locking action I guess we need to consider what is going to let go if anything did. I suppose we would imagine that the 'weakened' loading ramp which supports the bottom lug on the bolt is likely to shear? Usually the top lug support is not touched during the opening up of the action therefore retains full strength and with a Mauser action we have the third safety lug. If the loading ramp sheared leaving the bottom bolt lug unsupported then the top and third lugs would also have to shear from the bolt body. Looking at the metal left in the underside view of the FN there is a lot of solid stuff there. Similarly with my own opened up Oberndorf sporter. Although Mauser were not happy back in the early 1900's with the practice of opening up standard actions because it 'weakened' them (hence they produced the Magnum action for the trade), they did not provide any proof of damaged or blown up Mausers that had been opened up for longer cartridges so just like many manufacturers, were just taking a conservative approach. To open up a standard Mauser action for the 404 Jeffery or even the 416 Rigby cartridge as famed PH Harry Selby's Rigby Mauser was, does require quite a bit taking off the loading ramp area and extending the magazine box. It is impossible to gain the length required by milling the rear alone. I have photos of a standard Winchester M70 opened up for the 375H&H and the front ramp area looks to have had identical work done as my Mauser 404. I keep my face firmly cemented to the stock when shooting the 404, so far I've still got a full face | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia