The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Medium Bore Rifles

Medium Bore Rifles  .35 Newton

.35 NewtonGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

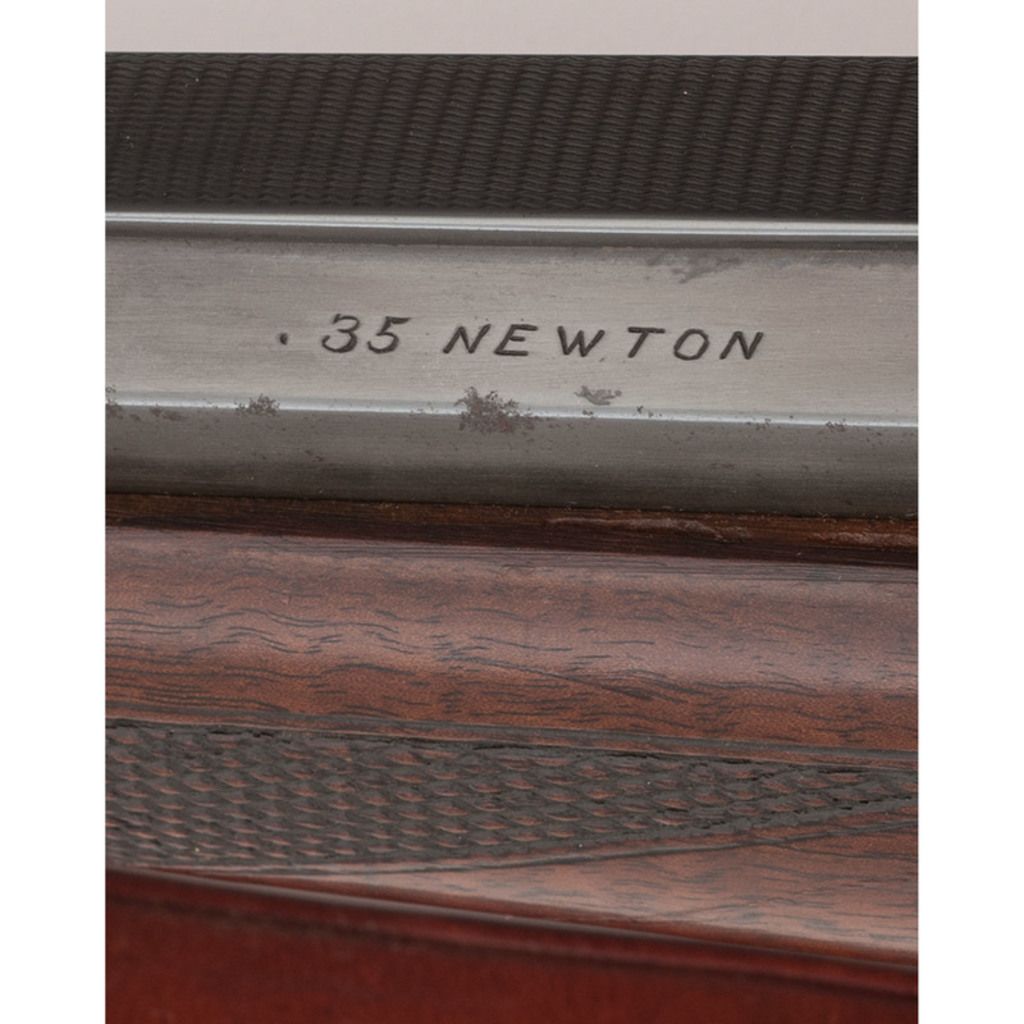

I picked up a sleeper at a recent online auction. It was advertised as a Griffin & Howe sporting rifle, but none of the photographs showed anything to confirm this claim. It does have a G&H single lever windage adjustable side mount, and I thought that was the basis of the attribution, but when it arrived, I was pleasantly surprised to find the G&H name on the full length integral rib. The rifle is built on a 1916 Newton action and the caliber is .35 Newton, not your usual run of the mill calibers. Since no factory ammunition has been manufactured since 1938, my first concern was locating a set of dies to load with. Inquiry at all the usual suspects produced no results, although Hornady agreed to make me a set, provided I come up with fired cases for them to take measurements from. I already have a .30 Newton, so I had a small supply of brass, and necking a few cases up to .35 caliber was no problem. I was able to seat bullets using .358 Norma Magnum dies, so I departed to the range with a couple of loaded rounds to try the new toy out. Much to my chagrin, however, when I pulled the trigger on the first round, all I got was a click. The same thing occurred with the second round. My first thought was a headspace problem, but then I thought of firing pin protrusion and stuck a bit of masking tape over the face of the bolt and pulled the trigger again. The tape was untouched: insufficient firing pin protrusion. I disassembled the bolt and compared the length of the firing pin with another Newton firing pin I happened to have handy: they appeared to be the same. The other pin, however, would protrude slightly from the bolt face. Working on the theory that the interior of the bolt body had accumulated some dirt in the 100 plus years of its existence, I attempted to clean it out, with the result that the tip of the firing pin now reached the level of the bolt face. More cleaning is indicated, but I had to interrupt my efforts, to be continued Tuesday, when I return from a trip to keep a doctor's appointment. In the meantime, here is what the rifle looks like. The new barrel is half octagonal, half round, with a full length integral rib, and the quality of the stock wood is much better than that of the average Newton rifle, of which I have several examples.     | ||

|

One of Us |

First off, color me jealous! Congratulations on a rifle I would trade my left nut for. I’ll trade the right one for your 350 Rigby. Please please pretty please can you do a chamber cast to confirm the dimensions of the 35 Newton at the time of manufacture? There is some debate here on the case head dimensions. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

Interesting find Newton’s wiki page has the rebates rim 11,2x72 Schuler as the parent case, that doesn’t fit with the drawing above Formerly Gun Barrel Ecologist | |||

|

| one of us |

Nice looking rifle. Hope you get it up and shooting. | |||

|

| one of us |

That's just a wonderful find! Hope your doctor's appointment goes well and you can get back to this thread ASAP. There is hope, even when your brain tells you there isn’t. – John Green, author | |||

|

| One of Us |

Thanks for the good wishes. The appointment is nothing out of the ordinary. I have an eye condition which requires a hypodermic injection in my right eye every six weeks or so. I have lost count of how many years this has been going on. Anyway, it takes about five or six hours for me to recover to the point that I can drive the 100+ miles home. In the meantime, I have been working on the problem with the Newton mentally. As an aside, I can remember driving back from California, where my father was stationed in the Navy, in the fall of 1945. We passed a sign which said something to the effect "White Sands Proving Ground" and my father said, "This is where they tested the first A-Bomb." That must be right in your back yard at Alamogordo. | |||

|

| One of Us |

I was watching that rifle as well and think it was one of the best in the auction! There is the possibility that brass can be made from .375 Ruger. It's very close in almost every dimension. | |||

|

| One of Us |

I too would like to know the dimension of the chamber casting if you can. Than you, Lowe | |||

|

One of Us |

I have an old 35 Newton Western case that measures.528” at the casehead and I see a lot of references that have the case head diameter like the one above like the 8x68 case. Since this is an old original, knowing the dimensions will help solve the riddle. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

I have never been comfortable with the idea of taking a chamber cast from a bolt action rifle. The distance between the end of the receiver bridge and the chamber itself is something I find daunting. Can someone point me toward an understandable explanation of how to overcome this? I'm OK with single shots, where I have direct access to the chamber or with detached barrels, but I'm afraid this is a job which stretches my capabilities. Unfortunately I live in a gunsmithing desert, where the lack of expertise is appalling. My stand=by gunsmiths are no longer living. | |||

|

One of Us |

Thank you for the consideration here is a youtube video on chamber casting. I see a few other how to videos there as well. One guy said the cerosafe shrinks a bit though. 577 BME 3"500 KILL ALL 358 GREMLIN 404-375 *we band of 45-70ers* (Founder) Single Shot Shooters Society S.S.S.S. (Founder) | |||

|

| One of Us |

Not to hijack you thread but my Mom watched from Alamogordo as a teenager. Remember her talking about it. Nice rifle, hope you get it shooting. | |||

|

| One of Us |

Does the firing pin appear be worn down, xausa? It seems strange that it would not have been replaced by the maker or early at least if the problem had existed from the start. A friend bought a s/h Ruger 9.3x62 and found it would not fire unless given a good oiling, so spring strength can be a problem. I don't suppose putting the disassembled bolt in one of those things used for cleaning pistols might remove some unseen crud that is holding things up? | |||

|

| One of Us |

I did a little reading and examined the spare firing pin (36) and cocking head (38). I determined that the cocking head is not fixed to the firing pin, but slides up and down on a flattened threaded portion of the firing pin, controlled by the firing pin nut (37). This means that the position of the cocking head determines firing pin protrusion. The problem is, the cocking head has a deep "V" shaped slot into which a corresponding protrusion from the front of the firing pin nut protrudes, and the cocking head is under pressure from the main spring (39) to hold it in place. To be continued. | |||

|

| One of Us |

Success! Despite confusion (it's hard to resist turning the wrong way with left hand threads) my problem of protrusion disfunction has been solved. Now I only need to get the safety working by hunting season and get some dies to load with. The numerical references in the previous post were to a chart showing the various component parts of the Newton bolt which for some reason I have been unable to post. I have asked RIP for assistance and maybe he will succeed. The Jamison cases which I have using to test feeding and function measure .527" at the head. The 8X68S brass which I have hoped to be able to use measures .524" at the same place. The Jamison cases chamber easily. The action, by the way, will chamber an empty case through the magazine, a pleasant surprise. | |||

|

| One of Us |

hello... just saw your new rifle...looks great....perhaps you already know..but, there is a outfit making a lot of the older, odd caliber case...it's "ammunition artifacts"..they have .35 newton new cases for 65.00 per 20...again, nice rifle..john | |||

|

One of Us |

https://www.rccbrass.com/product/35-newton/ What force or guile could not subdue, Thro' many warlike ages, Is wrought now by a coward few, For hireling traitor's wages. | |||

|

| One of Us |

I talked to Paul Chapman at Griffin & Howe today about the history of the rifle. It has G&H number 452, which he said probably puts it in the first year of G&H's existence. I had called about requesting a research project for the rifle, but was told that the researcher had retired and so far no one had been hired to replace him, hence my referral to Paul, whom I have dealt with for years. I did fire the rifle a couple of times today with forming loads and found it quite pleasant to shoot. I'll repeat the process, then send the twice fired, neck sized only brass to Hornady for them to create a set of dies for me, including a form and trim die to create cases out of 8X68S brass. | |||

|

| one of us |

There ya go Bill, an excerpt for your book review. Sorry not to get it done sooner. Give me a phone call if you want something done quickly. Great find, color me jealous too. I suspect the new .300 PRC (Hornady) brass will be easy to neck up and FL size to .35 Newton (.375 Ruger based like Huvius suggested), might have to inside-neck ream a dreaded donut, maybe not. Trim & uniform case mouths might be all you have to do. Rip ... | |||

|

| One of Us |

Glad to see you found the answer, xausa, and glad to see the drawings, RIP. Looking at the lugs and safety makes me think the design may have anticipated others in the future. | |||

|

| One of Us |

Indeed. A very interesting (and familiar) design. | |||

|

| One of Us |

I fired what I would consider a maximum load in the .35 Newton yesterday, resulting in very flat and slightly cratered primers. Afterwards the heads of the three fired cartridge cases measured .527", .526" and .525". The equally hot .275 H&H rounds measured .534", .533" and .533" across the belt. | |||

|

| one of us |

Jawohl, that is why I never got into measuring case heads with a micrometer to .0001"! The factory .375 Ruger-based cartridges seem to be a pretty uniform 0.530" as manufactured, to be less than the maximum brass spec! It would be interesting to see if you can use Hornady .375-Ruger-based brass of some sort to make .35 Newton. How much oomph does it take to size the .530" head/base diameter down to Newton? The Ruger rim diameter is also .530" on the ones I have measured. Surely there is enough slop in the bolt face of the Newton for that to fit nice and snug? Rip ... | |||

|

| One of Us |

I turned up a bag of once fired 8X68S brass yesterday, which I managed to acquire in Germany some time ago. I trimmed one case down to .35 Newton length using my trusty Wilson case trimmer and ran it through my .30 Newton dies. The result chambered easily in the .35 Newton rifle and did so again when necked up to .35 caliber. Now the problem is neck thickness. Setting the 8X68S shoulder back means that the neck thickness increases from .014" to .020". The latter is clearly unacceptable and some neck turning is going to be called for. Fortunately, I have a Forster power case trimmer which doubles as an outside neck turner. To be continued. | |||

|

| one of us |

It was way ahead of its time back when, it a sizzler even today.. Another great was the 300 G&H, a 375 H&H necked down to 30 caliber..I had a Win super grade in this caliber and it was an awesome sizzler then and even today its a top round, but not many have ever seen one. MIne was just too heavy as I aged it went down the road... Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Ray, I have a .350 G/H, but I never heard of a .300 G/H. Does it have a shoulder like a .300 Weatherby? | |||

|

| one of us |

Bill, Are you doubting your elder? Me too. Maybe he had a .300 H&H made by G&H? Maybe it was a .300 Hoffman? Hoffman Arms had two proprietary rounds that were not just an H&H version renamed to "Hoffman Magnum." One of those was the .300 Hoffman Magnum, IIRC. The .375 Hoffman Magnum was just an unadulterated .375 H&H. Rip ... | |||

|

| one of us |

It was a 350 G&H, fat fingers do not deserve such severe recourse! from the likes of RIP, (may he Rest in Peace!! RIP) get it? Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| one of us |

Atkinson, Good one! Rip ... | |||

|

| One of Us |

.35 Newton loading dies and a form and trim die arrived on Saturday. All it takes is one pass through the form die with either 8X68S or .375 Ruger brass and some trimming to produce perfectly useable .35 Newton cases. I can't wait to try them out off the bench. I tried the .275 H&H today and the first shot off the bench produced an "X" at 6 0'clock using 140 grain PPS bullets. I think it is going to be a shooter! | |||

|

| One of Us |

Bill, your obvious joy in these activities gives me hope for my own future! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia