The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  signs of pressure?

signs of pressure?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I have between 50 and 100 1898 Mausers, and maybe 3 or 4 look like they have set back from military service when I pull the barrels. I overload all the ones I play with till the brass fails and then back off. Most are nearly 100 years old. I have not get set back yet. I don't know what when on in the military to get it, maybe mud or water in the bore. I have rebarreled ~15 rifles and played hard with another 5 in the 8x57 chambering. I think I have ~ 50 of the Orberndorf 1903 - 1905 Turkish Mausers. Primers or brass will give up before they will. I am working on bushing the firing pin hole so I can get higher pressure with 6mmBR small magnum rifle primers. Maybe then I can get some set back. We will see. What experiments have you done? | |||

|

| One of Us |

"I have between 50 and 100 1898 Mausers, and maybe 3 or 4 look like they have set back from military service when I pull the barrels. I overload all the ones I play with till the brass fails and then back off. Most are nearly 100 years old. There you go! That just about sums up the mentality we are dealing with here. I concur with Warrior; This is the intelligent reloading method of those who criticise? Hot Core says I am dumb in his usual smart ass way but it is he who has no idea of my experience or education. I wonder what Hot Core could tell tnekkcc about his blown cases using CHE or PRE....probably something like; hmmmmm might be a little hot! I'll bet with the proper use of a chronograph tnekkcc wouldn't need to blow cases (or make them "fail") before he knew his loads were a little too hot. But then that take some intelligent use of the chronograph and understanding what it is telling you. That is something some can't seem to quite fathom. The fact that I use a chronograph and a Oehler M43 which does measure pressure seems to be completely beyong their mental capcity. Tnekkcc asks me to show him the math....apparently he doesn't understand that the computors in the chronograph and M43 "do the math". Hot Coe's responses are...well...just responses like some kid who wants to take his football and go home. Not much room for an intelligent discussion when we get responses like Hot Core's and tnekkcc's. If anyone else wants to reasonably and intelligently discuss the use of chronographs or the M43 I'll entertain that discussion. Larry Gibson | |||

|

One of Us |

I once worked out a 'constant pressure curve' for my 303 Brit, for different bullet weights and powder charges. This required measuring velocity, calculating bullet energy and momentum (total ejecta, actually), as well has using the classic brass case and primer deformation measurements and signs. This curve agreed very well with published loading tables (using max loads as a cross reference). So, I was then able to 'predict' velocity for a given load or the powder charge to use for a different weight bullet or to get a desired velocity for a given bullet. This does not mean I was bypassing the load development process, only that I had already done it in a different way and could go directly to the required load with a new bullet weight. But I still did not know the actual pressure values (other than 'low enough not to damage my brass' or 'too high'). I do not believe a 303 Brit is capable of entering the zone where velocity no longer increases linearly. That requires sufficient pressure to raise barrel drag by inertial expansion of the bullet against the bore - that's too late for the Lee Enfield! And quite unnecessary. My system must have worked since I am still using the same cases 25 years later. I never needed to trim a case nor did I lose any to head separation. Only to the odd neck split – from forgetting to anneal. Regards 303Guy | |||

|

| One of Us |

303Guy Excellent example of how many of us use the chronograph (even though it does not tell the actual pressure values) along with other loading techniques to develop loads that are safe pressurewise, especially in lower pressure cartridges like the .303. Thanks for your input. Larry Gibson | |||

|

| One of Us |

When I say "show the math", I mean pressure measurement error math. The M43 may calcuate the pressure, but you need to know the error involved in it's calcuation. Start at the gauge, and give it's accuracy, calculate the effects of mounting error, show the error in measuring the mounting error, calculate the stress strain of the barrel based on it's shape and Young's modulus, go through the M43 schematic and calculate the error in the amplifier, show how Voltage references are traceable to NIST [formerly NBS] and in calibration at the time, and go through the software and calculate the error, etc. In other words, calculate the error and certainty in your pressure measurements. Measurements have no meaning without the error being quantified. If you don't understand how to measure pressure and just bought some gear, say so. If you are using calibrated ammo, say so, and tell us where you got it and what you believe about how it got traced to NIST. In other words, if you think you know what you are doing in making a measurement, show your work. I don't care how bad your spelling is, I want to see the assumptions and math laid out, if you think you have a meaningful measurement. If your measurement has no meaning, say so. When people who know what they are doing make measurement, they have standards. That is why they call it "The National Institute of Standards and Technology" http://en.wikipedia.org/wiki/National_Institute_of_Standards_and_Technology When a company sells you a pound of hamburger or a gallon of gas, they have to be able to show how that measurement traces back to the NIST and have error calculations that shows the whole error budget in the chain. Not only does your pound of hamburger error calculation contain the accuracy of the scale used to weigh it, but it also contains the error in the instruments between the scale and the NIST. The other scales used in the chain of measurements are part of the calculation. That is the wights used to check the scale have an error themselves. Those weights get measured on a big scale, that traces back to Wash DC and the NIST. That trail is where the calibration ammo is going to get lost. They will have trouble with the tolerances of size and friction for the different chambers used. The bottom line is that calibration ammo will not be legal for transactions, like a bathroom scale. Just make a list of calculations of errors in calibration ammo, and the length and complexity will reveal why I call them "smart pills". I have have worked with strain gauges on shafts of motors to test the motor drive. A torque can be applied and a radio signal sends the information from the rotating shaft. But the stain gauges are only good enough for us engineers to get an indication, and we cannot sell any hardware or data based on that information. Finally, if you actually COULD get NIST traceable pressure measurements with your rifle, which you can't, then there is other problem that the actual pressure does not mater*, it is the effects of pressure that matter, which takes us back to the brass. And that takes us back to people who separate out the objective from the process. *If you are selling ammo, you are indirectly selling some vodoo pressure measurement with it. | |||

|

| One of Us |

I plan on shooting my 6mm AI for the first time tomorrow. (other than just a couple shots) To look for signs of pressure, how many shells should I load at each charge weight? I plan on using 45-48 grains of RL22 under a 105 grain Amax. Love shooting precision and long range. Big bores too! Recent college grad, started a company called MK Machining where I'm developing a bullpup rifle chassis system.  | |||

|

| One of Us |

Hey that's me!!! I put 16 grains of Blue Dot in a 19 Calhoon Badger case and found out all about signs of high pressure... ( Sorry, I couldn't resist, to my buddy who knows what this is about).... Okay, I am going to go sit in the "time out chair".. over in the corner now... Life Member: The American Vast Right Wing Conspiracy Jan 20, 2009.. Prisoner in Dumocrat 'Occupied America', Partisan in the 'Save America' Underground Beavis..... James Beavis..... Of Her Majesty's Secret Service..... Spell Check Division "Posterity — you will never know how much it has cost my generation to preserve your freedom. I hope you will make good use of it." John Quincy Adams A reporter did a human-interest piece on the Texas Rangers. The reporter recognized the Colt Model 1911 the Ranger was carrying and asked him "Why do you carry a 45?" The Ranger responded, "Because they don't make a 46." Duhboy....Nuttier than Squirrel Poop... | |||

|

| one of us |

Hey Seafire, I'm glad to say - I disagree. ----- If I didn't know tnekkcc better, I'd almost suspect that some "fool" got him wound up. Talk about on FIRE. | |||

|

| One of Us |

tnekkcc I think the question here is whether YOU know how to measure pressure of ammuntion in firearms. Your self stated method is to load 'em up till the brass fails then back off. That's a real expert on the subject's way of doing it now isn't it. Actually I do know how to measure pressure as I carefully follow the instructions. Like I carefully follow reloading instruction and have for many years. Thus I get predictible, accurate and safe results. Listen.....there is no such thing as "calibration ammunition". If there was SAAMI would well have made sure that NIST had the standard for it now wouldn't they? Since you and Hot Core don't want to call SAAMI and obviously don't want to believe me or Dr. Oehler why don't you check with NIST and ask them about "calibration ammunition for the arms industry's pressure measuring equipment? You seem to be such the expert I'm sure you're on first name basis with them and will get the straight story. Also it is blatently obvious you're apparently not well read in the firearms world are you? In what industry publications or even the gun rags have you EVER heard mention of "NIST traceable pressure measurements? Answer is you haven't and no one else has either. Not even close. Further more you obvious are not really aware of "the math" involved are you. Shot to shot variation of pressure varies just as shot to shot velocity with any load, even a very consistant load. Are YOU aware of the industry/military's acceptable standard for that variation of shot to shot pressure of an accepted load? I thought not as your method is to load 'em 'til they fail. I've got to wonder if you are as intelligent as you claim or are stupid enough to just be surfing the internet on pressure and making little quotes. Since most of them are out in left field and totally unrelated to measuring pressure in firearms I think perhaps you are that stupid. I've also got to ask where you come up with the stupid and accusitory statement of "If you are selling ammo, you are indirectly selling some vodoo pressure measurement with it." At no time did I state or even indicate I was selling ammuntion. Your accusation of such and that said ammuntion was faulty is a statement which I rightfully resent. That accusitory statement speaks well of your low integrity. You might want to eat a few of your own smart pills and keep to the subject here instead of the snide personal comments and nonsensical comparisons. So back to the discussion; why don't you and Hot Core just call SAAMI and NIST and give us there answer on "calibration ammunition"? It is obvious why you don't, the answer would not be what you want to hear. You have been continuously told there is no such thing as "calibration ammunition" and have been asked to confirm it yourselves. You fail to do so for obvious reasons. Larry Gibson | |||

|

One of Us |

If I may make a comment? I know what engineers are like - they look for the absolute failure boundry. By understanding what causes failure, steps can be taken to be safe in the working world. Someone has to do it! Good shooting to you all. Regards 303Guy | |||

|

| One of Us |

Nah its got to be Warrior. | |||

|

| one of us |

That is exactly what tnekkcc is doing. Of course it is obvious to anyone with enough sense to know which end of a firearm to put to their shoulder. As long as the follows read the posts from the beginning, and look at the links, they won't be mislead by larry's reading comprehension problems. As an example of that, I'd mentioned in a previous post in this thread that Dr. Oehler calls it Reference Ammunition, but it is Calibration Ammo to me. For some reason the ability to comprehend what was said waaaaay back there was/is beyond larry's cognative ability to equate the two. Hopefully the "new to Reloading folks" won't get sucked in to wasting money on a totally worthless HSGS. | |||

|

| one of us |

/ | |||

|

| One of Us |

there is only an implict standard, which is the elasticity of cartridge brass. nothing more than that. compare that to the science involved in Dr. Oehler's strain gauge system. I don't know. it seems like the CHE/PRE proponents take it very personally that people don't appreciate the system as much as they do. which is odd, as at least one of them is otherwise very level-headed and non-controversial in his postings. or the thickness of the brass, or the internal dimensions? or the ductility? CHE/PRE can't be that effective at sresses below the brass failure, as far as I can tell. no doubt CHE/PRE is handy, cheap and useful, but there is no way in hell it is as good as, or better than, the Oehler system. neither is absolute, both are relative, but one is more flexible. | |||

|

| One of Us |

There is a saying, there are two things you don't want to watch, sausage being made and laws being made. I would add to that, you don't want to see designs being made. There is a documents called ADCN: Advance Drawing Change Notice, or ECO engineering change order, etc. On an design with 200 off the shelf parts and 50 unique parts, there may be 10 ADCNs in design, or there may be 1000. You can think of it as each change makes the design better, or somebody screwed up, or the deign is evolving, etc. Engineers slop some ideas together, it doesn't work, and they keep tinkering with it until it works, and then keep tinkering with it for problems that do not show up until later. That is, if all goes well. It may be a disaster, and everyone gives up. My point here is that designs are partly made by math and science, but then lots of thing don't work, so they are experimentally tuned up to work, as man, or the men that can be afforded, don't understand everything. I have been in the middle of this process for most of my life as have most of my male relatives, also engineers. It is an experience of ironic surprises, as things do not turn out as expected. Anyone who thinks he knows it all, and can see the future, is too long on confidence. Based on what I have seen of the design process, I am going to imagine the engineering of handloading that got it to it's present day state: 1873 the 44-40 in the Winchester and 45 Colt in the peacemaker use large primers, black powder, and cast bullets. How much powder should we put in? Try filling it up. How thick do we make the steel chamber walls? To thin and it blows up, too thick and is too heavy. Make them thicker until they stop blowing up, then add a little more for safety margin. Check it with a proof load, like muzzle loaders. 1889 the 7.65x53 in a Mauser is a weaker cartridge with higher pressure and smokeless powder. Fool around until it works. 1898 the 8x57JS Mauser does 2900 fps with 150 gr bullets at very near the limit of pressure that the old 7.65x53 case head can take. There is a weak spot between the primer pocket and the extractor groove. The cartridge is loaded up until the primer falls out, and then backed off a safety margin. 1903 the 30-06 copies the 8x57 case head, but makes it longer, and uses the old 1892 Krag bullet. The cartridge is loaded up until the primer falls out, and then backed off a safety margin. 1923 the 270 copies the 30-06 for the Win 54 rifle. The cartridge is loaded up until the primer falls out, and then backed off a safety margin. 1926 SAAMI is formed, and manufacturers register dimensions, maximum average pressures, and makes some standard for proof loads. There is a problem in how pressures are measured. It varies too much from tester to tester. A system is developed of testing a batch of ammo, generating data, and sending some of the ammo to other labs to get a consensus of what the real measurement should be. The ammo is loaded up until the primer almost falls out. SAAMI needs to find a way to measure that pressure. They use C.U.P. radially, the Brits used bolt thrust. SAAMI registers the 8x57JS at 35,000 psi. The 270 Win, also loaded to the threshold of the primer falling out of the same case head, is registered at 65,000 psi. 75 years pass. Changes are made in pressure measurement, and some conflict between the registered pressure and the new way of measuring cases load books do decrease powder charges to a larger margin from the original criteria; "The cartridge is loaded up until the primer falls out, and then backed off a safety margin." This disconnect causes flames on the internet handloading forums between load book fundamentalist consumers, and experimenters. As the 7mm Mag becomes less than a hot rodded 7mm Mauser and the 357 mag loads drop below the old 38 special loads, it also helps to sell new magnums to over come the new anemia of old cartridges. The 65,000 psi of the 270 is not a reliable maximum average pressure for mass produced ammo in mass produced firearms, although it is reliable for a handload in a particular 270 in which the load is worked up. The primer will fall out of some factory ammo is loaded to 65,000 psi. This causes the newest cartridges, like the 260 Rem, which uses the same case head, to be registered at 62,000 psi, which has the safety margin needed to keep the primer from falling out in mass produced guns and ammo. The 6mmBR goes to a small rifle primer [fixed the 1889 weak spot], and leaves the pressure unregistered. The 6mmBR max pressure then becomes a function of the primer and firing pin and firing pin hole tolerances. The military crimps the primer pocket to keep the primer from falling out in situations where the pressure is increased by heat or fouling. What does it all mean? It is best understood through a joke: "Why can't Baptists make love standing up? It looks too much like they are dancing." The point of the joke is that dancing is banned becuase it might lead to fornication, but if they are already fornicating, why does the rule still apply? The sort of Baptist who will not make love standing up, does not want to exceed SAAMI pressure in his strong rifle. The sort of Baptist who thinks the rule does not apply to him and his wife, will load his strong rifle until the brass deforms and then backs off 6% ala Vernon Speer 1956. There are those that live by their wits, and those that follow an accredited procedure they believe in. And we get to mix it up here. Denton is gone, he was out of ammunition, and only had insults left in his bag. There are more process men to take his place. | |||

|

| One of Us |

far more likely the case was designed to hold the powder needed to achieve desired performance, or to replace existing performance. your scenario would have an existing bore (0.451) and performance and then the designers randomly pick a case capacity and then decide to fill it up. no friggin' way.

waaaaaaiiiit a minute. without the preceding assumptions, your entire post adds no information. do you have any independent evidence to support your theory that ammunition and firearm designers center their ballistic development aound the primer falling out???? if you do, that could settle much of this debate, and I would love to see it. if not, then you assume what you set out to prove. that's a big no-no. | |||

|

| One of Us |

Tnekkcc Apparently you have taken his place. "Changes are made in pressure measurement, and some conflict between the registered pressure and the new way of measuring cases load books do decrease powder charges to a larger margin from the original criteria; "The cartridge is loaded up until the primer falls out, and then backed off a safety margin." "The military crimps the primer pocket to keep the primer from falling out in situations where the pressure is increased by heat or fouling." With your self described engineer background if that's really how you think it was and is done then someone wasted a lot of money on your education. Many of us do regularly load many cartridges above the SAAMI pressure levels because we use those cartridges in actions capable of handling the pressures we load them to. As to your imagination on "the engineering of handloading that got it to it's present day state" I can only add that you truely are a legend in your own mind. Larry Gibson | |||

|

| One of Us |

I can't prove that, but as Rumsfeld said, "The absence of evidence is not necessarily the evidence of absence" I think I have plenty of circumstantial evidence, in my own load notes: 1) Get an 8mm up to the velocity they had 100 years ago and then overload until the primer falls out. How much extra powder did it take? 2) Get a 30-06 up to the velocity they had 100 years ago and then overload it until the primer falls out. How much extra powder did it take? 3) Get a 270 up to the velocity they had 80 years ago and then overload it until the primer falls out. How much extra powder did it take? I have done this with all three cartridges many times in many rifles, and it does not take much extra powder. Co incidence? No, anyone with any brains can see that was the limit of the design. What do you think is going on with the 6mmBR small magnum rifle primer and bushed firing pins? Just a novelty? No, anyone with any brains can see they want to exceed the pressure limitations of the 1889 Mauser case head. What does it all mean? 119 years ago, someone designed a case head, and many cartridges have used it near it's strength limit, when the primer falls out. So what are the pressure signs we look for with a Mauser case head? The primer pockets getting loose, or brass life. It was that way when I was born in 1951, and it will be that way when I die in ~2051. Are some people trying to measure psi to work up loads for their own rifles? Yes, they can if they want They can post about it, too, but something seems to be making them angry. Why are psi believers devolving into poor manners? | |||

|

| One of Us |

how'd that work out for him anyways? but back to the point, if you propose that historical ballistic engineering was centered around loose primer pockets, then the burden is on you to support your proposition with evidence. the burden is on you, and not even rumsfeld can shift it. if you propose something, you have to support it. it's not everybody else's job to disprove what you toss out. that is not circumstantial evidence that histroric ballistic development centered around loose primer pockets. it only shows that by increasing some of your loads, you go way over pressure. your base loads may meet original velocity, but at too high of a pressure from too fast of a powder. it is better circumstantial evidence that you rae using overpressure loads to start. mr. occam and his razor would agree. bushed firing pins do not favor PRE/CHE over strain gauges. and it is not something happening 110 - 80 years ago. and it has nothing to do with your assumptions above. that does not show that CHE/PRE is better that strain gauges for determining pressure. who is using poor manners? I politely direct you to your own ad hominem attacks: you call people who disagree with you brainless? you are obviously out of facts and useful arguments, so you resort to name-calling. that is impolite. why do you take it so personally that people don't agree with you? why can't you live and let live, and leave others to their opinions? why don't you and the rest of the engineers in your big family of engineers just laugh at us behind our unenlightened backs, so we don't know? | |||

|

| One of Us |

delloro I have dozens of powders, and I try to pick the best one. Quickload does a good job of sorting them for the cartridge and bullet. That's right, all three cartridges suffer case head failure as the real limit to handloading. I have also worked up loads until the primer pocket loosened in .223, 25acp .243, 257 Roberts AI, 32acp 7.62x25mm, 7.62x39mm , 308, 8x57mm, 380, 9x19mm, 9x23mm, 357 Sig, 40sw, 10mm, and 45acp. When I work up to some real limit in . 6mmBR, 32sw, 32S&WLong, 32-20, 7.62x54R, 8x57mm, 38 sp, 357 mag, 38sw, 45Colt, and 45/70 something else stops the work up. That is becuase the extractor groove - primer pocket area is not the weak link in the chain. Case life is the important sign of pressure in the Mauser case to some of us handloaders. Measuring psi is not as good for an individual rifle, but what else are you going to do for mass production? 100 years ago, they just backed off further. You can measure psi now with piezoelectric transducers, but that introduces error in maintaining a safety margin for primer pockets, the real limit. Strain gauges introduce even more error than the piezoelectric transducers. What does it all mean? I have done allot of experiments, and I can see some trends. | |||

|

One of Us |

tnekkcc I am very interested in the work you have done in this area. (Whether or not that is how it was done in the beginning, your work shows just how good they were back then)! Would you be so kind to explain how the other cartridges you mention, differ in the 'weak link'? It would be much appreciated. Regards 303Guy | |||

|

| One of Us |

Not all cases are created equal - having used different cases it becomes obvious. Here are some examples: Compare Remington with Lapua cases Compare Winchester with PMP cases Compare Highland with RWS cases, etc They differ in many respects when we look closer. The obvious difference in different cases is weight and thickness. This translates to different internal dimensions and that affects powder capacity and the combustion volume. For a given charge that will give different pressure, even if it is not a lot but close to maximum it will manifest itself. Other less obvious or hidden differences are ductility and hardness/softness of the brass and the effect of 'cold working' on brass after so many reloads - this introduces imponderables for the handloader. The same is true for different primers. PMP cases and primers are thicker and stronger than most other brands, and as such, they have the potential to mask high-pressure loads better than other thinner or softer brands. Warrior | |||

|

| one of us |

Very good thread with much depth. Chris/Warrior/Truvelloshooter, You have not been reading this thread, have you? OR You have been reading the thread, but not understanding what is discussed. Difficult to say with you. | |||

|

| One of Us |

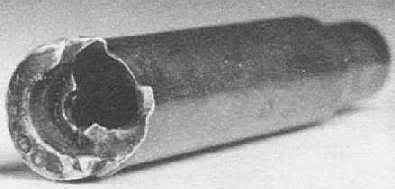

" .... the first five pictures (supplied by Stanley E. Watson) show the primer condition as pressures begin to elevate. The first case, going from left to right, is a once-fired factory round (55,000 psi). The next case is a handloaded round at about 60,000 PSI. The middle case is a handloaded round of around 68,000 PSI. The second from the right is a handloaded case of around 70,000 PSI, and the case on the far right is a handloaded case of around 73,000 PSI. You will notice that the first two cases have no apparent signs of excessive failure or pressure. However, when we get to the middle case, you will notice that there is a marked flattening of the primer. The next case shows some bright marks on the casehead, and the last case shows what a "blown primer" looks like." Stephen Ricciardelli      Another photo of a blown primer.  Warrior | |||

|

| one of us |

Hey Delloro, When the weakest link in the Firing Process is the Case, when Case hardness/strength can vary from Lot to Lot, and the measurements are being taken directly from the Case, why is it you view that as unimportant information? CHE & PRE have SAFELY has been in use, providing excellent Internal Ballistic data from the weakest link, longer than we have all been alive by: 1. Powder Manufacturers. 2. Bullet Manufacturers. 3. Firearms Manufacturers 4. All the old time Expert Reloaders - Hagel, Waters, Sitton, Ackley, and on and on. 5. By knowledgeable Reloaders today. I will agree that CHE will not indicate "Low" Pressure as well as PRE. But they are both far better than any noncalibrated, guessed at dimensions, fudge factored HSGS. ----- Delloro, have you tried using CHE & PRE the way it is described in that Link? | |||

|

| One of Us |

Measuring case expansion in the web area, or the belt in the case of belted magnums, before and after firing has its difficulties. The maximum pressure allowed is generally felt to have been reached when the web area measures .001" greater than that measured after the first firing of factory loaded ammo. Some writers though suggest to stop at around .0005 to .0007" for custom reloads. So we are dealing here with a rule of thumb or best estimate. Anyway, you need a 0.0001" capable Micrometer if you want to opt for this method and measure this accurately. Since dies do not size the web back to spec, once the .0001" maximum web expansion is reached, these cases may not be used for further pressure comparison testing. In addition, cases (webs) tend to grow gradually over a number of firings with loads that are at or near maximum, so false indications are a real possibility. Some propenents say one should easily get 10 reloads in a case and still have snug primer pockets, and others reduce this number to 5.  Clearly, Case Head Expansion (CHE) is not so simple/absolute to be interpreted by the novice reloader. This method also suffers from the possibility that when pressures are high enough to expand the web, some older and softer actions will have suffered damage. Sectioned views of cases will show us that some cases have been designed to be stronger in the web area and the section between the primer pocket and the inside of the case, such as the .338 Lapua Magnum case to withstand the rigors of high pressure (P-max = 68,168 psi). So primer pocket expansion is not the preferred method for me to judge presssure by. Other examples are ... Norma has quality brass, but it is softer than the Lapua brass that can handle higher pressures better. The problem with primer pocket expansion is quite common with Nosler brass, and so it goes on. I much rather stay inside recommended loads as per my reloading manual and still approach the max load with caution. Some factory loads are hotter than others - Federal High Energy is one example and I guess they use some special powders in those loads to get higher velocity but to contain pressure to some level (who knows what that pressure is and what their margin of safety is). Switching to faster powders with magnum primers to gain velocity must be tested when we move away from the traditional loads. So the type of powder also plays a role in pressure dynamics to get a specific velocity. You can get the same or better velocity with one powder and still be at a lower pressure than with another. And that is why pressure testing at a Lab is still the better way in spite of the equipment's inherent error level. There are no absolutes, just preferred methods and we seem to have different opinions about the best one in terms of safety to the general public. Warrior | |||

|

| one of us |

/ | |||

|

| One of Us |

I don't. I don't think it is generally unimportant. I'll tell you why: 1) I load to primer behavior, which is easier, and shows at a lower pressure than brass deformation; 2) whatever pressure affects the case will also affect the barrel thus the strain gauge system works at least as well. it's worse in that it costs more, it's better in it's data and ease of use. my point in joining this thread was not that CHE/PRE doesn't work, or is no good. you can check and see that I never wrote that. my point is that CHE/PRE is not better than the strain gauge system, but primarily that the CHE/PRE proponents take it very personally when the world does not agree with them. the first three do not, to my knowledge, use it today. we can both call and ask and see what the ballisticians use instead of crushers or peizo transducers, CHE/PRE or strain gauges, and report back here.the old-time reloaders like ackley would have loved the strain gauge system IMHO had it been available. they used what they had available. as to the fifth, are you implying that knowledgeable reloaders only use CHE/PRE and all knowledgable reloaders use it? no way. what happens to the case happens to the cahmber. if you can measure it at the case, you can measure it at the chamber. the strain gauge is a better instrument that gross measurement, IMHO. we simply disagree here. no. I go by primers, it's all I need. remember, I didn't say CHE/PRE don't work.... | |||

|

| One of Us |

Thanks Glenn, I missed the humor in that

6mmBR: CCI 450 small rifle magnum primers will pierce. Gre-Tan offers firing pin bushing bolt modification for 6mmBR. 7.62x25mm: CZ52 chamber will split*. Tokarev primer will fall out. 32sw: break action Iver Johnson revolvers will stretch the eye of the top latch from bullet friction and recoil forces on the barrel 32S&W Long: small Colt revolvers blow out the forcing cone, TIG welding forcing cone allows slow powder work up until cases stuck, fast powder splits the cylinder and breaks the top strap. 32-20: cases stuck in revolver 7.62x54R: bolt too hard to lift 38 sp: cases stick with slow powder. Cylinder splits and top strap breaks with fast powder. Thin Aluminum frame will bend before cylinder splits, thick Aluminum frame will not. 357 mag: cases stick depending on chamber wall thickness** 38sw: Break action Iver Johnson revolvers will stretch the eye of the top latch from bullet friction and recoil forces on the barrel. This happens with 38Super +P loads with jacketed bullets. 45Colt: With rifle primers in break action .410, 40 gr H110 405 gr cast, cases stick 45/70: With 32 gr Unique 405 gr cast the brass flows into miss fit of extractor to Handi Rifle chamber and some case head- case wall separation. *John Bercovitz RC hardness tested 10 CZ52 barrels at JPL, and a couple more I had lying around. The chamber thinness and wide variation in metallurgy is causing the unusual weakness, in a gun touted as strong by many load books **John Bercovitz in 1993 figured out how 357 mag chamber wall thickness affects max load for not just bursting, but for stuck cases: http://groups.google.com/group/rec.guns/browse_frm/thre...7aa/f002ce69fa01e631 1) Rimless with extractor groove 270 Win is registered at 65,000 psi with SAAMI and does not have 10% safety margin on the primer pocket strength. 2) Rimmed with no real extractor groove 45/70 is registered at 28,000 psi with SAAMI and probably has 200% safety margin on the brass strength. Anyone want to work up a wildcat, the 270 +P ? Of course not, the primer pocket strength safety margin is more than used up in that cartridge. What does it all mean? I have seen Randy Ketchum and Dick Casull independently built steel Mauser case heads and attach them to brass bodies. I have seen on this forum Ass Clown do Von Misses analysis on various cartridge heads. I have seen on Varmint Al's web site some computer analysis of the 243 case head strength. There is a reason they are doing that, and it has something to do with pressure signs they have seen. | |||

|

| One of Us |

Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| One of Us |

Roger, I think your MAS36 paint job is going to blow up US - French relations. | |||

|

One of Us |

Depends on the powder. With some "ball powders", a dramatic jump in pressures can occur when the maximum is approached, and sometimes as little as 0.5 of a grain more can cause "pressure excursions". This is GENERALLY not as likely to happen with extruded, single-base powders. If your brass is permitting several reloads w/o getting loose primer pockets, your load is not likely to unexpectedly jump pressures to a dangerous degree. "Bitte, trinks du nicht das Wasser. Dahin haben die Kuhen gesheissen." | |||

|

| One of Us |

Hey Warrior There is something wrong with that drawing of yours. It does not look right.  Did you make it yourself or did you Gooooooogle it from somewhere? | |||

|

| One of Us |

tnekkcc, Hot Core.... Here is my point; With the use of a chronograph and observing other signs we know to stop loading up when we have cases like the left one and velocities are consistant where they are supposed to be fps wise. We do not have to expose our firearms and ourselves to potential harm by loading to the extremes of the middle and left cases. Are you aware that "proof" loads, even for the very high pressure cartridges, do not blow primers such as in the middle, or certainly not the right, cases in the photo? As to CHE/PRE; CHE has been dicredited by all the big name writers and balisticians for the reasons stated here numerous times. PRE is still reasonbly valid only if one wants to duplicate factory loads. I have not had, on several occasions with a couple different wildcats and factory cartridges, any indication of case head expansion using CHE until the primer blew. These were cases of '06 capacity (and of 8mm case head size) using slow burning powders increasing in .2 gr increments. In fact the only rifle that was damaged from such of which I was a party was a .280 Remington. Let me use that case as an example to demonstrate CHE is not dependable but a chronograph is; The loads for the .280 were carefully assembled (none were over what was listed as "max" for H205 at the time) with all charges weiged to the same weight. The shooting tests proceded without any signs of pressure or any measureable increase of CHE. Five shots of one load appeared just fine with no CHE increase (new R-P cases). The first shot of the next load .2 gr higher blew the primer pocket big time and locked the bolt up tight. When the barrel was pulled we found the bolt was cracked on the Mauser M3000 action. About a year later the same barrel was put on another action and the loads, assembled with the very same componants, were then chronographed. The load of H205 that had not blown was approached very carefully and was found to be pushing the Sierra 168 MKs at 3012 fps! Had we been using a chronograph in the first place (it was in '75 and getting the chronograph was about 5 months away) we would have known that the load of about 2 gr less powder was max at around 2800 fps. That was the expected velocity we were looking for and anything over that would have told us we were treating in dangerous waters. CHE told us nothing in either test. That's how a chronograph works hand in hand with normal methods of pressure observation. I do not consider tnekkcc's method of "load 'em up 'til they blow" as a normal method of pressure observation and I don't expect too many other reloaders or ballisticians do either. Larry Gibson | |||

|

| one of us |

Hey Delloro, It does appear you can "discuss" the issue rather than go into an argument. I am so happy to see that for a change and look forward to talking to you about the entire subject. This is an excellent start. First off I'll say if it works well for you, I'm happy it does. Since it is non-measurable and requires a judgmental decision, it is not something I could recommend to a Beginner. Even trying to use pictures is difficult because the Primers "can" go from OK Pressure to BAD Pressure (for the Beginners) and be difficult to describe. And, in some HIGH Pressure situations, the Primer will appear to be normal (like early Lots of WSM Cartridges). Plus, there is a Lot-to-Lot variance in the Hardness of the Primer Cups. So, what looks OK may be Un-Safe for the Beginners. Actually, from an Engineering viewpoint, the Case provides direct First-Hand (Case Expansion) data from the Expanding Gas. The Barrel provides Second-Hand information, and(hopefully) recovers too quickly to get measurements. The Strain Gauges provide Third-Hand information, fed into a Software Mathematical Model. When things are done as well as the guesstimates will allow, the information coming from the Strain Gauges used with the M43 or an RSI Pressure Trace, can be off by 8K-psi according to Dr. Oehler. I'd suggest it could easily be (+ or -) 8K-psi. And you still have no known "Reference Point" for what you are trying to measure - Pressure. With CHE & PRE, the actual "Pressure Number" is irrelevent. You are looking for the effects of the Pressure and comparing them to a Standard. I do get defensive about it because it works better than, guessed at chamber dimensions, fudge factors, Haphazerdly(per Dr. Oheler) placed Strain Gauges, in a non-calibrated Pressure Detection System - being fed Third-Hand Information. And what really gets me defensive is when the HSGS proponents "imply" that good SAFE ammo can not be Loaded without an HSGS. Nothing could be farther from the truth, and you have not implied such foolishness. CHE/PRE also allows any Beginner that can "read and follow instruction" to detect Pressure Indicators long before you can see the Primer beginning to change in appearance. It also allows them to STOP adding Powder before a High Pressure situation develops that causes the Bolt to Bind, or create Ejector Marks on the Caseheads. No need for me to call, because I know what they use. I'd encourage you to call, and be sure to ask for the Quality Engineering Department, Production Evaluation Engineering, or their equivalent. You are correct that some Copper Crushers may still be in use for some Cartridges. Piezoelectric is a HUGE step up from the Copper Crushers and is the very best System the Ammo Manufacturers have. Strain Gauges have been "trying" to make inroads into the Test Labs, but is not the "Holy Grail" of Pressure Testing many would lead the uneducated to believe. And yes, good old CHE/PRE is still being used. I also agree Mr. Ackley would probably have enjoyed using a "Calibrated" Strain Gauge System. Didn't mean to "imply". Did mean that once a Reloader understands what is actually going on in a Case, and if he understands the problems associated with the HSGS, then it is easy to understand why "tnekkcc" measures Extractor Grove Expansion, why I measure CHE & PRE, and why other "knowledgeable" Reloaders do the same. Simply because the time proven Methods work, are not expensive, do not require hosing-up a rifle by attaching Strain Gauges and Wires to the Barrel, do not require taking a Computer afield, are easy to Calibrate, derive First-Hand information from the weakest link in the Firing System, will recognize differences in Case Strength(while the HSGS has no clue), are easily repeatable, and are easy to comprehend (by most). I have no problem with "disagreeing". I worked with Strain Gauges a long time and realize they have inherent problems that the folks wanting to Sell them have no desire to highlight. Not mad at all, I just base my position on many years of First-Hand Experience and if you choose to believe otherwise, hopefully we can still communicate at a civil level. Welllll, as hard as it is for me to "respect" a HSGS proponent I would encourage you to try them (by using the Instructions in the Link - DO NOT use other Instructions or preconceived notions) at your convenience. If you do a good bit of Load Development, you will realize the benefits quickly. If you are interested in trying, the old, time proven, very best Pressure Indication Methods possible If not, best of luck reading the Primers and using a HSGS. | |||

|

| one of us |

Sinclair International is usually judged as the foremost company providing extreme accuracy shooting and reloading equipment. I have never seen them offer the special thin blade micrometer needed for precise .0001" case head expansion measurements. If it can't be got from Sinclair (or MidwayUSA, for that matter), where does the 'beginner' that Hotcore keeps blathering about find such a tool? The only micrometer that begs distinction is the ball mike used to measure case neck thickness. Every internet company that caters to reloaders offers them. Where is this special thin blade mike to be found? | |||

|

| one of us |

Go directly to the source! http://www.starrett.com/pages/462_z011.cfm | |||

|

One of Us |

Thanks for the trouble tnekkcc. That is indeed interesting! Do you have any photo's you could post? Delloro Reading primers is my main pressure 'guessing' system. My hornet produces a little 'crater' ring like the first case in tnekkcc's photo but without the flattening at the edge of the primer. The firing pin indent is not that deep to start with. I do not get case head separation or even case length growth (if I do I back off). How would you 'read' that if I may ask? I am using Federal 205 primers. Regards 303Guy | |||

|

| one of us |

Starrett blade micrometers are only accurate to 0.001". How are they going to work for CHE/PRE when according to the instructions found herein a micrometer with a 0.0001" tolerance is required? Blade micrometers with 0.0001" resolution can be found numerous places for under $100. A blade micrometer with 0.00005" resolution will cost over $600. I've yet to see a blade micrometer be offered by a reloading supplies vendor. You learn something new everyday whether you want to or not. | |||

|

| one of us |

Hey fuz, You seem to be ready to pick a fight with your "blathering". Since I've no desire to fight with you, I'll stop there unless you want to just talk trash. For those of you interested in where to get Thin Blade 0.0001" capable Micrometers, Steve has provided a good source. Any of the Precision Measuring Instrument Companies will have them. They are expensive, but I got mine for $25 in a Pawn Shop a long time ago. ----- But, you do not have to use Thin Blade Mics if you have Belted Cartridges, or you can use a regular 0.0001" capable Micrometer to measure PRE on ANY CASE, ANY CARTRIDGE. If you read the link as "fuz" did, it also says the CHE will not work as well as PRE. CHE won't work at all on some of the older Cartridges because of their low pressure. ----- But, if you all want to deprive yourself of the very best, time tested Pressure Indication Methods ever devised, then you should. On the other hand, if you want the ONLY Pressure Indication Method which will ALWAYS keep you SAFE, simply follow what the Link says. ----- Hey fuz, What got you so riled up? | |||

|

| Powered by Social Strata | Page 1 2 3 4 5 6 7 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia