The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Head spacing

Head spacingGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I've been loading .300 Win Mag and I've had a few cases split just above the belt. I assume it's because I was full length re-sizing. If I neck size only, can I expect to get more case life by head spacing off the shoulder instead of the belt, or will it not make a difference? Brass is hard to come by and I'd like to make it last as long as I can. Molon Labe! NRA Endowment Member | ||

|

| One of Us |

Learn to partial full neck size with your die, to extend magnum brass life. Loading hot, full-length resizing and not keeping count of how many reloads per case you've done matter. Neck sizing may yield hotter loads (if already pushing the envelope beyond published data), so it isn't necessarily why you have split cases. _______________________ | |||

|

| one of us |

Yes, neck sizing or "partial full length resizing" will keep the pressure ring near the head of the cartridge from thinning and prevent head separations or annular cracks from forming. The usual way to do this is to back your FL die off of the shellholder so that the case is not reduced in head-to-shoulder length. However, you may or may not be able to use an FL die to neck size or partially size, depending on how compatible your die is with your chamber. The problem is that if your die is "narrow" near the shoulder it will push the shoulder forward as it squeezes the body of the case, thus making the head-to-shoulder distance longer than your chamber. If you find you are in this not infrequent situation, then you'll need to buy a dedicated neck sizing die. I'd recommend the Lee Collet die as the simplest and producing the truest case necks, but a conventional neck die will also do the trick. Unless your pressures are so great that they are swelling the case or actually stretching the action, you'll find with most bolt rifles that neck sizing-only works just fine for several loadings. | |||

|

| One of Us |

Do yourself a favor and purchase a L.E. Wilson Adjustable case gage for your belted magnum case. Will make correct full length sizing much simpler. www.lewilson.com. | |||

|

| one of us |

Just lube your fired case lightly, burn the shoulder and neck black with a kitchen match,that will give you a line showing how much neck your resizing..start at the half way neck marking and try the case in your gun and keep sizing a tad at a time until the round closes in your gun with a slight crush fit. then take a half turn or full turn on the die until the bolt closes with just a ever so tiny tad of snugness. that will increase case life somewhat, and get you near full length sizing. At any rate your putting less stress on the case than a full length resize but feed and function wont be impaired as much. The 300 Win mag by design headspaces on the belt, not the shoulder, but by doing the process above you by pass the inaccurate belt headspace and set your headspace on the shoulder. always a better option..Once you fire a cartridge in you guns chamber, it is perfectly headspaced..so you don't want to set the shoulder back or you overwork the brass and get the separation youdescribe. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

No gauge knows how long your chamber is, so for me, they are worthless; you can only fit the brass to your own chamber like Ray says. | |||

|

| One of Us |

Dpcd: That is why it is an ADJUSTABLE gage, amigo..... | |||

|

| One of Us |

Reddog: Your head case separations are not due to sizing. You can full length resize repeatedly 20 - 30 times. As to measuring shoulder, it's a piece of cake with the Stony Point comparator which I have owned for years. I think it was sold to Hornady some time. It measures the shoulder. I also have the Stony Point overall length gauge ................. <a href="http://www.amazon.com/s/?ie=UTF8&keywords=hornady+overall+length+gauge&tag=googhydr-20&index=aps&hvadid=32575235671&hvpos=1t1&hvexid=&hvnetw=g&hvrand=4060108094819152242&hvpone=&hvptwo=&hvqmt=b&hvdev=c&ref=pd_sl_85elllt88h_b" target="_blank">http://www.amazon.com/s/?ie=UT...f=pd_sl_85elllt88h_b https://www.youtube.com/watch?v=3lppK2jJ3XE It deals with bullet seating off the lands for the most part - none the less very important to consider for accuracy and other aspects of ballistics. If you will reveal to us your total load data, bullets, powder all inclusive - we will return to you our analysis of the cause of case head separation and propose remedies. Here's the link to the Stony Point headspace gauge's. [url=http://www.hornady.com/store/Headspace-Gauge-Kits/]http://www.hornady.com/store/Headspace-Gauge-Kits/</a> Be sure to click the "details" provision to see more. | |||

|

| One of Us |

Why would I want a gauge for each chamber when I already have a gauge; the chamber. I fit brass to the chamber and don't want to introduce another tool and step. Hence, I don't use nor need a gauge. As for Fl sizing belted brass; yes, it can certainly lead to brass separations when you have excessive space between the belt and the chamber, or put another way, between the case head and the bolt face.; SAAMI specs allow a huge gap between max chambers and min brass. | |||

|

| One of Us |

Do a search here on A.R...lots of information available including "How to's". This subject has already been covered extensively including magnums, how to make your own cheap gauges, how to use them, and what the numbers tell you and the best way to setup your sizer to maintain your press and keep everything uniform. Luck | |||

|

| Moderator |

use a sharpie .... opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

Different strokes for different folks. I just happen to be one of the mentality tilting to meticulous inquisition. And with an affinity for exotic developments, I always push the envelope into the land of new discovery. I bought the Stony Point tool( s ), *( plural as in two ) many years ago to tweak measure #1. head space on the shoulder and also #2. my bullets distances off the lands. It was, and apparently is still, a widely condoned practice to jump start bullets to improve accuracy. It gets very detailed. ____________________________________________ The bottom line is that until the poster comes clean and tells us his history of loads, pressures, bullet we are all left with the undesirable position of wasting dwell time. | |||

|

| One of Us |

I have always thought of headspace in bolt actions as the gap or clearance between the head of a chambered cartridge and the bolt face, irrespective of whether it is a belted case, rimless, semi-rimmed, or rimmed. I know very well that technically that is not the true definition of headspace but it is the physical representation of it and it is this gap if excessive that eventually will lead to incipient or full case head separations when reloading cases and can also lead to misfires if the gap is really excessive. The idea when reloading is to eliminate this gap so that what ever type of cartridge is being chambered does so with a very slight snugness felt when closing the bolt. With any one of the type of cases listed above with a shoulder, just size the neck/shoulder area enough to ensure the bolt closes snugly, no more and no less. This method will prolong the life of your cases irrespective of the load intensity. No need for gauges, markers etc just a few cases and carefully adjust your F/L die a bit at a time making sure to use a different fired case each time the die is adjusted. If the same case is progressively sized until it is a snug fit and the die is then locked, usually subsequent cases sized will be a little tight as there is a difference in spring back from a case sized in one movement as opposed to progressive. The exception to the rule is straight sided cases where there is no shoulder to 'adjust', often though there will be some taper to the case so a similar scenario applies, don't size the taper out. | |||

|

| One of Us |

Dpcd: Why do you own a toothbrush if you have a toothpick? Why do you have a dishwasher when you have a sink? Why do you own a vacuum when you have a broom? Answer: ease and efficiency of use. Same with a case gage. No fa*ting around with matches or sharpies with their inherent guesswork. | |||

|

| Moderator |

headspace, which this isn't about, is from breavh to datum - in this case, it would be measured from bolt face to the top of the belt, according to saami and cip.. with up to .005 clearance i have never heard of a SAAMI or CIP "to the shoulder" headspace gauge for HH cases -- this is a complete aside, btw the question is "proper resizing technique" but everyone understands, that unless you are dealing with excessive headspace issues, 99% of reloaders aren't talking about the rifle, rather then reload opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

Sorry have to disagree on this one. If your chamber has excessive headspace on a non-belted case. Or if the distance from the shoulder of the case to the shoulder of the chamber on a belted case is excessive and you load to significant pressure to stretch the brass to fill the chamber you will thin the brass usually just in front of the head and shorten life. As to the Wilson guage. I'm sure it works. So I need to spend $30-40 for each belted case I shoot so I can then set up the dies. Once the die is set for correct spacing why would I need the gauge again? The non adjustable std gauges make no sense to me. Yep you can set to std headspace. How does that help me fit brass to my chamber? I use a $2 sharpie or soot(pretty much free) set my die up for my rifle and leave it. Why would I need to change it? On the cartridge that I have more than one rifle I set the die up for each. Saving a labeled case for each rifle. Install the case, raise the ram and turn the die down until it touches. As usual just my $.02 Paul K | |||

|

| One of Us |

A properly trained wife renders all those questions moot. | |||

|

| Moderator |

sexist remarks aren't funny, opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

Not me brother my wife reads AR on occasion. As usual just my $.02 Paul K | |||

|

| Moderator |

actually, efficient has a cost advantage or at least value prop .. a sharpie, cost, 1.99, can cover ANY hunting cartridge you want, no additional charge - an OAL gauge - which isn't headspace, is ONE cart and costs, well, more than 1.99 let's say you have 3 rifles... 1.99/3 is about .67 cents per rifle... OAL gauges are, well, more INEFFICIENT in terms of dollars. you presented a false analogy, in that the sharpie is like the toothbrush, rather than pick ... though I am hard pressed to see how in the heck those are interchangeable in any fashion... opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

Jeffeoso: Well, if you did not understand the toothpick analogy it is easy to understand why you don't understand the value of case gages. How much is your time worth, amigo? You understand the sharpie pen has ZERO repeatability compared to a gage? Kind of like eyeballing the amount of gas you put into a gas can instead of relying on the meter on the pump. | |||

|

| One of Us |

I took some time to contemplate the perceived disagreements with me and also the various opinions and comment about headspacing I read Lyman's articles about it over 50 year ago and and I read it again last night in their 48th edition of their reloading manual. It still says just about the same thing. I endorsed it 50 years ago and subsequently my personal experiences reaffirmed. In going over posters comments here I find that basically there are not any glaring egregious errors, falsehoods or "wrongs". The reality is that the misimpressions stem from my being too brief and lacking in more in depth explanations. Essentially we are actually agreeing. The evolution of firearms and gun powders has been swift according to my calendar. 300 - 400 years, in human terms, from the most primitive to now astonishing advances in science and technology. Fast forward from black powder and cartridge cases to the present. We have thousands of cases. Vast numbers have also already been obsoleted. The differences in sizes, configurations, diameters, lengths, metallurgy are absolutely huge. Cases have a life. It is not indefinite. The life is contingent upon how the case is treated, used and abused. Necks will split. Case heads will separate. Brass will flow. But to point out the major contributor to shortened case life it is predominantly pressure, not head space. The two go together however. Here's what Lyman says, in general terms. 1. At 40,000 psi case life is expected to be 8 re-loadings. 2. At 55,000 psi case life is expected to be 5 re-loadings. 3. When 5% of cases split, separate, fail the entire lot should be scrapped. 4. There isn't really much difference in case life - neck sizing versus full length re-sizing. It is factual that neck sizing only is satisfactory. It is factual that partial resizing is OK too. It is factual that full length resizing is also acceptable. But the circumstances change from case to case. Although there seems to be 4 categories of shooters these days I will limit this dissertation to just two. Hunters shooting live animals and bench rester's shooting holes in paper. It seems to me that their goals and concerns also should enter into the attitude about neck/partial/full resizing. The bench rester is striving for perfection and milks out every tiny advantage to improver accuracy. He probably burns up more ammunition in a year than a hunter does in a lifetime. The hunter is interested in a cartridge that will chamber smoothly and be reliable. So full length resizing is more reliable. But in the end it all depends on the individual's preferences, likes and dislikes. Personally I'm not a bench rest shooter. But when I hunted small varmints at long distances accuracy was certainly paramount. There were times that I had to beat open my bolt, to extract, from too hot a load. It wasn't nice. I just go ahead and full length resize everything. Case life isn't a factor for me. I still have cases and loads that I prepared decades ago. And I sure do have a lifetime supply of bullets, cases and primers stacked up here. I have multiple rifles and handguns. Can't spend all of my time shooting everything. | |||

|

| Moderator |

Howdy -- however, a toothpick isn't a lesser replacement for a toothbrush, in your analogy thread -- one removes specific area, gross material with a toothpick, and wide area/ultra fine with a tooth brush -- the only things these two tools have in common is their location of use. 1: you are assuming that I don't get the purpose of these **GAUGES** I didn't say I didn't understand the value of them, when, in fact, 15+ years ago I was drilling and tapping cases to do EXACTLY this same - I am saying that you analogy string went from less to more efficient - and then broke logic - a fallacy thing whatever I can get paid for it i don't agree, in that I am pretty sure I can recoat the neck -- I KNOW that's not what you meant -- and it doesn't matter - if i can determine where a near minimum resize takes place, then, tada, goal achieved ..

nope -- you might drop the analogies for the rest of our dialog on this matter - what it is like is using a GAUGE rather than a caliper I get the value of your concept - Which isn't measuring headpsace no matter what the label says. It measurement terms, it is NEVER "more efficient" to measure finer with more precise tools, if you are using analogies like sink to dishwasher, or toothpick to toothbrush, as each of those goes from specific action to general action, with LESS time and tools spent on each SPECIFIC item -- when you buy pins, dowels, gauges, and advanced measuring tools, you will spend MORE money and MORE time, doing what can be done with a soapy rag in 5 seconds ... yes, the quality is likely measurably better, but efficiency, meaning less time or money for the same quality, goes DOWN... opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

Seems backwards, I agree a nice tight chamber and dies to match FL will work fine. My reference was excessive headspace, and excessive distance on a belted. Can happen if a chamber is to the long side of SAAMI and Dies to the short. You stretch the brass it thins. No way around it. Does it thin fast enough to cause a problem in a given rifle. MY answer is it depends. All that said all my wildcats I FL but each has a set of dies cut to it's chamber. As usual just my $.02 Paul K | |||

|

| One of Us |

Ram: It IS backwards !!!! Go back and read it again !!!!!! Glad to see that you are paying attention !!! | |||

|

| one of us |

Sure glad I've never posted anything backwards. Makes more sense now. As usual just my $.02 Paul K | |||

|

| One of Us |

I've been following this thread along but by this time I'm not sure WHAT this thread is about...resizing or headspace or defending a position with a WHOLE bunch of messy metaphoric rhetoric. There is WAY too much mis-understanding and mixing of metaphors going on that totally smoke screens the "ORIGINAL QUESTION????"...I've been doing this thing a couple years now and have learned that definitions don't quite fit...peoples understandings of all the aspects are WIDELY DISPARATE...AND THERE'S NO WAY IN HELL that every condition can be replicated even using ONE case to do ALL the testing. I take great care in matching chamber, case and sizer (and bench prep my brass)...AND amount of sizing, both DIAMETER AND SHOULDER POINT, using bushing type dies, comp shell holders, Stoney and home made gauges and belted case gauges that measure the distance from the belt to the case base...AND FORGETTING ABOUT THE CONSTANT MIS-READING/MIS-UNDERSRTANDING OF "HEADSPACE", HOW TO SET YOUR SIZER, HOW TO SETUP YOUR PRESS, ETC, to insure the minimum amount of RE-sizing in ALL dimensions...AND MINIMUM TRIMMING. As a result I can get 10-15 firings out of (most but not all) of my belted mags(I use once fired cases for hunting and the rest for load testing/squirrels/varmints etc.) and even more from my straight walled and bottle necked cases. I've fired ONE each, 223 and 308, cases 50 and 40 times respective, until I just got tired of the process and quit...NOT ONCE BUT SEVERALS TIMES. I have one 444 M case sitting on my desk as I type that I loaded and fired 40 with a "normal" pressure load for a 240 gr bullet...it shows NO evidence of head separation either by using a bent paper clip or a magnifying glass after cleaning the residue from inside the case. Doing these procedures isn't something new to me...I do/did the same thing for almost ALL my rifles and I'm getting ready to do it again for my latest 9.5x57 AKA 375 JDJ. All this rhetoric is great when sitting around the campfire after a successful hunt and more than a few sundowners and everyone is feeling rosy, but if you are confusing me you are sure the hell confusing newbies and even some of those that are experienced. As I said previously, Roaddog, this subject has been covered extensively already and a search will give you ALL the nuances and ways to keep your brass living long unless you kill it by over pressure loads...easily done with ANY CASE. As always...NO FLAME OR DISS INTENDED, JUST MY OBSERVATIONS. Luck | |||

|

| One of Us |

It is also possible that your problem has nothing to do with head spacing as such, but that you have a slightly larger than usual chamber diameter. If so, all the more reason to experiment with partial, or neck sizing. Just be sure that every round that you take on that expensive hunting trip has been cycled through your action | |||

|

| One of Us |

Misconceptions rule, it seems with all the answers given. I understand that headspace is a misconcieved term used by reloaders to refer to there cartridge cases, what is really being described is case head clearance for a given FIRED CASE. Anyway, the problem with belted cases is that the belt headspaces the case on the initial firing, which in turn holds the case from driving forward from the firing pin strike, because the shoulder is not held to any tight tolerance and is not in contact with the chamber, it grows forward until it hits the chamber. Now, this is where FL sizing a belted case poses a problem, if you continuously push the shoulder back, the case stretches at the web every time it is fired to make up for the distance the shoulder has been pushed back. Neck sizing is not the answer, as this will pose a problem in short order as the case grows it will get hard to chamber. Partial full length sizing is the best cure, whether the cases are belted or not makes no difference, as you will be using the shoulder to control how much head clearance, and therefore how much stretch, the case will have. Measuring your fired cases is the easiest way to determine this, but as has been mentioned, sizing so that there is a slight feel on closing the bolt with the FIRING PIN ASSEMBLY REMOVED is a good place to start. Marking 12 equidistant indexing marks on the lock ring of your dies also works in controlling how much sizing is taking place when adjusting it for finer sizing. Hope this makes sense. Cheers. | |||

|

| One of Us |

Jefeosso: Give it up, amigo. Unless and until you have used a case gage for reloading your opinions are as washed up as a soapy rag. Frankly, you have no idea what you are talking about. End of discussion. | |||

|

| One of Us |

Very interesting discussion. Thanks | |||

|

| One of Us |

Where did I hear... "To measure is to know."? Santa Claus | |||

|

| One of Us |

Why do you have to remove the firing pin? | |||

|

| one of us |

You want to feel the actual force to close the bolt against only the case. As you close the bolt with the firing pin in place you will feel the resistance of the spring as the sear picks up the load and you compress the spring that last fraction of an inch. On something that cocks on closing like the Enfield it is even worse. As usual just my $.02 Paul K | |||

|

| One of Us |

thank you ramrod. | |||

|

| One of Us |

I am about to enter the headspace world,, just bought a barrel,brass, and cases from PWS in 400 Whelen!! This forum got my juices going and when an opportunity popped up I jumped. | |||

|

| One of Us |

Lots of good info here for top quality, super accurate reloads, I think. I reload 460 Weatherby. Not to the tippy top, rather about 2410 fps with 500 grainers. I have an RCBS neck sizer. I lube the necks inside/outside with graphite, do it, then clean. Shell holder just touches the die, sizes the neck just right. After the fourth go the bolt gets a little tight on closing. I'm still working through my brss supply so one day I plan to pick up a FL die and adjust it so the bolt will close nicely on the round and call it good. I'm not expecting to push the case all the way in or move the shoulder. A couple points; I shoot strictly for fun, no DG hunting. That means no emergencies. If I was DG hunting I'd probably use factory ammo. | |||

|

| One of Us |

I'd like thank those that contributed to my question. I, for one, learned a lot about headspacing and partial length resizing that I didn't know. Thanks for your help. Molon Labe! NRA Endowment Member | |||

|

| Moderator |

you are right ... oh, wait

perhaps I might have just a LITTLE conceptual knowledge of the *gauge and its use opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

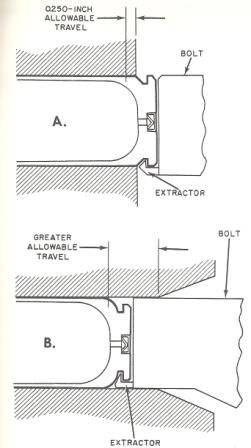

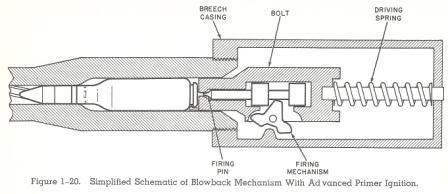

"Headspace" is something that must be controlled between the ammunition and chamber for safe reliable functioning of a firearm. Let me start off with axioms: Firstly, the cartridge case is a gas seal and it must be supported or it will rupture. Secondly, it is always operating above yield. For reloaders, setting the case shoulder back is the first time they typically run into the concept of cartridge headspace. These pictures are examples of improper headspace. It was not obvious to the reloader that he had set the shoulder too far back, because that was not something addressed in the instructions of his sizing die. Most sizing die instructions simply tell you to size to the shell holder and add a quarter turn. Sizing instructions are written so even a trained monkey can size brass. But there are assumptions that have to be met for it to work. Sometimes these assumptions don’t all line up properly and there are unfortunate reloaders who do not understand what went wrong, as they dutifully followed directions.   The cartridge can only stretch so much before it ruptures. In Col Chin’s book that .006” is the standard maximum safe stretch for a 20mm cannon round and I keep seeing that number associated with other cartridges. Maybe it is a coincidence, but generally, after 0.006” sidewall stretch the cartridge is highly likely to separate. Case head separations are seldom dangerous, but they can be dangerous if the case separates outside of the chamber. From a risk viewpoint, the most common issue with case breakage is a failure of function. Part of the case is left in the chamber and the weapon is down till it is cleared.  Reloaders and shooters seldom have to consider the engineering that it takes to support the case. Only when a firearm is improperly designed, and that is rare, do we find out what other aspects of chamber/cartridge headspace are important for function and safety. One of the most safety critical issues about headspace is just how much of the case head is unsupported: that is how much of the case is allowed to stick out of the chamber. Unless you are going to knock the case out with a cleaning rod, there needs to be relief for the extractor, a bit of beveling to align the case, etc. This is one of the most fundamental issues that confronts firearm design: how much of the case head is going to be sticking out of the chamber. This issue is overlooked by reloaders and shooters as it is generally something outside of their experience. The shooting community does not decide just how much case head protrusion is built into their firearms. The shooting community uses firearms assembled and built by others. Decades ago minds more brilliant than any here came up with a system so simple that even a trained monkey could assemble, maintain, safety check, a firearm, given that the monkey used the parts, tools, gages, and followed the procedures provided to him. As long as the monkeys don’t start grinding off material someplace, use the proper cartridges, case head protrusion is something that the monkeys don’t need to know anything about. If the firearm swallows the field gage, the monkey knows that something is wrong and has been trained to go to higher authority for issue resolution. Something I have noticed, simians are interpreting the world based on their headspace gages and sizing dies. I got into a dispute with a big baboon on another forum who considered unsupported case head distance to be of no importance at all. I could tell, the baboon thought a case was similiar to a pressurized bottle: self supporting. To him, the chamber was simply a way of aligning the cartridge with the barrel hole, and how much of the case stuck out of the chamber was no consequence at all. I did not realize the importance of cartridge head protrusion until I read Stuart Ottensen’s book “The Bolt Action”, and until after I read Vol IV of the Machine Gun by Chinn, I did not realize the fundamental importance and limitations case strength/case head protrusion imposed for automatic mechanisms. http://www.milsurps.com/conten...-(by-George-M.-Chinn) I have not found any table providing guidance on appropriate case head protrusion. Conceptually it can be understood that case sidewalls taper and at some thickness the brass will burst at a given pressure. This is something that could be, and most certainly has been calculated, given the hardness of the brass, the thickness of the sidewall, a rupture strength could be calculated, and the limits of safe case head protrusion calculated for a particular mechanism. When I have asked gunsmiths, they get their numbers from examinations of existing rifle mechanisms. I highly recommend to all to read the section on Blowbacks in Chinn’s Vol IV Machine Gun. As the blowback is the simplest mechanism, that is where the book starts, and the foundations for all the other mechanisms, particularly cartridge design, start there. Chinn clearly shows in easy to understand pictures that the case head must be supported, and depending on the mechanism, how designers altered chamber design and/or case design to make the mechanism function safely.  It is all about the case being the weakest link* Here, given a heavily lubricated case (such as oil or grease) the distance from bolt face to shoulder is not as safety critical as case head support.  The military is primarly interested in reliable, safe function and the military does not reload cases. Any greased case fired in this advanced primer mechanism is likely to be blown out at the shoulder and case mouth. However even in this mechanism, the bolt face to shoulder distance must be controlled as timing and primer ignition would be defeated by an overlength, or short case. In the mid nineties, 40 caliber Glocks were having a number of blowup reports, and it was a combination of insufficient case head support and high pressures. http://www.thegunzone.com/glock/kb-notes.html http://www.thegunzone.com/glock/glock-kb-faq.html http://thefiringline.com/forums/show...8&postcount=23 As you can see in the pictures early Glock 40 S&W chambers left more case head unsupported than later chambers. Too much of the thin case sidewall was being left unsupported and given the high pressures and thin case sidewalls of the 40 S&W, and manufacturing variances in sidewall thickness, shooters were blowing case heads. If you Google this you can find a lot of pictures of blown sidewalls and case heads. I think this is a 45 ACP case, the sidewall did not rupture.   Chamber headspace gages are made under the assumption that the action was properly designed with a proper amount of case head protrusion. If you have a rifle gunsmith who does not have a clue about controlling cartridge head protrusion, considers sidewall support a metaphysical idea, be afraid. Even though the bolt face to chamber shoulder distance may be within specs, if he cut the barrel cone or chamber bevel too deeply, the rifle could very well be unsafe to fire. Belted magnums are a particular pain to load for as the case headspaces off the belt. I am not a fan of belted magnums, head spacing is one factor, another is that I have had rim lock in my 375 H&H M70 rifle. The belt from the top cartridge caught the rim on the next cartridge down, resulting in a jam which I cleared by pushing down on the cartridge stack. If time had been critical, and had I been not had the problem enough times to know how to clear the jam, things could have ended badly for me. Since the base to shoulder distance is not standardized, unless you know the actual bolt face to chamber shoulder distance, and have gages to adjust your sizing dies correctly, what will occur is terrible stretching of the sidewalls and a short case life. I bought the belted magnum case gages pictured in this page: http://www.realguns.com/Commentary/comar46.htm However, since base to shoulder dimensions are not controlled from manufacturer to manufacturer, or even by manufacturer, you end up having to buy one of these gages for each belted magnums you own, unless you don’t care about case life. Also, something else I do, on first firing of a belted magnum case, I lubricate the heck out of the case. Since the base to shoulder distance of a factory belted magnum case has nothing to with the bolt face to chamber shoulder of any particular factory rifle, the lubricant prevents excessive sidewall stretch on first firing. The case simply slides to the bolt face, the shoulders fold out, eliminating case head and sidewall stretch. Makes the cases last longer, in my opinion. * There are people who believe that the case is a load carrying member. They did not come up with this idea on their own, this was something they were taught. It all came about from the early 1900’s problems with the single heat treat 03 Springfields and the Army coverup of these problems. The 03 Springfield was properly designed to carry the full thrust of the cartridge case, but the single heat treat Springfields were not properly built. The Army built over 1 million structurally deficient rifles, kept them in service, issued them, sold them to Civilians, and whenever rifles blew up, blamed the blowups on the shooters. To give logic to this cover up, the Army created this theory that the case carries load and removes load from the bolt face. There was actually a method to this madness as at the time shooters were greasing their bullets, because the bullets of the period fouled something awful. Grease eliminated the fouling. Instead of acknowledging that their defective rifles were at fault, the Army told people that grease in the chamber removed the friction between case and chamber (which is true) and thus, dangerously, increased bolt thrust, which is the lie,... sort of. In a properly designed rifle firing ammunition within specs, there is no problem whatsoever with greased or oiled cases, but in a defectively designed or defectively built rifle, ANY BOLT THRUST is a problem. The Army successfully scapegoated innocent shooters and misdirected the problem they created. The authority of the US Ordnance Department is so high that no one has ever questioned this, nor challenged the idea that anyone would so stupidly design a rifle to break at a load less than the full thrust of the cartridge. Instead, you have generations of people faithfully adhering to the lie that the case is supposed to carry load, and there will be generations more will believe this in the future, such is shooting community’s belief in the infallibility and inerrancy of the US Army Ordnance Department. In fact, even today, whenever any problem happens with an Army weapon, the first thing the Army looks for is an oil can to blame. | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia