The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Head spacing

Head spacingGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Slamfire: Great post. I'm still digesting it so this is a preliminary response. My background is Geotechnical/geology/earth science. My Grandson is in his second year of advanced engineering and he is a chip off of the block "aficionado" of firearms like his Grandpa. | |||

|

| Moderator |

No, it's not - Headspace is the length from breech to datum. The end, period. Class dismissed. resizing brass is what we are discussing as headspace is a GUNSMITHING term, and, frankly, nothing to do with what we are talking about. A rifle can have "0" headpsace .. or even less than minimum (it can happen, and does, several times, while chambering a barrel) and then -- resizing brass. Nothing you can do, within reason, changes headspace of the gun. You CAN change how you resize, and many people, mistakenly, call this head space. sigh - this isn't that hard guys - get a sharpie and partially resize. opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

Been sleeping on this one. I agree with everything Jeff said. I disagree with Slam on the "brass can't carry any load" theory; it is invalid. It is easy to prove. And for whoever suggested it; who said I owned a toothbrush anyway? Anyway, once I set the die for a particular chamber, I have no need for a gauge, which costs money, which I avoid spending, which is more efficient. Works for me. | |||

|

| One of Us |

So how much load does the case carry, or rather, how much is it supposed to carry? | |||

|

| One of Us |

#1. Head space: The term has a double entendre" - two meanings. a. Cases can be rimless, rimmed, belted and/or rebated. The rimmed and belted's "headspace on the rim or belt. Headspace is also the distance from the bolt face or base of case to a point on the shoulder. The "space" between the shoulder and chamber is the head space. It can be any of several dimensions or length and include reference to the brass shoulder touching the chamber steel. Since it would be in contact - headspace would be zero. #2. Brass capacity: " (So how much load does the case carry, or rather, how much is it supposed to carry?)". The case isn't supposed to "carry" any weight. It is supposed to be in contact with the steel inner chamber. Thus the metallurgist would answer that the compressive strength of brass would be such and such. However, that is not a component in calculating the pressure a gun's chamber will withstand before failing. The upper, recommended, safe operating limit is 65,000 psi. Some are limited to 62,000, some 60,000 and in some older guns down around 35,000 or so - varying. And lower in handguns and other types. In the world of internal ballistics, normally, there isn't any provision for reporting the strength of cases as the matter pertains to rating a guns "safe" load pressure. That "safe" pressure is quite far below actual bursting, or failure, pressure which could be 90,000 psi in some cases. The old CUP copper crush method and the newer piezo tests entail drilling a hole in the chamber and attaching devices to the chamber to capture pressure. The case gets drilled too. Later/latest technology is an external strain gauge attached/glued to the gun. It records the expansion of the chamber when firing a round and reports it in psi. None of these methods can, or do, separate out the amount of pressure load carrying the brass will take and separately the steel - in internal ballistics calculations. | |||

|

| One of Us |

Ah yes... the old backwater swirl of confusion surrounding terminology... There is case fit to the chamber, and there is headspace. While headspace is a measurement of chamber fit, it is not the only dimension that is important for good case fit. Especially when we are talking about belted magnums. I think of belted magnums as a shotgun shell with a shoulder and a bullet. They were designed for use in drillings. The belt was supposed to be the important consistent measurement for manufactures and gun smiths. But, because some belted magnums have a shoulder, proper case fit for reloading is important. Brass will rupture if the fit is not proper, even if the belt is correct. So.... Jeffeosso is correct, in that making sure that a resized case is fitting the chamber is relatively easy. The tools that some use to determine case dimensions, are necessary if you are manufacturing rifles, a gun smith, or a gun buyer, where you may be dealing with multiple guns chambered in the same cartridge. But for the average reloader, who can keep separate, well marked, reloaded ammo dedicated to each gun, they are not a necessity. When resizing, most of my bolt actions have 3 position safeties. I set them on the center click, which allows for working the bolt, while still blocking the sear, so I can feel the bolt close on the resized case. If I feel any resistance, I nudge the die, resize, and check it, till the point when the resistance ceases. I then lock down the die, resize them all, and then give them all a run through the chamber. If I find one that is giving resistance, I adjust it out with just a nudge. For me, that creates the best effect in accuracy with minimal case stretch/expansion when fired. Using the sharpie to color the shoulder eliminates the need to chamber each case, and works well for bolts that I cannot relieve the firing pin spring tension when working the bolt. | |||

|

| One of Us |

Wetibbe: Good post, you would have been fun to have around when I went through the Petrified National Forest, you would have known the geology. I was trying to explain the “why” of headspace and that went over the heads of some. As can be seen, there as those who want to argue over the terms of measuring shoe size, but are clueless why we have feet in the first place. They are interpreting the world from the viewpoint of their sizing dies and headspace gages without any understanding why cartridges and chambers are dimensioned the way they are, and why this has any import at all. I never liked not knowing "why" but there are those who are happy just knowing "how". Case head protrusion is a fall out of firearm design, and is the most important measurement that we reloaders don’t make and should not bother with, so perhaps it was too much information for some.

When calculating the size of the locking elements of a firing mechanism, the members are sized assuming the case does not carry any load. In practice there is always some parasitic friction, but that is not used as an excuse to weaken the locking mechanism structure. When the case carries load, either axially or radially, it is deformed and that creates material stress that reduce the lifetime of the case. Hench, “case head separations”. If the case is not supported it will rupture. I was hoping one poster would calculate the axial load carrying capability of a case as I have been lazy to do the simple calculations. I have sectioned a .223 case but have not taken the dimensions. The worst case scenario would be the load carried by the thinnest part of the case, and the best case scenario would be the load carried by the thick part of the case. It would be wishful thinking to assume that the strongest part of the case bursts or separates before the weakest part. Brassey’s claims unsupported cases will burst around 650 psia, but that is a pressure measurement, not load. Obviously the case head supports all the pressure, assuming it is supported radially by the chamber walls and axially by the bolt face, with the assumption that the thin case sidewalls are not dangling in the air. Again the importance of case head protrusion. Case head burst strength would be an interesting number to know. We do know the yield of quarter hard brass is around 45,000 psia, so measuring the thickness and figuring out the axial and hoop stresses in the case head would likely result in an revealing number. | |||

|

| One of Us |

Brass will "carry" around 30,000 psi, or so. NOW, that is for a fully supported head, brass. Just by the obturation of the front of the case, it won't rupture somewhere around that value. Many variables involved; and different calibers, and chambers, might react differently. But for a DRY case in a supported chamber, it will hold some pressure. PO Ackley showed it and I have seen it; any time you have a primer protrude, that means that the case didn't back up to touch the bolt face. At what point does brass burst in a radial manner, unsupported? I don't know but it ain't much. | |||

|

| One of Us |

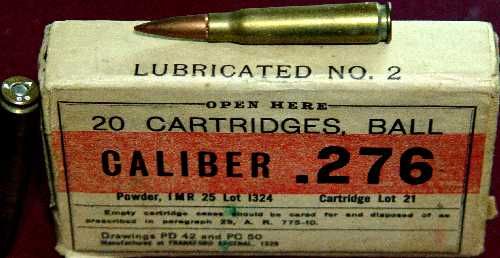

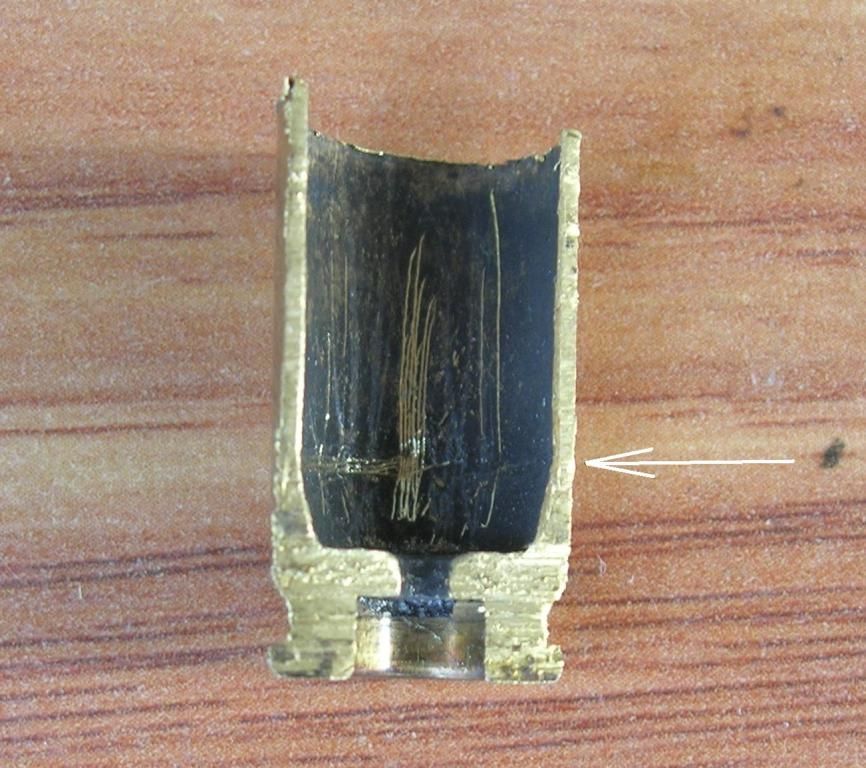

I agree, there is always some friction between case and chamber and sometimes if the pressures are low enough, given a dry case and a dry chamber, you will see things like this:  Now given a little higher pressures and a dry case and dry chamber, the case sidewalls would have been stretched as the case head moved to the bolt face, taking up this clearance. This clearance is the distance between the case shoulders and the chamber shoulders, something I have been inconsistently calling "cartridge headspace" and is related to the discussion in this thread. I think Boatwright claimed that the sidewalls give away on the 308 (or 243?) around 21,000 psia. He did the calculations on the tapered sidewalls. The thinner sections of the case lock in at low pressure, then the thicker sections lock in as pressure climb, and when pressures hit about 21,000 psia, that is when the sidewall locked against the wall starts to stretch. Thus creating the classic case head separation you see:  What is undesirable is that not only are the sidewalls stretched in dry case/dry chamber, but so is the case head. You can view this in Varmit Al’s finite element analysis. This is the absolute worst place to stress a cartridge case because if the case head ruptures, gas escapes directly into the action. On older, plain carbon steel bolt actions, you can blow the receiver ring.   While P.O. Ackley did show, using a 30-30 Ackley Improved case , is that there is case to chamber friction. But that was not the point he was trying to prove: rather he was selling Ackley Improved snake oil. He was supporting his claim that making the case straight increased friction between the case and chamber. His experiment did not prove this as Ackley created no auditable data: no bolt face loading and no combustion pressures inside the case. Ackley was trying to prove that insanely increasing the pressures, which is what he was doing with his Ackley improved cases, was safe, because he was not increasing the load on the action. Many in the American shooting community believe that Ackley's case design makes the case carry load and therefore they can pour in the powder and safely increase velocity and increase pressures. People don’t challenge this concept due to the high status Ackley has within the American shooting community. (When you challenge the authority of Gods, their worshippers will burn you at the stake.) Even if he had reduced bolt face load, something I don’t believe in the slightest, the load did not go away. It would have been carried somewhere else, and that else is the barrel chamber. The barrel already carries most of the load created by combustion, because, most of the surface area of the cartridge is in the barrel chamber. He was overstretching chambers, he goose egged one on a Savage M99 action, put on a higher strength barrel and claimed that since the action did not fail, his cartridge concept worked. He never considered the idea that the original barrel materials might be different from that on the action, or that the safety factors of the action were different from the barrel. All of this will cause Ackleyites and Hatcherites to foam at the mouth, clap their hands to their ears, and roll around screaming as if demon possessed. They believe that the action is weak, and the cartridge case is strong, because that is what they were told, and they don’t want to hear anything else.

I looked at one of my Brassey’s books: Small Arms, and chapter 10 starts off with this:

Someone else can do the unit conversions, I have got other things to do. | |||

|

| One of Us |

Wow, that was my only point from the start; that brass in a dry chamber, will hold a lot of pressure by itself. Axially, not radially; it must remain supported. | |||

|

| One of Us |

ONLINE CONVERSIONS... http://www.onlineconversion.com/...takes only seconds to use even if you are too busy to talk or don't know how to do the math....I use it all the time. All of which shows that simple and double talk is only applicable to those who know and blows WAY over the heads of most...and basically is willy waving among the "Illuminati". P.O Ackley's "stuff", if you will or won't, came from a time when most shooters knew LESS THAN diddley and liked it that way and drooled over all the old gun scribes Like O'Connor and Field and Stream. No diss or flame intended, they were the forerunners who stepped first on the "moon" of this sport, made the sacrifices and paid the cost themselves....how many of "us" nowadays can say that...we mostly piss on those around us and think it "Kool" AS I've said before NO weapon system, rifle or ammo came into the world fully decked out...it took MANY baby steps to arrive and P.O. was only ONE of those steps. If you didn't learn anything from him or all the others like Col. Whelen, that is YOUR loss. We know NOW that they were wrong more times than they were right, but we now stand on the shoulders of THOSE GIANTS and STILL shoot off our faces and get it wrong more times than we get it right. Now we have all the tools to dispel all the "by guess and by golly" and get a truer picture of what is going on. and we, hunters and reloaders, STILL CAN'T GET IT RIGHT because of all the BS, smoke being blown and insistence on NOT DOING ANY HOMEWORK. ALL this "HEADSPACE AND WHAT IT IS" is STILL being miss-stated, mis-understood and continually being mis-represented online. It ALWAYS misses the point AND UNDERSTANDING that headspace INCLUDES the TOLERANCES inherent in the manufacture of weapons, ammo and ALL components. Tolerance that can stack together and cause excess headspace or no headspace at all. Very few understand what tolerance's do and I'm not speaking of tolerances in the singular. In a custom rifle the only "headspace", the distance between the base of the case and the bolt face, that is required is the amount necessary for functionality...PERIOD...as long as the sizer die reduces the case dimensions so the loaded round will function, i.e., load, fire and eject, the very minimum "headspace" is fine...phuc whatever definition is used or taught in gunsmithing schools or spec drawings indicate... In a factory or military rifle the same thing can be done...FIT ALL THE COMPONENTS to reduce sizing to a minimum using the CHEAP AVAILABLE TOOLS, the few minutes it takes to prep your brass and LEARN the procedures required to give your brass AND WEAPON SYSTEM long life. This is the same reason I keep screaming for reloaders to FIT THE SIZER DIE TO THE RIFLE CHAMBER OR VISAVERSA, use bushing dies, WAX for sizing and comp shell holders for regulating shoulder setback. Doing so pretty much eliminates case stretching from sizing buttons. This will produce ammo that is "squished" the bare minimum, can be reloaded MANY TIMES and for the most part eliminates case head separation, and requires trimming....AND PRETTY much SHOULD eliminate the ONLINE BS, but never will because the mis-BS keeps re-cycling. What gets me, gentlemen, is the fact that all of you that I would consider "experts" seem to resist, in word online, that doing these SIMPLE PROCEEDURES is anything but worthless. All these procedures work with ANY brass, rifle and pistol and to a limited extent to brass shotgun cases. ADD in annealing and keeping the chamber pressures below the yield point and the brass will last into the hundreds of reloading's. Ah, Well, the horse and the trough seems to rule supreme...and AGAIN...ALL THIS INFORMATION IS AVAILABLE THROUGH A SIMPLE ONLINE SEARCH here on A.R. and if you did, you might find your answer PLUS maybe posit more questions for you to ask...BY USING THE SEARCH ENGINE...then letting folks know of any value. Luck | |||

|

| One of Us |

Right on all counts. I know how to end the confusion; everyone STOP reloading, Use only factory ammo and throw the brass away. There would be no stretching, shrinking, sizing, etc, to worry about. Guys who shoot only factory ammo aren't concerned a bit about all this. | |||

|

| One of Us |

Speaking for myself, I am not at all happy, nor satisfied, with my understanding of what exactly causes case head separation. And I say that in the context of scrutinizing the processes, meticulously, in milliseconds, as they occur. The shot goes BANG. Powder ignites. There is a preliminary spike in the pressure curve just in the short relative distance from the chamber. As the bullet progresses down the barrel the pressure curve drops until the bullet exits the barrel. The height of the pressure spike is contingent on several factors but one that is certainly important is the burn rate of the powder. Internal ballistics calculators show that a person can use a certain powder and far exceed safe pressure level. Then by changing to a slower powder using the same grains it is perfectly acceptable and safe. Then there is the cross section of the chamber, leade, throat, rifling *( sub-categorized as lands and grooves ). Prevailing conventional wisdom indicated that the bullet should be set back from the rifling a distance to get a "running start". At the moment of ignition the case is driven back against the bolt face i.e., recoil. The internal pressure forces the brass out against the chamber walls and up against the shoulder. Now should we consider the difference in rimmed cases, belted cases and rimless cases? A belted case is essentially a rim with a groove. The rim or belt will hold the case head back. Thus the forward portion of the case can be propelled ahead. Of course the huge diversity of calibers, case sizes, and more preclude making one universal conclusion that would fit all. Somewhere in the scenario there is a physical process that apparently holds back the case head and forces the rest of the case forward to cause separation. I just do not have my head wrapped around the precise order of events - yet ! I'm looking at Ken Howells book Designing and Forming Custom Cartridges, and particularly, now, at the rim and belt thicknesses which vary from case to case. This clearance, or wiggle room, between the brass and the chamber still escapes me as I don't have sufficient data on the rifles. I have plenty more to say but will curtail for the moment. From my perspective it is perfectly OK to go ahead and expound more on this issue. Beat it to death. That's how we learn and how we progress. ________________________________________________ Links: http://www.hornady.com/ballistics-resource/internal https://www.google.com/search?...leade+throat+rifling | |||

|

| One of Us |

The firing pin hits the primer and that moves the case forward. Sometimes the blow is sufficient to shorten the case. The thinnest part of the case, which is the case mouth, obdurates and adheres to the front of the chamber. If friction between case and chamber is sufficient high it stays fixed at that location. Then, as pressure builds, case sidewalls are pressed into the chamber, starting with the thinner sections up front. At some point the pressure inside the case is sufficient to stretch the sidewalls axially. And that is when, given a fixed case front, the back of the case touches the bolt face. If the thinnest parts of the case did not expand first, then my tests on the phenomenology of greased bullets would have had different results. Grease was clearly squeezed from the front of the case/chamber, to the back. Some went out the barrel with the bullet, and some was squeezed down the entirety of the case into the action. The picture on the left is an example of "big" grease. The bullet was dipped in lubriplate with the grease completely covering the case shoulder.  The case to the left is unfired "big grease" the case to the right is "big grease" after firing. I noticed no evidence of pressure, for example, the primers of fired, greased rounds.  As can be seen in these pictures, the huge excesses of grease that I applied are squeezed out back of the case, filling the extractor groove in the process.  [/URL [/URLGrease is squeezed into the action areas making for a very messy rifle. [URL=http://smg.photobucket.com/user/SlamFire/media/Reloading/Case%20Lubrication/Greased%20bullets%20test/DSCF069430-06Wherethegreasegoes_zps38e26eef.jpg.html]  I pictured this same phenomena with my 1873 Trapdoor. Here are 45/70 cases heavily greased after dipping and twisting.  The first cartridge to be fired is in the left picture, and a greased, fired case is in the right. Notice how much grease is in the action after a number of these heavily greased rounds have been fired.  A tray of fired, ungreased 45-70’s on right, greased fired 45-70 on left. Ungreased on left, greased on right  In actual fact, cartridge headspace is not critical for heavily greased cases. You will not have case head separations if the case walls do not adhere to the chamber in the early portion of the pressure rise. With low friction, caused by a heavy lubricant layer, the case slides to the bolt face in the early portion of the pressure curve and the case mouth and shoulder area do not lock onto the chamber. This prevents sidewall stretching. Of course this is assuming the firing pin can reach the primer, it is possible to set the case shoulders so far back that the primer can't be hit by the firing pin. I am uncertain whether any lubricant works in the 20,000 to 50,000 psia range. Obviously there was some grease left on the sidewalls but I have no idea whether the friction reducing effects of oils and greases are lost at these high pressures. I am not a bearing designer, but it seems to me that expecting a bearing to stay intact with contact loads of 10 tons to 25 tons a bit pie in the sky. Considering how messy grease is, whether or not you want to grease your cases is up to you, but rest assured, use as much grease as I did in this test, the air will be filled with grease particles. It was very messy. I regularly shoot cases that I have sized with RCBS water soluble lube and fire without removing the lube. They function fine and are just a little greasy to handle. I have shot perhaps tens of thousands of pistol cases, and maybe a thousand rifle cases that had RCBS lube. I have shot tens of thousands of rounds with Johnson paste wax coatings, the wax coating melts under the temperature and pressures of combustion and provides a lubricant layer, just as in the Pedersen round. I do this so I won't have case head separations in my M1a's or Garands.  | |||

|

| One of Us |

Slam: Excellent post. Thanks infinitely. At the risk of repeating myself I'm schooling my grandson and he is most definitely capable of soaking up this sort of information like a sponge. He will be over to see me in a couple of weeks and this is certainly on the next agenda. Yes, I do understand the role of the firing pin. I'm looking at the space/tolerance of the rim or belt movement back and forth but it is elusive due to lack of information. It could be assumed that a rimless case would be more likely to shift fore and aft but the extractor hook has to be included in holding back the case from moving forward. I'm an old, dedicated Mauser aficionado and I rank their system/design tops above all others. Am I on solid ground when assuming that case head separation is essentially and primarily due to excessive loading and pressure ? This reduces to basic physics and economics. Push the envelope and pay the price. Be conservative and enjoy. I'm not judgmental. Whatever floats a shooter/gun enthusiast's boat is perfectly OK with me so long as it is reasonable, safe and doesn't jeopardize the shooter or his bystanders or family. | |||

|

| One of Us |

Wetibbe, Close. It is due to high pressure, but not necessarily excessive pressure. And, even taking care to get a close chamber fit when resizing, a near max load will cause incipient head separation at some point. My 300 Win Mag will be good for about 6 reloadings, and then time to get new cases. My 25-06 will be good for about 10 reloadings, and then time for new cases. Those are both high performance cartridges that are designed to work best when loaded to near max. In some cases, Incipient Head Separation may not be avoided, but it is predictable, and one can decide to recycle their brass after X number of loadings, so as to avoid an actual separation. | |||

|

| One of Us |

Case head separation is due to case stretch. The case can only stretch so far before it breaks. There are several assumptions: we are talking about a fully supported case, not something where excessive case head protrusion causes rupture of the sidewalls. Also, there has to be enough internal pressure to stretch the case sidewalls. And the last assumption is that the friction between case and chamber is sufficient to lock the upper portion of the case to the chamber The gap, between case should and chamber shoulder, something I have been calling cartridge headspace, that gap has to be filled once pressure reaches a maximum. If the front of the case is locked into the chamber walls, the case has to stretch to the bolt face. That is what causes case head separations, given all the previous assumptions. Another unstated assumption that pressures are less than the ultimate of the brass. Early on I stated that the brass case is a gas seal. With normal loads, we are operating above yield but below ultimate. Ultimate is where the brass ruptures. I don't know the ultimate pressure necessary for brass cases to burst. This has to be around 80,000 to 100,000 psia. At some pressure, the brass must go through a phase change and that will cause a complete rupture of the case head. Pressures high enough to turn brass into liquid will damage the rifle, on older rifles, it will burst the receivers if not barrels. I have not spent a lot of time or thought on burst pressure conditions nor the mechanisms, so I could be all wet on this. I mean, who operates their firearms at burst pressures and what do they expect to learn? | |||

|

| One of Us |

Slamfire... there is also the flow of brass from heat and pressure that causes the incipient case separation. The brass has a tendency to flow into the walls of case necks causing them to become thicker after multiple reloadings. Even when proper fit and safe pressures on the high side of the range are maintained, separation will happen eventually. Keeping on the very mild side of safe loading range, and good case/chamber fit will enable brass cartridges to be reloaded for a very long time; much more than 6-10 reloadings. Then the enemy of brass becomes cracks from working the brass around the mouth and neck areas. | |||

|

| One of Us |

I have read that in several gun magazines but I have never seen that in practice. As an experiment, I took one set of 100 LC Match cases through 23 firings. This took more than a year of XTC matches. I never saw any evidence of brass flow front or back. These were fired in a M1a. The Garand action is very hard on brass, experienced shooters recommended to me that I only take a case four or five reloads, which is about 5 to 6 firings, and discard the cases. I would be shown their cases, I would take the worn out ones home and section them, and find that their cases had severe case head stretch. Cost is an important consideration to me. There are those to whom case life and case cost are irrelevant. But for me, the cost of replacing cases after five firings is significant, especially if you are shooting a M1a to earn the Distinguished Rifleman’s Badge . An accomplishment I succeeded in doing with the M1a. I was able to reduce my brass cost after I met a Distinguished HM who was shooting lubricated cases in his M1a. He left the RCBS case lube on his cases, never tumbled or cleaned them, and he said he could take a set of brass all shooting season. And I found the Distinguished HM was 100% correct. Brass life in a bolt rifle can be orders of magnitude higher than what a gas gunner can expect. Bolt rifles are easy on brass, less scratches and dents, and because the bolt is opened when chamber pressure is zero, brass is not extracted under pressure. But bolt gunners do get case head separations and it is due to setting the shoulder too far back when sizing. During combustion the thin front of the case sticks to the chamber and the sidewalls of the case now have to take the stretch to the bolt face. Cases are really meant to stretch once. If cases stretch more than that depending on a number of variables, brass hardness being a primary factor, cases will break due to case head separation. If a bolt gunner only pushes the shoulder back 0.003” his brass has the potential to last tens if not hundreds of reloading cycles. M1’s, M1a’s, are much harder on brass than bolt rifles. Gas guns are hard on brass and it is because they unlock while there is still residual pressure within the barrel. Col Chin calls this the residual blow back effect. This is deliberate and aids in the function of the mechanism. Residual blow back effect will get the case moving out of the chamber if case to chamber friction is low. Unlock must occur while pressures are below case sidewall rupture strength. This also has the effect of stretching the case. Case life in these mechanisms can be greatly extended by the practice of cartridge lubrication. These images are of typical dry cases fired in a M1a. These are from a shooting bud and they are five times fired. Scratches are from a bent paperclip inserted in the case mouth, I was trying to find the side with the deepest stretch ring.  More of the same five times fired dry cases.  Loads: With a 168 SMK/Hornady/Speer/Nosler match I used 41.5 grains IMR 4895 or AA2495 whatever was cheaper. I shot estate sale IMR 4895, I shot 32 pounds of AA2495 through my M1a. AA2495 is a copy of IMR 4895 and the Chinese made version I bought shot exceptionally well. I cut loads, sometimes by half a grain in 90 + weather, but of the brass sectioned below, most of the time I shot a 168 Match with 41.5 grains AA2495/IMR 4895. I also shot 175 SMK’s with 41.0 to 41.5 grains IMR 4895/AA2495. These are hot loads, especially 41.5 grs IMR 4895 and I used them at 600/1000 yards. These are cases fired in my M1a and fired as lubricated rounds. I either left the RCBS case lube on them and primed them that way, or I put on Johnson paste wax on the loaded cases with my fingers. I don’t like the feel of greasy cases and if I had time between matches I would wash the cases to remove the RCBS lube after sizing and then apply paste wax. . If I did not have time I fired the cases just as they came out of the die, minus whatever lube that was lost in handling. I found at Camp Perry in cold weather I had bolt over rides with some of the Johnson paste waxed rounds. This stopped when I polished the rounds. Pervious to that I shot the rounds with swirls and gobs of paste wax but evidentially that caused sluggish round rise in the magazine in cold weather. From then on I polished my rapid fire rounds and have never had a bolt close on an empty chamber even in competitions in snow. I have tried various lubes, paste wax takes the most time to apply but is the most satisfactory for handling. Paste wax dries hard, it is easy to wipe off dirt if you drop a round, and it is cheap. I tried wire pulling wax, bought a bottle at Home Depot, works but not as hard as paste wax. http://www.shop3m.com/wire-pulling-lubricant-wax.html Sometimes I left Kiwi Mink Oil shoe polish on the cases. The picture below are of sectioned cases, R stands for reloaded, R5 five times reloaded, etc, all of these cases the shoulder was set back about 0.003” and the cases fired in my M1a. Even though you see cases 5 times reloaded (6 times fired) , R18, R22, as long as the case is not excessively stretched during firing or extraction, there is no reason for the sidewalls to thin. The FAL cases are from a Bud’s rifle. I think they were separating after 2 or 3 three firings, FAL’s are hard on brass.  My basic conclusion is that if the brass does not failure through case neck cracks, body splits, and you have not stretched them so they develop case head separations, you can load them until the primer pockets get too large , which is why I stopped reloading these cases. I was reaming the primer pockets about every five firings, the pockets seemed to be getting shallower and I reamed them to ensure that the seated primer was below the case head. This is an important safety consideration, nothing should hit the primer except the firing pin. Ensuring that the primer was below the case head in a semi automatic mechanism prevented primer ignition through incidental contact with the bolt face. | |||

|

| One of Us |

I agree fully with Slamfire that case head separation is caused by case stretch...that should be obvious...it was to me and I'm not the sharpest pencil in the coffee mug...way back when I first almost blew off a 30-30 case head in a 94 W...a combination of case stretching through pressure, sizing, action weakness, lockup problems, seating muckups, etc...I don't know HOW I survived those months before finally arriving at Mr....'s doorstep. I took it to a buddies father who was instrumental in teaching BOTH of us just "what the hell and why" and started me on my road as an "experimenter", and to question the "status quo" by "empirically ascertaining" pretty much everything I read as to it's "level of veracity"...what I keep trying to do on forums. Sizing(the reason I keep squalling about FITMENT and tool use) is just as much a causative factor of brass displacement/stretching and is coupled to headspace problems...the case is sized to dimensions less than chamber dimensions, the round is fired and fills out to case dimensions, BELOW BRASS YIELD POINT...(otherwise IF THE PRESSURE EXCEEDS YIELD POINT...the case basically almost welds to the chamber walls)...the brass springs back enough to release its wall grip and the cycle continues...the displaced brass has to come from SOMEWHERE and GO SOMEWHERE. Because the case walls are thinner, require LESS pressure to deform\ and so get plastically "stuck" to the chamber walls...BEFORE the thick portion of the case base starts to move...the base is basically flopping in the breeze and the junction of the wall/base is the weak point and that's where the brass comes from and is basically plastically moved, thinned out, and you trim that amount of movement off when you "cycle" again...hence "HEAD" separation. Several of my early benchrest shooters had chambers so "tight" I didn't have to resize anything but the neck and only enough to hold the bullet...some I didn't even have to do that, just seat the bullet using a Wilson type seater and shoot...others I turned off a section of the neck equal to the depth I wanted the bullet seated at which left a bump that was plastically transferred to the inside of the case by firing, now called a "donut", hand seated the bullet and shot. AS LONG AS I DIDN'T EXCEED THE YIELD POINT OF THE SPECIFIC BRASS CASE...those cases were still going strong after 25 plus firings and needed trimmed only every 10 firings or so...usually on the order of 0.0005" or so. Of course it was easy to "KILL" a case by over pressure and/or stretch out a primer pocket because all the "Normal" pressure indicators that keep getting bandied about were NOT present...so I used accuracy and common knowledge as to where to stop "stuffing in the powder". I've used 30 wt oil mixed half and half with STP(slick as ****** and hard to hold loaded rounds) to fireform some wildcats, basically following something I read that earlier wildcatters did, to ease the fire forming process and also to form in a sizing die. Yes, it was messy, not sure if it was any more successful than just fire forming the "regular" way, and gobbing up the bullet and case front doesn't help now that we should know WHERE the brass movement actually is. I definitely don't agree with beating something to death and going over and over old ground is in any way conducive to anything but basking in the light. ANONE that want to understand "headspace" has tons of data at their fingertips...MODERN DATA...which I thing is more pertinent than beating the horse to death with an old stick, and I would MUCH rather read of the LATEST innovations or experiences of posters.. I would ALSO much rather read of rifle building or ammo development exploits and problems, amusing anecdotes and muckups that DO TEACH, than going over old, already answered questions. Yeah, yeah...DON'T READ. I'm STIL interested enough to try to redirect to an more appropriate direction and never knowing if my efforts are appreciated or not. Most posters(me included) are attempting to answer the basic question, but due to excess verbiage and getting into extraneous examples, talking about the same thing but using different words and not quite understanding the others, the old problems of communication rear it's ugly head, and we go wide of the mark. It is these times that my failures to communicate makes me cranky which also doesn't help. Headspace to me is a very simple problem compounded by complicated and inadequate definitions. For those "Illuminati" the question has already been answered and understood. For those others, understanding comes with experience and actual "doing", then thinking/figuring it all out...and that CAN'T be learned just from online words, NOR TAUGHT online, unfortunately...following directions only doesn't mean your are learning...getting your hands dirty and keeping things SIMPLE...K.I.S.S., you know, along with the books, has been shown by teachers and psychologists to be the better way to "Illumination". Luck | |||

|

| one of us |

Headspace and case separation, whether in the rifle or caused by the loading process, drove me nuts. Especially because I was loading many different cartridges and allowing many people to use my loading setup. I solved the problem by keeping record of load development for a particular rifle and by using this method for seting up the sizer for every rifle. On the record at 'Sizer Die Clearance from Shellholder', the reloader takes the measurement with a feeler gauge. I have been doing this for 15 or more years and no reloader, who uses my bench, has ever had a case separation in that time. | |||

|

| One of Us |

I have a set of dies for each rifle that has a different chamber (the ones I build all have below minimum headspace chambers); That way, you set it and forget it. No adjusting, no gauges, no grease; no worries. That way keeps your brass from stretching as it all fits it's own chamber perfectly, meaning, with no excess room from the bolt face to the shoulder. | |||

|

| One of Us |

Smiley Face: I'm an old Buck dating back decades. I knew EVERY THING back then and I have forgotten 50% currently. Great bunch of Guys. | |||

|

| One of Us |

______________________________________________ Slam: I'm a very old customer of Lyman. As you know they date back to 1878. I phoned and spoke to customer service who gratuitously sent me their 49th edition of Reloading as well a Cast Bullet manual, mysteriously free of charge which I greatly appreciate. Upon reading - they specifically warn against applying lubricants to cases as you specify in your post. Thus it works for you but I'm wondering if the attorneys are issuing CYA *( Cover your axx ) advice ? Where should we go with these dilemmas and conflicts ? | |||

|

| One of Us |

The concept that grease or oil on the cartridge creates a dangerous condition is an interesting case of the fallacy of “argument from authority”. After reviewing all the information I can find , I am of the opinion that this was originally created by the US Army Ordnance Department to hide and misdirect failures from the population of 1 million “low number” M1903’s. These rifles were made at Army Arsenals and as the designer and manufacturer, any inherent problems with rifle, in the hands of civilians or Navy and Marine personnel, were the responsibility of the US Army. The Army also wanted competitors to stop greasing their bullets. At the time the Army was loaning out rifles to Gun Clubs and to competitors at the National Matches. Eliminating greased bullets would eliminate the risk of dirt getting on the grease and scratching the chambers/barrels of their loaner rifles. The idea that greased bullets or greased cases creates a dangerous condition would have died decades ago if it had not been in the 1947 book “ Hatcher’s Notebook” . Hatcher’s Notebook is the ground zero for all the concerns expressed in the American shooting community about greased bullets, oiled bullets, lubricated bullets, lubricated cases, oiled cases. Townsend Whelen is the man actually responsible for creating the data set that the Army and Hatcher used to claim dangerous pressure increases. These men are revered by the American shooting community. Given the statue of Hatcher and Townsend Whelen (recently called “Mr Rifleman” or “the Dean of Riflemen”) within the shooting community, and the decades spanning their unchallenged claims that grease (and/or oil) dangerously raised pressures, it is no wonder that the shooting community is thoroughly indoctrinated with this belief. It is however, fallacious. The only real problem I have, since the participants are all dead, particularly General Hatcher, is the extent to which they themselves believed this, in spite of all the evidence they had to have seen which contradicted what they were telling the American public. General Hatcher is a most peculiar case and the strong reverence for General Hatcher is such that by claiming he is not infallible, in fact, is quite fallible, will result in strong and vicious push back from his fan base. When authority is considered so highly that no one dares or cares to challenge them, when these same Authorities are wrong, they can cause amazing damage and delay progress within society. It is very human to appeal to authorities, and since no one can know everything about everything, at some point we all rely on experts. But time has shown again and again, experts are not infallible or inerrant, they have their bias, their knowledge gaps. No matter how high a pedestal they are put on, eventually they are shown to be imperfect humans. I think it is totally amazing that Hatcher writes what he does and yet he was the Head of Ordnance during WW2. He had access to the interiority of the Ordnance military industrial complex. He had authority over all the test labs, test facilities, even equipment manufacturers, which is why of course, why his authority is so high among the shooting community. We don’t know all of what Hatcher knew. He is a primary source on single heat treat 03’s, the blow up lists, the development of the Garand, his Textbook of Firearms Identification and Evidence was a primary forensic source for law enforcement. In so many instances Hatcher is the sole and primary source. And yet, knowing what he actually did know, knowing what his associates knew, knowing what he therefore should have known, I find his section on greased bullets and the tin can ammunition extraordinary. How could he not have known that what he was writing was bunk? I waffle between believing that Hatcher knew it was a cover up, but, based on readings elsewhere, I am discovering that the human capacity for self deception is infinite, so maybe Hatcher actually believed in what he wrote, ignoring anything contradictory to the nonsensical theories he prints in his book. This is going to torque the sensitivities of those who put Hatcher on a pedestal, and live with a romantic view of Springfield Armory and the Army, but I am going to call Hatcherism the belief that Cartridges should never be greased or oiled, and the bullets should never be greased. Grease on the cartridge or in the chamber creates excessive and hazardous pressure. It operates to reduce the size of the chamber and thus increases the density of loading and the pressure. These are Townsend Whelen’s words; General Hatcher did not come up with this belief system , it is in fact based on a data set created by then Major Townsend Whelen, but Hatcher is the “St Paul” of this religion. Without him this would have faded away and at best, would have been a historical curiosity. Hatcher is the source from whom all Hatcherites go, quoting chapter and verses from his 1947 book, Hatcher’s Notebook, on greased bullets, greased cartridges, lubricated cartridges and pressures. While General Hatcher and Townsend Whelen are educating the public about the evils of greased bullets, they are in fact, only reflecting an Army official position. The Army built over 1 million “low number” Springfield rifles and from Hatcher’s Notebook, about 33% will fail in high pressure incidents. A un known number failed structurally in normal service after firing issue ammunition. The dollar amount for the population of suspect rifles was close to a billion dollars, in today’s money, so this problem is not trivial, nor were the injuries caused. Since the Navy Department, the Marines, and civilians were using this rifle, the cross service embarrassment factor of making and issuing defective rifles would have been extremely high. No one in the Army accepted responsibility for the defective rifles, in fact, I can’t find the Army ever admitting in public that they made defective rifles. It did leak out after 1927, but I have not found an official statement from the Department of the Army. At the time of the creation of Hatcherism, which goes back as far as WW1, the Army was not telling anyone about structurally deficient M1903’s. Instead the Army is misdirecting the cause of M1903 rifle blow ups onto shooters. The root cause of the Army’s problems with low number M1903’s is the Army’s institutionalized failure to confront problems within their Arsenal system. The human capacity for denial and self deception is infinite, infinite too is the Army’s capacity to shift blame from itself on to others. These behaviors are not unique to the Army; the longer I live, the more I find that all large organizations are totally self centered, have no guilt or shame, never accept fault for the problems they create. And they are all outstanding at finding scapegoats. This is regardless of whether the organization is a commercial concern, a religious organization, or a Governmental unit. So, what does the historical record say about Hatcherism?: Well, how could Hatcherism be true, and yet Hatcher be wrong? Here is an excerpt that Hatcher wrote in 1933: Army Ordnance Magazine, March-April 1933 Automatic Firearms, Mechanical Principles used in the various types, by J. S. Hatcher. Chief Smalls Arms Division Washington DC. Retarded Blow-back Mechanism……………………….. There is one queer thing, however, that is common to almost all blow-back and retarded blow-back guns, and that is that there is a tendency to rupture the cartridges unless they are lubricated. This is because the moment the explosion occurs the thin front end of the cartridge case swells up from the internal pressure and tightly grips the walls of the chamber. Cartridge cases are made with a strong solid brass head a thick wall near the rear end, but the wall tapers in thickness until the front end is quiet thin so that it will expand under pressure of the explosion and seal the chamber against the escape of gas to the rear. When the gun is fired the thin front section expands as intended and tightly grips the walls of the chamber, while the thick rear portion does not expand enough to produce serious friction. The same pressure that operates to expand the walls of the case laterally, also pushes back with the force of fifty thousand pounds to the square inch on the head of the cartridge, and the whole cartridge being made of elastic brass stretches to the rear and , in effect, give the breech block a sharp blow with starts it backward. The front end of the cartridge being tightly held by the friction against the walls of the chamber, and the rear end being free to move back in this manner under the internal pressure, either one of two things will happen. In the first case, the breech block and the head of the cartridge may continue to move back, tearing the cartridge in two and leaving the front end tightly stuck in the chamber; or, if the breech block is sufficiently retarded so that it does not allow a very violent backward motion, the result may simply be that the breech block moves back a short distance and the jerk of the extractor on the cartridge case stops it, and the gun will not operate. However this difficultly can be overcome entirely by lubricating the cartridges in some way. In the Schwarzlose machine gun there is a little pump installed in the mechanism which squirts a single drop of oil into the chamber each time the breech block goes back. In the Thompson Auto-rifle there are oil-soaked pads in the magazine which contains the cartridges. In the Pedersen semiautomatic rifle the lubrication is taken care of by coating the cartridges with a light film of wax. Blish Principle….There is no doubt that this mechanism can be made to operate as described, provided the cartridge are lubricated, …. That this type of mechanism actually opens while there is still considerable pressure in the cartridge case is evident from the fact that the gun does not operate satisfactorily unless the cartridges are lubricated. Thompson Sub-Machine Gun: … Owing to the low pressure involved in the pistol cartridge, it is not necessary to lubricate the case. If lubricated cases dangerously increase bolt thrust, as Hatcher says in his Notebook, which is the authority Lyman bases their warnings, how come lubricated cases are not dangerously increasing thrust in the blowback or delayed blowback mechanisms? Maybe the laws of physics are different for these firearms than other type of firearms? Maybe one mechanism operates using one set of physical laws and another mechanism has its own unique laws of physics. Maybe certain mechanisms use magic, and operate outside the known laws of the universe. Or perhaps, Hatcherites believe in magic. What about Melvin Johnson and his comments?: Army Ordnance Oct 1936 What Price Automatic?, by Melvin M. Johnson, Jr. Several methods have been devised to retard the unlocking of the block or bolt mechanically. The most appealing point in such a system is consolidation of the “automatic” parts in the breech. However, there is one serious difficulty. The conventional cartridge case does not lend itself to such a system unless adequate lubrication is provided, such as grease or wax or oil on the cases or in the chamber. Thus, the Schwarzlose machine gun has an automatic oil pump: the caliber 30 Thompson rifle (not the caliber 45 T.S.-M.G.) had oil pad in the magazine, and special “wax” was needed on the cases designed to be used in the Pedersen rifle. Pedersen was granted a patent for coating cartridges with wax lubricants. PATENT OFFICE JOHN DOUGLAS PEDERSEN, OF SPRINGFIELD, MASSACHUSETTS, Nov. 4, 1930 http://www.google.com/patents/US1780566 In the preparation of cartridges having metal cases for storage and for use, it has been found desirable to apply to said metal case a relatively thin coating of some protective substance which will preserve said metal case for comparatively long periods of time against-deterioration, such as season cracking. In the present invention, the material for said coating has been so chosen as to perform the additional function of acting as a lubricant for the case of the cartridge, both for facilitating introduction into the chamber of the gun and the extraction thereof after firing. The most suitable wax which I have found for this purpose and which I at present prefer is ceresin, a refined product of ozokerite; but I wish it to be understood that other waxes having similar qualities may exist which might serve equally well. Some of the desirable features of ceresin are that it is hard and non-tacky at ordinary temperatures having a melting point somewhere between 140 and 176 Fahrenheit. It is smooth and glassy when hard and does not gather dirt or dust. However, when the ceresin on the cartridges is melted in the chamber of a gun, it becomes a lubricant. Other lubricating waxes have been employed for coating cartridges, and the method most generally pursued for applying said coating to the cartridge case has been to prepare a heated bath of a solution of the wax in a suitable solvent, dip the cartridges therein so that a film of the solution will adhere thereto, and finally withdraw the cartridges to permit the solvent to evaporate from the coating film. This former process is comparatively slow and has been found lacking in several important respects. A patent was in 1977 for coating cartridge cases in teflon. It is worth reading the whole patent, I have only copied a small section. http://www.google.com/patents/US4041868 Polytetrafluoroethylene US 4041868 A 1977 A thin walled steel cartridge case having a substantially larger internal volume than a conventional cartridge case. The cartridge case is fabricated from a high strength, heat treated carbon steel or boron steel and the wall contour in the head area is designed to avoid localized high stress. A low friction coating is applied to the outer surface of the cartridge case and serves to reduce stress concentrations in the head area and to reduce extraction force in the event of interference between the case and the chamber during extraction As to the historical use of oilers in fielded weapon systems, I recommend that all read The Machine Gun History, Evolution, and Development of Manual, Automatic, and Airborne Repeating Weapons by George M. Chinn Lieutenant Colonel, USMC VOLUME I OF FIVE VOLUMES http://ibiblio.org/hyperwar/USN/ref/MG/I/ Do notice that Major General Hatcher is mentioned on the acknowledgements. Schwarzlose Machine Gun, 8 mm. page 231 This system is appropriately designated retarded blow-back. Due to the fact that the cartridge is extracted under relatively high gas pressure, it was found necessary to lubricate the ammunition. Schwarzlose settled this problem by installing, as an integral part of the weapon, a pump to lubricate the cases. This device pumped a squirt of oil in the chamber between each extraction and loading. The combination of the lubricated ammunition, heavy spring, large bolt assembly, and short barrel allowed the use of an unlocked action which proved quite satisfactory. Chapter 16 Revelli Machine Gun --251-- An oil pump for automatic lubrication of each round was an integral part of the receiver. Chapter 8 Nambu Automatic Weapons page 353 All Nambu machine guns were gas operated and air cooled with many radial fins giving more surface for cooling. The earlier models had rectangular gravity oil reservoirs so that as rounds were fed into the feed opening they engaged a spring-loaded lubricator. This action caused oil to flow through perforations onto the cartridge cases. Such lubrication was needed because manufacturing the components to such close tolerances as to permit a workable head space had not been possible at the time. The oil permitted the cartridges to slip back against the bolt until lock clearance was taken up, thereby eliminating the danger of a ruptured cartridge case Such lubrication was needed because manufacturing the components to such close tolerances as to permit a workable head space had not been possible at the time. The oil permitted the cartridges to slip back against the bolt until lock clearance was taken up, thereby eliminating the danger of a ruptured cartridge case Chapter 9 Revelli Aircraft Machine Gun page 354 The Italian Air Force during World War I was so desperate for an adequate rifle-caliber machine gun of native origin that it ordered the lightening of the water-cooled 1914 model Revelli. This was accomplished by the removal of the water jacket and use of an air-cooled barrel with longitudinal ribs. It not only gave more cooling surface but also strengthened the barrel, cutting down dispersion. The rate of fire was increased by use of ammunition more thoroughly lubricated by means of a built-in oil pump. Chapter 21 Breda Machine Gun page 416 A large oil reservoir was built into the top of the receiver, directly over the feedway. This lubricator was operated by the recoil and counterrecoil movement of the barrel and barrel extension, squirting oil with each complete cycle on the rounds then being positioned on the floor of the feedway. Page 419 Like all Italian machine guns oil was used freely on the ammunition since head space was not adjustable on the weapon. The fixed relation between the front face of the breech-lock receiver and the gas port in the barrel made impossible rotation of the barrel in order to advance or retract the chamber for correct head space. The oiling of the ammunition was resorted to in this case in order to compensate for the above condition. Chapter 29 Sistar Machine Gun page 465 The light machine gun, while having only a 20-shot magazine, did have a feature that the company made great effort to demonstrate on every occasion. The gunner, without rising, could pivot the swinging magazine forward from the prone position and insert in a matter of seconds a fresh supply of loaded rounds directly from the cardboard container into the feed system. By this ease and speed in loading he could keep up practically uninterrupted fire. The weapon was recoil operated, the barrel having an open jacket that gave it support and a bearing for "floating" the recoiling parts. A built-in oil pump on the left side of the receiver sprayed a small jet of oil on the incoming rounds as each was positioned for chambering. This device was actuated by the recoil and counter-recoil movement of the barrel extension. Polsten Cannon page 521 One of the principal differences between the Polish-designed gun, known officially as the Polsten 20-mm Automatic Cannon Mark I, and the original Oerlikon was the built-up receiver of welded construction which had heretofore added greatly to the machining problem in mass production. The Polsten gun was also lighter in weight, but as the weapon was intended for shipboard and ground use, this did not seem of too much importance to the British. It could be fed both by clip or drum magazine, and could only be fired full automatic. Chinn does not mention that the rounds for the Polsten Cannon were greased but this will be found in Brassey’s “Small Arms” by Allsop and Toomey. In fact, Brasseys Small Arms has a whole section starting page 70 about case lubrication. The Machine Gun Part V Chapter 14 Birkigt Type 404 20-mm (Hispano-Suiza) Cannon --578-- After further comparative tests in late April 1942, it was again definitely decided by the Ordnance Department that all American-made 20-mm automatic guns continue to be made with the chambers longer by one-sixteenth inch than the British regardless of the employment of the same ammunition. This decision was final as far as American production was concerned, but in no way did it change the British representative's view on the longer chamber's performance. Oddly enough, the question was again raised, not by the English or our many proving grounds, but by manufacturers of 20-mm ammunition. In testing their cartridges for reliability of action, they encountered a series of malfunctions known as light-struck primers that were all out of proportion for such a weapon. These were not isolated cases, the reports coming in from practically every maker of 20-mm ammunition that was engaged in function firing his products. Since the munitions companies pointed out that the faint strikes were due to lack of impact on the primer resulting from error in the gun, and not as a result of defective materials or workmanship, it was decided to conduct another test on an extensive scale at Aberdeen. Ninety of the 20-mm guns, M1 and AN-M2, selected from every facility producing them, were expended in this test with all types of ammunition, both from accepted and rejected lots. A complete record was made of every malfunction during the entire test and the probable causes of the trouble. The engineers in charge of the project in the early stages of this test recommended that two modifications should be made to overcome the serious malfunctions: "(1) Shorten the chamber one-sixteenth inch, thus modifying it to approximately the British chamber. "(2) Replace the extractor spring with a solid plug, thus positioning the rounds by means of the extractor. This change would include such modifications to the extractor, the bolt, and the ejector, as were deemed necessary."--588— During war all that can be done is to install and make function as reliably as possible that which is issued. With the mounting of the 20-mm cannon in Navy, planes a series of malfunctions began that could not be properly corrected at the time because manufacture was at the peak of production. The slightest change would practically mean retooling. The most serious problem was the oversize chamber. There still remained considerable variance in dimensions between the chambers of the British and American cannon, even after the latter chamber was made one thirty-second inch shorter Due to an outmoded agreement of long standing, everything above caliber .60 in the Army is considered artillery and the manufacture of the Hispano-Suiza cannon therefore came under this classification. In other words the production of this high-speed machine gun was done under artillery manufacturing tolerances. The resulting poor mating of parts, coupled with the inherent fault of all gas-operated weapons whereby the breech locking key in the receiver is immovable and the position of the gas port in the barrel is permanently fixed, made it impossible to adjust the relationship between barrel and breech lock to establish head space. Thus the most vital measurement in any automatic weapon was governed by chance in this instance. An unfortunate discovery was that chamber errors in the gun could be corrected for the moment by covering the ammunition case with a heavy lubricant. If the chamber was oversize, it served as a fluid fit to make up the deficiency and, if unsafe head space existed that would result in case rupture if ammunition was fired dry, then the lubricant allowed the cartridge case to slip back at the start of pressure build up, to take up the slack between the breech lock and the breech lock key. Had this method of "quick fix" not been possible, the Navy would have long ago recognized the seriousness of the situation. In fact, this inexcusable method of correction was in use so long that it was becoming accepted as a satisfactory solution of a necessary nuisance. Over 150,000 of these machine guns were built by General Hatcher's Ordnance Department during WW2, and they all used greased rounds. The Navy also used the same mechanism. There is a neat copy of the manual for the Oerlikon at the web page referenced below 20 mm Oerlikon http://archive.hnsa.org/doc/gun20mm/index.htm

So, as a sort of wrap up, that Lyman manual warning, how credible is it based on the historical use of grease, oils, waxes, and teflon to reduce case to chamber friction? And, considering all the weapons systems that used grease, oils, and waxed cartridges that Hatcher shot, built, fielded, as head of the Ordnance Department, how could he write what he did in Hatcher's Notebook? Is Hatcherism based on science, or magic? | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia