The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Case Head Separation Waiting To Happen

Case Head Separation Waiting To HappenGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

[QUOTE]Originally posted by Hot Core: Simple, you CAN NOT be Thingy King Jr. without Thingys. [QUOTE] I've got my work cut out for me. woods, I obviously am Thingy deprived. Can you please post a list of Thingys that I will need to avoid problems like this in the future? Signed, TKjr in training | |||

|

| One of Us |

Without the Stoney point tool or similar you have no way of knowing what happens to each case when it is FL sized. The location of the shoulder can be changed .001 to .002 just by the amount of lube on the case or speed of the resizing stroke. With the tool you can check every case after sizing and know how it fits your chamber. A lot of the rest is just "ferry tells". | |||

|

One of Us |

Grasshopper

Best wait until you run across problems and then you will be more amenable to suggestions. If I had told you a month ago that a Hornady headspace tool was a good tool to have, you wouldn't have been ready to accept it.

Also

OK I made that last one up! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Add to that the stage of work-hardening that the brass is in. Hopefully that can be managed by firing the brass in lots and firing each piece an identical number of times... | |||

|

| One of Us |

| |||

|

| One of Us |

Butchlambert, Thank you for the question. I do have an intent, an intent to provoke someone to think, there are times in my effort to provoke I am accused of building boobie traps into a response, I deny that, I do not have to make an effort, boobies are too easy to catch. The choir started with 'most of the stretch' and' first firing', I gave 5 examples of first firings of cases that did not stretch between the head of the case and case body, I gave two examples of 2 rifles, 03 Springfields, that had two completely different outcomes, Hatcher for one, predicted the case would separate with .080 thousands head space, the other, two friends that used Springfield actions to build 5 rifles, they made the reamer, they cut the chamber, they did it all and had 4 case head separations out of 10 cases fired on the first rifle completed. and I said to one of the individuals that built the rifles Hatcher was correct but did not get the results he anticipated, my friend anticipated the getting the same results Hatcher got during his experiment, but instead got the results Hatcher anticipated, and I said to him, "I could have fixed it" , before the rifle left the shop or after the problem was discovered at the range, if they got to the range, they were in wide open West Texas. Hatchers cases did not stretch even though he had a built in/known head space of .080 thousands, again I fired 8mm57 ammo in an 8mm06 chamber, my cases did not stretch between the head of the case and case body despite .127 thousand head space, and straight away for those that can read and are not dunces there is no guessing what barreled/action I was using, it was not a Springfield. my friends and Hatcher used the Springfield and got different results and I said "I could fix it" in an attempt to provoke thinking I bring out the 'silly' in 'some' people. As with the collector, resource type builder, he handed me a box of head space gages, he wanted to know what the head space on his new period correct 1911 Rock Island straight bolt handle rifle, he did not want to know if the go-gage would chamber, I told him I could use the go-gage to determine head space in thousands, I told him I could modify the go gage to a go, no and beyond to infinity gage that could be used to measure the length of the chamber from the bolt face to the shoulder in thousands, but, he was not shooting gages, he was shooting ammo. And he had a hydraulic reloading press, install a case in the shell holder at the top of the ram, touch a button and like a punch press or trip hammer, the case was sized. And then there are the 308 Winchester cases fired in 'machine guns' ?, my favorite 308 Winchester fired case, my favorite 30/06 case is the 280 Remington, not all the cases I acquire are acquired with the intentions of firing, cases are tools, tools can be used as transfers and standards, gadgets are nice, not necessary but nice. And when determining the predictably of a case separating when fired and checking head space some remove the extractor and firing pin, NO? they check for one but not the other. F. Guffey | |||

|

| One of Us |

| |||

|

One of Us |

/////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

| One of Us |

I bet Mr. Guffey has intimate knowledge of the proper alignment between the Panometric Fan and Spurving Bearings he'd like to share... | |||

|

| one of us |

Whoa there, cowboys! Take a look at those two cartridges again. One of them definately shows case wall thinning which is probably due to brass flow. However, the other shows no appreciable thinning -- only as much as normally occurs with the first firing in a chamber that is within normal headspace dimensions (meaning short enough to make the primer go off every time). It looks to me that rcamuglia's primary problem is with work hardening, not with brass stretching. I could be wrong, but since no one here is my wife, at least I stand a chance of being right | |||

|

| One of Us |

Confucious also say: Woman who fly airplane upside down has crack up!! I couldn't resist Rick | |||

|

| One of Us |

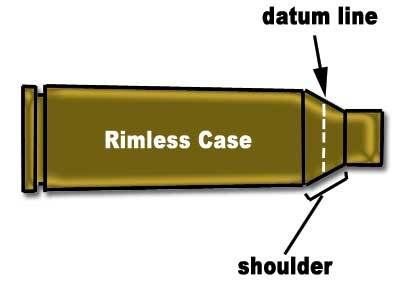

Just used the HC approved headspace Craftsman 3/8" socket gauge to check a factory once fired case and a factory unfired case. The fired case grew .002" Please keep in mind that the socket may have been inhibited from contacting the "datum line" on the shoulder by the thick grease in the hex's and I also neglected to use my feeler gauges because I couldnt find them on the bench | |||

|

One of Us |

You will get a more accurate measurement from a ThingyKing approved proper tool but there may not be much difference. The case will grow some more if you only neck size and don't push the shoulder back after the first firing. You should be able to reload at least twice more before you get a harder to chamber case. So you have a chamber with headspace of ~.003" and you were pushing the shoulder back .006". The constant pushing the shoulder back and restretching caused your head separation. Classic example. If you want easy chambering in the field then you can achieve that with pushing the shoulder back .0015" and the brass will last much much longer. But you've already figured that out.

____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

You must find the "datum line"  but feeler gauges  are pretty useless on the reloading bench. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

I've been looking for a datum line. I checked in a few reference manuals and they said a line up of good lookin' babes is great and you should try to date 'em all. I'm glad I've been doing something right. Where's my feeler gauges?... | |||

|

One of Us |

datem line  feeler gauge  ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Would I lead you WRONG? I DO NOT remember mentioning about the Grease, but that is one of those close-to-the-vest Secrets. It holds the Gauge(Aaah Socket) onto the Case better so you can get Precise Datum Line measurements. Of course, everyone probably knows that anyhow. ----- Absolutely! Or, you can eliminate Bumping-Back, go to a P-FLR for a "Snug Crush Fit", eat your Wheaties and have Cases that last a l-o-n-g time. | |||

|

| One of Us |

Woods, I have never seen and or heard of any one look at the datum illustration and say anything that indicated they understood the illustration and I do not know of anyone that can use the illustration in a practice demonstration. Those that have advanced beyond repeating what they have heard and understand describe the datum line as a round hole, circle, the round hole for the 30/06 is 3/8" or .375, those that have gotten past the datum as a hole make up thieir own datums, they simply choose a datum, circle, round hole that fit into the understanding of varying diameters created by a tapered cylinder, and if on this forum members spent as as much time trying to understanding as they do being silly some could take advantage if simple tools if they understood the tool and it's uses. Claim to adjust the die to avoid setting the shoulder back by adjusting if .0015 etc., etc. How do you do that!!!? I am not so conceited, arrogant or overbearing that I can guess the gap to .001 thousands, I do not claim to have the ability to adjust the die in fractional turns as in 1/71 turn of the die = .001, I do not claim to have an index on my press that allows adjustment in degrees or thousands (there is one press that does) but if I could or did have the index, I would use the companion tool to the press, the feeler gage to verify the gap, but why, for those that keep up with two thoughts at once, why not go straight to the feeler gage and and skip the the busy work, skip the guessing. Others that have caught on have started to give dimensions to the illustration as in depth, then they have an epiphany, they realize it is not that complicated and understand I purchase datums, and they understand what they look like and then they understand my critique of cute, nice to have tools, that would be tools that are not necessary but nice to have. A man claimed to be the inventor/designer of the add-on tool to the dial caliper did the same thing you did, he ignored me, the nice part was he did not have the big ego and being a very smart and cleaver person knew his way was not the only way, not a problem but he was pushing his tool on a reloading form (like Larry Willis) BUT he did not introduce himself as being the the designer/developer/maker of the tool, was not my intent but somehow he found it necessary to defend his tool. There have been times I have attended gun shows and find a box of what appeared to be junk for for junk prices, I look at the junk and say "DATUMS", the dealer will say "I do not have DATUMS" someone else will say "WHERE" and then the person that has a chance of learning and does not know all they will ever know will say "What does a datum look like" and I say "The datum is not a line" and it is possible to search the archives and find the datum illustration, most have 'datum line', I thought the illustration was insulting to reloaders, then there was the datum was half way between the junctures of the shoulders and the same datum (3/8= .375) was used for the 25/06 and 30/06 and the 270, and 8mm06 and then I ask "How can that be"? if the shoulder on the 25/06 is longer than the shoulder on the 30/06, and they did not understand the varying diameters created when by a tapered cone. The die, seater or full length, can be adjusted with a depth micrometer, dial caliper height gage height gage, a depth micrometer, a dial caliper OR A FEELER GAGE for some task, then there are those tha claim they can make that adjustment in thousands by checking the day light between the top of the shell holder and bottom of the die, me? I am not that arrogant, even if I was I would still verify the gap with a feeler gage, so rather than show off, I go straight to the feeler gage. I received an e-mail an enquiring reloader he received from the most prolific pusher of reloading tools on the Internet, the pusher of reloading tools omitted things like transfer, standard and verify, anyhow, the inquiring reloader ask the prolific one "Yeah, how do you get the measurement from your comparator? to the press" and the inquiring reloader said to me "You just might find this interesting". I agree, the reloading bench is no place for a feeler gage if you do not understand, transfer, standard or verify. I make this effort based on the outsidde chance there are reloaders reading this that do not know ever thing there is to know and understand this is an effort to share, not sell a thought and or an ideal. F. Guffey | |||

|

One of Us |

Hook,line & sinker! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

| |||

|

| one of us |

| |||

|

One of Us |

Hole sizes on the Hornady inserts '06  win mags  6mm  224  The pin gauges that were .001" larger on each insert were just a little too hard to get in but since they were all within .001" then the intent is clear. SAAMI datum line dimensions vary from caliber to caliber but still the most important thing is the relationship of the measurements to each other. IOW use the same insert that hits the same place on the shoulder every time on the same calibers and the tool will give you a measurement you can use. Hornady is making the inserts so that they hit very very close to the datum line  Mr Guffey, would it make you happier if we called it the datum circumference Although the definition of circumference does use the word line a lot

Just can't figure out how to make this simpler than it is! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Man are you confused. The standard datum circle is necessarily depicted as a line on a 2D drawing. The standard datum location for a 30-06 was also used for the derived cartridges. Only a bone head would expect the datum to be move a few thousandths just because the cases were necked up or down. The datum can be where ever it is standardized to be. That includes the rim face, belt edge, mouth of the case or datum circle on a shoulder. Datums are a necessary thing in the real world or manufacturing. | |||

|

| one of us |

They died of old age. | |||

|

| One of Us |

I don't think so. I have never had a split neck. I anneal every 3 firings. The cause of death was bumping the shoulders too much too often | |||

|

| one of us |

Yes, w-a-y tooooo much Datum Line Smashing! | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Case Head Separation Waiting To Happen

Case Head Separation Waiting To Happen

Visit our on-line store for AR Memorabilia