The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Case Head Separation Waiting To Happen

Case Head Separation Waiting To HappenGo  | New  | Find  | Notify  | Tools  | Reply  |  |

One of Us |

That's the one. See the collet does not have to hit exactly on the datum line as defined by SAAMI. The measurement you get is just relative to the next measurement. IOW if you get a reading of 3.00" on a new case and then a measurement of 3.008" on a fired case then you know the shoulder has moved forward .008". When you get a crush fit on the 3rd or 4th firing and you get a measurement of....say....2.551" then you can set your sizer to push the shoulder back to 2.550", even if it does not apparently relieve the crush fit. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

I will now disappoint HC and enter the realm of "Thingynessism" | |||

|

| One of Us |

That's factual an thanks too Woods He's set me on the path of super accurate handloads .Group sizes don't lie !. YES with the thingy ! One of the best investments made is the THINGY , because it WORKS AND YOU KNOW WHERE YOU"RE AT !!!. An it ain't Kansas Toto !. | |||

|

| One of Us |

I just ordered it from Midway. I hope HC can find it in his newly reconfigured amiable heart to forgive me. Wait, it's 7:30. HC is asleep with a rooster under his arm. | |||

|

One of Us |

I just had a vision of HC waking up, turning on his computer with his rooster under his arm, reading your post and getting so shocked and pissed off he wrings the rooster's neck!! And it craps all over his keyboard! Save one of your loaded rounds so you can measure it and compare it to one of the fired ones. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

I've got factory fired brass that was loaded INTO the lands. When I get the thingy should I just measure a factory loaded round and then the fired factory round? | |||

|

One of Us |

Yes but that won't tell you the source of your case head separation problem. The question is whether you have actually been pushing the shoulder back the minimum or not. Whatever measurement difference you get between the new factory and a fired round will tell you what ~85% of your headspace is. I suspect that will be around .006" or so. The main application will come when you do your sizing. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Aaaaahhh....., Fried Chickey for Dinner. ----- The only problem I anticipate when R gets the Thingy King approved Thingy is when he tries to repeat a measurement. Come to think of it, the old Tea Leaves indicate that Makers Mark will be in short supply within the N.M. area when that happens, over, and over, and over, and over.... | |||

|

| One of Us |

I agree that the bulk of case stretch comes from the first firing BUT brass continues to stretch with each subsequent firing and resizing no matter what you do. The milder the load the less noticeable this becomes. The hotter the loads, the more noticeable. With each firing the case stretches or "flows", which would be a more accurate description. That is why we all eventually have to trim our cases. If you load very mild loads and hold resizing down to a minimum then this all occurs in very microscopic amounts and case trimming is very seldom needed, some would say never needed but that is not true. Someday you will have to trim it will just be sometime down the road. The brass ALWAYS expands outward to fill the chamber and beyond, and always flows forward towards the case mouth as this is the open end with no restriction against it. Then when the case is resized, this expansion is forced out towards the case mouth even more, as this part of the die is also open ended just like the rifle barrel and action. R-C, As a one of my high school teachers once told me: " There are things that you must have and things that are nice to have". IMO The only "thingies" you really must have are a caliper or some form of accurate measuring device, your rifle action, a piece of wire with a 90 degree bend to use as a feeler, and your fired brass from that action. Use the caliper to measure your cases and see how much they are stretching in OAL with each firing/resizing. Use your rifle action to see if you are resizing the brass enough to properly close the action and fire it. If your rifle is a bolt action then it will more readily tell you if you are moving the shoulder back enough or it could also be said; the case face forward. Use the piece of wire (paper clip), with a short 90 degree bend, to stick inside the resized case and feel it to see if you are getting any thinned out "valleys" anywhere in the web or case wall. You can easily feel the difference with the bent paper clip. Once you find one, take it and cut it open with a hack saw and examine it and keep it for future reference. I am sure you have already figured this out, but you will get a visible line in the area where the brass is thinning. Sometimes a mis-leading line will appear in that same area from having the cases rattle around in a plastic cartridge box. But this is where the wire "feeler" comes in handy. Make adjustments to your resizing techniques accordingly using these four "thingies", the fourth one being your resized and fired brass. Those other "thingies" are nice to have but really are not necessary. (Of course resizing dies, press, etc. could be called thingies" also I suppose.) I prefer to keep it simple for the most part. "The right to bear arms" insures your right to freedom, free speech, religion, your choice of doctors, etc. ....etc. ....etc.... -----------------------------------one trillion seconds = 31,709 years------------------- | |||

|

| One of Us |

It already is! | |||

|

| One of Us |

Woah, that's what I get for not reading all of the postings! Sorry, I just felt compelled to type something this morning. "The right to bear arms" insures your right to freedom, free speech, religion, your choice of doctors, etc. ....etc. ....etc.... -----------------------------------one trillion seconds = 31,709 years------------------- | |||

|

One of Us |

Hey rc Always reset your caliper to zero after installing  and the slot that goes over the caliper blade is not on the centerline   so make sure the knurl screw is on the backside away from the dial and through the thin side  this will center the case head on the caliper on the other end, don't want to slant the case while measuring This is exactly the opposite from the setup when using the OAL tool because the tool is offset on the case head so you want the knurl screw through the thick side  It is only a tool like any other and you will figure it out but maybe this will keep you from making some initial errors and throwing up your hands in disgust and blaspheming the damn thing and wringing your rooster's neck like some others (not mentioning any names HC!) ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

If there were more thingy users out there, there would be fewer threads like this one. The strangest thing happens when using a thingy. When you get your dies set dead on accuracy improves significantly. How to set headspace with a thingy?? Use a case that is longer than your chamber or expand the neck of a case until it is way too large to chamber. Then slowly set the shoulder of the case back with no expander in the die. Keep doing this until you find the exact measurement where the bolt goes from HAVING drag to having NO drag. Once you have found this number you can measure cases and find that just the amount of case lube or sizing speed can change the headspace of a sized case. The non-thingy users will never discover this. | |||

|

| One of Us |

Do you believe that the brass should have lasted longer? With about 300 pieces I wore out a barrel with about 2500 rounds. I then began using the same brass on the new barrel and have about 500 through it. | |||

|

One of Us |

Here's a thought: If you started using this brass in a previous chamber and that chamber was tighter than this one, it became work hardened down the case body, now you are using it in a chamber that is larger, then the work hardened case body would have had to expand more than usual the first time it was used in the new chamber. Also did you have a crush fit when you first loaded this brass for the new chamber? If your new chamber had a shoulder that was farther out than the old one then that would have caused more stretch on the first firing of the old work hardened cases. IOW it may be that your problem happened because of the use in 2 different chambers. Because the brass should have lasted longer. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Same chamber, same reamer, same gunsmith. Good thinking though. I just must have bumped the shoulders a little too much. | |||

|

| one of us |

Hey TK Jr., You might want to do a bit more thinking about that first one. | |||

|

| One of Us |

Virtually When I checked a fired case in the new chamber initially, the bolt needed effort to close. I could see if there was no effort needed that maybe the reamer was run in a bit further. Point is I still needed to bump the shoulders for the new chamber. | |||

|

| One of Us |

This is my "gizzy". I make these with my chambering reamer. It also tells you how much your seater is putting the bullet on a fresh barrel. It is a starting place. Take your measurement with a fired piece of brass, unsized, and with no primer.   You can get a crush fit if your dies doesn't size the body enough allowing you to think the crush is the shoulder. You can only verify by measuring properly. Butch | |||

|

| One of Us |

You can always ask the gunsmith to cut you a dummy chamber with the reamer he cut your chamber. Compass Lake will do that on barrel stubs. My cost was $35.00 . Frank cut the end to gage minimum. Your example of case head separations should be an object lesson to all that reloading without gages to measure what you are doing is a hit or miss affair. | |||

|

| One of Us |

It's my turn to show off my "thingy" a bit fancy for sure but it works. 440 stainles OD/ID ground just for the heck of it with a full .0625 ground radius mouth.   Fired case from 7RM  New case from same lot#   ________________________________________________ Maker of The Frankenstud Sling Keeper Proudly made in the USA Acepting all forms of payment | |||

|

One of Us |

Good pics Ted Shows you have .0205" gap at the shoulder between new and fired cases (notice I did not say headspace). Typical of belted cases. Now go wash your hands. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

It takes a weeks vacation to cure "machine shop" hands. I hope to not have a couple weeks off until November. ________________________________________________ Maker of The Frankenstud Sling Keeper Proudly made in the USA Acepting all forms of payment | |||

|

| One of Us |

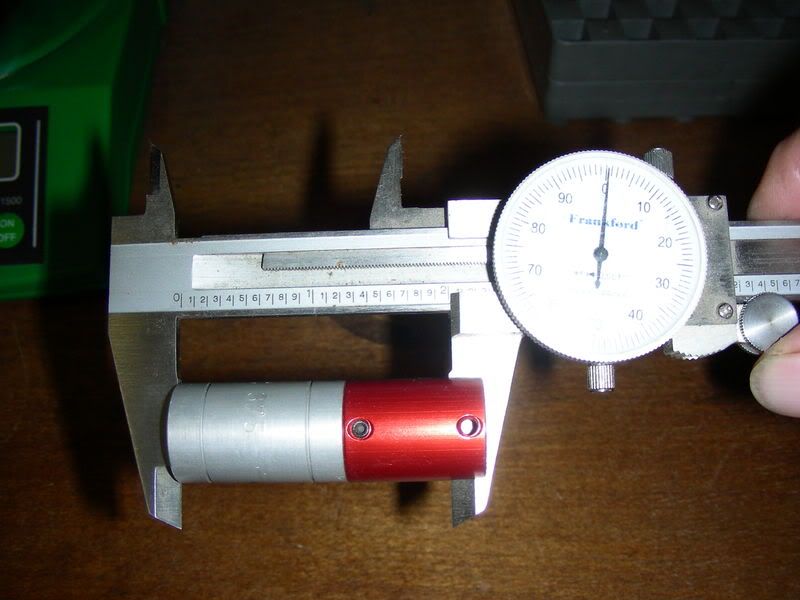

You're a sick man there Ted, showing your thingy off to everyone on the board! I bet the HC Approved Craftsman Socket thingy is just as accurate. Looks like I've bumped the shoulders .006" Difference between a fired case and one resized :  The socket works | |||

|

One of Us |

There you go if you are pushing the shoulder back .006" everytime, that will cause a head separation in short order. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

I'll disagree with that. ----- Good to see the TK is """ FINALLY """ back to giving correct responses. ----- Could you expand on this a bit? Are you saying you want the Bolt to close "without a Snug Fit" on the Case? Be sure to put the Socket back in the Set, so you can find it when you REALLLLLLY need it. | |||

|

One of Us |

I am assuming it's chicken for dinner tonight then? Thank you guys, great thread. | |||

|

| one of us |

It was "Finger Lickin GOOD" (as long as you were NOT using Ted's hands). | |||

|

| One of Us |

During these cases "middle age", I was shooting the precision match a lot. This match has timed stages and a lot if bolt work. You really want to be able to "work the bolt" rapidly to chamber the next round. No time to chamber cases that need some effort to thoroughly close the bolt. I adjusted the dies as I described, by sizing a fired case, chambering it and minutely screwing the die down til the bolt would close smoothly. I must have gone a tad too far | |||

|

| One of Us |

Now I'm wondering why I bought the 35$ Hornady Thingy when I have a couple of tool boxes full of HC Approved headspace gauges, ang HC Approved Bullet Comparators? | |||

|

| One of Us |

Your snuggy case may have been not headspace, but a large base. As you screwed the die down it sized the base of the case more allowing the bolt to close easily. In doing so you bumped the shoulder back too far. Butch | |||

|

| One of Us |

Is there method to tell the difference and to make the correction? | |||

|

| One of Us |

And with all the equipment on display, no one checks head space first, then forms and then fires, a bad habit of the choir is fire first and then learn from the mistakes, or do they, the first firing thing resulting in the most stretch should start with "Once upon a time" as in a ferry tell. I have fired 8mm57 ammo in an 8mm06, to catch most of you up, that is .127 thousands head space, just a few thousands over 1/8 th of an inch, then someone says the case will survive the trauma once but making a habit of firing those cases will result in case head separation, the tough sell, the case did not stretch, the shoulder did not move forward, the problem, reloaders promoting them self's up to the class of wildcatter/case formers without knowing how they got there. Hatcher moved the shoulder forward .080 + thousands and I can only guess said 'Now that should do it" and as history proved, 'it didn't', cases ejected from his new creation (the 30/06 Hatcher Modified chamber +.080 thousands) came out of the modified chamber as 30/06 cases with the shoulder formed forward of the 30/06 chamber .080 thousands and with short necks, as with modern reloaders his technique or method of testing left a lot to be desired, modern reloaders think the firing pin drives the case forward, not on my rifles, my firing pins crush the primer first before the case, bullet and powder know their little buddy has been crushed, had Hatcher scribed reference/index lines on his cases before firing he would have known the neck got shorter, meaning the case was not driven forward, had the case been driven forward, the neck would not have shortened and he would have been correct , excessive head space can cause case head separation on the first firing. Case head separation on the first firing: A friend when forming cases for his/their new creation had 4 out of 10 cases separate on the first firing with new Winchester brass and said therefore; you are wrong (talking to me), and I said had I been at the shop and tested the rifles before you went to the range I could have told you it would do just that, separate, I then informed him had I met him at the range and discovered the cases were separating, 'I could have fixed that' at the range. My friends and Hatcher were using Springfield's, Hatcher did not get case head separation, my friend built 5 magnificent rifles out of 5 magnificent never issued Remington 03/A3s chambered to 7mm modified/improved chambers, not a 7mm06, not a 7mm Gibbs, not a 280 Remington Ackley Improved, the chamber reamer was made by the builders, they solved the problem by necking the 30/06 case down and adjusting the gap between the top of the shell holder and bottom/head of the case, they did mindlessly adjust the die down to the shell holder, I would have used the companion tool to the press, the feeler gage to adjust the gap. adjusting the gap allows me to cut down on all that case travel, and as I have said before, I am a big fan of cutting down on all that case travel, I form first then fire, the rest fire first then become consumers of gadgets, I make gadgets out of nothing and or tools I already have. What to argue about first, try to start with the firing pin driving the case forward before the firing pin crushes the primer, if you find the case, primer, bullet and powder can accelerate to a speed that enables it (loaded round-case, bullet, powder and primer to out run the firing pin before the firing pin crushes the primer you are making this stuff and should start the story with "Once Upon a Time". F. Guffey | |||

|

| One of Us |

Well if your case is sized properly headspace wise you may have a die that is not sizing the base enough. Even with the same reamer you can have a larger base on some chambers. Has to do with chambering setups and chambering methods. The easiest way to fix it is to get a small base die. If you shoot a lot it will come in handy. Butch | |||

|

| One of Us |

I'll adjust my die (when I get the $$ thingy) to bump 1 to 2 thousandths. If it chambers hard, I need a small base die? | |||

|

| One of Us |

Stretch on first firing, Hatcher's cases, had he measured he would have found his cases were shorter, I form 30 Gibbs from 30/06 cases, after forming and firing the cases shorten .040 thousands, the 35 Whelen shorten .035 thousands, the 338/06 cases shorten .035 thousands when using 30/06 brass, and I am not a big fan of building rifles with the Springfield action. And when forming the shoulder it neither moved forward or back, the shoulder does not move, the shoulder stays in the same place, not easy to keep up with two thoughts at once but when I form cases part of the case body becomes part of the shoulder and part of the shoulder becomes part of the neck and had Hatcher scribed an index at the case body/shoulder juncture and at the shoulder/neck juncture he would have found the case did not stretch between the case head and case body, Hatcher was correct in his theory, he just could not figure out why it did not work when he carried out his experiment. And bumping sounds like an accident, getting the shoulder where I want it is no accident, again I prefer the companion tool to the press the feeler gage, I use standards and transfers, there is no better way to accomplish transferring a measurement from one place to another than with a transfer and or standard. F. Guffey | |||

|

| One of Us |

You sure wrote a lot Mr Guffy. Did you say in firing that the headspace always remains the same and doesn't stretch? Butch | |||

|

| One of Us |

or a bent paper clip | |||

|

| One of Us |

A paper clip will do nothing to stop the thinning, and that's woods' point. The "thingy" he is talking about is a headspace gauge so that the dies can be set up properly to avoid the problem all together. I caused the problem by bumping too much and oversizing | |||

|

| one of us |

Simple, you CAN NOT be Thingy King Jr. without Thingys. Maybe!!!

Try eating some Wheaties for breakfast and BBQ for dinner. By the way, you need to pick out a small Cigar of some sort to begin smoking. | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Case Head Separation Waiting To Happen

Case Head Separation Waiting To Happen

Visit our on-line store for AR Memorabilia