The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  Is There A Rifle RPM Threshold

Is There A Rifle RPM ThresholdGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I agree mostly. When I up the velocity in that 7 twist with the 50/50 alloy the bullets don't go crazy, don't keyhole, and all of them hit the target. It's just the group is larger then I prefer. So yes I would love to be able to capture fired bullets totally undamaged through a wide range of pressures/velocities to see if they can tell me something. | |||

|

| One of Us |

To capture some bullets you'll need to modify a butterfly net. Replace the netting with Kelvar. If you are fast enough you'll catch em. But I don't think they'll talk. | |||

|

| One of Us |

Or you could use a long box filled with oily sawdust like Merrill Martin used to catch his cast bullets.. | |||

|

| One of Us |

Low Wall, don't forget the metal detector. I had the privilege of meeting Merrill and Roger Johnston several times at Scheutzen matches over a number of years while I was writing for PS Magazine. | |||

|

| One of Us |

We know all about the oiled sawdust. Mann used it in his testing. Geargnasher is in the process of building a sawdust trap. | |||

|

| One of Us |

Many years ago I was with a gent about a dozen years younger than me. We walked by a store front that had a Daisy Red Ryder BB gun in the front window. I mentioned that kids today don't know who Red Ryder was. He said "I don't know who he was". I bet there are many here that don't know. My point is in just a few years things fall by the wayside. Years ago, kids knew how to spin a top with a string. I bet there are many on this forum that have never done it. Perhaps they should learn and observe the action of the spinning top. People have theories about how the bullet behaves; even while in the barrel. Just theories, they can't climb into the barrel and observe. Back to the top, the harder thrown the faster it would spin. When the top hit, it would dance around, before settling in at one place. The faster it was spinning, usually, the more it would drift and dance. SOMETIMES a fast spinning top would quickly settle in. It would reach an rpm to where it settled down and remained stationary, then as it slowed it would start to wobble and again move. Keep in mind that this spinning top is going very slow in comparison to a bullet--almost as if stopped in comparison. Even an out of balance top would react the same way. You could cut grooves up and down the top and the grooves would make a buzzing noise. I whittled grooves in many a top and it was not done with precision. I also drilled holes in them and filled with molten lead to add weight---again a non precision operation. The point of the top (the part that made contact with the surface it was spinning on) was also altered--anything from a round shape to a very sharp point. All of these modifications, but the top would never just stay where it first hit and remain there, it would dance a round to varying degrees and the faster it was spun USUALLY meant the more it moved before settling down. I read that European barrels usually have left twist and thus the bullet drifts left and American barrels have right twist and drift right. Don't know why the difference--maybe because Europeans drive on the wrong side of the street--that may not be a factor. So the solution is simple. Put a Maytag twist in the barrel. The bullet starts off spinning one direction--then reverses like a washing machine paddle--when it exits it wont know if it is coming or going so it will be confused and not know whether to drift right or drift left and thus will remain on course, regardless of RPM. | |||

|

| One of Us |

Ray, what do you suppose would happen if you fired a bullet in outer space, are out enough that it's a vacuum and no effect of gravity...two different barrels. One with right hand twist rifling and the other with left twist. Do you think the bullets would drift in the direction of the twist? Explain your answer. | |||

|

| One of Us |

What would happen in outer space? Well my experience in outer space is rather limited. In fact only been there once when our cow jumped over the moon and I had to go fetch her back. My main concern at the time was not what would a bullet do, but how could I keep her from doing this again? Decided shooting her would do the trick. But all I had was a smoothbore shotgun. So I didn't know whether to compensate to the left or to the right or not at all. While I was pondering all of this, the cow decided to go home. So I decided there was no need to shoot her unless she did it again. So far she has stayed in the pen and I wont be able to answer your question unless she tries it again. | |||

|

One of Us |

How many folks realize that spin stability is only slightly influenced by velocity - and then sometimes in the opposite direction, meaning that increasing velocity reduces stability. Not much mind you and only really becomes negative above 3000fps, depending on bullet shape. It's the Europeans that drive on the right hand side and the Americans on the wrong side. Anyway, the spinning top analogy is a good one. Throwing technique made a difference. I could throw a top with a pretty high spin that would land and spin true straight away. Not so much when I was trying to peg another spinning top as we often did. Makes me think the same could be true of bullets being fired. After all, a 1-in-16 twist hornet is not supposed to stabilize a 60gr spire point bullet but it does and over a long distance. In outer space the boolit would be tipped into a yaw that would not be able to dampen out as there is no atmosphere for the boolit to 'fly' in(and to cause drift, which requires gravity to cause an arced trajectory). Regards 303Guy | |||

|

| One of Us |

During the time after I posted about the top, only two people have responded. I guess the rest are trying to find a top and learn how to spin it. Either that are googling Red Ryder to see who he was. Been years since I have seen one of these tops. In fact several years ago I made one on my sons in law's wood lathe and that is the last one Ive seen. Actually the spinning top has a couple of factors that might negate every bit of the comparison. One big factor is that the point of the top is making contact. That contact creates friction and vibration that a bullet would not have--that could make a 100% change??? It could be that the only true comparison is that short moment the top is spinning in the air before it hits. Even that would be skewed as it is thrown in an arc, not launched through a straight barrel. As I stated the rpm's are vastly different--could be like comparing a bicycle tire that does not distort to a dragster tire that vastly distorts??? I think the real answer is that we really don't know and we could beat it to death forever--which has happened. BTW 303 Guy you have experience with those tops you must be a pretty old geezer. SmokinJoe has posted since I first posted about tops--we know he is an old geezer and is not out looking for a top. All the info I related is hear say from guys that have spun tops--I'm too young to have actually seen it. | |||

|

| One of Us |

I believe in outer space where there is a total vacuum and no gravity that a barrel wouldn't need to be rifled to stabilize the bullet as there are no outside influences that would make the bullet tip or yaw. I've shot my 22 Hornet with up to 70 bullets with no tipping up to 100 yards. That 22 NATO bullet that is a group buy on CB I've shot quite a lot. It's in the 60 some grain bracket and my CZ 22 Hornet loves it. I have measured my twist per Felix's request and it is 1 in 16. Tops move all around on the surface because of the irregularities of the surface even though it maybe appear smooth such as glass. It starts to yaw because gravity is trying to topple it. Gyroscopes are falling out of use because it's damn near impossible to make a frictionless bearing on them. They have some new devices to replace them. One involves lasers. | |||

|

| One of Us |

I stated SmokinJoe is an old geezer. He did not confirm nor deny this. He would have done one or the other if it were not for senility. | |||

|

| One of Us |

Young at heart and definitely not a "geezer". | |||

|

| One of Us |

Young at heart and not a geezer. That is geezer I'm talking about not Old Faithful. You got confused again Joe. Yes indeed a young man. Sex almost everyday. Almost on Monday almost on Tuesday......... | |||

|

One of Us |

I'm just a kid! The muzzle blast would tip the bullet and so would barrel vibrations. If bullet were launched in space with no disturbances and a very slow twist it should travel true, I'd think. We only had tops in primary school. And marbles. Do kids ever play with marbles on the playground anymore? Regards 303Guy | |||

|

| One of Us |

If the crown is a good one and the bullet base good also, and the bullet was straight in the bore..why would the muzzle blast tip it? | |||

|

One of Us |

Because absolute perfection does not exist. Even if the base were perfect and the crown perfect, there would be small high frequency and perhaps large amplitude vibrations which would cause an imperfect impingement of the high velocity gas jet on the bullet base. It is said that there is a small acceleration of the bullet after it leaves the muzzle Those same vibrations (think of audio range frequency) would impart the tiniest but quite fast tipping vibration into the bullet. From then on I can only speculate the effects because I don't know. Regards 303Guy | |||

|

| One of Us |

I want to make it perfectly clear to my nemesis that I have not changed my opinion on the false RPM Threshold unproven theory and stand firmly behind my convictions; whereas my nemesis has modified his beliefs more then a few times. For the average rifle and cast bullet shooter the faster twist doesn't ruin accuracy enough to be of concern, it only makes it harder to achieve for amateur cast bullet reloaders. Please leave my friends alone with your insane drivel through pm's and emails. | |||

|

| one of us |

Your letting assumptions and supposition get in the way of achieving your goals. First get an alloy you can repeat correctly that is suitable for the pressure range that you want to shoot at, then make some bullets. Smooth sided PP bullets do not work well with smokeless powders.......... Roll your smooth sided bullet with a rough file to provide some bite for the patch..... then try again. | |||

|

One of Us |

Ahh... that was speculation about a bullet being fired in space. I agree that my next step should be to produce a repeatable alloy. I do use the knurling trick with harder alloys when I had some. I'm planning on going to shallow grooved bullets for the grip. Softer alloys will grip the paper just fine in a tapered throat. Harder alloys do indeed slip in the paper. Regards 303Guy | |||

|

| one of us |

I do use the knurling trick with harder alloys when I had some. Softer alloys will grip the paper just fine in a tapered throat. Harder alloys do indeed slip in the paper. When dealing with smokeless, they both slip.......... Until you find what real accuracy is, you'll be making assumptions. | |||

|

One of Us |

Rest assured - there are no assumptions. One speculates and examines what evidence one can find and researches and listens to what others have found or speculated. But one should never assume anything. I have found evidence of slipping and I have also found evidence of not slipping. A slipped patch produces a crinkled pattern on the core and a patch that has not slipped produces a rough paper impression on the core. OK so I'm saying I've seen both, BUT, that is at lower velocities where one can actually recover a boolit for examination. At higher velocities the boolit gets so damaged that one cannot deduce much from it. This is a core that slipped in the patch.  This is a patch that slipped on the core.  The slipping was radial which produced the longitudinal crinkles. This patched boolit that would likely not have produced any accuracy even though the patch did not slip in this instance. The boolit twisted on a shear plane and forward of that plane the patch got cut into the rifling groove on the boolit.    I'm not asking anyone to double guess me on this one. I would have to find that sample and send it to anyone who wants to see for themselves and that's not going to happen. If I could find it again I could take more pictures of it that show more clearly. But for me, I've held it in my hands and turned and twisted it in good light under a magnifying glass so I'm not asking for second opinions anymore. It was on a casting flaw with an alloy prone to weak plains due to constituent separation.  If a 'cold shut' happened to coincide with the gap between case mouth and chamber end, then that softer layer would be able to upset into the gap which could have softened the alloy in that that plane, allowing the section forward of that shear plane to skid on the rifling while the bit behind it followed the rifling. That bottom bit could have been a little harder too due to the more rapid cooling that mold produces at the base. Here one can see there was no slip.  This one too - it was a half patch.  But none of that means anything because the velocity was too low to produce any form of accuracy anyway! Regards 303Guy | |||

|

| one of us |

I see your going to have a very hard time.......... Accuracy is final and the real yardstick of your accomplishment or not..... | |||

|

| One of Us |

303guy 45 2.1 is right, you are going to have a hard time especially if you keep believing in the BS from the original RPM Threshold BS man...the one that has the M60 picture. The distances that they think they are talking correctly about, that is where the groups start really open up at, are far beyond the normal distances that we shoot. Take my AR10 with the 180 cast bullet at high velocity. At 350 yards it's still shooting less then 2 inch groups, no MOA, but inch. The same with the 6x45 with even a higher velocity is shooting less then 2 inch groups at 350 yards. Simply put 303guy you are going to the wrong school. | |||

|

One of Us |

I'm dabbling with toughening my alloy using copper which should theoretically produce a bullet that can handle higher pressure and spin and still hold together on impact in game. The stronger alloy should resist nose slump and base extrusion for a higher muzzle velocity. This is not about twist rate but bullet distortion in the bore.  This is what I mean. The base is undistorted and has no trailing edge feathering or extrusion. It also has about 99% weight retention. This is a fairly fast rifle bullet so that's mission accomplished. The base edge damage is from the nose folding right over into it. I pulled it off for examination. Getting back to nose slump.  This was at a much lower velocity as can be seen by lack of impact damage in the same medium that caught the above bullet. This bullet is going to loose accuracy exponentially at higher velocities/spin. It's not the twist rate that's the problem but bullet distortion in the bore. This bullet also shows rifling skid (paper patch, remember). So while the bullet base damage/distortion problem may be overcome, I still have to overcome the nose slump problem. Most folks have no idea nose slump is occurring since the nose gets damaged on impact and can't be examined. The top bullet also shows that there was no rifling skid but not whether there was patch slip. The lower pic shows no patch slip but one cannot be assumed the to be true at higher pressure. So, I still have bit of playing around to do with alloy strength (not hardness) and bullet shape i.e. a shorter nose with a wide meplat to promote expansion and generally produce an effective wound channel. Regards 303Guy | |||

|

| One of Us |

...and 45 2.1 and I,plus others, are getting what you want with the 50/50 alloy and apparently with no nose slumping proved the accuracy we're getting....all at the higher velocities. It's good you're experimenting. Don't get too deep in the copper alloy, it's nothing new and been tried before. It'll end up in the same place where it was rediscovered. | |||

|

| One of Us |

Hey Idaho Bill, put that in the drunkard friend wheeler's whiskey bottle and have a drink. That's with 50/50 alloy without copper from a fast twist 7.62 NATO AR10 that I built myself, and at HV. I'm not finished with the grouping yet, that's just what it's doing till I tweak it more and that one isn't blended powder, the fast twist 5.56 NATO HBAR is the one I use that in. I see you're starting to get senile. | |||

|

| new member |

You say HV. How high? | |||

|

| One of Us |

Jacketed bullet velocities. | |||

|

| one of us |

I'm dabbling with toughening my alloy using copper which should theoretically produce a bullet that can handle higher pressure and spin and still hold together on impact in game. Yep, you'll have a fine FMJ if you get it to shoot. This bullet also shows rifling skid (paper patch, remember). With PP, skid marks only happen with too hard an alloy or smooth sided bullets. So while the bullet base damage/distortion problem may be overcome, I still have to overcome the nose slump problem. The first doesn't matter with regards to accuracy and the second is generated by your coices and actions. You might try getting a better mold or improving the technique. Ross Seyfried showed several pictures of cast out of his "majic mold" without the wrinkles. You could do the same. So, I still have bit of playing around to do with alloy strength (not hardness) and bullet shape i.e. a shorter nose with a wide meplat to promote expansion and generally produce an effective wound channel. With PP.... really? A very soft alloy can be driven at 2400 fps or above and get that easily. Hard alloys defeat your purpose. | |||

|

| One of Us |

Lamar, I did fool around with the copper alloy. I got it into my batch with a hell of a lot better looking molt then swheeler's wonderful looking conglomeration. Let's just say I found it more a hassle to blend up alloy then the 50/50 I've been using. For all the trouble it takes to make it I really didn't need it as I was getting what I wanted out of water quenched 50/50. Tip: I believe you fellows need a super flux to insure the copper blends uniformity. Scott, I noticed a bottle in the back area from your pot to the right marked buffer. Now isn't that interesting. Did the Golden Boy give you that after his failure? What is that bottle in the back to the left that is black with a green label. By the way that alloy you were mixing matches your shooting ability. At first I thought it was a blend of mash, corn, water, and sugar...ya know...for making a little sipping liquid. That little baby funny of yours was indeed funny, but unlike Edd I certainly can't say that is the funniest thing I've ever seen. Okay guys, here's how I feel about the copper alloy. Back when I was on the forum and getting into lots of arguments over the HV 6.5 Swede, some of the naysayers said "Who needs that HV?" "I don't have to shoot that fast" "What's it good for?" Remember all that, I do? So now here we are with copper alloy. Why? Because now all the sudden you all want to shoot HV. Sure, copper will let you do that easier then I get 50/50 to shoot HV. Now you all can beat around the bush all you want to about it going to be the greatest alloy for hunting there is, but the little tell tale sign that you all also think it's too hard is the fact you are designing bullets with big flat meplats. That right there admits that you know it's hard. | |||

|

| One of Us |

I'm going to try the copper alloy again. I wasn't satisfied with the previous attempts and have gotten some answers on a better way to blend up the alloys. The amount of copper in the mix is one of the issues. I've now been told that there should be a little amount of copper, more not being better in this case. I'll give that a try. They sure need to age pretty long from what I was told. I'll cast the first batch up for the 5.56 NATO since that 7 twist AR will be a real good test for the accuracy part of it, then go from there. I need to assemble my alloys and I'll start. | |||

|

One of Us |

I should mention that I was using reject bullets for test tube firing. Slump can only be caused by the applied stress exceeding the yield stress of the alloy. The shank of the bullet is supported by the bore and the base by the gasses acting on it so only the nose slumps. However, one should remember that the nose is subject to far less stress than the base so for the nose to slump means there is a problem to be overcome. I shouldn't think rifling skid through a patch would be greater on a smooth side than a grooved bullet, especially considering that grooved bullets usually have a bore-ride section which offers no driving surface. The driving bands on a grooved bulled is a far smaller surface area than on a smooth side. What we are seeing on that example is the edge of the rifling land wearing into the patch, something that seems to happen if the rifling lands are a bit rough which was the case with the rifle this one was fired in. This is something I can actually prove as I have rifles with varying degrees of bore roughness, one being mint. In fact, I have two, two-groove rifles, one with a pretty rusted bore, the other like brand new. Those two are going to be put to the test when I get a round too-whit. Here is rifling skid in the two-groove with a rough bore  And the bore  They don't all skid  Again, reject castings for the tests. Again, reject castings for the tests.Now this is a rust damaged bore!  Yet there is no patch slipping or rifling skid. Then again the velocity is not all that high but pressure is not all the low either - the barrel is very short! That's a copper toughened alloy. But getting back to RPM thresholds, I'd suggesting that what is happening is that as the velocity is increased, the increased pressure induces greater nose slump, the effect of which is exacerbated by the higher RPM. I'm suggesting that a slower twist would be less sensitive to nose deformation than a faster twist. Regards 303Guy | |||

|

| One of Us |

We'll find out when Geargnasher makes his bullet trap that doesn't damage the bullet. But I don't think it's nose slump. You can take pointed jacketed bullets and bend the noses and although they aren't match grade accuracy then they don't shoot as horrible as one would think. Try it sometimes. Gear and I think the twist is doing something to the surface of the bullet which it is in contact too. I know that the 50/50 alloy isn't up to the task in the 22 caliber with a fast twist. That's why I'll do the 22 with the copper alloy first. | |||

|

One of Us |

I made some updates while you were posting your reply! I'm looking forward to his bullet trap results too. It's true about damaged bullet noses but how much influence would bullet slump have as it distorts more of the bullet than a damaged soft point on a spitzer? Good point you raise there. Regards 303Guy | |||

|

| One of Us |

Maybe that calls for a test where could somehow deform a known good shooting cast bullet and slump the noses and shoot them. Question is if they shot reasonable would anyone believe it? I don't shoot reject bullets for testing as they aren't the same as good ones. I want to know what the good ones do. About the only thing I may use them for besides going back to the pot is velocity checks over the chronograph. | |||

|

One of Us |

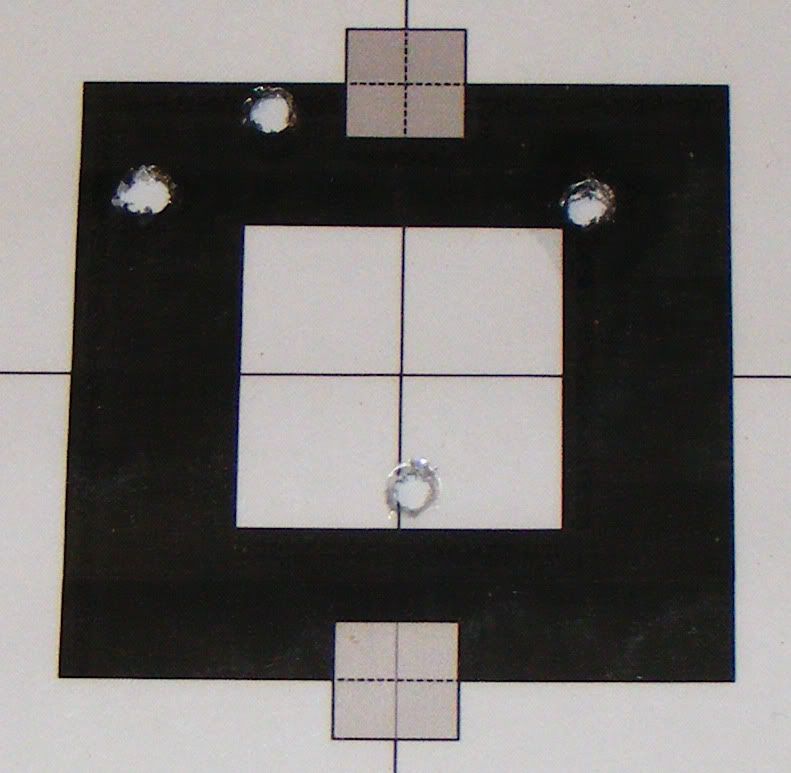

My tests were into a firing tube - the gun muzzle is pushed right into it. It traps all noise so allows testing in my shed. I use it to test alloys and patches and fillers as well as to develop loads, pressure wise. Also for fire-lapping and polishing. From there I make my way out to the fields for range testing. This might look OK for a 100m group but it's not. The fifth shot was just on the edge of the sheet! Velocity was 2400fps I think - I'll look it up and correct. It hit pretty hard into a clay bank. It's a 194gr paper patched bullet.  Regards 303Guy | |||

|

| One of Us |

303 guy, In many instances you can take a softer alloy with a paper patch and exceed the velocity of the same bullet made of your normal alloy that isn't patched. That kind of debunks the nose slump theory. | |||

|

| One of Us |

303 guy, Tell me what you think nose slump is and how it happens. | |||

|

One of Us |

I've thought about that. I should mention that that low velocity bullet was launched with a fast shotgun powder or Trail Boss. I have found strong evidence of bump up in the neck and throat with those powders. I'll give you an example - I have this rifle with a rust pit in the neck area of the chamber. Those two powders will lock the neck into that rust pit while a much higher pressure, slow powder load does not. So mean pressure which takes into account the duration of the pressure (lead flows under sustained pressure) as well as pressure spikes need to be considered. High velocity paper patch loads tend to have lower peak pressure and higher mean pressure and a slow initial pressure rise so the comparison may be a bit more complex than we think. I do not have the answers, I'm just throwing ideas around.

Nose slump is setting back of the unsupported ogive or forward section of the bullet. This could mean the nose tilts to one side or the ogive sets set back without tilting of the nose itself. I'd suggest that the setting back of the ogive would tend to be a bit uneven which would adversely effect the air flow over the boolit and also upset the centre of mass, all of which would cause the bullet to gyrate in an ever increasing spiral if the slump is bad enough. In short, the bullet would be out of balance, both in form and in centre of mass. Regards 303Guy | |||

|

| Powered by Social Strata | Page 1 2 3 4 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  Is There A Rifle RPM Threshold

Is There A Rifle RPM Threshold

Visit our on-line store for AR Memorabilia