The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  Is There A Rifle RPM Threshold

Is There A Rifle RPM ThresholdGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

No there is not. Let me explain. Is there a RPM limit for the bullet. Yes there is and this is for and because of bullet alloy strength. This also applies to jacketed bullets, mainly the ones with lead cores. Why do many rifle cast shooters stay at the 1800 to 1900 fps bracket? Few reasons. One is because of the lack of good factory molds. They produce bullets that don't fit the throats good. Sometimes one lucks out and a factory mold bullet does work. Another reason, which most won't like to hear, is that many cast shooters lack the ability to assembly good loads. If you load cast bullets like you load a normal jacketed bullet you are only going to achieve and certain level of accuracy and velocity. It's a prove fact that RPM effects the accuracy ever so slightly. Probably where RPM is closely watched is mostly benchrest shooting. So I think the RPM Threshold really should have had another name of RPM Level Of Experience Threshold. The rifles most cast shooters are shooting are in most part standard sporting rifles old and new, and in large part military rifles. The slight accuracy lost because of over stabilizing the bullet is not really measurable in those rifles. For lack of better knowledge the first argument you will get will be "Yeah, well how come benchrest shooters don't choose fast twists?" I can tell them that the slower twist isn't the only reason they choose such a twist. | ||

|

| One of Us |

another unsubstantiated opinion. I used to have disagreements with my wife. She would state what she called her "Opinion" and become irritated, or get her feelings hurt when I asked for empirical data to back up that opinion. One day she just said "That's how I feel about _______." Eureka, the light bulb in my head comes on. One of the things I learned in school, and in life, is that there are two different thought processes going on in our minds. Feelings, you see, are not subject to discussion, they are, as the kids say these days, "it is what it is...". It establishes a sort of moral and intellectual superiority, and takes the discussion from a scientific to an emotional level. I think that is your issue here. Without sounding condescending, you simply have no significant scientific empirical reference data to base your "Conclusions" on. You could fill a large bookcase, or ten, ceiling to floor, with the data generated at Picatinny Arsenal the last twenty-five years. Internal vs External centrifugal forces; as they pertain to projectile design. They can tell you, out to a mile or so, what the data shows about going up or down 1/2-degree on a boat tail bullet. Add or subtract .0005" to the cavity diameter of an HP design. I would personally recommend that you buy a good rail gun, Young over in Oregon makes a fantastic one for about $2500. I have reamers cut for the 30BR and fl 308W cartridges. I have throating reamers for several of the NOE 30 caliber designs. I am retired, so I hunt Africa, and experiment with things that interest me in ballistics. regards, Rich healing... | |||

|

| one of us |

I see... nothing to do but mess with somebody else.....You need a hobby while your healing........... | |||

|

| One of Us |

If you've been following Joe's shooting over the years, you'll know that he has a great deal of "empirical evidence", as you like to put it, to substantiate his "opinion" about HV cast bullet shooting, and the factors that affect accuracy and the factors that DON'T affect accuracy. The problem most cast bullet shooters have with his conclusions is that they haven't learned what he has, don't know how to load accurate ammunition, and therefore can't duplicate his results. Speaking of emotional factors, one of the biggies is "If I can't duplicate what he says, he must be lying". Ego gets in the way of the pursuit. Like I've said before, how do I know this? Because I listened and started learning some things, mainly that things are possible with cast bullets that most people wouldn't believe. I don't care all that much what they learned at Picatinny, really, what I care about is what my targets and my chronograph tell me, with CAST bullets, and how the little things I do at the reloading bench affect those two yardsticks of measurement. Gear | |||

|

| One of Us |

Rich, I know that fast twist effect the accuracy just a tad. What I've been trying to say is for the shooting we do, which isn't bench rest or competition, and for the rifles we use including target models or heavy barrel varminters, that the rpm doesn't make an iota of difference in accuracy at any rate. In fact a little more spin helps it way out there when the bullet is really slowing down. Let me tell and ask you something. You stated you shot bench rest, that you wrote for a magazine a number of years, and that you hunt big game in Africa. What would you think if I called you a liar?? I'm not, just asking. Okay I've posted what I've done with quite a few rifles shooting cast at HV with excellent accuracy and from fast twists. I was called a liar after not only posting targets but chronograph pictures for velocity. I was just trying to get input to what the 7 twist did to a cast bullet. It's not the loading of the round, it's not the rpm of the bullet, something is going on inside that barrel to change the bullet. Harder alloy doesn't really solve the problem. That's when I happened on blending powders. That worked...then again WHY? | |||

|

| One of Us |

Dang! Got the whole clan here. You guys joined at the hip or something? Fast twist affects velocity more than a "tad". $600 dollars cash money, and button makers will make you a button with your exact dimensions. Plus or Minus .0005" and .005" twist rate. Ron Smith and two other barrel makers will make you a cut-rifled barrel with any twist/dimensions you wish, including gain twist or tapered dimensions. .001" +/- of choke alone, can make a tremendous difference in velocity and subsequent accuracy. Twist for a given projectile is not much of an area for experimentation. It is 99% established, by controlled indoor testing, which exact twist works the best for any given projectile. I know Dan Lilja, I know Ed Shilen, and I know Ron Smith. I spoke with them at BR and Schuetzen matches. Speak to Dan or Ed about a barrel: they want to know which bullet, cartridge, and the purpose of the project. BR competitors who plan to win or place very high at the Super Shoot all shoot a 6PPC with a 1"14 twist. A dozen of fifteen custom actions form the rifle, ditto on custom barrels, five or six different scopes makes and models, and most shooters seem to have their own system of windflags. They agree, 99% plus of them, that you have to shoot a 1:14 twist 6PPC. Ron Smith, just ask him sometime what is the 95% answer. The 32 Miller Short cartridge Dean Miller and I drew out on a picnic table at Golden twenty years ago. Tremendous range on bullet weights, but the winners will have a 190 to 220gr semi-spitzer to full spitzer design ahead of 10-12gr of AA9. Your successes are blips on the radar where they stray from established guidelines. The article was interesting reading, but cruising down the equipment lists from Camp Perrydoes not support the conclusions drawn by the author. | |||

|

| One of Us |

Joe I wish you'd delete this thread for 2 reasons. (1) subject has been beat to death (2) I have SOME agreement with Idaho Sharpshooter and that is scary. | |||

|

| One of Us |

Okay a smidgen. You're still stuck on high dollar precision specialty rifles...bench rest. Like I mentioned I'm talking regular sporters, which can include old and new, and varmint rifles; and military rifles of all kinds...for shooting cast. Why can't you get that through your noggin? | |||

|

| One of Us |

Ray I can name of a whole list of people I know in the industry too and not just barrel makers if that would make you feel any better. | |||

|

| One of Us |

Maybe I'm straying from the intent of the article, or maybe the whole thread, but what interests me is not the most ideal barrel/action/cartridge/twist/taper/contour/bullet weight/shape/ad nauseum. That's fine for what those guys are doing, but what I'm interested in is getting higher performance from cast bullets in stock, factory or military guns than the usual 1600 fps with shotgun powders. I don't care if it's ideal or not, I care about making it WORK. Cast bullets present their own challenges at high velocity, and much of the hoopla about those challenges is incorrect. If I have to do what some would call "overspin" a cast bullet to get what I want out of it, that doesn't bother me one bit more than it does the bullet. Gear | |||

|

| One of Us |

Gear when they can't or refuse to answer the question asked, then they resort to bench rest shooting and shooters. You're right, I'm not interested in that either. Let's stick to cast bullets, this is after all the CAST section, not bench rest and jacketed. | |||

|

| One of Us |

Joe, where did you get it that I might have even been slightly impressed with his list of barrel makers? Name dropping doesn't impress me. | |||

|

| One of Us |

Actually I didn't get that from what you said Ray. It was just an opportunity to say it. | |||

|

| One of Us |

What does this really mean? | |||

|

| One of Us |

It means that there are other reasons besides choosing a slow twist which just barely stabilizing the bullet for benchrest shooting and all them combined make an accuracy difference. | |||

|

| One of Us |

What other reasons? | |||

|

| One of Us |

There is a reason they are called the L-A-W-S of Physics. You cannot bend them to suit your theory. My Oehler M43 pressure monitoring, BC calculating chronograph does not lie. The muzzle RPM does not decay noticeably. The bullet arrives at its' target/impact area so quickly it does not have time to. Again, there are two centers in every bullet. 1. unchanging center of gravity. 2. unchanging geometric center. #1 is not determinable, although you can get close by spinning the projectile. Imagine the crosshairs of a scope, but put a dot not quite centered on the intersection. #2 is easily determined by drawing horizontal and vertical center lines on the bullets largest diameter. Looks like the crosshairs on a scope. That center is exactly on the crosshairs. Always. While the projectile is in the launcher, the two are in stasis. Once the projectile is ejected, if those two centers are not identical, they cause an instability inside the projectile. The effect, recorded using high speed cameras, 5,000 frames per second or higher; is that the projectile begins to destabilize (ie wobble) trying to rotate around two centers. It looks like a spun top, as it slows down, it begins to wobble, and eventually topples over. Fortunately, for small arms at least; the time in flight is so short, that it is not harmful to the trajectory, or the stability of the projectile. That said, the faster the twist, and MV, the more the quality of the projectile is stressed. Cast bullets demonstrate this phenomenon more than jacketed, which demonstrate the phenomenon more than monolithic solids. 1. Cast bullets are very difficult to produce in quantity without having two centers. 2. jacketed bullets are less difficult, especially by Bench Rest bullet makers. 3. pure solids allow the pressure of swaging/forming them to eliminate the variance. The reason BR competitors shoot short(for caliber) bullets at Mach III or a bit less, and use the slowest twist that will stabilize them; is to minimize the rotational torque the rifling imparts. I would suggest you try and shoot five 5-shot groups in a row at 300yds that can be completely hidden by a dime before refuting scientific reality. regards, Rich | |||

|

| One of Us |

I'm only going to touch on this a little bit. If you have a BR rifle that barely stabilizes the bullet for 100 yards you aren't going to be shooting that less then dime size hole at 300 yards. Yes a cast bullet is harder to make (or should I say cast) perfect...but you can get pretty dang close to it. Also think about this Rich, paper patched bullets get closer to shooting bug holes at HV then the naked ones, but yet can be made of the same alloys. Many paper patched bullets are cast. Others are swaged. | |||

|

| One of Us |

I don't know what your angle is, but you call all the top barrel makers (the owners, not some tech) and also the bullet makers and ask them the parameters for BR barrels and bullets...what makes them work. I know a good number of the barrel makers personally. | |||

|

| One of Us |

45 2.1, The beginning of wisdom is the admission that we know very little about very few things. Please illuminate us with your technical background, or something that otherwise qualifies you to add to this thread. I wrote for Precision Shooting Magazine for two decades. During that time I was privileged to converse with a couple of the PHD scientists working on projectile studies at Picatinny Arsenal. Two of them rewrote the entire set of algorithms used to predict projectile decay rates, and effect of twist rates as they relate to projectile stabilization. Proof of their data exists in modern reloading manuals, where long distance flight characteristics are vital to predict the trajectory. One of their discoveries was how BC's change as velocity declines. Another one, which pleased me to no end; was how geometric and actual centers seldom coincide. One of them was a bench rest competitor, and I asked him a basic question about how the two opposing centers effected in flight integrity of bullets/projectiles. Their studies let to a major overhaul of space packaging to minimize or eliminate the differences between the two centers in space probes and later, manned space flight. Space missions, you see, require stabilization of the craft in flight. The craft have to spin to create gravity inside. Without it manned space flights must needs be of short duration. The exact rate of spin has to be programmed in to simulate Earth's specific gravity at the earliest stages of zero gravity flight. That program is much like a gain twist barrel. Start slow, and gradually speed up. This issue here, is not a matter of opinion. My thoughts are based on a study at the arsenal that began in the late 1980's, and continues to this day. Their studies conclude that stabilizing the rate of spin is critical. If the rate increases past optimum, the internal gravity will increase, and in a matter of hours can cause the space craft to explode, if not corrected. As that applies here, too rapid a spin will cause any projectile to disentegrate (sp?). That data, proves that there is an exact, or nearly so, optimum rate of spin for each projectile, based on length, and to a lesser extent, on velocity. It was valid twenty-plus years ago, and it is equally valid as I type. Nobody here has posted any scientific data to show otherwise. regards, Rich I will admit to not knowing a lot about this stuff, but I do know PHD's who have made it a career at PA working with it. | |||

|

| One of Us |

Cast bullets aren't disintegrating from rpm. We're not talking about HV thin jacketed jack bullets that do such as in the 220 Swift for example. We're not shooting cast bullets to that velocity. The NRA took the 300 Win Mag and paper patched for it. They shot it to a little over 3000 fps with very very usable accuracy. We're not talking super high rpm, but still higher then the average cast shooter and their bullets performed very well. What I'm after is what is going on inside the barrel of a 7 twist 5.56 caliber. You get to a certain velocity and then it's just like a switch and accuracy goes bad. I know part of it and it's the strength of the alloy we're using. But what exactly happens to the bullet that makes the accuracy change. Yes we know it's the rpm...again what's it doing to the bullet? Is it distorting it's surface? Is it twisting it inside the barrel? Don't reply back it's bending leaving the muzzle, I won't buy that. What I need to do is recover more then one bullet 100 percent undamaged except for rifling to see what happened to it. That's very hard to do. The other questions you asked me are only for a pissing match which I will not entertain you with. I don't care where you went to school, what equipment you have, or who you worked with. I want to know the answer to the question I asked above. For my your information I have exceeded the rpm of that cast 22 caliber bullet in other calibers of near equal twist and repeatedly. That is I'll shoot those HV small groups on demand. Now I'll tell you the one difference in them and the 5.56 is that the caliber is larger. So what's happening to the smaller bullet. By the way one of us is working on capturing the bullets undamaged. If you can't stick to the topic and can't fathom that cast can be shot very accurately even at high rpm, then take a hike. | |||

|

| One of Us |

Show me the results of your work. Preferably at a rifle match with impartial witnesses. Not a word of what you have posted here is verifiable by anybody. Wishing or wanting will not make it so. Again, no offense, but I am not accepting anything you have said just on your say so. The data I have listed from Picatinny Arsenal is verifiable, just ask the technicians at Sierra about the data they cite in their reloading manuals. The fact is that the two centers cannot rotate around each other at much RPM. The integrity of the bullet is strained by the RPM, which is an exact linear speed the twist defines. Cast bullets have a low Brinell Hardness, they are the weakest metal used in volume. What you postulate is contrary to every rifle discipline findings RE twist rate as it applies to accuracy. Nobody uses a twist rate any faster than the minimum required to stabilize their chosen bullet. That bullet is the highest BC available that can be stabilized in a reasonable twist. One area of the Picatinny testing centered around shooting the bullets into water tanks. They could be loaded again with the same MV and fired several times. Several years ago I built a 22-416 Rigby, Ackley Improved. It was a ballistical twin to the 22-378 Wby, just going to a 35-degree shoulder, and omitting the belt. I blew every commercially available 22 bullet available up within 25 yds of the muzzle, with the exception of the Nosler Solid Base 60gr HP. It was grouping less that 3/8th of an inch at 100yds pushing 5500fps in a 1:8" twist, but every bullet made it to the paper. I took the rifle to someone else, who replicated the results at a range in Seattle in front of several witnesses. The article was written up in Precision Shooting Magazine several years ago. With the proliferation of quality video cameras and U-tube, it would be a simple thing to set the camera up behind you at the bench, and fire three or four consecutive 5-shot groups at 100 yds thru your chronograph. As each group is fired, you can walk the camera down to the target and document the actual group fired and measure it. Even Stephen Hawking is challenged to prove his theories at scientific gatherings. I actually was born in Missouri, so just SHOW me! I have no issue with being shown up if you are able to do so. regards, Rich No axe to grind, just a seeker of truth... | |||

|

| one of us |

If they shot cast bullets at 100 to 600 yards then I might say you have something not withstanding the mistakes you made in what you just wrote. I'm not concerned nor do I care that you write.... I see the results of many unknowing writers out there and here. You still need a hobby.................... | |||

|

| One of Us |

Projectiles are projectiles. Neither the material or the method by which they are formed has any bearing on the Laws of Physics. Cast bullets are the worst for accuracy, the method by which they are produced does not allow for consistency in diameter, weight, or length. Any occlusion moves the two centers farther apart, as does any void. Please feel free to correct any errors in what I have posted. Just list your sources. | |||

|

| one of us |

Lots of assumptions.......... I believe you know what assuming makes one. As far as your list of sources, your couple of scientists really is good ... ehhh! I would have trouble straightening your prose out due to ASSUMPTIONS and non relevant items... so your on your own Mr. Writer.................... | |||

|

| One of Us |

The United States Government does not fund the Picatinny Arsenal research to the tune of six-Billion dollars annually, and employ over 1100 PhD Physicists working on projects centered on projectile design and testing to produce, over the last half-century "assumptions". Their algorithm data regarding BC change as velocity speeds up or slows down was a major breakthrough in the field. Sufficient proof for Sierra, generally regarded as number one in the commercial bullet design field, to cause them to completely revise their reloading manual. regards, Rich One other little thing. Use Spell Check from now on. The spelling is "you're", not "your", as in "you are (you're) on your own Mr. Writer." As an aside, being paid for non-fiction (as opposed to what you two have posted here) work you create that is published is a way of saying that what you wrote had merit. What the two of you post is mere prattle, unless it can be backed up with credible test results. Although the two of you are obvious paragons of virtue, inquiring minds want more than your say so on statements that fly in the face of all published scientific data. Either the entire scientific world is wrong or the two of you are... | |||

|

| one of us |

Those boys are NOT experimenting with cast bullets......... You can't seem to see that for some reason. This forum is about cast bullets. See if you can talk about them or post your drivel on the proper forum. Nobody here gives a damn about spell check. Your own prose is quite deficient in itself. | |||

|

| One of Us |

I agree 45 2.1 he can't distinguish between cast and jacketed bullets. He would be a dangerous person to demonstrate our shooting as he would probably drop over death upon seeing it. With all the problems in this country (or should I say world) and he picks on spelling or grammar he is a very little man. | |||

|

| One of Us |

There is no angle. If a benchrester picks a slow twist what are all the reasons for picking a slow twist? If a given barrel shop can lap any barrel twist to the same level of precision what are the other variables that you alluded to that cause someone to pick a slow twist barrel? I think the slow twist is picked only for performance. There is NO OTHER criteria for specifying twist in a BR rifle. | |||

|

| One of Us |

Don't waste band width arguing with smokeyJ. He is right, the rest of the ballistics world, including several hundred PhD Physicists at the Picatinny Arsenal and I are ruh-ruh-wrong. If he were not so modest, he would take his magic stuff and set all of the records in the Cast Bullet Assn in one weekend match. This is the same thing that got him banned from other websites. The slow twist in BR rifles also helps keep the RPM down. Note to 45 2.1: the Arsenal does research using cast and swaged bullets. They are a pure research center. Also, you need to point out my spelling errors. The next one here will be my first. You on the other hand, average better than one a post. Also, your grammar and sentence structure are atrocious. Should'a stayed in school. | |||

|

| One of Us |

What part of the world population that shoot belong to the CBA? A very small fraction. So somewhere is someone or maybe more then one that can clean everyone's slate in the CBA. Just because a person doesn't belong to that organization doesn't mean they can shoot. | |||

|

| One of Us |

SR, I didn't mean it to sound like it's just the slow twist. The rifling is not only a slower twist, one that barely stabilizes the bullet, but also has shallower grooves. The idea is get the bullet down the barrel undamaged as possible. The bullets for BR usually have thinner jackets, another reason to try prevent rifling damage. They use different reloading tool and different reloading practices rather then use says factory dies and a Rockchucker. This of course is an abbreviation of what all they do. | |||

|

One of Us |

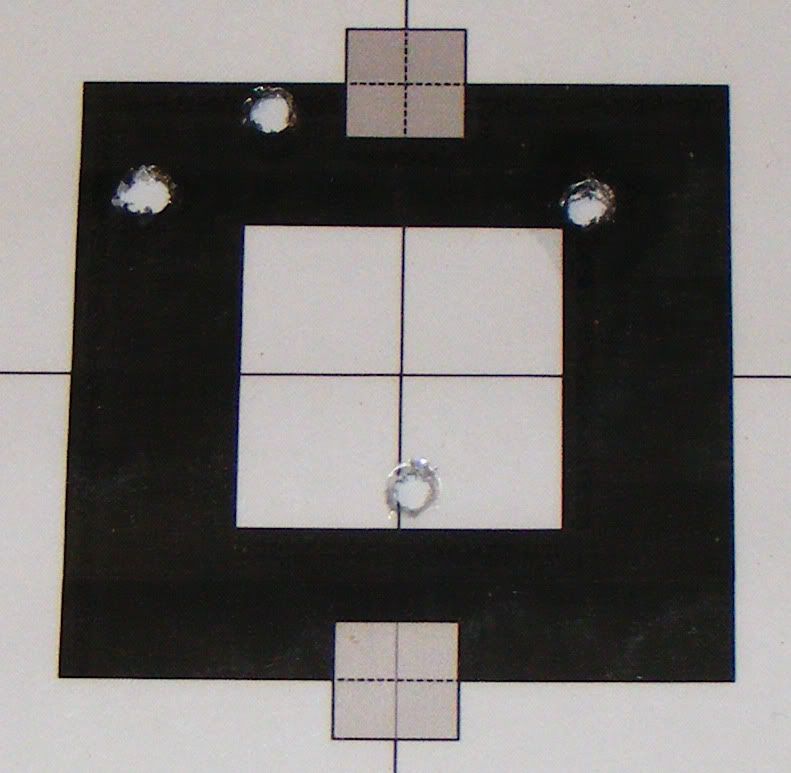

My interest in this thread is gaining knowledge - I have nothing constructive to offer. I'm in the milsurp cast and paper patch shooting group. To me, the 1 in 10 twist Lee Enfield is a handicap for cast boolit shooting, one that I would like to compensate for. Difficulties I need to overcome include a large and tapered throat and deep grooves on some rifles and shallow and rounded grooves on others, not to mention badly rusted bores that have been fire-lapped to a shootable condition. In this photo rifling shear is very apparent. First problem with fast twist and rough bore.  The same rifle that fired that one is reasonably accurate out to 50yds after which the bullet goes off in unpredictable directions - that's with full power loads and a paper patched bullet. Here's the bore  Here is a 100m group using 192gr paper patched bullets at about 2200fps.   Bullet spinning too fast? I suspect that might be a contributing factor since I know there were some surface casting defects. Would the bullet form have an influence? Perhaps Idaho can comment? Regards 303Guy | |||

|

| One of Us |

Idaho doesn't know. What you have and what ammo you have assembled is all that combination is capable of. You're totally way off about it being the twist. Take a look at the target below. It's a 1 in 10 twist 30 caliber shooting a 180 grain cast bullet of 50/50 alloy at over 2300 fps. Does it appear the 10 twist made a terrible group? I'd say not.  Quit following the blind 303guy. | |||

|

One of Us |

No, absolutely nothing wrong with that group. But how can I achieve that? Might I ask how you achieved it? One of my problems is base edge deformation as the bullet gets swaged down through the throat causing base cupping and base edge feathering. Less than such bullet size results in flame cutting.   I'm thinking that all these factors cloud the twist rate issue. Even so, there is a limit of spin that a cast bullet can tolerate without deforming. I'm not sure that threshold can be reached before the other factors destroy accuracy. My bullets were captured at much lower velocity to be of any use in identifying high velocity and spin problems. Regards 303Guy | |||

|

| One of Us |

It has all been explained on CB and not many people listen. One thing I don't think you're going to do it with a bone stock Enfield and certainly not with iron sights. There's a lot going against you in that sloppy chamber too. It was explained that you have to fit the bullet to that particular rifle...the throat. I'm at the limit with my 50/50 alloy in my 7 twist 5.56. You may ask why when I have done so well with other calibers. That's the answer there..other calibers and larger ones. The cross section of the 5.56 is much smaller then the larger calibers and the 50/50 alloy can't handle it. The pressure works on a much smaller area. | |||

|

| One of Us |

303guy what alloy are you using and what powder? If you bases are getting destroyed in the throat the bullet isn't starting straight. The powder may be too fast hitting the base with too much pressure at the initial launch of the bullet out of the case. You have to start that bullet as gentle as possible. This is something that buffer can protect, but I'm not saying to use buffer in ALL loadings. I have a Finn39 that will shoot 10 shots into 1/2 group at velocity and it's a 10 twist too. That Finn will do it with the Lyman 314299 50/50 alloy. Now I did an experiment with that Finn by upping and upping the powder charge until I could cause the bullet to go crazy and thus found the pressure limit for my 50/50 alloy in that caliber and rifle. | |||

|

One of Us |

My alloys have not been very scientific, being made from scrap lead pipe, solder joints and more lately some copper rich babbit. A bit too soft. The base cupping is from the bullet been swaged down to bore size. The dimpled base bullet is from powder kernel impact. The smooth one had a buffer. The powder was H4350. I'm now trying W748 with a buffer - Dacron. The flame cut bullet had a flaw in it which caused that. What's not immediately obvious is the flame cutting on the smooth based bullet. That was caused by leading in the bore. Paper patched bullets don't gas cut all that easily. My choice in powders is to get a gentle launch but with paper patching one also needs enough muzzle velocity to shed the patch at the muzzle and anyway, since the object is to hunt deer and pig, enough velocity is needed anyway. However, for plain cast, the idea is for target shooting. My first attempt at plain cast was with 225gr bullets with integral gas check like the flame cut one. Velocity would have been around 1800fps and accuracy was good but I didn't pursue it. Now I want to try it again. Regards 303Guy | |||

|

| One of Us |

I think Lowes is having a big sale on RPM Thresholds this week. | |||

|

| One of Us |

Hooboy. Joe's question seemed simple enough to me. First, we've established that there is an ACCURATE VELOCITY LIMIT to a given combination of components, tools, techniques, and gun. This is not debatable, there are 25K members on another site of which maybe half a dozen can shoot cast bullets to their potential. Ask most anyone and they'll tell you a ten-twist .30 caliber can't be shot accurately past 1900 fps with cast bullets. Reason? Really bad castings, the "factory dies and a Rockchucker" as was mentioned, poor alloy choice, poor bullet fit, poor cartridge/chamber fit (misalignment), etc. which all adds up to damaged bullets exiting the muzzle. Damaged bullets don't fly true, and YES, there IS and RPM threshold for a damaged bullet, starting at 1 fps and getting progressively worse. I haven't even touched on improper powder selection and other component issues the average caster has. SO, eliminate those things. Fit the bullet and cartridge properly to the chamber. Correct the pressure curve. Sort out the barrel harmonics. Build an alloy that has the strength to handle a proper launch. Cast good bullets. Ok, NOW you can shoot much faster with good accuracy. Most people can't even do that, and say that their mangled bullets have a limit based on rpm alone. They're right in a way, but there's more to it than that. How fast one can go depends on the skill of the reloader and the equipment he chooses to execute that skill. Once the skill set has been exhausted, another accurate velocity limit is reached. Ultimately, it comes down to alloy again. Some folks are using exotic alloys to go beyond the limit of the 50/50 alloy. Yes, there is a limit to 50/50 as well. Now back to the TOPIC, why is there a limit to it? What's going on? Fast twist and high velocity cause something to go haywire eventually even with the best reloading techniques. Another example is pure lead. That stuff has an accurate velocity limit, well below commonly use lead alloys. Lyman #2 has a limit. 50/50 has a limit. This limit seems to be related to rifling twist, so it's naturally assumed by some (and can be loosely related to RPM) that it must be the RPM causing the problems. Well, that may be, because damaged bullets magnify the effect of that damage as rotational velocity is increased. But that's not the deal. The deal is that something is happening inside the barrel to CAUSE that damage which makes HV bullets begin to scatter at a certain point, something that fit and pressure curve can't fix. The RPM going up is merely an effect, not the CAUSE of HV cast accuracy issues. On to the CAUSE. We don't know. Some of us postulate that there is some sort of damage happening at the bearing points of the bullet which gets magnified at higher velocity in fast-twist rifles. We think this because (for one thing) of the paper jacket, and what that does and doesn't do. Take ten good bullets, lube them, check them, and shoot them above the accurate velocity limit. Take ten more, size them to .001" over bore diameter, wet-patch with two wraps of 16lb paper, lube with anything greasy you can find, stuff them in the same brass (sans check) and they will group. Same casting, same alloy, same nose shape, all the same except for the paper on the driving bands. I've done this with bore-riders and bullets whose noses terminate in the ball seat. I've paper-patched to full copper-jacketed velocities with castings that wouldn't shoot at 800 fps slower when just greased and checked. So don't tell me that it's casting voids, nose slump, base out of square, or any of the other excuses for not being able to shoot cast bullets at accurate high velocity. If I can wrap a scrap of paper around the same bullet and shoot it to the pressure limit of the cartridge with accuracy, the only explanation I have is that the paper both adds strength to the driving surfaces and maintains a more consistent bore friction shot-to-shot than a grease-groove bullet. Paper is very strong under compression, and when embedded into lead alloy reinforces the sliding surface considerably. My answer is that there is no RPM threshold, there's a threshold to how hard you can jam a bullet of any sort into the rifling and have it come out of the muzzle in good enough shape to fly straight. If you don't prevent this damage, the RPM monster will eat up your groups. But the RPM monster works at many different velocities based on the aptitude of the reloader, and is not THE factor in question here. Gear | |||

|

| Powered by Social Strata | Page 1 2 3 4 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  Is There A Rifle RPM Threshold

Is There A Rifle RPM Threshold

Visit our on-line store for AR Memorabilia