The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Mauser 98

Mauser 98Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Now I don't follow you...why are we loading the 375 and the 416 to the same pressure? | |||

|

| One of Us |

Factory loads dont load to the same presure, but many reloaders dont now that mutch about presure. And dont forget the tendence for overbore cartridges with reduced loads to generate "Detonations" | |||

|

| One of Us |

I understand that...but in this business, you can't even acknowledge handloads exist. It's an unknown area and I stick to factory ammo only. I know some folks handload, but I caution them that if they handload, they are "on their own" | |||

|

| One of Us |

I truly understand your warning. But in my buisness i think that one has to make an rifle so strong that even an optimistic reloader has to make his utmost to get himself into trouble. As every accident will have an extremly negative influence on your reputation. Nest you have to spend piles of money on lawyers , followed by raised incurancecosts. So i guess that the best is "rather safe than sorry" | |||

|

| One of Us |

It seems to me that this chap is all over the place trying to "prove" that HE has some unique knowledge that is beyond we mortals. The comment about the Schultz and Larsen was quite telling; these are nicely machined and are about the most USELESS POS actions/rifles for any serious FIELD use that I have EVER seen since I shot my first one in 1965. So, my apologies to Duane as I did/do not mean to exacerbate the situation by my humble opinions, but, I kinda think that an ulterior motive exists here in that our "learned" friend Jeurgen actually works for a rifle manufacturer and thus is hardly objective about this topic. Very simply, Jeurgen, your laudable concern for safety IS shared by all of us; it is your initial posts which tended to sneer at this that I object(ed) to and still do. What you evidently do not seem to grasp is that men like me would have probably died, alone and blinded, if we were foolish enough to use inferior guns and/or load to unsafe levels.....I do not doubt your expertise, however, some of us here ALSO just may know what we are doing and that is all I have to say on this as my point is made. No hard feelings, I hope, a concern for safety is a hallmark of a wise man, IMHO. | |||

|

| One of Us |

Dewey: appreciate it, but there's no need for anything resembling apology...Yes, jorgen is super critical...We've plowed this ground before. | |||

|

| One of Us |

Dewey, you need to do more reading and less typing. You're merely proving what an idiot you are. | |||

|

| One of Us |

Jeez...where did rolltop come from? had a bad day? | |||

|

one of us |

Duane I have always thought that a great wildcat could be made by cutting the rigby's long neck down and loading it to 3.6 OAL. It would be fine for a std. 98.... It is not like it lacks in case capacity. Now the new ruger 416 fills this hole. Jason "You're not hard-core, unless you live hard-core." _______________________ Hunting in Africa is an adventure. The number of variables involved preclude the possibility of a perfect hunt. Some problems will arise. How you decide to handle them will determine how much you enjoy your hunt. Just tell yourself, "it's all part of the adventure." Remember, if Robert Ruark had gotten upset every time problems with Harry Selby's flat bed truck delayed the safari, Horn of the Hunter would have read like an indictment of Selby. But Ruark rolled with the punches, poured some gin, and enjoyed the adventure. -Jason Brown | |||

|

one of us |

Can these FNs be heat treated(like military 98s) to bring them up to snuff? Jason "You're not hard-core, unless you live hard-core." _______________________ Hunting in Africa is an adventure. The number of variables involved preclude the possibility of a perfect hunt. Some problems will arise. How you decide to handle them will determine how much you enjoy your hunt. Just tell yourself, "it's all part of the adventure." Remember, if Robert Ruark had gotten upset every time problems with Harry Selby's flat bed truck delayed the safari, Horn of the Hunter would have read like an indictment of Selby. But Ruark rolled with the punches, poured some gin, and enjoyed the adventure. -Jason Brown | |||

|

| One of Us |

Baseless speculation that doesn't hold water. It assumes that Selby neglected his rifle. Corrosion would only ensue if it wasn't cleaned after use with corrosive primed ammo. Further, Selby bought his .416 in 1949. The only supplier of Cordite .416 ammo in the world in those years, Kynoch, switched to non-corrosive primers a few years later. Selby used his for almost 50 years. Cordite itself, like any other double-base propellant, has no corrosive properties whatsoever.

That has everything to do with the user, and nothing to do with the gun. The Pedersoli .45/70 double rifle is built and PROVED for standard .45/70 ammunition - 31,900 PSI/28,000 CUP. There is FACTORY ammunition available loaded to an operating pressure that's higher than that rifle's proof pressure and would be unsafe to use in it. Does that mean that the Pedersoli is a "questionable" or unsafe build that should be taken off the market? The rifle under discussion here, a .416 Rigby on a standard Mauser action, was commonly built in England and the required safety margins established by the proof testing legally required there, so it can be safely and successfully done. What simply doesn't follow is that a perfectly safe rifle built and properly proved for .416 Rigby (max 47,000 PSI) should automatically, by some magic, be safe with a steady diet of .416 Weatherby (64,000 PSI) class loads. That expectation is militantly ignorant...but we ALL know "advanced" handloaders that "know" that the proper way to determine a "safe" max load for a bolt rifle is to increase the load until the primer falls out, then back off a couple grains. Any rifle can be wrecked by a fool, but that doesn't make rifles "unsafe". It's kinda like drivers. Lot's of folks drive cars everyday, yet never learn how to do so safely, let alone ever actually learn anything about what makes them work. ----------------------------------- "Serious rifles have two barrels, everything else just burns gunpowder." | |||

|

| One of Us |

I still have a pertinent question or 2: What are the disadvantages of this conversion? Seems that future safety is the main issue along with a large labor cost for the conversion itself. So, in my mind, the disadvantages are that the owner is paying lots of money to be less safe, by whatever margin whether real or imaginary. But always remember that any removal of steel will weaken the action. What are the advantages of this conversion? I'm unclear about this part. One advantage would be the use of factory ammo but other factory chamberings seem to work just as well with much less expense and hassle. Another advantage would be the relative cost of the action itself and its conversion; a Magnum action or cutting-&-lengthening a standard one would cost more, but how much more? Another advantage in some minds would be the uniqueness and 'stunt' value of the braggin' rights among their peers, but again it seems to me that a Magnum or custom-lengthened action would carry even more of an admirable cachet with a truly knowledgeable audience. Still another advantage in some minds, probably subconscious to some degree, would be the sheer size of the Rigby cartridge as opposed to the other 416s and the relative daintiness of the standard action into which it's being crammed by its forceful owner, suggesting all sorts of things...... So, what's YOUR reasoning? Always remembering, of course, that this is a DGR and the maker will be risking his own professional & financial future as well as the user's life on its performance? I've always been a dedicated hot-rodder of both guns and autos, pushing things up to and frequently well beyond limits to the point of destruction, but this is one conversion I won't do. It'd be different if it was something like a 408 Cheyenne target rifle to be used on long-range paper, but I don't think that that big black buff is gonna stop his charge to laugh at you when your 416 fails! Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| one of us |

Oh, so now is a racial thing?  Aut vincere aut mori | |||

|

| One of Us |

JBrown: If we could convince CIP to issue new standards for OAL..we might not be having this lively conversation..but I like it! JD Steele: Your hot rodding is an individual choice, but I shake my head in bewilderment. from what I've seen on action "failures", due to "hot rodding"...it happens over time...the bolt lift gets siffer and stiffer until even an idiot could figure something must be wrong... Sudden failure? The only time I saw that is when some stumbler stuffed a 308 Win in a 7mm Rem Mag chamber...gas escaped everywhere...except into the shooters face! says a lot about the 98 design! | |||

|

| one of us |

Duane, purely out of curiosity if someone wanted to build a .416 Rigby on a M98 action and use one of your bottom metal assemblies which model or version would be the best for that purpose? How many would it hold down? This not something I am looking to do. I'm just asking out of curiosity. I am going with the 404 Jeffery and will be using your bottom metal for it. Allen It's a Mauser thing, you wouldn't understand. | |||

|

| One of Us |

A ...racial thing..., well, perhaps, but, "neo-Freudianism" occurs to me..... | |||

|

| One of Us |

[QUOTE]Originally posted by AllenBosely: Duane, purely out of curiosity if someone wanted to build a .416 Rigby on a M98 action and use one of your bottom metal assemblies which model or version would be the best for that purpose? How many would it hold down? This not something I am looking to do. I'm just asking out of curiosity. I am going with the 404 Jeffery and will be using your bottom metal for it. Well, the 3MX would work ...three down for sure. possibly four. Actually, I do not have a unit here to try out, You might have seen my post...mistake in machining the front radius, had to scrap all 30...working overtime now! While doing that...we took the oppurtunity to slightly re-design the box...moving it back as far as possible | |||

|

| One of Us |

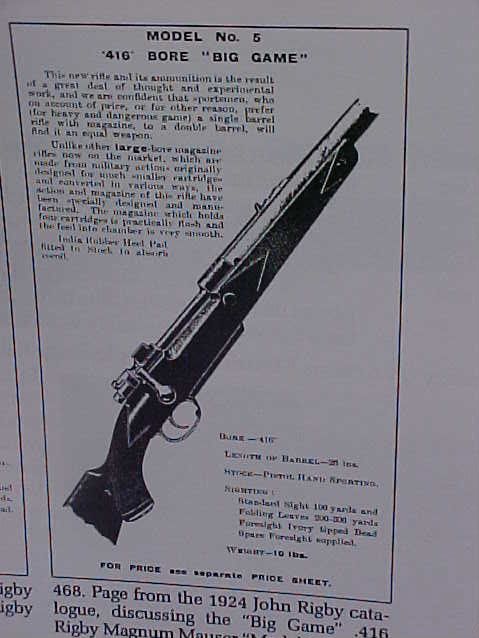

The receiver/bolt failure mode isn't the only thing to consider here. Duane and I have briefly discussed this on another thread and shared info but reached no conclusion that I remember. When lengthening the box to the rear, it's also necessary to cut back the front of the bolt stop in order to allow the bolt to travel farther to the rear to be sure of picking up the next round. The maximum allowable cut-back dimension is what was discussed and no firm conclusions drawn. 0.060" was mentioned, as was 0.100" as I recall, and I've done this on several plains-caliber ELW rifles built on small-ring actions. However when the front of the bolt stop is cut back to allow more rearward bolt movement, then the raceway protrusion dimension is also lessened. This happens because the rear of the stop is beveled to allow the bolt head to push it aside when the bolt is inserted back into the rifle after inspection. As the protrusion dimension grows less along with the increase in rearward movement as the stop is cut rearward, the effective engagement of the stop also becomes weaker & weaker until finally a spirited effort by a motivated shooter might actually pull the bolt clear out of the rear of the receiver past the stub of the stop. This is the scenario I had in mind when I referred to the big black buff stopping to laugh at the hapless hunter with his rifle in one hand, his bolt in the other hand and a look of comical terror on his face as he stares bug-eyed at his multi-thousand dollar sucide machine. Wish I could draw better... I respectfully draw your attention to the following Rigby advertisement reproduced on pg 221 in the fine Mauser book by Speed et al.  It's a little hard to read but Rigby makes a point of specifying that they use special actions and not the military ones that have been altered. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

...and Rigby also made many on standard M98 actions - very successfully - especially after WWII. The dire predictions here certainly haven't come to pass with respect to them. ---------------------------------- "Serious rifles have two barrels, everything else just burns gunpowder." | |||

|

| one of us |

I met and talked to Selby back in the early 80's. A very knowledgable gun nut actually. I handled and talked to him about his 416. it certainly was NOT rebarreled from rust and neglect. He took very fine care of that rifle, it was just plain shot alot. Selby was never worried by it being a standard 98. To me, the one thing it had/has going for it, is that it makes such a nice trim rifle. I'm not wedded to the 416 Rigby, so my 98 416 is a Taylor. | |||

|

| One of Us |

JDSteele:/400 Nitro Express: You're absolutely right about the bolt stop modification. Years ago, Jim Wisner machined bolt stops for GMA. He feels 1MM (about .040) is the absolute max for modifying. Jim says the heat treating is usually good for that. I mentioned .060, he says...yeah, but you have to make a new bolt stop! On our new 3MX bottom meal, we have moved the box back to take up all possible "slack", any modification to the bolt stop will be well under .040 About all I know...didn't take long did it? | |||

|

| One of Us |

Thread has more life then I expected. Gee, do the math etc. I guess that means increased bolt "thrust" from a larger case head. On the other hand, (new can o' worms coming) some argue that cartridges with little case taper, like Ack. Imps. and (I think) the Rigby have much reduced bolt thrust against the lugs due to better pressure distribution. Of course a 416 Taylor makes more sense on a standard 98, but if all we want is to make sense then lets eliminate all cartridges but .22 RF, 223, 308, 338 and 458W. We make our choices based on challenge, individuality and fun. Many have been injured or worse shooting Springfields w/ broke firing pins or brittle steel. I knew a fellow that nearly lost an eye shooting factory loads in his pre 64 M70 300HH. A primer let go and the M70's poor gas shielding let him get an eye full of gas and brass. Please don't get on me about the M70 cause I love em'. But facts are facts. If one does not want any risks they should stick to playing with toys intended for 3 yr. olds | |||

|

| One of Us |

Lakin: good post! I have been crucified for having the balls to criticize the gas route along the L. wall of the pre 64 M-70. Pete Grisel, who designed the Dakota action changed the bolt stop to eliminate the potential (his dad suffered injury just such as you descibe) For the interest of all, Ed La Pour has a new bolt shroud/saftey for the M-70 that has a gas shield...good move! I know this is getting off subject, but felt it was important to mention. | |||

|

| One of Us |

There's an interesting thread on the doublegunshop.com forum down at the bottom in the single-barrel section, entitled Springfield receiver on Gunbroker or some such. Re safety of the low-no 1903s. My friend 1878 makes a good observation: "There are always people who maintain that anything which has not killed them yet is good practice." When I was in the nuclear power industry we saw this attitude in action at Chernobyl; the laws of physics are just like the sea, very unforgiving in the final analysis... The theory that less case taper means less bolt thrust is largely negated by the examples of the 22 Jet handgun and the comparison of the various cartridges developed on the 219 Zipper platform. Case taper is only one of the several factors influencing bolt thrust and, sometimes at least, seems to operate (in the real world at least) in a counterinituitive manner that suggests that less taper sometimes can mean more thrust. A thoughtful review of the history of the Jet's real-world usage and a reading of Frank de Haas' article on comparison of shooting the various Zipper cartridges with their differing wall tapers will soon put some new colors in your paint box. Basically these data seem to indicate to me that the case taper theory is a non-starter until specific tests are run. I further postulate that UK smiths were desperate for actions in the time frame from the late '30s until well up into the late '50s when their economic situation had finally eased somewhat. This, in my mind, largely accounts for their (temporary, it seems) practice of using actions formerly considered unsuitable. But, as always, you guys can do whatever you want. Good luck, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

If you have ever seen the results of a case letting go in a M98 you will regard it's gas handling characteristics as mostly fluff. | |||

|

one of us |

I have experienced a case head letting go in a 98, and I damn sure wouldn't regard the characteristics as fluff. What I recall about it was a shrill report, the sound of the mainspring compressing to the limit and the rifle falling apart out of my hands. What could have been a disaster for me turned out to be a shattered stock. When the gas vented into the magazine box, it swelled it enough to break the stock in two. Except for the triggerguard unit, the metal survived unscathed. Oh, that and my eyes and face. Fluff, I don't think so. Roger Kehr Kehr Engraving Company (360)456-0831 | |||

|

| One of Us |

Have seen case heads let go in Mausers, 1903s, M70s and M700s among others. Shattered the 1903s & M70s, bent & deformed the Mausers and gave the M700s a coating of brass all over the inside but no permanent damage. My friend Jerry Dykes, an engineer working for the DoD back in the '60s in a government installation in my home town we call The Lab, was tasked with experimenting with hyper-velocity in an effort to improve our artillery capabilities. This early experimentation later led to the development of the magnetic rail gun among other things but that's another story. Anyway Jerry was a capable gunsmith although he made his living as a Professional Engineer, and his experiments began with loading magnum cartridges to maximum and beyond, in an effort to determine the roadblocks to truly high velocities. To make a long story short, he could achieve 5000 fps fairly easily but velocities of 6000 fps and above required the bore to first be evacuated among other things and so proved to be increasingly impractical. In the course of these early experiments he blew up many rifle actions of various types, and actually ended up making his own action for ease of disassembly after firing since the case head would disintegrate upon firing these 150K psi loads and braze everything together. He could not damage his Rem 600 Magnum action except by his attempts to remove the bolt after firing. He did this repeatedly, and had already blown up many other actions before he finally bought the 600. Winchesters and Mausers were early casualties, for different reasons, as were Weatherbys and Sakos. The only other action he found to be close to the strength of the 600 was the Savage 110. He didn't try the Rem 700 since he got such good results with the 600, nor did he try the Arisaka. My point is that he had the greatest respect for the gas-handling of the Mauser, far more than any other action tested. True, the multiple right-angle turns designed into the Rem & Savage actions were also a great help in this area but the Mauser's redundant safety features were better for the shooter. Too bad the Mauser steel wasn't as good as the Remington's, I don't think there's a better bolt action for gas protection of the shooter than a good Mauser. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

There having been several responses to the original question, hopefully no one will mind if I piggback a little off that to ask about something a bit related. How do you guys feel about the standard length Mauser action as a platform for a custom built .416, in the Rem Mag instead of the Rigby? How should the metal work end of it be built? Are there any safety issues that come to mind? | |||

|

| One of Us |

Good Grief...we gonna start all over again? | |||

|

| Moderator |

its excellent for a 416 ruger, 416 AR, 416 taylor, and will work FINE for a 416 rem. yes, it will work, now, i'll ask.. are you willing to PAY for it to work? opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

I think I already have, or at least I've said I would. Should I look to be paying for the standard action as is or with special features or mods for the Rem Mag? I assume it shouldn't have any metal removed anywhere or anything done to the bolt stop as discussed here, right? Btw, on the reference above to the 22 Jet, I just discussed that recently with the manager of a handgun mfg co and was told the main difficulty with the round in the Model 53 was headspace problems. | |||

|

| One of Us |

That is just another way of saying that the fired cartridge case had backed out enough to freeze up the cylinder. The revolver was NOT made with headspace issues, the 'headspace' dimension was and is fine but the case body/shoulder angle was not suitable for a revolver, the casewall springback is insufficient. IMO either the fellow didn't explain far enough or perhaps he was ignorant. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

The discussion about the 22 Jet was brief and just in passing; I had really called to talk about what features I wanted on a new gun. Before we left the subject I asked if someone wanted to do a small bottlenose hi velocity round for an N frame, instead of the 22 Jet why didn't they do one of the existing rounds or maybe even the 223. He said the same problem would exist. That was about the extent of the conversation. I've since done some investigating on the Mauser .416 Rem Mag and may back off from buying it. I believe it's built on a standard military 98 action and I'm starting to suspect that's not the best way. Btw, the price is $2,500. That should probably tell me something as well...too bad, it's a great looking piece. At just a quick glance it really does look like something far more expensive. | |||

|

| One of Us |

I walked up to a shooter moments after a .243 case head failed in a M98. The stock was split open through the grip from the gas expanding into the magazine box. The bolt was locked shut. He was bleeding from 30 or 40 places on his cheek, nose and forehead. The only thing that saved his eyes was his glasses. No one would claim the M98 has decent gas handling characteristics based on his face. | |||

|

| One of Us |

Of cause many would claime that the m98 handled the gas rather decently. Many other actions would have smashed his glases, and eyes to. The problem with most rifles with controled round feeding, is that casehead fails at about 50% of the presure needed to cause caseheadfailure on a decent PF rifle. This is most problematic when using standard dia casehead, at those calibers need more casehead suport to withstand excessive presure. To be a litle predictive, Several posters later, will clame that you are lying, and that this incident never hapenet. Then many would tell that the shooter is an idiot. Some might tell that the "Bubba" that rebarreled this rifle, made it with excessive headspace, or it was reloaded and to heavy resized. All this because that the "Mauserbible" tells that this could never happen | |||

|

| One of Us |

All anyone has to do to back up the claim that the M98 handles gas well is pull the trigger on a round that blows back like that. Then they can tell me they like how it handles gas. | |||

|

| One of Us |

I think you just hoisted yourself on your own petard, so to speak. The split & splintered stock is undoubtedly the source of all the cuts; if it was gas then his face would have been burnt and discolored instead of bleeding from multiple small wounds. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

Hi SR4759 To be honnest the m98 is one of the absolute better actions to handle this type of gasleak. Or said in another way. Ther is many actions that would do a lot worse. Paul Mauser learned the hard way, he lost his one eye from a gasleak, from a former model, Therfor he added alot of shields and details to reduce the problem, when designing the m98. Some would say that he had a lousy startingpoint, but he managed to make it mutch safer than other rifles of that basic construction. The problem starts with the CRF boltface, that does not support the casehead at all on the diameter. This results in many more casehead failures percentage wise than what would be seen on decent pushfeed rifles. The simple logic is that the higher presure that can be contained inside the case, the fewer leaks. Another "problem" with older and more traditional actiontypes, is the 2 or 3 raceways along inside the reciever. They has a nasty tendence to leed gas towards the shooters face. Hi J D You are most certainly right about the source of the splinters, it is most likely caused by stock splinters, and brass fracments. But the problem would most likely not have occoured at all, if the casehead had ben supported better. This because it requires betveen 50% and 100% higher presure to create a casehead failure on a actiontypr with limited overhang and suficient casehead support. | |||

|

| One of Us |

Joe, You are making assumptions that the punctures were wood splinters and you are wrong. I did not say the stock was splintered did I? His punctures were from the powder grains and case particles. I take it you have never ever witnessed a major gas leak from your comments. Again I ask would you like to touch one off like that? | |||

|

| One of Us |

I can't imagine why anyone wanting a 416 Rigby would not just buy one in the CZ 550 like the one in classified now? To me this whole issue in a no-brainer. It seems to me that if a relatively inexpensive action like the big CZ 550 was avaliable back when those 98s were being used for the 416, I think a 416 Rigby on a '98 action would be very rare indeed. And I also think the 416 Rigby would have been a lot more common. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia