The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Picatinny Base Working Loose on Muzzle Loader (pics added)

Picatinny Base Working Loose on Muzzle Loader (pics added)Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

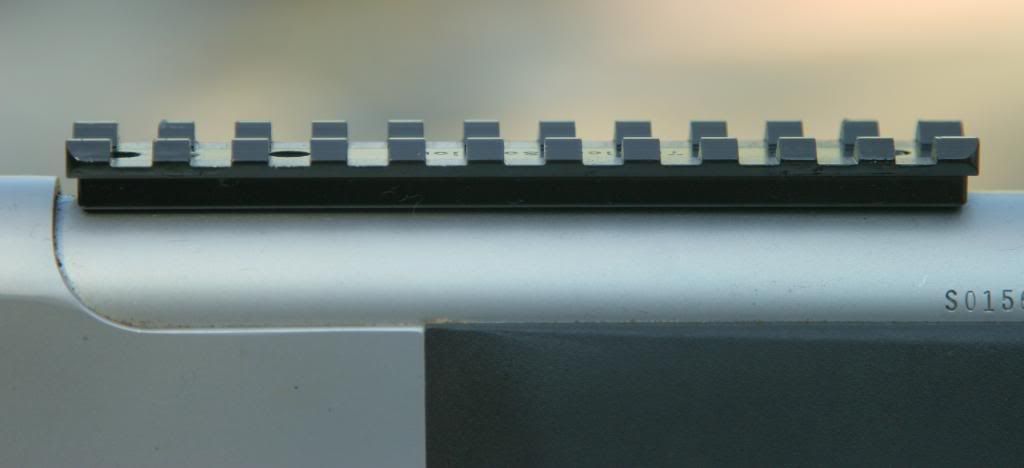

Rifle: Knight Revolution II Scope: Leupold 3-9X40mm with SABR reticle Rings: Leupold QRW quick release Base: Tactical Solutions picatinny rail I’ve got a question about bedding a scope base to my muzzle loader. As you can see, there are three screws holding the base on. Two of them are factory drilled into the base (front) and one looks like a blind man did it with a pocket knife. I am really pissed at myself for doing it with a hand drill (knowing better too), but I did not have access to my drill press at the time. Anyway, it is what it is, so now I have to make do. The base is not contoured well to the top of the receiver. This combined with the fact that only three screws are holding the base onto the receiver, it didn’t take much for it to rattle loose at the range (about 15 shots using 250 gr. sabots in front of 150 gr. of Triple Seven). So what do you recommend I do here? My thoughts were to bed the base to the top of the receiver. If I go that route, what should I use? Marine Tex, Brownell’s bedding compound, JB weld? The other thought is to contour the bottom of the base to the top of the reciever using coarse sandpaper draped upside down over the reciver. Maybe I need to do both. Your thoughts and suggestions are appreciated.      | ||

|

| One of Us |

Did you use any lock tight on the threads??? That would be my first try. www.KLStottlemyer.com Deport the Homeless and Give the Illegals citizenship. AT LEAST THE ILLEGALS WILL WORK | |||

|

| one of us |

Sorry. I just took that much for granted. Yes, I used blue Locktite. However, it did not hold well. Perhaps I used too little or maybe I didn't get all the oil out, but I think the misfit between the base and receiver is the main culprit. Thanks for the suggestion and input. Much appreciated! | |||

|

| one of us |

I'd use some Steel Bed or Aluma Bed by Devcon. Actually, first I'd call Tact. Sol. and ask why their rail doesn't fit the gun... | |||

|

| One of Us |

The fit could be a problem if it is able to rock around on the receiver. But if that were the case the scope could not be bore sighted. I think you should try cleaning out the holes with acetone and use enough lock tight that you have to clean it off the receiver after you mount the base. And put a good torque on the screws Maybe get new screws as well. www.KLStottlemyer.com Deport the Homeless and Give the Illegals citizenship. AT LEAST THE ILLEGALS WILL WORK | |||

|

| one of us |

Thank you both for the responses. I need to clarify further. I could not find a picatinny scope base that would work for the Knight Revolution II, so I ordered the rail from Tactical Solutions knowing that I would have to re-drill holes. Fortuitously, the front two holes lined up! That left a little less work for me to do. I actually think the base is meant to be mounted on a Ruger Mk II .22 LR pistol. Sounds like I should shop around for some Devcon at this point. What do you think about contouring as well? Overkill? | |||

|

One of Us |

For those calibers that like to shake mounts loose, I recommend going up a screw size so you can apply more torque. Also, to be sure it stayed put, I would recommend 271 (red) Loctite and Torx screws all around. . _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| Moderator |

I suppose the "best" way at this point would be to buy a blank section of picatinny rail, contour the base and drill the proper holes. I can't speak for anyone else, but if I had this situation on one of my personal guns first thing I'd do is decide that I could live with the scope base staying put for ever and ever (i.e. it looks like your base is aluminum, and you are positive that next year you aren't going to convince yourself you really need to put a steel base on it, or something with a silver finish, etc). After I decided that I had the mount I'd want forever on the gun, I'd bed it with a quality epoxy like marine tex, devcon, JB Weld, Permatex Cold Weld, etc. (my current favorite is JB Welds "Industro Weld", rated to 500F) Scuff the base with some 80 grit, degrease religiously, and then glue & screw. Depending on how the overage squeezed out either wipe it off carefully with a bunch of moistened Q tips or wait a couple of hours and when it is hard like a tootsie roll carefully trim it off with an Xacto knife. I'd also darken the epoxy to black by adding some carbon or other coloring agent. The added benefit to doing this is you can also fill in all the screw holes, which will assure the screws will never back out and have the added benefit of covering up the boo boo forever and look pretty nice to boot. The best way to contour that by hand is to find a piece of wood, conduit, PVC or iron pipe, etc that is close to the diameter you want and use that. Darn near every time I try using a gun for a form of some sort I wind up regetting something, even if it is so tiny you have to look hard, because you'll always notice it. However, if you do decide to use the gun as a template if you give it a wrap of masking tape first you'll probably be OK but personally I try not to use the gun itself for anything involving abrasives or shaping. for every hour in front of the computer you should have 3 hours outside | |||

|

| One of Us |

JB weld. | |||

|

| one of us |

Using emory wrapped on the barrel will result in an inside radius on the bottom of the base that is the thickness of the emory paper greater than the radius of the barrel. Your base will be bearing only in the center of the barrel countour & will still be unstable side to side. If you use a piece of round stock that is about .015" or even .060" smaller then the OD of the barrel & use the emory method W/a guide somehow secured along said round stock to assure a straight countour, that might do the trick. That way your base would be making contact along the outer edges only & would not rock. The screws pulling down @ the center would clamp those edges down tight. You could use some Dykem or inletting black to check for even contact like in this picture of a M98 rear bridge.  GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

I like all these suggestions. It sounds like this to me: 1. Contour 2. Bedding 3. Red thread locker I will look around for another blank picatinny base, but last time I tried that it was more money than I wanted to spend. That's how I wound up with the Tactical Solutions option. I'll look once more for a blank rail before I begin a permanent mount. It will give me a chance to do a more aligned hole. Thanks everyone for your responses! | |||

|

| one of us |

You must get contact all along the edge before you do anything. Having FULL contact @ the edges makes for a triangular effect. 1 point in the center where your screws are & the 2 edges. A traingle is the most rigid geometric form. look @ steel truss bridges. All conections are made to form triangles. A Triangle can not chamge form W/O one of the sides changing in length. Try the smaller diameter round stock/emory trick. Use some inletting black or even your Wifey's lipstick applied sparingly W/a Q-tip to assure full contact along the entire edge (or cloes to the edge) of the base. Use some loc-tite & I don't think you will have any nore problems. You can glass bed it if you want. My order would be. 1: Contour 2: Red Loc-tite 3: Glass bed or JB Weld, but use a release agent if you use JB Weld as heat won't even release it easilly like regular epoxy. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

It looks to me like the problem is that the radius on the mount doesn't even come close to the barrel radius so you don't have much contact between the two parts. You're expecting those four little mis-matched screws to take all the recoil. And, loctite should never be used on scope mounts or scope rings; never, ever. If that's the mount you want to use and can't mill the right radius on it, glass bed the mount to the barrel, with release agent on the barrel. Here's how I'd do it: With the mount on the barrel, put masking tape on the barrel all around the mount, then remove the mount. Sand the bottom of the mount to remove any paint and give it a slightly rough surface. Apply release agent to the area on the barrel outlined by the tape and to the screws. Mix up some Acra Glass gel and dye it black--don't need much more than a teapsoon. Apply the glass to the bottom of the mount and then screw it down, torquing the screws to 20-inch/pounds. Use a paper towel to carefully wipe up excess and shape the glass square with the mount edges. Remove tape and let the glass set up overnight. Mount the scope. Don't take the mount off to see what a nice job you did, it will come off when you want it to. John Farner If you haven't, please join the NRA! | |||

|

| One of Us |

In all the scope mounting I have done I have always used "araldite" epoxy glue (not the clear 5min curing but the original curing mix). This will serve to contour bases to the receivers although of course better to do most of this with the method you have alluded to. I also always use this glue on the screw threads. Never had a instance of bases or screws loosening if applied to clean degreased surfaces. Araldite can be 'broken' with application of heat if required at a later date. I don't like the look of your star headed screws as the heads do not seem to be large enough in the base holes. The slotted screw head is perfect. Maybe just an optical illusion but don't rely on screw shanks to hold everything, the screw head plays a bigger part in this. | |||

|

| One of Us |

must come loose during rapid fire | |||

|

| one of us |

I slightly contoured the bottom of the base using course emory cloth placed upside down on the barrel (covered in masking tape first). I really didn't do much good here as the anodized aluminum was harder than I expected it to be. I then degreased the surfaces using Brownell's TCE cleaner and then masked off the base. I mixed and applied the Marine Tex epoxy and let it set up for a couple of hours before trimming the edges with a razor blade. I consider this a permanent mount, so there was no point in removing it to "see what I done." Should be a raw metal to epoxy finish. I did locktite the screws in as well. Lastly, after 24 hours of curing, I sighted in the rig without a hitch! No loose screws, no loose base... just rock solid goodness. Unfortunately, weather and incompetence at the airline ticket counter is making me miss opening morning of deer season, but I'll arrive a little later in the day to do some damage. Thanks everyone for your advice with this project! Here are some pics:     | |||

|

| one of us |

Good fix. And if you ever want to take it off a gentle application of heat via propane/map gas torch will take it off. Good hunting. John Farner If you haven't, please join the NRA! | |||

|

| Moderator |

thanks! I've got a handirifle that does the same thing .. 10-20 shots, and its a 223, .. i put clear nail polish on it.. worked for awhile, broke free the other day.. i guess i can just marine tex it up, too! opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

For those of you that don't check the American Big Game section, I wanted to let you know that the scope base bedding held up two two days of brush busting and slipping and falling. It helped me kill this once-in-a-lifetime trophy on Saturday: (More pictures in the Big Game thread)  | |||

|

| one of us |

Now THAT was some time well spent! Congrats on a spectacular trophy! Shoot straight, shoot often. Matt | |||

|

| Moderator |

Jeepers, nice elk you got there! for every hour in front of the computer you should have 3 hours outside | |||

|

| One of Us |

Incredibly fine harvest! Congratulations... | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Picatinny Base Working Loose on Muzzle Loader (pics added)

Picatinny Base Working Loose on Muzzle Loader (pics added)

Visit our on-line store for AR Memorabilia