The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Square Bridges

Square BridgesGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Before anyone gets nuts, this is purely an edumacational question - NOT anything I would ever try to do myself at this stage. I could be wrong but, I could swear that I have seen some military Mausers that have had square bridges added to the front and rear of the receiver. My question is - exactly how is this done? I've always presumed that the bridges are welded to the receiver, machined and finished, and then the receiver re-hardened? Or, am I seeing receivers that came that way from the Mauser factory? Thanks guys -- remember: I AM NOT GOING TO TRY THIS AT HOME! | ||

|

| One of Us |

Yes, weld them on. I only do bridges so I don't have to re-heat treat. There is one in the Mauser Sporter book that is soldered on; supposed to be factory original. You are not imagining things. | |||

|

| One of Us |

You weld bridges on so that you do NOT have to re-carburize? I thought that once you touched the receiver ring with a welder, re-carburizing was absolutely required? | |||

|

| One of Us |

. The Germans created a whole sideline in the sporting industry by converting military Mauser's to sporting rifles by tin soldering square bases to the front and rear receiver rings for claw mounts. The large footprint was strong enough with tin to hold both the heavy claw mounts and massive 56mm x 30mm steel tubed scopes of the day. They never re-heat treated the guns after and I have seen hundreds of them chambered to high intensity cartridges with no ill affects. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Suppose someone were to do this today - would they silver solder the bridges on, or Tig weld them on and have the receiver re-carburized? | |||

|

| One of Us |

. It would be cheaper, simpler and a lot less risky to simply tin solder them on. If care is taken to properly mate the surfaces prior to soldering and cleaned up properly after and rust blued, the solder joints wouldn't even show. I have seen several modern jobs done in that way. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Ok lets try it this way - is it possible to Tig weld them on and re-carburize the receiver? Let's presume the receiver needs to be re-carburized anyway. What I am really trying to find out is, is Tig welding on the receiver where a square bridge might go, and re-carburizing, necessarily going to result in a dangerous rifle? | |||

|

| One of Us |

Why would I need to have the receiver re hardened when all I did was weld a bit on the bridge, which I have done? Understand that modern TIG or MIG welding affects only very small areas; you might be envisioning using an acetylene torch and heating the whole receiver cherry red. It is nothing like that. Of course you can if you want to, but it is not needed. There is no strength requirement in the bridge, and the extracting cam area is the only place that needs any hardness, and that is minimal, and not for strength. Yes it is cheaper and simpler to solder them on as then, there is no weld to clean up. But with welding, I don't have to fit them as close as Speer does; that welding rod will fill in all those huge gaps. Dangerous rifle? Welding on the bridge will not result in a dangerous rifle except out the front end. | |||

|

| One of Us |

The process of welding and non uniform cooling can result in the steel being in different atomic crystalline structures and having different carbon contents in the heat affected zone. Which make welding on the critical receiver ring not a good idea. Especially with 100 year old mystery metal which has already had carbon added to the surface. | |||

|

| One of Us |

I am talking about welding on the bridge only. I have done several of these and never had a problem. Welding on bolts should be far more difficult, given the hardness and high carbon steel, mated to low carbon bolt handles, yet, these never cause problems either. In theory, it seems hard to do; in real life, it ain't. | |||

|

| One of Us |

dpcd is talking about welding on the bridge. You could cut the fawking bridge right off and safely chamber a round and fire it by striking the firing pin with a hammer. (don't try it, but it could hypothetically be done) The rear of the action is just there to hold the bolt stop and the trigger. I imagine he's drilling and tapping the front receiver ring. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Yes but the OP is talking about both the bridge and ring.

| |||

|

| One of Us |

I wouldn't weld the front ring. TIG is localized but really hot and it would leave a brittle line of material on each side of the weld. The rest of the receiver would act as a heat sink and super cool the weld as soon as the torch came off of it. I would assume anyway. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

No, I am asking exactly the question you answered - NOT anything about gas welding. I do understand that TIG welding heats a much smaller area than gas welding. I could swear I have seen on one of the well-known rifle-smiths web site (though I cannot recall who), square bridges that were TIG welded to the front and rear of a military Mauser receiver. Now, here is the catch - I have a VZ24 that someone butchered (I got it cheap). One of the scope base holes is WAY off center, and the guy try to re-engrave a portion of the lion crest. I am wondering if the scope base hole and a small section of the crest can by TIG welded so a new hole can be drilled and tapped in the right place, and the area where the crest weld might go, just smoothed off. It's a shame, it is a nice receiver and they're getting so hard to come by. I have a beautiful 7mm polygon barrel that Gary Schneider gave me -- I wanted to make a nice 280 Ackley. | |||

|

| One of Us |

OK fine - DOUBLE SQUARE SCOPE BASES (front and rear). I've always heard that to be referred to as double square bridges - though I never understood why. Sorry for the cornfusion. | |||

|

| One of Us |

... | |||

|

| One of Us |

If I could afford a Satterlee action, I would have one! | |||

|

| One of Us |

... | |||

|

| One of Us |

You know how internet forums are... Someone will tell me its garbage then offer me $25 bucks for it I'll look for another action. | |||

|

| one of us |

A competent metalsmith could surface grind the receiver ring, fit and attach a custom base using the misdrilled hole if necessary, then machine dovetails into the base for Talley rings. Had it done on a pre-war M70 that had four holes in the receiver ring. It's hard to tell the base isn't integral. Not sure I would do it on a bubba'ed VZ24, though. | |||

|

| One of Us |

Ah, ok, I know what you want now, and it was a circuitous route. One hole off center in a Mauser doers not equal a scrapped receiver. You can plug the hole with a screw and just melt the top with the TIG gun. That won't hurt anything. Best, and easiest, way is to put a scope base on it, using solder, or other holes, and shoot it. | |||

|

| One of Us |

I will keep my eyes peeled for a better receiver - and section this one in half lengthwise and use it for a conversation piece. | |||

|

| One of Us |

You would be surprised how nice a job you can do on receiver rings front and back by mounting them in a spacer, dividing head or horizontal rotary and resurfacing them with a brand new 4 flute carbide end mill running at ludicrous speed. I just lightly buff them with 400 W&D and kerosene and a hockey puck after recutting to get all the lines going the same direction. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Thanks, Duane. I'll find a better receiver. | |||

|

| One of Us |

| |||

|

| One of Us |

Why don't you just put a scope base on it and use it? Covering the errant hole. | |||

|

| One of Us |

Feel free to PM me with details if you want to sell it. Dave In 100 years who of us will care? An armed society is a polite society! Just because they say you are paranoid doesn't mean they are not out to get you. | |||

|

| One of Us |

Maybe I will go back to using M700 actions! | |||

|

| one of us |

No go to Ruger MKIIs they have a very nice integral mounting system. | |||

|

| One of Us |

Karl, If you what you are after is a rifle with irons and a restored ring with that cool lion crest (like your avatar), you might consider fitting soft screws into the existing holes, cutting off the heads, then peening and filing them flush. After re-engraving it should be hard to tell they were ever there. Not perfect, perhaps, but close. | |||

|

| One of Us |

Good eye, Redoak8! I was going to mount a scope, I just wanted a fully intact crest underneath it. I thought it could be TIG welded and cleaned up. I didn't lose a college fund on it so, eh. Some minor pitting near where the front ring meets the loading port on the right side of the receiver was TIG welded - I smoothed the weld off (it was just a tiny area - the weld actually looked real good) - I always intended to have the thing re-carburized but combined with everyone else's opinions, I'll have to keep looking for a good receiver - or an M700... Used to be a person could find a decent receiver on GunBroker - not anymore! | |||

|

| One of Us |

Ok, I will sell you a VZ24 action with intact lion for $350. | |||

|

| One of Us |

| |||

|

| One of Us |

You just have WAY to many purdy guns Butch. You should be ashamed of yourself ! he he he When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

| |||

|

| One of Us |

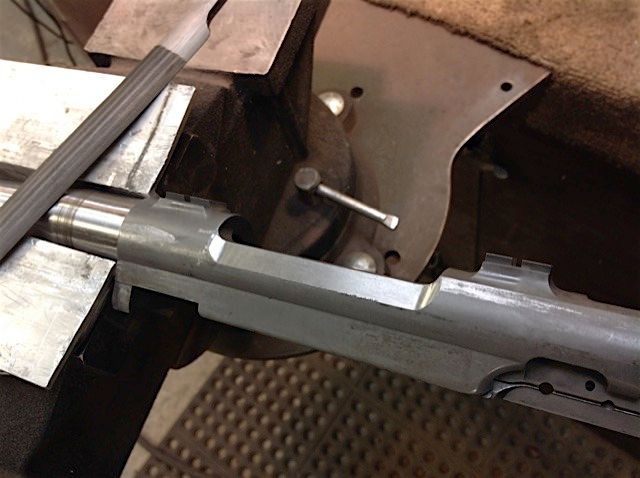

Patrick Holehan does it on his rifles. Here's one from a pair of Mod 70s he's about to finish (.270 Win and .340 Wby)   And the finished product on a (Dakota) 416 Rigby   There are two types of people in the world: those that get things done and those who make excuses. There are no others. | |||

|

| One of Us |

Wait - is that scope bases WELDED to the front ring of that receiver? | |||

|

| one of us |

Since a MAUSER is cased harden metal over a soft core to prevent fragmenting if it blows, I have had them softened to shape weld on square bridges then had them reharden as suggested by D'Arcy Echols, who does this on any Mauser. D'Arcy is a gunsmith whom I have a lot of confidence and respect for. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Spending a day or two welding it up, recontouring in the mill, polishing, a one off at the heat treaters, final polishing and bluing is a quick $1,500 to $2,000. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

I agree with you Rod. | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia