The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Best Cold Bluing?

Best Cold Bluing?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

OK, I realize it isn't going to be as good as hot bluing, but who makes the best cold bluing for new chrome-molly steel? I have had good success with Birchwood Casey for touch-ups. Once "blended in", it's very difficult to tell it has been done. However, I have heard there are better products for a complete job. | ||

|

| One of Us |

I have used everything from Herters Model Perfect blue to the latest concoctions; they are not for whole jobs. I recommend rust bluing; it will look better and be far more durable. Not much harder. Get the solution from Bobster. Steam the rust; it will be black the first time. The problem with cold blues is that they all work by copper plating your steel, then turning the copper black. and smell like selenium; not a good smell. And they rub off easily. | |||

|

| one of us |

As usual just my $.02 Paul K | |||

|

| One of Us |

Brownell's Oxpho blue seems to work well. 60 years ago my dad cold blued a Rem Model 12. Even with heavy use it has held up with no wear in the bluing. I would sure like to get what he used then..... | |||

|

| one of us |

If it worked that well, they probably made it illegal like so many other things! Other than the cream not running or dripping, is there any difference of the quality of finish between the liquid and the cream? | |||

|

| One of Us |

There is no difference in any cold blue formula; they are all just for touch up; not for whole guns. Sixty years ago they probably used mercury in it. Rust blue. | |||

|

| One of Us |

They f**king stin k of it in fact. And puts buyers off if you ever want to sell it. The smell never fully goes away. | |||

|

| One of Us |

I have never found one I like for anything other than a small touch up. What dpcd said. Dave In 100 years who of us will care? An armed society is a polite society! Just because they say you are paranoid doesn't mean they are not out to get you. | |||

|

| Moderator |

yes, yes they do stink - i think the brownells stinks the least, but it STINKS here's some of the one's i've used  btw, if you MUST use this, degrease, heat with either torch or heat gun, apply, allow to "frost", even if you must apply more heat, and repeat twice more, buff with a very mild scotch brite pad with APF or some other good oil.... best thing i've used as a non-caustic is, well, i hate to say it -- plum brown --- then boil it, turns a pretty blueblack, then oil it... you can use just about any "acid" to strip the existing blue off --- diet coke is one of my favs, though CLR (or your local equal toilet cleaner) does a good job ... apparently hog/deer blood will strip blue right off, too... i was experimenting with a turk action, put it in some yankee "picante" sauce, took the blue off, may have improved the taste of the salsa, then a couple coats of plum brown, boiled it for 20 minutes, and came out looking great.... easier than rust bluing, didn't stink like cold bluing, and just boiling water, not 300deg caustic in my tanks.... and yes, i had used my caustic tanks to do this for my own guns ... WAY faster, way easier .. just put in the oil bath (6" PVC pipe with oils in it) afterwards .. still looks passable opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

I use Brownell's Oxpho blue for small stuff, never thought about doing a whole gun with it. Steve........ NRA Patron Life Member GOA Life Member North American Hunting Club Life Member USAF Veteran | |||

|

| one of us |

Plum Brown is a hot water blue formula. Essentially a type of accelerated rust blue. The copper chloride in it helps tint the brown a plum color. It works but does require boiling tanks. Boiling converts the brown to blue/black. Not many hobbyists have access to or are willing to purchase that equipment. Cold rust blueing on the other hand can be quick, easy and cheap to do even by the rank amateur. Especially if you have proven effective formulas. Check out my site and blog. You can use commonly available items to fashion equipment that can give you professional results. Usually less than $40 if you buy it all new. I like rust blueing because I can do other things while drying,rusting, and steaming are going on. Very little labor involved in steaming and carding when using my techniques. I can usually do 3-4 passes if required within a half day. Sometimes only two passes. Probably less than an hour spent on labor. The end result is a highly durable uniform finish. Bob www.rustblue.com | |||

|

| Moderator |

Bobster, you are correct -- though i submit that for about $120 bucks, anyone that might be interested could have a tank and lid, from brownells http://www.brownells.com/gunsm...g-tank-prod1062.aspx http://www.brownells.com/gunsm...-cover-prod1100.aspx and since many folks have a "fryer" bottom, they could do this ... i rigged up my first tank out of tin and rivets, with a "fold over" cover, at least 20 years ago .. i was broke broke, and had the "formula" for rust blue ... cost? a pop rivet kit and high temp RTV .. worked well enough ... used my bbq for heat source -- wasn't very efficient... wasn't very safe, but it did work fine, and worst case, i spilled hot water.. i've had caustic tanks, tried many things for metal finish ... and i can't stand the stink of cold blue ... anything that smells that bad has to be nasty opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

" smells like selenium....". I had always thought that selenium was the magic ingredient. Not so? | |||

|

| one of us |

I like Oxpho blue. An an aside, I used it on a bunch of machine tool stuff I made. After over 20 years of hard use they were still blue but a little faded. Dave | |||

|

| One of Us |

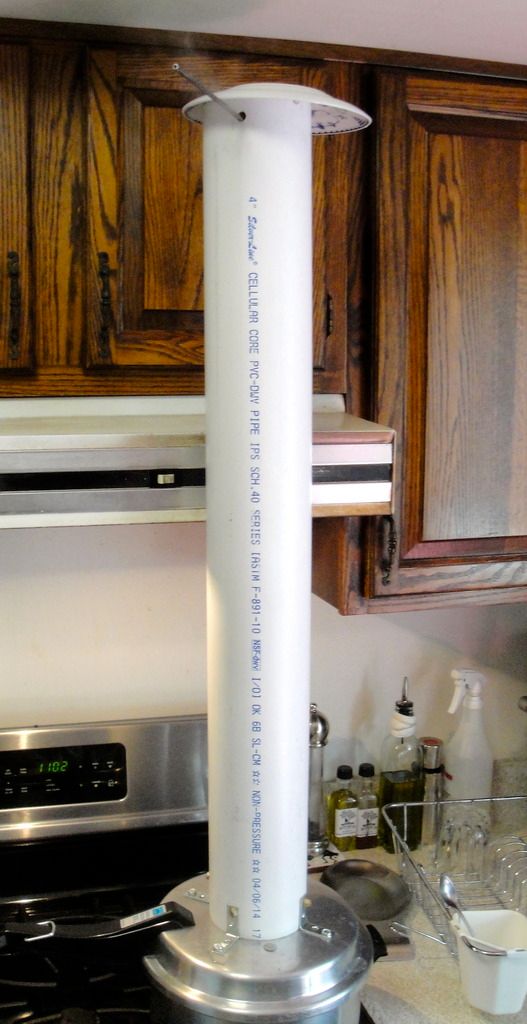

Yes. al cold blue uses selenium as the main ingredient; hence the bad smell. BUT, rust blue, as Bobster describes, is far better and very slightly more expensive. NO tanks or gallons of boiling water is required. you STEAM the parts in a vertical PVC pipe which costs 12 bucks max, and you need an old pot. That's it. . 120 bucks; Not necessary at all. I did one last week in two coats; dead black. I used a pressure cooker only because it has a locking lid; there is no pressure involved; there are 5 one inch holes in the lid.  | |||

|

| One of Us |

Your wife must love you. | |||

|

| One of Us |

I no longer use the saucer on top; that was a yelling fit waiting to happen; now use a pice of foil to keep the steam in. I have a butane burner in the shop but this way is faster; best to do it when she is not there. | |||

|

| one of us |

| |||

|

| One of Us |

As dcpd says, Selenium is the stinker. Selenium oxide, I believe. Good for touch-up. I did my Dad's Western Field .22 40+ years ago with Birchwood Casey's version. Held up OK for a few years. Now that I've inherited it, I plan on stripping it and rust bluing, as well as restoring it to it's 1945 original shape. Bobster's Rust Blue is damn near as easy and a whole world better. After I saw Tom's arrangement for steaming, I built one of my own. I put that up there with quitting smoking as one of my better decisions. Doug Wilhelmi NRA Life Member | |||

|

| One of Us |

| |||

|

| One of Us |

Ive tried rust blue and I suck at it. I hope to get back to it someday and build a sweat box, (Utah is Semi-arrid, not very humid) but that is a project for the future for me. I tried the Plumb brown/boiling job that Bobster mentioned and my derision of it turned out butt ugly. I have tried every cold blue on the planet and oxpho is about as good as it gets. But what I have been using in preference to cold blue is Browenells Dicropan IM. It can be "splotchy" but frankly I have been getting better and better results and it definitely holds up better than any cold blue. Looks way better too! I fashioned a pan similar to Mauser98's and use a 3 burner propane stove from Harbor frieght. Not the best, but it suits my needs for now. Like rust blue, metal preparation is key. And since I have been improving at that I will have a go at rust blueing again for sure, in good time. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

Your humidity can't be lower than here in the winter; I have a ready made sweat box; the bath room. fill the sink up with hot water and close the door; You will get rust. Yes, metal prep is paramount; I degrease with alcohol, then scrub with a scotch bright pad and detergent, then alcohol again. Never any oil left after that. I have used Dicropan too; it will turn steel black. | |||

|

| One of Us |

My barrel boling set-up is just like Craigster's. and, yes, across the cooker, on the angle, like him. | |||

|

| one of us |

Was just going to ask if Oxpho was still the best cold blue product when I saw this thread. There is hope, even when your brain tells you there isn’t. – John Green, author | |||

|

| One of Us |

Yes it does, but not as black as boiled plumb brown.. There is no bluish hue to that stuff whatsoever. Is there any particular detergent you like to use for de-greasing? I just use liquid dish soap. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

I am not inferring that any cold blue, including dicroopan, is as good as rust bluing. I use a scotch brite pad with cheer laundry powder on it; that is a very powerful degreaser and the pads make the steel surface microscopically rough to take the acid. Boiled Plum Brown is, rust bluing. Just uses heat instead of time, to produce the rust. | |||

|

| one of us |

FWIW I did a chrome moly barrel a couple of years ago with Oxpho Blue. It looks fine and has held up well. Good prep and lots of coats seemed to work. Mine smells like whatever oil/rust inhibitor was last used so don't know about the smell. It's probably not up to gumsmith standards but for a home/hobbiest shooter it looks fine.  Have gun- Will travel The value of a trophy is computed directly in terms of personal investment in its acquisition. Robert Ruark | |||

|

| one of us |

Could it possibly have been Formula 44/40?? http://www.brownells.com/gunsm...n-blue-prod1112.aspx | |||

|

| Moderator |

As mentioned already by a bunch of people with tons more experience (and better taste too!) than I, the cold blues do not give the best finish in the world and with only slightly more work rust blue can. However, I'll sat that for me at least a cold blue can make a cheap gun look much better, especially if it is a gun you would like to look a little nicer but do not want to do much extra work on. Typical example of this is a cheap 22 rifle that has killed more game than most custom rifles as it sits next to the back door or wherever. Anyway, for those projects I use a 2 step process with Oxpho blue and T4. I have to say that I like T4 as a finish but it doesn't really protect IMHO, and I like Oxpho for durability but it is too gray for my tastes so what I do is degrease with whatever is handy, usually either brake cleaner or rubbing alcohol, then give a couple coats with the oxpho followed by a couple coats of T4. Then heat it up and oil it (hair dryer & WD40 or similar method). Looks nice enough to me, is durable, and if you don't have to root around to find your stuff you can be pretty much done in 45 minutes start to finish. Also, I apply the blue with an old toothbrush and pour the cold blue in a small plastic cup like what you get ketchup in at a restaurant, then scrub the barrel with it going over each area a couple times. When finished toss the blue in the cup. for every hour in front of the computer you should have 3 hours outside | |||

|

| one of us |

I have on more than one occasion rust blued a .22 rifle within a 4 hr period. Removed rusted spots, textured with abrasive and rust blued over the whole. I watched TV most of the time waiting for the rust and conversion in the steam pipe. Got it back to the customer the next day. Bob www.rustblue.com | |||

|

| One of Us |

One coat? | |||

|

| one of us |

3 passes. 30 min ripening in low steam chamber followed by a 15 min conversion in a high vol steam pipe. Scratching about 10 min per pass. This is just a simplified version of what armories did 120 years ago. Except they used large steam rusting chambers and retorts with live steam to convert. I use cheap cardboard moving wardrobes and Cell Core PVC. I ripen with a clothes steamer and convert with high boil water under the PVC. See dpcd's setup above. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia