The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Project update - New Stock for take down model 1910 Mannlicher Schoenauer

Project update - New Stock for take down model 1910 Mannlicher SchoenauerGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

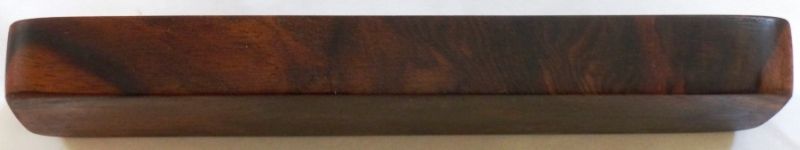

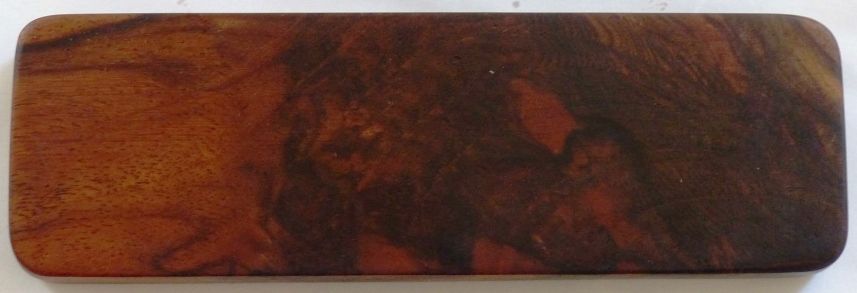

I had made up a reloading block for my 416 Rigby, using some off cuts from the blank. Here are some pictures of what it looks like with one simple wipe down of Boiled LSO infused with Arkanet root for 2 yeras! Another piece from the but end of the blank to give you some idea of how the marbled swirls can look when done.      "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

First steps of oiling I used BLO to oil the barrel channel, but end of stock and all the inletted areas. After a few days I applied paste wax (Bee's wax with olive oil). Then I used the BLO with alkanet root infusion and applied a liberal coat and left it for a few hours and then sanded it with 240 grit. A couple of days later it was dry. I applied another liberal coat and after a few hours I sanded again with 240 grit. A couple of hours later I used a cloth and wiped the slurry across the grains. Most of the pores have been filled. This is very dense wood.     I have now mixed the BLO with the Alkanet infusion from IPA alcohol and applied that as a thinner & quick drying coat. Now it is will a case of multiple coats and sanding with 400, 600 & 1000 grits. Finally I will do the same with Truoil diluted with Mineral spirits for the final seal and waterproof finish IN THE WOOD. "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

4th coat with 400 grit sanding     I would appreciate any suggestions - particularly from those who have done this before. Should I now stop the BLO / alkanet root infusion and just let it dry for a week and then do the truoil coats /sanding? Murphy's law prevailed and I put a few dents on the wood! "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

one of us |

Nakihunter The final product is amazing! At times during this project I had my doubts, but you have really created a beautiful stock. I can't wait to see it with the barreled action in place. Jason "You're not hard-core, unless you live hard-core." _______________________ Hunting in Africa is an adventure. The number of variables involved preclude the possibility of a perfect hunt. Some problems will arise. How you decide to handle them will determine how much you enjoy your hunt. Just tell yourself, "it's all part of the adventure." Remember, if Robert Ruark had gotten upset every time problems with Harry Selby's flat bed truck delayed the safari, Horn of the Hunter would have read like an indictment of Selby. But Ruark rolled with the punches, poured some gin, and enjoyed the adventure. -Jason Brown | |||

|

| One of Us |

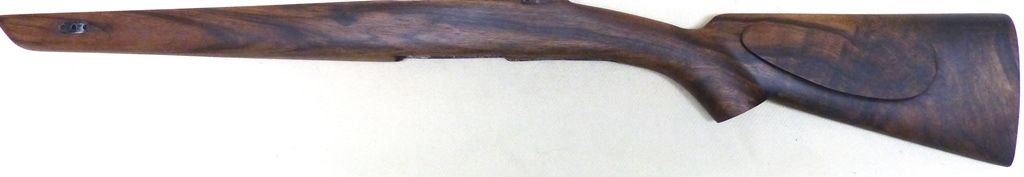

Thanks to Jason for some inspiration! Here are some photos - before the Truoil coats. I am just allowing the stock to dry and I just keep handling it. I have removed some wood to accommodate the bolt handle on the right side. This needs fine tuning. The length of pull is too long - 15.5 inches. I need to remove 0.75 " but I'll wait and see how the stock ends up in appearance before I remove the extra wood (if at all). I really lik some of the wood contract at the end and hence I had left it. On the other hand, if I decide to install the steel trap door after all, then I do not need to shorten it!       "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

Hi Naki The stock looks great, well done! | |||

|

| One of Us |

Man .... this oil finish is a PhD research project! having done one rifle with TruOil, I though I'd do BLO with Alkanet root & then TruOil. Well ... the BLO coats were fine & I got the desired colour and filling of the pores with wet sanding. The stock was drying for a couple or 3 weeks. When I tried to apply a thin coat of TruOil 50% diluted with mineral spirits, I found the TruOil was not penetrating into the wood by staying on top. So I sanded it off. This actually helped seal the wood even better. Now I tried Watco Danish oil (someone here suggested i try Danish oil). So far I have found it easy to apply and it does soak into the wood. No film on top. It dries in 8 to 12 hours like it says on the can. But the finish is really dull. I am not getting the sheen I got with Truoil on the last stock. I searched the internet and found that Watco Danish oil is actually 30% Linseed oil! There is a lot of info and a lot of myths. Well ... I have waited so long ... no harm spending more time ... May be I should take some photos. BTW - I shot the rifle at the range & the bedding held up. No movement. The tang sight was screwed in and it has not moved with 3 shots. The recoil is similar to the 9.3X62! But the straight stock & the recoil pad make it very shootable. "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

| |||

|

| new member |

hi naki dont suppose you feel like doing another stock? haha ive got a rifle the same 9.5 mannlicher m1910 without popup sight | |||

|

| One of Us |

I am happy to share what I have and help you mate. Where do you live? I have the CAD drawing that can be used by a joiner with the right machine. Or if you live near New Plymouth area we could meet up & I can take you through the steps and introduce you to Wayne who did the CNC work. The guy in BOP who has the walnut blanks is a good source if you want a blank. These rifles are classics and a real piece of craftsmanship and should be hunted with. PM me your email.

"When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

Next phase of this project is checkering the stock. I am moving some posts from another thread so there is some continuity. Since the 2013 finishing the only thing I have done to the rile is to try melting bee's wax and raw Carnauba wax. The result was that I got a wax that was still a bit hard but possible to force on to the wood. I am not confident of using flammable liquids like turpentine or mineral spirits with the hot wax. I did scrape the hard wax and rub it on the stock with a cloth. The finish is improving. But I thought that I will do the checkering first and then do any further hard surface finish. "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

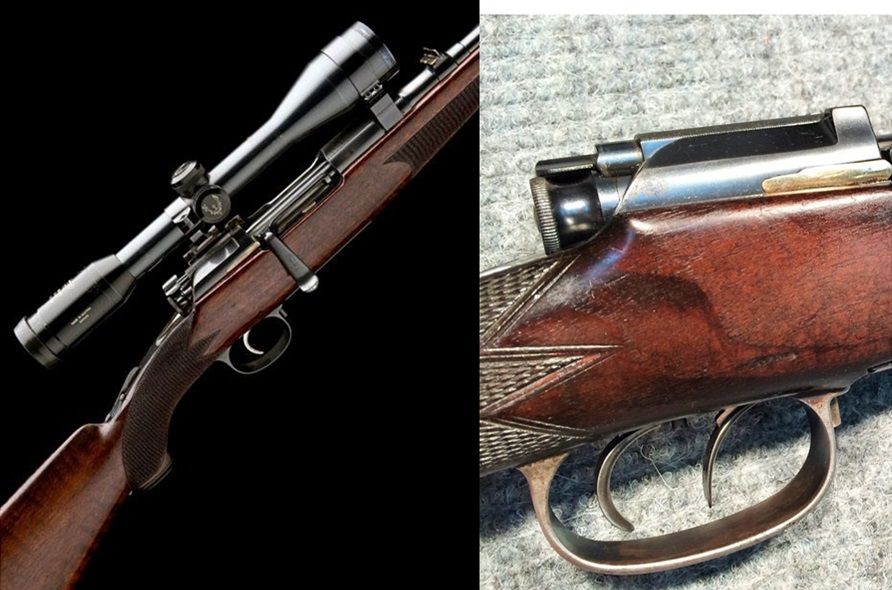

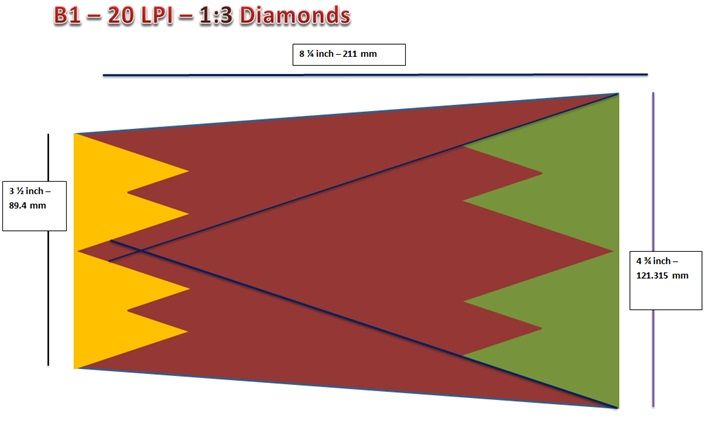

http://forums.accuratereloadin...043/m/5691003641/p/1 http://forums.accuratereloadin...043/m/347103474/p/14 I found these great threads. Thanks for the help guys. Thanks for the offer of the CD too. My rifle stock has 3 issues that I need to address with checkering. First - the cut on the pistol grip that has an inlay - easily fixed with checkering. Second - another insert behind the trigger guard to fix the blunder of taking too much wood out - Duwane's pattern will cover the joint of the insert. I am wondering if I should do a full wrap around on the pistol grip of do 2 panels. Third - my rifle has the tang extension diopter sight and so I'll have to work around that. Yup I am going to get that Kennedy book. About to buy a checkering kit with book, visor etc. In a checkering kit I presume that the single line cutters - 60 degree & 90 degree are universal for all LPI. The No4 spacer & No 2 two-line cutters and others are unique to each LPI. So if I wanted to do 18 LPI & 20 LPI & 22 LPI, all I need is extra No 4, No 2 etc. I have found a 7-tool kit (used Dembart), Kennedy's book, magnifying visor, wax pencils, etc. for US$100 here in NZ. Waiting for the auction to close next week the guy has been trying to sell it for 2 months now! That kit includes a joiner, which is not part of a normal kit & quite expensive. Searched the Web and found some MS rifles with nice period checkering. Really motivated ..... Here are some pictures. I really like the one of the pistol grip. My rifle has a steel grip cap but I want to get a similar effect around the trigger guard area so that I can hide the wood insert.   These are more like my rifle. I will have the border as close to the steel pistol grip cap as possible. I hope I get a nice finish around the diopter sight.  I really like the top one below.  The left one would suit my rifle. I would still like to get the finish around the diopter sight.  Plenty of examples to work from   Here is my pattern done on the computer. I will practice with this a few times on bits of wood and on my Remington .22LR.  "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| one of us |

Nakis rifle is a RIFLE not a carbine, and is a collectors piece. That rifle should get new wood formed exactly like the stock it was made in originally. The reason Mannlicher Shoenauer rifles are so accurate is in large part due to the very precise bedding. These rifles are treasures and should be kept as first built IMO! .................................................................... ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| One of Us |

Mac Yes I agree. The two MS rifle I restocked were both bought with very poor restocks - as you can see in the earlier parts of this thread. I am looking at photos on the web and I found many carbines. The final pattern will be something that suits the rifle. Just planning it now with ideas. Sharing it so I get feedback & keep the motivation going! Thanks for the constructive challenge. Please continue to do so. "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

Found this on the Web & ordered it. I think I can make a simple checkering cradle (like the one on Brownells) and fix it to this vice and have a good stable & flexible platform. I would appreciate any comments. "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

My Checkering cradle set up. The Tilt vice with the 2X4 and the "L" angles give it a profile that is not too different to many cradles you find on the web. I bought an adjustable ball joint footing used for joinery / desks etc and screwed a plastic piece (from a CC TV camera housing!) I now need to use a large GI bolt with a wooden clamping bit. I will use thick carpet material and rubber tubing to hold the stock. The Dembart checkering kit arrived. I will now spend a few months practicing on other bits of wood. "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| one of us |

It appears to me that your stock design is too straight, as if you overthought, you could cut the comb and heel down just a tad, and have a good purchase, its just a little over done IMO based on photographs of your bland drawings..Add to that a .500 high NECG gold faced partridge front sight then file it to zero if need be..A .500 front post will not hang up in the brush I assure you, if it did then so would a .200 high sight, you would be in the wrong place is the culprit...Happy hunting and good luck with your project, nice wood. The above comes from your original mark on the stock blank, the near finished profect is different,in that you modified the original plan, therefore your problem is the tang sight that's absolutely an low comb project as in the original factory stock..You could probably solve the problem by not using that particular peep, however it would be a shame, and use a receiver sight on the action to lift everything up to a level that's fine for scope and peep..and of course the .500 NECG that give you a lot of room for error..MS solved the problem as one can see by doing away with cheek weld, and the old timers didn't feel it was a problem much like the early Americans felt about the low comb mod. 70s, and believe it or not they for the most part could probably out shoot 90% of todays American hunters as life was different back then and they certainly made do.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Tries the 3 loads today on Saturday after having released the tight spot from the magazine floor plate that was locking the stock very tight. That seemed to have solved the problem of very high point of impact. The IMR 3031 load seems to be the way to go. I could go up 2 grains to get 2300+ fps for 250 gr bullets. I need to load some of the 270 gr bullets at the book 47 gr. A pity that the 270 gr RN bullets are not easy to find unless I go premium with Woodleighs "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| one of us |

Be careful. I have that vise and if you over-tighten the ball joint it will crack and destroy the joint.

| |||

|

| one of us |

Naki, can you send me the link to that vise? Thanks, Bob | |||

|

| One of Us |

https://www.amazon.com/SE-8436...e-Vise/dp/B0013E2AQY Bob, there are hundreds of ball joint vices in the market - just google "ball joint vice" and look at the images https://www.google.co.nz/searc...igB&biw=1217&bih=582

"When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| one of us |

Looking at your first posts and at your finished job, its an amazement to me how you got there, but you certainly deserve all the praise in the world, you did good.. If I were to suggest a couple of things it would be when glass bedding and your applying your glass to the stock, warm the glass with mamas hair dryer and you won't have any gaps, the other is the line of the underline of the butt stock and the recoil pad don't match, cut the bottom of the recoil down to match the stock, its the little things that count. congratulations.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Thanks Ray, much appreciated. Now that the sighting in issue seems to have been resolved, I still need to do the following 1. Checker the stock 2. Find or make a dovetail insert for the flip up diopter tool 3. Rust blue the rifle 4. Shoot some game with it - some goats and probably a fallow deer 5. May be fix a scope (I have the base on my 6.5 and could move it over or get a new one from Watts Walnut - his last CNC run) It has been a fun project and very satisfying to learn that I did have the patience and tenacity to persevere. "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| one of us |

Well you certainly did that, and did it well. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Project update - New Stock for take down model 1910 Mannlicher Schoenauer

Project update - New Stock for take down model 1910 Mannlicher Schoenauer

Visit our on-line store for AR Memorabilia