The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Dakota, Shilen, after market, etc...

Dakota, Shilen, after market, etc...Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I personally have not, no. The T&D maker that taught me most of what little I know told me that it is pretty close. In his world that means a few tenths. I'll take a few measurements this evening if I can. If not tonight, tomorrow. I also hope to get pictures of the dakota safety and see if I can scrounge up a plunge indicator. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| Moderator |

.0055 on an UNTURNED BLANK .. really? this merits a discussion? you asked for an unturned bank, and got it. tada, order fulfilled. shilen started with a 1.25 bar.. this is unturned, rough bar, as delivered .. then drills a 28" hole... that roughly comes out on the other end ... after a heat soak, their barrel profiles are then lathe turned ... and any runout is machined out, resulting in concentric barrel profiles. making a mole hill out of a molecule. opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

I suspect that what you are getting is vibration from the out of balance barrel, rather than actual chatter. It is almost impossible to get chatter on an interrupted which is what you will have when making your first few passes. If you do get chatter, the first thing to do is of course reduce speed and increase feed. Chatter is nothing but flex. Flex of the tool and workpiece from the force of the cut. Just make sure your tool setup is as rigid as it can be. Many of the quick change tool holders being used have a lot of overhang that will contribute to chatter. Also, try different inserts, some chatter much easier than others. (I assume you are using indexable carbide tooling). A small nose radius and more of a medium machining insert rather than a finishing grade will usually help. Once you have the first end of the barrel trued up, chuck the just turned section in the chuck when truing the other end. The support given by the chuck will make the barrel much less likely to chatter. Just a few random thoughts for what it is worth. John | |||

|

| one of us |

That is not what he said Jeffeosso, go back and read again. John | |||

|

| Moderator |

John, I certainly might be wrong, but this is how i read it .. help me understand what i got wrong

opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

John[/QUOTE] John, I certainly might be wrong, but this is how i read it .. help me understand what i got wrong

[/QUOTE] "I took the 7mm barrel in question and turned it between centers. Then using gauge pins I mounted the barrel in 2 v-blocks on a surface plate and indicated the diameters. The V-block's are close, not perfect, but close. The guage pins were vermont minus pins." You missed the part where he turned the barrel between centers. He then put the just turned surface in v blocks and pins in the bore. This allowed him to make a comparison between where the factory centers were located, which was not true to the just turned surface and resting in the v blocks, and compare it to the true bore center as indicated by the pins. John | |||

|

One of Us |

Also, if you are not using some kind of coolant system while turning the barrel, you will also have to deal with Mr. Heat and all the dimensional changes that occurs when he shows up. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| Moderator |

John, i am not being difficult .. i don't see where "unturned blank" is the wrong statement... shoot me a pm and we can swap numbers and we can talk through opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

gasgunner, I believe you are right. I do appreciate your input. I have tried a few different inserts and even tried a HS bit I ground. The HS helped a little. I will try using the chuck on my next one, thanks. Jeffeosso, you are combining two seperate topics. Westpac, during turning I take (usually) 4 passes, .025, .010, .010, .005. I agree heat is an issue, but for these short and light passes, I do not think coolant will make a difference. Milling, then I use coolant, the barrel never gets more than warm to the touch. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| Moderator |

thanks Nat.. i was cojoining those opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

Jeffeosso, Butch, gasgunner, westpac, etc. After waiting for someone from shilen to call me back about all this I decided to go ahead and give shilen another call. Most of the shop guys are in my backyard shooting at Kelbly's this weekend so I was given to Jay (sp?). She was very helpful and confirmed a few things along with giving me some advice about machining their barrels. She said they do recommend putting in your own precision centers. There should not be an issue with stress or movement as I would be following the same steps they do. She said that if the barrel in question seemed more out than "normal" to please send it back and they would take a look at it. She did also let me know that if I wanted to send them one of my cut barrels they would air guage it to see if the bore expanded or moved due to my cutting. Very interested in having this done! I also want to thank all of you, I think this has been an EXCELLENT and informative conversation. Photo's of the Dakota to follow. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

Sorry I can't agree with the comment on "There should not be an issue with stress or movement as I would be following the same steps they do." Well if you actually did follow what "they" do then maybe . But anytime you machine a piece of steel you are inducing or relieving stress. Which you have no idea which you are doing. Granted 4140 is a good stable tool steel and "should not move too much" when machined it will still move. The real question is how much? and is it enough to cause you an issue. Westpac comment on heat. That is the single most prominent problem when working with tool steels. A good water soluble cutting oil would be ideal in a flood system. Keep your rpm's low and the feeds high to get the heat in the chip not the part. www.KLStottlemyer.com Deport the Homeless and Give the Illegals citizenship. AT LEAST THE ILLEGALS WILL WORK | |||

|

| One of Us |

Nat, Don't fool with "J". She is a professional football player for the Dallas pro women's team. They won their Super Bowl in Las Vegas last year. She is a linebacker that likes to hit. She is a very attractive young lady. The guys should be back to work Tuesday. Hooking up the 5th wheel after the finish of the Super Shoot this afternoon. Hope to make Bowling Green tonight and home Sunday. Butch | |||

|

| One of Us |

Dang Butch! If I had known I would have run over to meet you and have a beer. J was very helpful and I look forward to meeting her in July. kcscott, yup. Even though I am running TiAn cutters I run them a lot lower RPM with a lot higher feed than I normally would. Also I am VERY mindful of heat. The way J put it was like this. There is no way I can remove as much material in a pass as they do when they contour their barrels. As long as I took reasonable cuts then I should be fine. They machine after stress relieving just like I will be doing. The only issue she mentioned was the bore expanding which was why she offered to guage a light profile barrel I had cut. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

| |||

|

| One of Us |

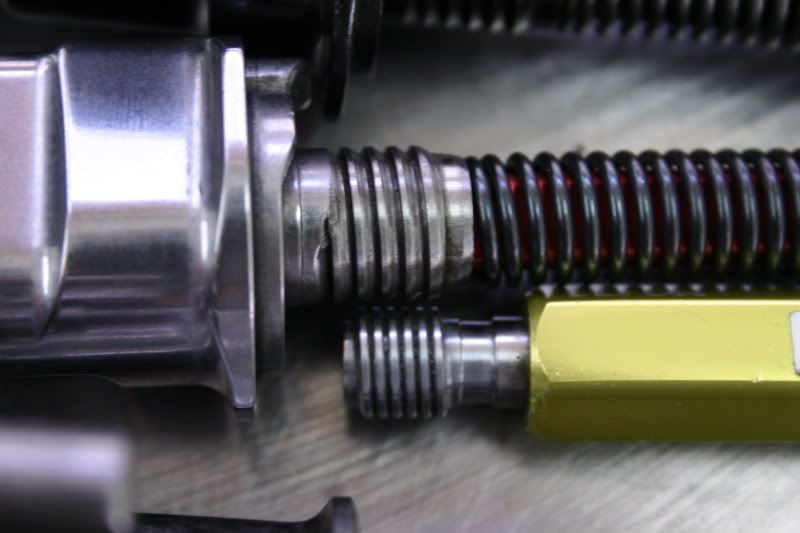

Here are the pictures of the Dakota. This picture is of the shroud next to a metric No-Go thread guage.  Lineup: L to R Gentry, Dakota, FN prewar, 1909.  Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

This is a good thread, guys! Lots of useful information and views included without a lot of heated name calling as in so many other forums. Way to go!! My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| One of Us |

Just a quick glance makes the safety's threads look like a form of buttress thread. Butch | |||

|

| One of Us |

Mauser bolt thread are buttress. Don | |||

|

| One of Us |

Don, It appeared to me that the thread gauge wasn't the right one. Butch | |||

|

| One of Us |

Got two more in, both were 180* out of time. Back to brownells! Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Dakota, Shilen, after market, etc...

Dakota, Shilen, after market, etc...

Visit our on-line store for AR Memorabilia