The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Progress Photos

Progress PhotosGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

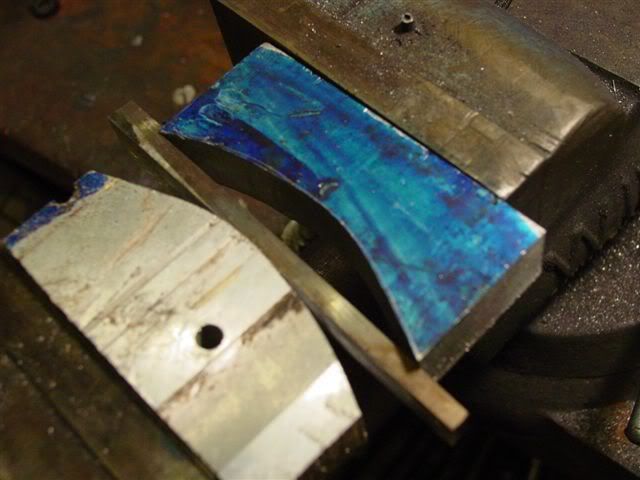

Here's some of the tang process...in the last photo, I'm making sure the extension is somewhere close to center.     | |||

|

| One of Us |

Integral barrel work…I hope these are in the right order. I pick up the taper with a dial indicator. The junction of the rib and barrel is a steeper taper...which makes life interesting! Cutting dovetail, then lots of hand work...using carbide scrapers and pieces of file epoxied to a "handle".       | |||

|

| One of Us |

How big of blank do you start with? Is this where your DRO gave up? | |||

|

| One of Us |

Kreiger is really accomodating...I have them turn the blank to whatever I specify..i.e. .650 muzzle a 24", sporter contour, stop 9" from the breech end and leave cylinderical I usually specify a 1.4-5" blank...costs an extra $50.00 or so, but can you turn down 20" of barrel for $50.00? | |||

|

| One of Us |

Gunmaker: Sorry I missed the last question. No, DRO gave up about 10 yrs ago..took me this long to figure that out! HA! | |||

|

| One of Us |

Duane, Beautifull work. I really love how it looks. With due respect, gunsmith in Argentina do not reccomend to lenghed the 1909 action to the front because sometimes the lower lung set back. A friend of mine have this problem on a .375 H&H Mag comercial barreled action (do not remember the maker) Thanks Martin Double Rifle Shooters Society member from Argentina. My doubles: .577 Snider by W.Richards. .58" ML by Pedersoli | |||

|

| One of Us |

Matin: That's a fair comment...thanks! I've never experienced that problem, though I've seen some conversions that are pretty scary. The lower lug having been cut to a severe angle, leaving a thin wedge for a lower lug. I notice you said "open to the front" Some believe the action can be opened to the rear...maybe so with a complete re-design, but the limiting factor is the bolt stop...it can be thinned only so far...maybe .075 in. or so. Now the bolt face doesn't line up with the front of the rear magazine wall, causing loading problems...etc etc Of course these "issues" have been discussed before.. Duane | |||

|

| One of Us |

I like the integrel features on a barrel like that, so much so i have signed up for a class this summer with Mr. Nelson. Thanks for the pictures, i had some questions and figured as such, just wish the class started next week and not in July! _____________________ Steve Traxson | |||

|

| One of Us |

Mr.Wiebe, Thanks for sharing. You are a great inspiration. So when altering the magazine, you set back the rear wall in the mag., but does not lengthen the mag well to the rear? Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

In these cases, I used Blackburn bottom metal, did not alter. I could be wrong, but I remember Ted telling me that he designed the box slightly to the rear. | |||

|

one of us |

Amazing work. NRA Life Member, Band of Bubbas Charter Member, PGCA, DRSS. Shoot & hunt with vintage classics. | |||

|

| one of us |

Duane, I dont write alot, but I just keep coming back to the thought that it is extra special for you to take the time to educate a bunch of us. I kind of feel like the kid that lives next door and is welcome to vist your shop. I am just a basment hack but between this thread and some stuff I picked up from the Scholarship build you have helped me with a pattern stock I am working on. Thanks for the help. Many Thanks HBH | |||

|

| One of Us |

HBH: You're welcome! anything to swell the ranks of millionaire gunsmiths! | |||

|

| one of us |

Any updates?? Keith IGNORE YOUR RIGHTS AND THEY'LL GO AWAY!!! ------------------------------------ We Band of Bubbas & STC Hunting Club, The Whomper Club | |||

|

| One of Us |

No updates...I'm awaiting some 48 mm rings from Recknagel. I like to get all the metal work done before moving on to the stock. | |||

|

| one of us |

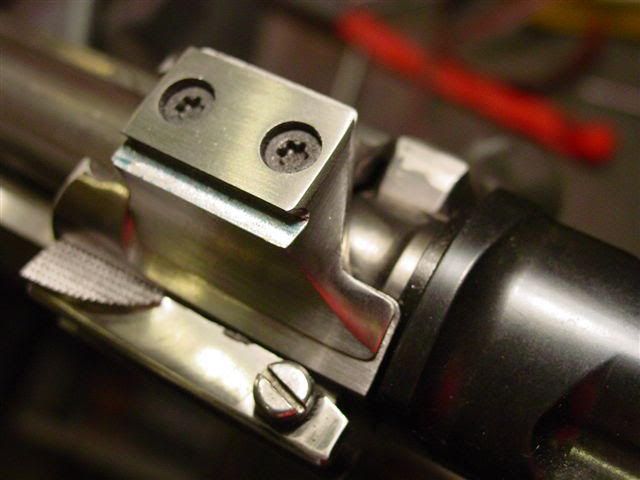

Keith, maybe this will satiate you while we’re waiting for more photos from Duane: Duane sent me these photos of some stock work he’s currently doing on rifles for a friend of mine and me. Thanks to the Recknagel delay, we got to jump ahead in line. James’ action with bolt on custom mounts for Talley rings  Stock layout for James’ rifle  More layout  Bandsaw work  Ready to start inletting  Two more blanks cut and ready for inletting; the top one is mine and the bottom one is for Duane’s own rifle.  ______________________________ "Truth is the daughter of time." Francis Bacon | |||

|

| one of us |

Client 8, Thanks for the fix! HBH | |||

|

| one of us |

Duane, Are those front banded ramps NECG ? They look as though the could be, but dont look just like the masterpice banded ramps I have from them, and dont look like the H&H sight from them either. Many Thanks HBH | |||

|

| One of Us |

They are modified Recknagel front ramps...though not the ones imported by NECG..purchased direct, though NECG is very accomodating and will usually special order. My e mail is cgrs@earthlink.net if I can be of help | |||

|

| one of us |

Duane, I'll try and not be to much of a pest. Many Thanks HBH | |||

|

| one of us |

Duane I have a question for you. What brand/composition of welding rod do you use to weld on the tang extensions? Thanks James | |||

|

| one of us |

Duane Any updates on these beauties? Thanks. James | |||

|

| One of Us |

If I failed to answer you, please accept my apologies Radnor ER 70S2..I use the 1/16" The metal is off to Scrollcutter...(who knows when)....HAR! | |||

|

| one of us |

Duane Apologies are not necessary, but I do thank you for your reply. I don't want to be a pest but I love to see your work. James | |||

|

| one of us |

Mufasa, Congratulation's on a classic matched pair!!! | |||

|

| One of Us |

Forrest, Can you tell us where you got those Custom screw on Talley's. They look interesting. Michael J | |||

|

| one of us |

michaelj, Duane made those bases. ______________________________ "Truth is the daughter of time." Francis Bacon | |||

|

| One of Us |

Thank you Forrest. Duane's work does nothing but impress me more and more each time I see it. Great project you have going. Michael J | |||

|

| one of us |

That rifle project wasn't for me. It belongs to another one of Duanes customers from Houston (who doesn't post on AR). I just thought it was worth sharing with everyone here. ______________________________ "Truth is the daughter of time." Francis Bacon | |||

|

| One of Us |

Hi Duane I must admitt that you are extremly skilled and a tru craftsman, my deepest respect. I just wondered, have you made some tests or calculations of how mutch the lengthening of the magazine forward, reduces the overall lockingstrength. And what safetyfactor is left after reducing strengh and increasing preasurearea inside the cartridge, and increase the workpreasure | |||

|

| One of Us |

The short answer is "no" I'm relying on about 80 years of opening actions by H&H, Rigby, Weatherby.., etc. I've never heard or one that failed or has anyone come forward that says HE heard of a failure. A review of Ackley's experiments are pretty eye opening. For instance, he removed the locking lugs of a M-94 Win, fired the rifle and know what happened....NOTHING! He concluded that at the moment of firing, the case seized the chamber walls, resulting in negligable bolt thrust | |||

|

| One of Us |

Duane, Do you make those scew on bases avaiable for sale for 98 mausers? They look great and I would love to have a few sets if you do. Thank you and great work and many thanks for all your posts they are very inspiring. P.S. You have been a millionare gunsmith for quite sometime shouldn't you be approaching billionaire status soon? Michael J | |||

|

| One of Us |

Duane! It is an enjoyment to follow details of your work. Its always perfect, when one have a good classical architecture combined with best materials and best quality craft. Take one of them out and everything falls apart. If I were the lucky fellow who have ordered the .300 H&H and .375H&H, I wouldn`t sleep for a minut. Thank you for sharing. DRSS: HQ Scandinavia. Chapters in Sweden & Norway | |||

|

| One of Us |

....Glad you like them...life is full of experiences and I: 've had the experience of making these mounts...so...don't have to do that again...seriously, they;re just too damn much work. Welding on a square bridge is easier | |||

|

one of us |

I'll bet fitting that scope base to the rear of the charger hump was just a hoot. lol...nice work Duane. Roger Kehr Kehr Engraving Company (360)456-0831 | |||

|

| One of Us |

Thank you Duane for your reply and I was afraid that would be your answer but I do understand. Thank you once again for all your posts and your graciousness with us posters. Have a wonderful Labor Day weekend. Mchael J Michael J | |||

|

| One of Us |

Not to scare the shit out of you, but there are several old incidence with both HH and early weatherby.(There was a reason he went for stronger actions.)The thypical was setback on the lower lug, resulting in ½ or total loss of the upper split lug. We have performed a series of Blowup tests indicating that a 6,5x55 loadet to 6500 bar destroyed the lugs of a m98 action, if there is oil on the chamberwalls. The same load in a modern under same conditions didnt even provide heavy boltlift The Ackley 94 test might be correct if: the chamberpresure is lower than 1800 bar, and the chamber and case is completly dry. After one of our rifles had a misfire because of a firingpin breaking in the springloaded area. We performed many tests of phe potential danger of a misfire when the bolt was not enough closes. Most situations was rather harmless, resulting in fireformed brass, and a limmited boltmovement. But in the situations where the locking was strong enoug to keep the case in plase till the presure has gone up so the brass stuck to the chamber, but the lock was not enough closed to withstand the rest presure. THIS BOLT WOULD FLY MORE THAN 50 yd high. In those cases the front 70% of the brass stayed in the chamber, while the rest was pulled of and whent flying with the bolt. I would estimate that by opening the action forward to accept a 375HH you reduce the strength of the action from 25% to 35%, this combined with the fact that a 375HH deliveres a Thrust about 4 ton compared to the thrust from a 8x57 about 2.5 ton. This with a lubricated chamber. I dont doubt that it works , but with a highly reduced safetyfactor | |||

|

| One of Us |

Well...if you had all your proven data in front of you, why ask the question?. Please provide me and the rest of the observers with demonstrable proof in the form of scientific data that would be court admissable. We can go from there...really have to see a movie of a bolt flying as high as a 15 story building for starters! | |||

|

| One of Us |

Duane, Thank you for your generosity.. That's HUGE!!! Don | |||

|

| One of Us |

When Jim WIsner was still making bottom metal, I asked him how his differed from the Blackburn stuff for the 375. He told me his was made longer in the back and the front so not as much material had to be taken from the.front. Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Professional member American Custom Gunmakers Guild | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia