The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Reamer Freebore Dimension??

Reamer Freebore Dimension??Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

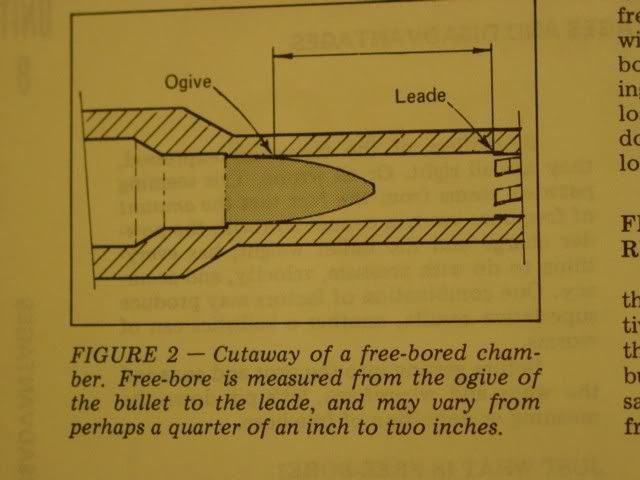

Dear All, I'm working on the specs for a reamer I want to have made. I want a pretty minimal freebore (.005"), but I'm unsure of where that dimension is measured from?? On this diagram (courtesy of Clymer): Is the freebore length (dimension N) measured from the case mouth?? If so, what relation does the freebore length have to dimension K "Base-to-Case Mouth"?? Or is freebore measured from the *maximum* length of of base-to-case mouth (as long as a case can be without being trimmed)?? - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | ||

|

| Moderator |

Hmm, well, unless you are designing for a single specific bullet, nil freebore is a bad idea, as it totally limits you oal, your bullet choices due to design, and unless its a benchrest gun, it will be a non-stop hassle for several reasons... can's really adjust seating/oal, brass will have to be trimmed just about EVERY time you shoot, and you will then have a super critical length/pressure issue. IMHO, .100 should be a minimum for a general purpose, hunting round... for a bench gun? i have no valid opinion opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

One of Us |

Assemble a dummy round with the bullet of choice seated where you want it. Most folks like to have their bullets seat just short of mag length when the bullet it touching the lands. Using this as an example, measure from the case head to the ogive and give that data to your reamer maker. Since the throat length will be fixed, you will be able to control the amount of freebore by seating the bullet in or out without over running the mag box. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

Westpac covered it completely. Butch | |||

|

| one of us |

mho Length of the freebore, or lead, or leade, is dimension "N" on the drawing. It is that part of the chamber forward of the neck that has the rifleing removed and is, essentially, bullet diameter plus .0005" +/-. You have to understand that "zero" freebore is realistically not possible. You will always have a certain distance from the mouth of the case to the end of the chamber plus the 45 degree transition from neck (dimension "F" on the drawing) to the actual lead (dimension "G"). But, unless you are working with a match chamber, one specific bullet, and carefully fitted brass, a certain amount of lead or freebore is always preferable, as the guys pointed out above. JMHO Ray Arizona Mountains | |||

|

One of Us |

moh, one more thing; where you are having the reamer made to your specifications, have them use a gradual 1 degree 30 minute lead, and hold the diameter of the throat to no more than .001 over bullet diameter. All my standard throat reamers cut .0005 over bullet, match stuff even tighter, but I think .001 over should be absolute max. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

I am interested in something like this. I want to wildcat a 300WSM to the same length as a .30-06 while keeping the 300WSM taper and shoulder angle. How do I draw such a thing? | |||

|

One of Us |

By connecting dots. Take your calipers and mark the diameter of the base on a piece of paper. Measure from there, forward, to where the shoulder should start. Using the calipers, mark the diameter at that point. Draw a line from the base to the shoulder. That represents the body. Work forward with your calipers and pen until you have something that resembles what you want. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

.222 Rem, hopefully to be shot with 50 grs Vmax or, alternatively, with 52/53 grs Sierra HP Match. A short freebore is exactly what I want! I have tried supplying smiths with loaded dummy rounds on mutiple occasions and received ridiculously long throated chambers from nationally acclaimed outfits. This time, I decided to try something a bit different. - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| one of us |

Yes, my leade diameter will be specified at bullet diameter plus .0005" = .2245". Throat angle at 1.5 degree. Seems like you have done this stuff before... - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

One of Us |

What were they nationally acclaimed for? _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

Yes, one wonders... - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| one of us |

Westpac I think you've got your terms reversed. The "throat" is the angled part of the chamber, the transition from freebore diameter to bore diameter ("R" on the drawing). The leade, freebore, lead, - whatever you want to call it - is the non rifled part between the case end and the beginning of the throat. While a 1.5 degree throat is a good compromise, the actual angle should be based on the bullet that you will be using. JMHO Ray Arizona Mountains | |||

|

| one of us |

mho Don't depend on "nationally acclaimed" smiths to do it right. Send a sample round to a nationally acclaimed reamer grinder, phone him personally and tell him what you want and he'll make the reamer the way you want it. Grinders like Dave Kiff, Hugh Henriksen, etc. all speak the language. Ray Arizona Mountains | |||

|

| one of us |

That is what I learned (the hard way), so this time Dave Kiff will get my reamer dimensions directly. The last .222 Reamer I had made (shared with my smith), I gave the dimensions to the smith, including a dummy round to determine length of freebore. Inexplicably, when the chambers were cut (smith took over the reamer), the bullets needed to be seated out almost as far as they could to touch the lands. Rifle still shot well, but it was not what I had specified... The lower weight .224 cal bullets really don't have a lot of bearing surface - in particular the BTs. As I am not looking for velocity, and since the .222 Rem has such a lovely long neck, I want to be able to seat bullets with the full bearing surface in the neck and still be about .005" (or so) off the lands. When and if the throat recedes with erosion, I will still have some leeway to load out bullets a bit. - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

One of Us |

Too me the throat is the area where the bullet resides and is measured in thousandths, and is based on bullet diameter (throat diameter, throat length). The lead is the transition angle that tapers from the throat to the bore and is measured in degrees and minutes (lead angle). Freebore is the area between the ogive (o-Jive) and lead, and varies depending on seating depth. In this order, body, shoulder, neck, throat and lead. This terminology has gotten me through life for over 30 years and continues to serve me well. I deal with custom reamer manufacturers a lot, and so far, knock on wood, they understand everything I say. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

westpac You say toe-mah-toe, everybody else says toe-may-toe. Ray Arizona Mountains | |||

|

| One of Us |

Mr. wespac is hardly the only one who says "toe-mah-toe". Not only is he not alone, he is correct. Glenn | |||

|

| one of us |

Glenn Correct in what regard?? How to pronounce the word or chamber terminology? Ray Arizona Mountains | |||

|

| one of us |

Here are reamer prints from 2 of our premier grinders, Dave Kiff and Clymer. It looks like they say toe-may-toe also. What Westpac calls "freebore" BTW, the distance from ogive to lands, most shooters call "jump" or "off the lands" as in, .020" jump, or .020" off the lands. Ray   Arizona Mountains | |||

|

One of Us |

I see your problem. Dave Kiff's glossary stops at "S" so you are stranded. Well, trust me, the throat is that parallel portion ahead of the case mouth where the bullet sits, and includes a transitional angle to the bore known as the lead. On Daves site; under the heading freebore, it reads: Freebore: The parallel Section of throat for bullet clearance or distance before bullet touches land. Also reloaders sometimes refer to this as Jump when setting up there round. Next time you talk to Dave, or, a "technician" at Clymers, ask them to make you a custom "freebore" reamer. If they ask you what diameter you want the freebore reamer to cut, tell them you don't care; that you are only interested in the throat portion. "Toe-Mah-Toe" Actually, you'll probably do better by asking for a "throating" reamer that cuts a .2245 diameter throat with a 1'30", or, 1.5 degree lead. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

Westpac That bottom reamer print IS one of my custom wildcat reamers made to my specs as far as freebore and throat angle. Not sure what you mean when you say Dave's glossary stops at "S". My print clearly shows the "THROAT" as well as the "LEAD". Neither fit your definitions. Nor does the Clymer print. I have several Kiff custom reamers as well as a couple of Clymers and two of Red Elliot's. They all show the lead and throat the same way. Post one of your reamer prints so I can see what it shows. I didn't intend for this to get into a pi$$ing match. Ray Arizona Mountains | |||

|

One of Us |

No pissing match here. I see what your print say's. Frankly I think he's got the 'throat' and 'lead' labels backwards. That's certainly not the nomenclature I, or, many like me use when referring to certain aspects of chambers. While I realize this isn't as official looking as a reamer print, it none-the-less, illustrates my point about freebore and lead.  _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

The next time I talk to Dave I'll tell him he has it all backwards. Enough of this. Let's talk about something else. Ray Arizona Mountains | |||

|

| One of Us |

This is pasted from another thread. I post it here not to intensify this discussion but to point out that many of us know not that all this terminology is carved in granite and yet we have been communicating with each other for many years. Maybe you can glean something from this; During one of our last conversations my first wife said to me" Roger! I have never met a man as right as you always are, but who needs you." Had it been my mother I was talking to she would have said to me at that point. ; "So What" My father would have said "mox nicks" These are my concepts not based on any published standards and probably not acceptable by all. This exchange of information from different view points , frustrating for some at times I'm sure, was handled in a most dignified manner; human at times but dignified. JMHO Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| one of us |

Roger The biggest problem we have when discussing things like this is that a lot of people have a lot of different ideas as to what the terms mean. But, the original question from Mike concerned REAMER SPECS. I would think that the authority on reamers would be the reamer grinders and there we have a clear consensus among the best known. Guys like JGS, PTG, and Clymer are very clear as to how they define the various parts of a rifle chamber and their reamer prints leave no questions as to what they mean by freebore, lead, neck, throat, etc. JMHO Ray Arizona Mountains | |||

|

| One of Us |

I was glad to see the forums back up and found this thread when I went in to see what had transpired. "Reamer Freebore Dimensions" or throating, is, in my experience, one of the most important and least understood aspects of chamber reamer design. First, there's nomenclature. Ask 3 gunsmiths to define "throat" or "freebore" and you'll likely get 6 answers as each reconsiders his first definition. We consider the throat to be that section of the chamber ahead of the case mouth where the bullet sits when the gun is in battery. The throat has to be configured so there is sufficient clearance around the bullet for the round to chamber without the bullet being pushed back into the case. The throat may or may not have a "freebore section" or "lead angle". Think of the throat in a revolver cylinder--it's all freebore, with no lead. Alternatively, the SAAMI throat for 458 Win Magn is a taper, with no parallel section. We call the angle that guides the bullet into the rifling, the "lead". Others spell it, "leed", "leade" or even "lede". Doesn't matter as long as we know what is meant. If we're on the same page for nomenclature, what's the best way for the shooter to transmit his throating requirements to the reamer maker? In my opinion, sending a dummy round and describing the desired bullet/rifling relationship is the best way. Or, to put it another way, sending a dummy offers the least opportunity for misunderstanding. By sending a dummy round--with the bullet seated where he wants to shoot it--and telling the reamer maker how far off the lands the bullet should sit when chambered, the shooter eliminates any confusion over nomenclature. Further, by examining the dummy, the reamer maker can determine whether the shooter's request is possible and advise accordingly. For example, the shooter may want the throat on a 300 WSM shortened so a 210gr VLD bullet is .005" off the rifling when loaded to an overall length of 2.850", presumably, for a short action. This seems to be a reasonable request, but reducing throat diameter and length as much as possible would still leave the bullet a long way from the rifling--why is this? A throat can only be reduced in diameter to that of the bullet or it will not engrave smoothly. Further, the lead angle can be made only so steep in an effort to bring it close to the bullet's ogive. Finally, the lead angle can be brought back toward the case mouth only so far. If one were to measure the bullet diameter just ahead of the case mouth on our hypothetical dummy, he would likely find it to be .306" or .307". Because of the VLD's long ogive, and the depth to which it had to be seated to achieve the 2.850" COAL, only part of the full-diameter bearing surface of the bullet would be in the neck of the case, with the rest below the neck/shoulder junction. This is why the reamer maker wouldn't be able to provide the throat requested by the shooter. In this instance, the shooter would be better off with a longer action, or with another bullet. Sending data from a Stoney Point gage, or RCBS Precision Mic can be misleading as well--mainly because of differing ogive profiles. Both these gages provide a length from a reference point to a specific diameter on the bullet ogive. It doesn't, however, tell the reamer maker anything about the profile of the bullet between this diameter and the case mouth OR the throat profile required for minimal bullet clearance. With our hypothetical dummy, the profile would be a very gentle angle. With a dummy loaded with a conventional, low-ogive bullet, proper throating would likely require a parallel section close to bullet diameter, combined with a lead angle roughly tangent to the ogive at point of contact. Those who haven't had enough of this discussion may want to locate a copy of the 1995 Precision Shooting Annual. Mike Walker, Bill Davis, Keith Francis, Dan Lilja, myself, and Dennis Bellm each offer our thoughts on the subject. All of the above explains why we like to be able to examine dummy rounds, but do we HAVE to have a dummy round? No, we don't. If you're not able to assemble one, or can't blow out the shoulder of an "improved" case, simply send a sample of the brass you'll be using, a sample bullet, and tell us where you want to seat it, eg: "2.250" overal length" or, "bullet seated so the start of the boattail coincides with the neck/shoulder junction". With this information, we can design the bullet/rifling relationship you want, or tell you why it's not possible. Are separate throating reamers a good idea? They are certainly useful for extending throats in existing chambers or for changing lead angles. Integral throats are preferable, however, when cutting new chambers because they avoid any concentricity issues caused by the use of two reamers AND eliminate the possibility of cutting the throat too deep. With the throat section cut at the same time as the rest of the chamber, it WILL be concentric. Further, if the chamber is headspaced properly, the throat will be located where it's supposed to be and not run long because the 'smith got heavy-handed. There are, of course, other considerations when designing throats--we won't even begin to discuss the "ideal" lead angle or bullet clearance. For every specific configuration that works for one shooter, a different one can likely be shown to work equally well for another, and that's what makes this business interesting. Dave Manson | |||

|

| One of Us |

[QUOTE]Originally posted by Cheechako: Roger The biggest problem we have when discussing things like this is that a lot of people have a lot of different ideas as to what the terms mean. JMHORay[/QUOTE} Lead; Not controlled by reamer at all but by the ammo loader and how far out he places the bullet. It is the distance the bullet travels before it starts to engage the rifling. I think I was having a brain fart when I posted this Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| One of Us |

I remember my first reamer. I was told to seat a bullet and send it in. I did just that. I just slammed a bullet into the case and mailed it in. I didn't know that it needed to be the way that I would shoot it. I got a PPC reamer with zero freebore and the pressure ring of the bullet was below the neck shoulder juncture with the supplied bullet. I do use it now with the long skinny boat tails. Butch | |||

|

One of Us |

It would appear you forgot to mention one of the authorities. I think Dave Manson is pretty hip on terminology and with the various technical aspects of a chamber and reamer. Good explanation Dave! _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

Thanks Dave, food for thought! What I'm trying to achieve with my particular reamer, is that I can seat the full length of the "full diameter" (.224) of the bullet into the case neck. That would not only give me a max amount of bearing surface in the neck, it would give me a bit of leeway of loading the bullet out when the throat recedes. I don't know if it is true, but I have a feeling the thin jacketed .224 cal bullets (50 grs VMAX or 52/53 grs Sierra Match) do well with as much bearing surface in the case neck as possible. Fortunately, the .222 Rem has such a lovely, long neck, and even seated such, the start of the boat tail will still be above the neck/shoulder junction. So that is as much bearing surface in the neck as I can take advantage of. At that point, I'd like the bullet to be about .005" off the rifling. Does that make sense?? It would seem, that this point of "max full bullet diameter in neck" can only be achieved when the case is as long as the chamber allows. I.e. when the case is trimmed back from this max (normally .010"), then that amount of the full bullet diameter will protrude from the neck. So if I want to supply a dummy round must I supply a case which is at (or close to) the max case length to be allowed by the chamber?? (Somewhat complicates matters, I'd have to find a case at max length... - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| One of Us |

Hello Mike: In practice, it doesn't have to be as complicated as we tend to make it. As you noted, some case necks are longer than others; likewise, some bullets have longer bearing surfaces than others. I don't think there's anything magic about about the full length of the bullet's bearing surface being contained within the case neck. What is more important to you, the bullet's proximity to the rifling, or containing the bearing surface within the case neck? The reason I ask this has to do with necessary length clearances and the geometry of the gentle lead angles used in chambers. We use .010" as a minimum clearance between case neck length and chamber neck length--this is a LOT less than is found in the typical sporting rifle. This clearance makes a closely fitted chamber a little easier to live with and doesn't give away any accuracy. Even though it won't add any length to the throat length, a 90-degree shoulder at the transition from chamber neck diameter to throat diameter isn't desireable 'cause it will do bad things to a precision bullet, so a 45-degree angle is used. The length of this angle, as it transitions from chamber neck to throat diameter, pushes the throat a little further away from the case mouth. The throat lead angle then starts at the bottom of the 45-degree angle. Since it contacts the bullet a little forward of where the ogive starts, there is still more length--down the lead angle--from where the bullet sits to where the ogive contacts the lead. I went through the above description to explain why we suggest to shooters that they need .040"-.050" of full bullet diameter ahead of the case mouth if they wish to touch the rifling. Because of the limitations on minimum throat diameter and lead angle steepness (discussed in a previous posting) the throat can't be brought closer to the case mouth than this figure. So back to the question of chamber priorities. If the bearing surface of the bullet is to remain fully within the neck, you'll have to accept .040"-.050" uncontrolled bullet jump, or "freebore". If being near the rifling takes precedence, then .040"-.050" of bearing surface will have to be ahead of the case mouth. Chasing the throat as it erodes means you'll eventually have bullet bearing surface ahead of the case mouth anyway. If it were me, I'd place the bullet close to the rifling at the outset. It ISN'T me, however, but you who is building the rifle, so it's up to you. Hope this has helped. Best regards, Dave Manson | |||

|

| one of us |

Hello Dave, Dave Manson posting here is too cool! He has said everything you need to know about describing a throat. I am but a grasshopper who has studied this master reamer maker, and have at least a dozen of his reamers at home in Kentucky, and I have sent a couple to South Africa too. Just to recite Master Manson's enlightenment, and correct me if I screw up, oh Master: In the Clymer generic chamber drawing (copied below), follow along with me please, as we progress like a bullet from grasp by brass case to full grasp by the rifling: E = neck-1 diameter F = neck-2 diameter (Some discussion here of how much room is needed for brass expansion to release the grip of the bullet at firing, and whether neck-1 and neck-2 should be the same diameter, would provide further enlightenment.) Then that 45-degree step-down/transition from the neck to the throat: it is visible in the Clymer drawing. Next, parallel-sided freebore: G = freebore diameter N = freebore length R = leade, specified by the angle of the slope from freebore diameter down to the bore/land diameter of the rifling where the throat vanishes into fully intact rifling: Preferred angle on Dave Manson reamers appears to be 1.5 degrees semi-angle, or "per-side-angle," in the same way we commonly refer to a shoulder angle of the brass case. The leade angle is from the sides of a cone with a 3-degree angle at its tip. The G and N in the drawing below can refer only to "parallel-sided freebore." Some throats have no parallel-sided freebore at all, as Master Manson pointed out, but they still have a lot of "slope-sided freebore" if the start of the leade is wide (G >> bullet diameter) and the angle of the leade is gradual. For instance, the .458 WinMag: It has about an inch of leade, a long, wide, and sloppy throat with zero parallel-sided freebore. Throat = parallel-sided freebore + leade Sometimes throat = leade only, and some of those are pretty tight throats, with little "bullet jump." Many of the old Nitro Express cartridges, 404 Jeffery, 500 Jeffery, etc, are like that. They have a narrow diameter at the start of the leade and sometimes more acute leade angles, like 2 or 2.5 degrees. Further discussions of parallel-sided freebore diameter for various bullet diameters would be interesting. Does one increment fit all, i.e., .0005" or .001" greater parallel-sided freebore diameter than bullet diameter? The lesser for a benchrest/target rifle, the greater for a general purpose hunting rifle/DGR? How much greater? I think we have a handle on freebore and throat "length" now. | |||

|

| one of us |

Thanks Dave, it has helped - even though it may not have been what I wanted to hear... - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia