The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Index threading methods?

Index threading methods?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I've read some threads on other forums regarding this subject. Often cited is the method used by Steyr/Austria to manufacture Mauser pattern 98 military rifles. Also suggested for Yugo M48's. Steyr military barrels and receivers are stamped on the undersides with +/- numbers from 0-5. Original guns will have receivers and barrels with opposing +/- numbers. So, a +2 barrel would be mounted on a -2 receiver. Speculation was that barrels and receivers were manufactured and gauged for headspace dimensions. When gauged, they were stamped accordingly within a given variance range, +/- from a datum of 0 and given a deep index mark. The barrels would have sights pre-installed. Then, at assembly, corresponding +/- units would be mated and proper sight alignment and headspace achieved. My question is: If an indexing method was used, was this achieved through standard lathe methods or was a tool akin to a Rigid pipe threader used? Insights appreciated. Bob | ||

|

| One of Us |

My understanding is that the threads were milled, not turned or tapped. | |||

|

| One of Us |

None of the documentation I have seen has the sights pre-installed. To date no Steyr or FN documentation has been published, and none has been available privately. Not that it doesn't exist, I don't know about it. Barrel and receiver threads were milled. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| one of us |

Please explain how barrel and receiver threads were milled using 1890's technology and machines. I'm familiar with conventional lathe threading techniques and modern CNC mill procedures but cannot envision how milling was done with older manual machines. A comment or two about the machines themselves would also be appreciated. Thanks. | |||

|

| One of Us |

for barrel threads check page 18 in "Manufacture of the MODEL 1903 SPRINGFIELD Service rifle" Machine used- Pratt & Whitney thread miller... Bolt shroud page 116. great illustrations of Machine used- Special fox lathe made at hill shops. | |||

|

| one of us |

I found this surfing around: http://vintagemachinery.org/pubs/9380/24879.pdf Looks like the machine was set up for 1 task only. | |||

|

| One of Us |

Fascinating. Thank you. | |||

|

| One of Us |

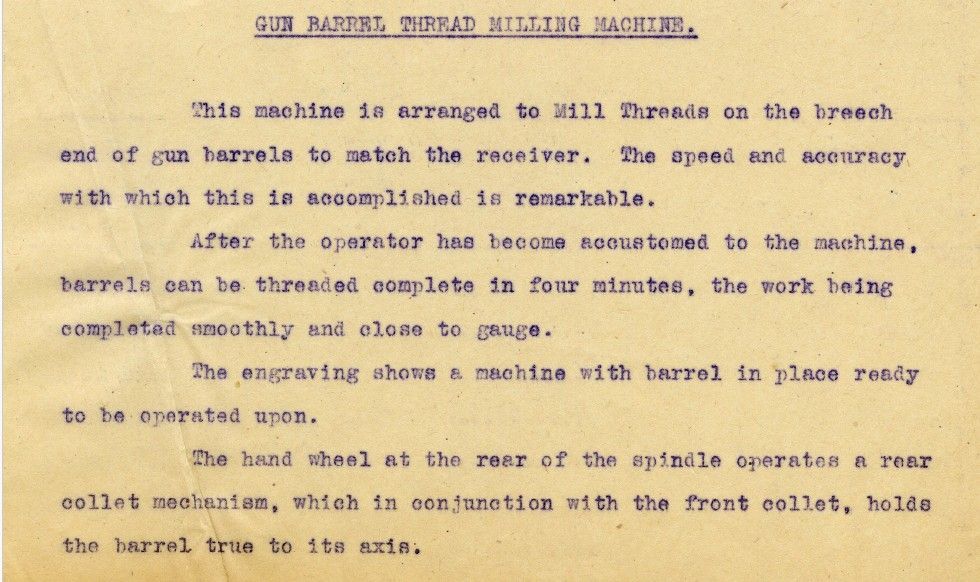

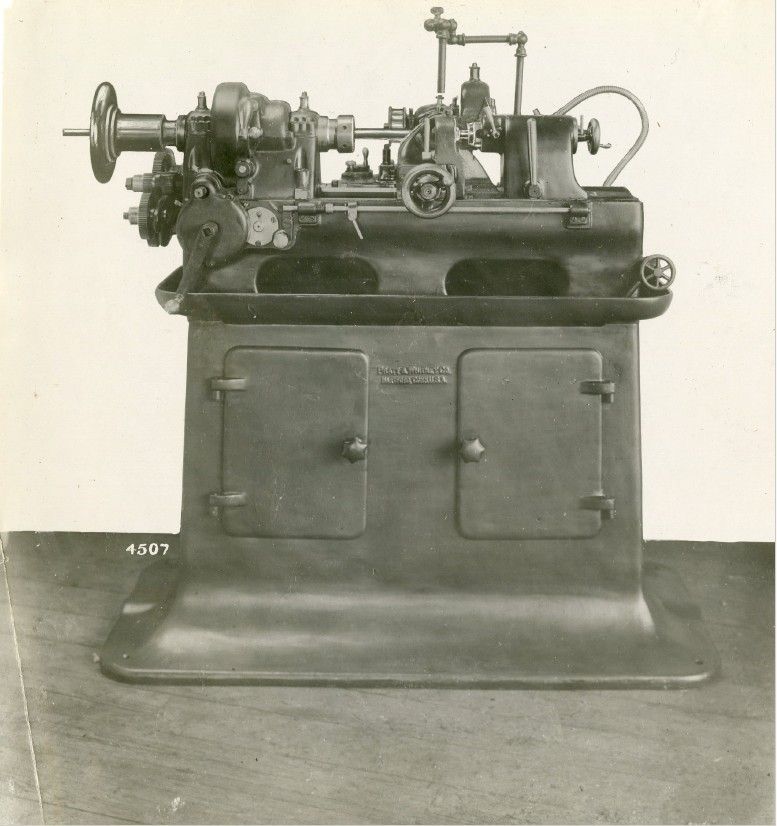

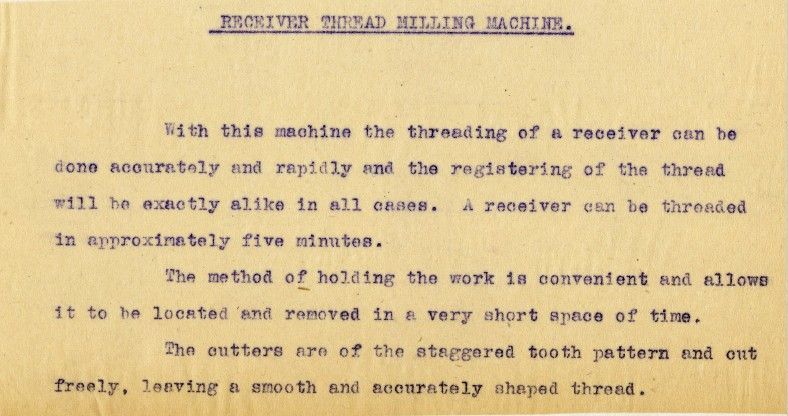

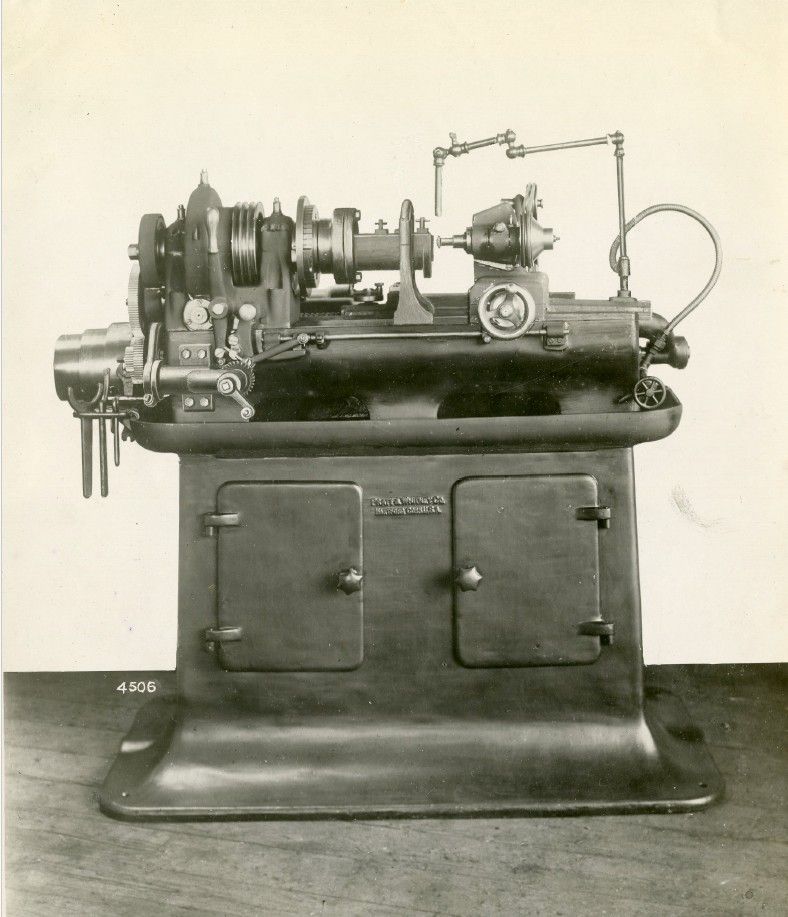

All of the machines of that era were set up for one task. Factories planned for Mauser production, or any production, had a target rate, typically pcs per day, and machinery was tasked, arranged, and setup to accommodate that production. As an example, to produce 170 Mauser rifles a day, required 104 machines to produce the receiver. Alternatively to produce a mere 25 rifles per day, required 23 machines to produce the receiver. At it's peak, Mauser was producing something between 300 and 350 rifles per day. Never mind, machine guns, aircraft cannon, stampings for other companies and industries, and more. These were the machines supplied by Pratt & Whitney for threading the receiver and barrel. Prior to WWI nearly all the government arsenals and some private companies in Germany purchased large quantities of machine tools from P&W and other US suppliers. Several European companies, Ludwig Loewe being prominent among them, began producing machine tools in competition with P&W. In a report in the early 1900's on US machine tools in Europe, many European companies reported that they still preferred US machine tools for their rigidity, accuracy, and precision, when needed.     Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| one of us |

/\ /\ /\ : That certainly answers my question. Thanks Mr. Myers | |||

|

| One of Us |

Visit Harper's Ferry in WV, as soon as the shut down is over. You can still see how Civil War rifles were made, with some of the equipment still on display. It was water powered. The old guys were smart, our world is built on their work. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia