The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Question on contouring Mauser actions in a knee mill...

Question on contouring Mauser actions in a knee mill...Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

Given that I have a Bridgeport J2 mill, a Mauser mandrel appropriate to the VZ-24 action, and the jig to hold the mandrel: 1. Should I use a 1/4" end mill cutter, and advance the work a degree or three between light cuts? 2. Should I have the action annealed first before cutting on the rind, and then have it heat treated when all machining is done? 3. Should I just use a carbide cutting tool, and work with the receiver as is, then have it re heat treated after all machining is done? 4. Assuming a carbide cutting tool, liberal use of high sulfur cutting oil, and a slow hand on the X-axis, what would be a ballpark figure on RPMs? (Subject of course to what the metal is telling me during the reality portion of this exercise. 5. Same question as #4, except with an annealed receiver, and an HSS cutting tool (Or do I just stick to carbide?)? 6. I of course, will start with using my nastiest receiver. 7. This receiver will be used as a boat/truck gun in .416 Taylor (I picked up a couple hundred NIB cases from Jameson with correct headstamps). When I remove the charging hump should I enlarge the hole to, say, .550" in width to facilitate feeding, and topping off the magazine. 8, Perchance, does anyone make stripper clips that fit standard belted magnum cases? If that were so, I would endeavor to widen the clip slot enough to load the magazine with clips, and go to a scout scope, red dot, or simple iron sight aiming set up. Too much too hope for, eh? Thanks for your patience, and your continued help as I learn.  Major Lyudmilla Pavlichenko, late of the Red Army. 309 Confirmed kills. Highest score in history for a female sniper.  | ||

|

| One of Us |

It's actually dead simple to do. Don't bother with HSS. The light cuts and unpredictable steel will just wreak them. I just use a 1/2 inch carbide slot mill or end mill. Run a bar through the action and hold it between the spacer or dividing head and a tailstock. The angle per side on each flat is 24 degrees off center. If memory serves I cut 6 flats of 4 degrees per on either side of center to form the radius. Then I just slab the flats with the X and Y axis. The radius is then cleaned up with 600 wet & dry on a flat stick or hockey puck cut in half. Cut a couple practice ones on a chunk of aluminum first to get the feel of it. I put together a quick video for a friend a while back that may be of some help. https://youtu.be/nnxqblNmuq0 When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

South of the longest undefended border in the world, a "hockey puck cut in half" is about as common as a micrometer marked in cubits. There might be some, but rare indeed. There's an export market for ya Rod. Custom made polishing pucks. Huge markup. Take advantage while NAFTA is still around. If I am working, hunting season is too far away to imagine. If I am getting things ready for hunting season, opening day is perilously close. | |||

|

| One of Us |

If all you want to do is remove the clip guide hump, then it is two steps instead of your 14. No need to anneal or heat treat anything. Bear in mind that they are not all exactly the same on Mausers, and some are actually undercut at the the radius at the rear of the hump. I mill the flats on either side of the longitudinal radius, then do two more cuts. Grind and/or hand polish from there. Sort of like Rod does, only no horse hockey involved. | |||

|

| One of Us |

Cubit-schmubit. They are all marked in Arshins, which measure exactly twenty-eight English inches (71.12 cm). Thus, 80 vershoks = 20 piads = 5 arshins = 140 English inches (355.60 cm). A lot of gunsmiths I know simply re-contour them by hand, on the belt sander. Which is OK too. He asked for a mill. He-got-da-mill. LOL When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

I don't see anything wrong with grinding as much of that charger hump away, as can be gotten away with, on the pedestal grinder before taking the action to my machine tool of choice for a final 'clean-up'.. | |||

|

| One of Us |

The only reason I favor the mill (outside of neatness and being 100% square) is that it allows you to take off the ABSOLUTE minimum from the top of the bridge. Because of the slot for the anti-bind bar you only get 5 threads for the scope base at the best of times. If you grind them by hand, you had better be sure that it's square and true the first time. If you have to re-grind it because you got it a bit low in one spot, you will soon find yourself with only three or less threads to play with in the rear bridge. I have seen many nice Mausers ruined by making the rear bridge to thin. Good, sharp carbide end mills will slab off the entire thickness of the stripper clip guide in one bite if your setup is solid. They will also allow you to cut .001 inch if you demand it. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| one of us |

If one wishes, one may anneal the bridge easily enough then re-harden the extraction cam after machining. Personally, I can grind and file two or three receivers in the time it would take to set one up in the mill. Eschewing the hockey puck, I opt for a piece of hockey stick handle instead. Regards, Bill. | |||

|

| one of us |

Thank you guys! I always suspected that there was a lot more to the process than was shown on the Brownells and Midwayusa videos. Dream Date:   | |||

|

| one of us |

Is there a company that sells quality used dividing heads and tailstocks for Bridgeport mills? For the front portion of the receiver, I imagine that you take a light cut, and keep advancing a few degrees between cuts until you reach the recoil lug on either side. Is that a reasonable assumption. Spearchucker, thanks for that video.  | |||

|

| One of Us |

Dagone guy, I didn't say 'do finish work on the pedestal grinder',,if you didn't understand I mean 'rough it down so you leave some to clean-up with finish passes on the machine. It'll save time and tool. I do mine on the surface grinder when I do a Mauser , anymore. | |||

|

| One of Us |

[/QUOTE] Dagone guy, I didn't say 'do finish work on the pedestal grinder',,if you didn't understand I mean 'rough it down so you leave some to clean-up with finish passes on the machine. It'll save time and tool. I do mine on the surface grinder when I do a Mauser , anymore.[/QUOTE] They always hit me with the surface grinder. I don't gots no room for a surface grinder. I don't even gots no room for a can opener - - - - and I could use one to get around in my jam-packed-little-shop ! But if I had a surface grinder, I could hog those stripper clip humps off in the mill with a big-ass carbide snag and finish em up on the surface grinder ! ! ! LOL When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Dagone guy, I didn't say 'do finish work on the pedestal grinder',,if you didn't understand I mean 'rough it down so you leave some to clean-up with finish passes on the machine. It'll save time and tool. I do mine on the surface grinder when I do a Mauser , anymore.[/QUOTE] They always hit me with the surface grinder. I don't gots no room for a surface grinder. I don't even gots no room for a can opener - - - - and I could use one to get around in my jam-packed-little-shop ! But if I had a surface grinder, I could hog those stripper clip humps off in the mill with a big-ass carbide snag and finish em up on the surface grinder ! ! ! LOL | |||

|

| One of Us |

Yup, no argument from me and one day I will get one. I have used them to death and they are the bees knees for a lot of work. But, as I said, space is a premium for me right now. As far as worrying about carbide end mills, I don't, not so much. I dropped the card on a Cuttermaster grinder clone a few years back so a carbide end mill or slot mill lasts me a VERY long time. As long as you don't try to drive the tool completely through the mill vise under power (done that) or crash the cutter into the work piece with the rapid traverse (done that too, several times) I can usually get 10 or more grinds out of each tool. On top of that the diamond wheels on the tool grinder last virtually forever, with little to no dressing and no heat issues to deal with while grinding. I don't even use HSS anymore. It's just to big of a pain in the ass. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

This is how I surface grind them on the mill. When I first started out I used this dinky little stone, but I soon got a 4" white cup wheel which works well. You can hog off most of the hump on the linisher then onto the mill with a slot drill & then clean up with the stone. Heat treat? Don't know if there is any H/T firms in OZ that do Mausers so I just keep my loads sensible and don't worry about it.   | |||

|

| one of us |

That is what I am shooting for: Roza Shanina, Hero of the Soviet Union, KIA, 1945. 59 Kills Died at age of twenty.   | |||

|

| One of Us |

I do it the way that Metal does with a vertical mill and a fine 4" diamond cup wheel. I hand grind the hump to close on a pedestal grinder, then clean it up with the mill and cup wheel. I also use it to sharpen end mills with an old fixture I got at an auction for $5. Works great on HSS and good enough on carbide. Jeremy | |||

|

| One of Us |

When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Used to be plumb swell to remove all the markings...I don't get it! Perhaps with a really rough action? Bear in mind, you may be removing a case hardened skin If you really want to screw around with a stripper clip, better leave all the charger hump material you can | |||

|

| One of Us |

I used to see a lot of Mausers with the crests ground off back in the day too. I never understood the practice of it either. I was always of the opinion that it weakened the action. (probably not enough to argue about unless I catch you in one of your phone booths) I also never saw the logic in grinding off the charger hump if it was just a beater hunting rifle. You can modify a basket full of #55 and #45 Weaver bases in the mill that will look and work just peachy in a half hour if you have a mind to build the cutter. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Outstanding thread from you guys! Thanks a bunch for taking the time and sharing the knowledge. . | |||

|

| one of us |

A surface ground action is so clean and sharp, I always have my actions surface ground, then they are square to the rest of the world, and with fitted bases they return to zero no matter how many times you take them off and on. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| one of us |

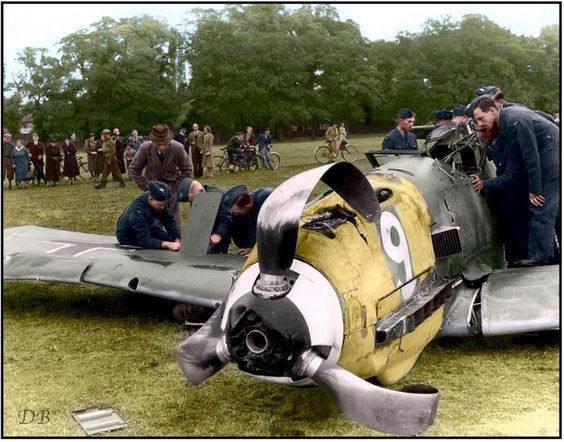

I don't like the idea of having abrasive dust on, in, or around the mill. Any crests present will be left in place. I just want to clean up the surface gouges. Any scout scope setup rifles would of course retain the charging hump. A Yugo in .308 Win would make for a nice scout rifle. I remember on the silver lining scholarship rifle how Tom Burgess ground the action all the way around. That looked pretty slick. I'm surprised that no one has come up with a filler block for the clip slot to strengthen the overall action, and provide a longer "foot" for scope mount positioning. Any old style Mauser that I work on will be re-heat treated before a round is fired out of it, and I may even anneal it to a light blue color befor I start screwing with it to start. Maybe I can shape it with a butter knife then. Spearchucker, Is this the type of spacer that you are using? Super Spacer I assume you just turn the wheel until you have spun the required number of degrees. BF 109E downed during the battle of Britain   | |||

|

| One of Us |

Well, no. Unless my definition between a spacer or super spacer and a horizontal/vertical rotary is all confuzzled. Basically the link you showed took me to what I call a horizontal/vertical rotary. A spacer or super spacer, as I was always taught is exactly the same unit but it also has a bunch of plates that fit into the back of the unit for quick indexing. The spacer plates are of little value for gear cutting and doing Mauser cleanup but they are invaluable if you are doing fluting or if you have to make a half a thousand bolt heads or common bolt hole patterns in flanges or motor unions. The one I have is made by Yangzhou. The only 2 down sides to the one I have is that it's a heavy bitch, about 130 pounds or more. And the cost. I think I paid $1,100 USD for mine. I think this one Grizzly sells is the same one, Grizzly sells a lot of Yangzhou product. http://www.grizzly.com/product...ble-with-Chuck/H7506 I don't think that you really want a true spacer for what you will be doing. What you showed is just fine for this sort of work. The only time you need a spacer is for production work. You disengage the hand wheel and just spin the chuck by hand and lock it into one of the divisions in the plates. It's quick and idiot proof. But it only does division x24 so you only get quick spacing for 2, 3, 4, 6, 8, 12 and 24. For all other divisions it's back to 360 and the hand wheel. I just use the spacer because I have it and because it's always bolted to the left end of the mill table. If I didn't have it I would be using one of the 3 dividing heads that I have. A dividing head works just as well. Actually better because I think it's it's a bit more precise. A spacer is however more ridged, especially if you are using the unit to drive the material into the cutter. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| one of us |

Honestly, I find it almost laughable that such a simple procedure, a procedure which has been accomplished with simple tools for decades, is now beyond the capabilities of anyone without a shop full of machinery. About 35 years ago, Martin Hagn showed me a Mauser-actioned rifle he had recently completed. On it, he retained the hump but had slotted it to accept a Talley base. I liked the look of that so did the same thing on my own rifle. Martin finished his with a file and I did mine the same way. In both cases the bases were level and aligned. There is no doubt that a receiver can be screwed up by some klutz attacking it with a bench grinder but a reasonably skilled gunsmith should have no problem. Regards, Bill | |||

|

| One of Us |

When I got started we did pretty much everything by hand Bill. We didn't even really have a mill at The Custom Gun Shop. Slowly, over the last 25 years I started doing more and more of this stuff in the machines. The biggest reason was the availability of cheap, carbide tooling. In days gone by, working with hardened gun parts with HSS was just an exorcise in frustration and hard on tooling. Even the advent of cemented carbide tooling for the mills and lathes was no big help as it was meant for heavy stock removal. Not light work. Modern carbide milling cutters and disposable inserts have sort of changed all that. Pretty much all of the stuff that I used to do by hand, I now do in the machines in half the time. You can remove material at 100 times the speed and maintain all of your lines without worry. After cutting, clean up and polishing is just a quick buff with 400 wet & dry on a hockey puck or stick and you're done. Plus the carbide is cheap, easy to maintain and sharpen. Most machine shops have those plug and play grinders for end mills now days. They work as simple as the old-timey pencil sharpeners that we had in grade school. As far as disposable inserts. The ones I use today are shock proof and you can run them in coolant. You can run them on interrupted cuts there is no sharpening and a single insert lasts for months in a gun shop. I have been using the same full form 28 TPI threading insert since last December and I have probably threaded over a hundred barrels for brakes since then. I haven't even rotated it out to the next point. I haven't even sharpened a drill bit by hand in close to seven years. I have two of the production drill grinders. Again it's as simple as using one of the old pencil sharpeners and the two I have will sharpen drills from 1/8th to 1-1/16th inches in under 5 minutes. It's just gotten faster and cheaper to do it in the machines now days Bill. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

A nice job by New Guy  | |||

|

| one of us |

You would be amazed at how many "Gunsmiths" are not reasonably skilled.  Aut vincere aut mori | |||

|

| One of Us |

So true. Weld a spacer in the clip slot to strengthen the receiver? Please. I know that one was put there to confuse the young guys. | |||

|

| One of Us |

When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

I think the "Golden Age" of gunsmithing is slowly drawing to a close as CNC machines and 6-7 dimension machines and tools get into the hands of gunsmiths. The "'smith" is being taken out of "gunsmith" as those that came before are lost from the profession and the new professionals don't have the expertise of "hands-on" mucking about trying to figure out just HOW to accomplish a given task with manual tools and the proliferation of "cheap guns" from automated factories becomes de rigueur and continues unabated until outlawed by governments or replaced totally by military weapons. LUCK | |||

|

| One of Us |

The new guns have changed a lot with materials. Mostly they have gotten cheaper to produce. But, there was cheap shit on the market in the 1800s too. Most of those cheap guns of yesterday and today guns can't be repaired or shouldn't be repaired and if they can it's just parts replacement. As far as what gunsmiths do, the work is all the same. You still have to know how and why it works. You have to know what to replace to make it work when it stops. You have to be able to make parts if you can't get them. (if they can be made in a jobbing shop setting). You have to be able to make the tools you need to repair them and run the tools needed to make the tools and parts and repair all of the tools. You still have to know what a gun has to look like and you have to be able to make it look the way it is supposed to look. On top of that you have a huge learning curve today and most of us can't even begin to cover all aspects of the trade. The CNC has made it possible to make to many new models for us to keep up with. But outside of getting much broader with more specialty people in the trade, the trade is the same. Only the files and hammers have changed and they have gotten a lot bigger and more precise. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Hey, I use a can opener machine to knurl bolt handles. I thought everyone did it that way. | |||

|

| One of Us |

Great perspective! It's easy to get pessimistic over an industry that seems to be moving away from quality and towards plastic parts and throw-away guns, but as you've said, cheap has always been around. And there'll always be a market for products that endure and a demand for those with the skills to work on them. Those skills haven't changed all that much in the last 100 years. | |||

|

| one of us |

Damn, I was hoping that someone would bite on the welding thing. Thanks for the link to the Grizzly tool. It looks certainly capable. I will probably keep my eyes open for a decent used dividing head and matching tail stock. DPCD after I ask an inane question, or posit an inane idea   | |||

|

| One of Us |

Well, if you think about it, this specialization has allowed people to do stuff that was never possible 60 years ago. Guys like Jerry Fisher, Curt Crum, Hagen, Duane Wiebe, Dave Miller and a host of others took classic rifles far beyond what Kennedy, Linden, Bone and all of the old timers used to put out. I've seen all their work and I know what the shit is supposed to look like. It's the same with the high end shotgun work and the (little gun) work. The stuff that's being done to the 1911 and it's clones is LIGHT YEARS ahead of the junk that was being done when I went through CST. Even the BB guns are off in a whole different world. My two Theoben pre charge guns both shot better than any 22 rim fire I have ever owned and I've owned some nice stuff over the years. So the good stuff is still out there. But one guy can't do it all. Bring your $3,000 BB gun to one of the guys building classic hunting rifles and watch how fast you see the "other side of the door". The world may have gotten smaller, but it's a whole lot more complicated. The world is made up of millions of little parts today. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| one of us |

A very, very nice job indeed. Regards, Bill | |||

|

| one of us |

What is the radius of the concave curve below the woodline? Is that usually cleaned up by a form tool, or by hand with a convex sanding block? Lillian Wolf, British SOE radio operator, caught by the Gestapo, and executed at Ravensbruck concentration camp while holding hands with Violet Szabo:  Violet Szabo, code named Louise. She was also an SOE wireless operator. After capture and torture/interrogation, she was also executed at Ravensbruck concentration camp.   | |||

|

| One of Us |

That red bird is funny, but the story about the English girls is a downer. | |||

|

| one of us |

Yeah, My photograph files are split half and half with things of beauty, and the insane cruelty of humans. I find myself heartbroken over what happened seventy five years ago, and uplifted by birds and examples of humanity in wartime. Here is what got me on this subject in the first place. I have a set of these bases; they require grinding/milling/filing/sanding of the rear action bridge to fit. These are Brownells/Warne 7.3 bases for a modified Mauser. I like the idea, because I think they will keep the scope axis closer to the bore axis. It also seems that a peep sight could be fitted to the rear base without too much drama.   | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Question on contouring Mauser actions in a knee mill...

Question on contouring Mauser actions in a knee mill...

Visit our on-line store for AR Memorabilia