The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Bolt handle

Bolt handleGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

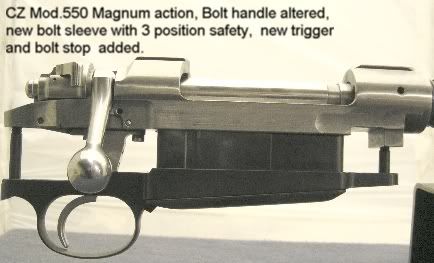

Can the bolt handle on a CZ 550 magnum be straightened to look more like a Obendorfh? I understand the hole thats located in the end of the bolt knob can be filled. So do you just build it up with weld, and shape with a file? Any ideas or comments please. Thanks Thanks | ||

|

| one of us |

You can't reahpe the one that is there and get anything even remotely approaching an Oberndorf handle. But you can replace it and get a different one. I think if you paid some one a fair wage, you would have just as much in a reworked factory handle compared to a new one, and the reworked one still would come up far short. If you are not happy with it, it needs to go. Here is a Talley handle:   | |||

|

| One of Us |

I'll take it !! Thanks so much for the picture. How much time would it take for a gunsmith to install? I think this Talley bolt handle is the way to go. Is this the same company that makes Talley scope rings? | |||

|

| One of Us |

I straightened the handle on both my 416Rigby 550 and my 375H&H 602, reshaped the knob slightly to more closly approximate the Mauser knob shape. I filled the hole in the knob with a piece of wood I had brought back from Zim and turned a small piece of Warthog tusk I had killed in Zim to approx 3/16". After checkering the insert I drilled and inserted the ivory dowel in the center. Looks pretty good cost nothing and has mementos of the hunt. The Talley handle does look better in my opinion SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

Maxbear, here is a pic of my cz550 .375 with a straightened and filled bolt handle. It was done by American Hunting Rifles in Montana. www.hunting-rifles.com sorry for the pic quality. (a little blurry)  | |||

|

| one of us |

This is my personal favorite. Sorry, only pic I have available at this hour.   Aut vincere aut mori | |||

|

| one of us |

Max- BOlt handle prices are all over the board, and to a large extent depends on what quality level you want. $150 will get you just about any handle job you want. Jim Bair at Half Moon makes some very nice bolt handles too. I am going to use one of his on my next bolt handle job. Dave Talley used to make several metal components for the trade. he sold the ring and base business, I have no idea who makes the bolt handles now | |||

|

| One of Us |

Z1r, Thanks. I like this one as well. From the picture it appears that the knob is larger then the Talley. Where did you find this bolt handle? | |||

|

| One of Us |

Marc, here is a link to brownells that I found. Is this the same bolt handle thats on your rifle? http://www.brownells.com/aspx/NS/store/ProductDetail.as...le=CLASSIC+BOLT+KNOB Also what do you guys think of these knobs? http://www.brownells.com/aspx/NS/store/ProductDetail.as...=ENGRAVED+BOLT+KNOBS | |||

|

| one of us |

Maxbear, That handle was done by Tom Burgess. The handle is his design. The knob is larger, very much like the original magnum mauser handle. Much nicer than a Talley. Jim Baiar does have some very nice handles, I rather like them. His oberndorf style is larger than the Talley and smaller than the Magnum I had Mr Burgess install.  Aut vincere aut mori | |||

|

| One of Us |

Who is Jim Baiar? How can I reach him? | |||

|

| one of us |

I believe this is the correct contact info. If not, someone will correct me. Half Moon Rifle Shop- 490 Halfmoon Rd, Columbia Falls, MT. Phone: (406) 892-4409  Aut vincere aut mori | |||

|

| one of us |

Yes, that Talley is what is on the rifle I posted. Th echeckered knobs are smaller than the Talley-something to consider when uou are dealing w/ a big action such as the CZ. I talked to Jim at Half Moon a few months ago about his handles, and I think he said he has 2 sizes. Anyway, as stated in my first post up above, I am going to try one of his the next time I have a bolt handle to weld on | |||

|

| One of Us |

Z1r, that contact information is correct. I gave him a call, and ordered one of his bolt knobs. By the way he's a real nice guy. I want to thank you guys for your help. | |||

|

| one of us |

Maxbear, Glad that worked out for you. Yeah, Jim is a real pleasure to do business with! You will like his handle.  Aut vincere aut mori | |||

|

| One of Us |

If you have a copy of Tom Turpin's book on David Miller, take a look at the photo on pages 172-173. The best bolt job I have ever seen in my life on a 1909 Argentine. How he gets those 4 raised panels for checkering on there is beyond me. | |||

|

| One of Us |

I don't know about Dave Miller's 1909 bolt but several years ago I took an end mill and cut 3 recesses or holes if you will in a bolt knob then silver soldered short rods in and dressed to contour of knob but slightly raised then checkered the 3 panels. If I must say it turned out rather nice. Wanted to case color but didn't know how. SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

Zimbabwe Maybe thats what Miller did. (Turpin, if you are reading this come on and tell us how he did it) So, if you did it with round rods soldered in the bolt knob, surely it could be done with little teardrop pieces of steel welded in the knob and dressed off to be just a checkering depth above the bolt. Wanna try it. I will supply a new Baiar Bolt handle. Once again, take a look at it on pages 172-173 of the Turpin book. | |||

|

| One of Us |

22WRF Thanks for the offer but at 73 and arthritis I don't do much work any more. SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

Here's a different knob from the book.   | |||

|

| One of Us |

Brownell's used to sell a cast replacement bolt handle that had raised panels already there. Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Former Professional member American Custom Gunmakers Guild | |||

|

| One of Us |

They were only two panel and three panel, and both the knobs and the shaft of the handle were quite small. | |||

|

| One of Us |

thornell, thanks for posting the picture of your rifle. Onward.... I just thought of something that I should of asked the fella over at the half moon gun shop. Its a question regarding the bolt knob on a OG magnum mauser. What is the knob diameter? | |||

|

| One of Us |

question: can a piece be CC'd if it is soldered, or would the temperatures used remelt the solder? | |||

|

| One of Us |

Have absolutely no idea as I DON'T have the foggiest idea HOW color case is done which is why I didn't do it. I know how to case HARDEN something using a preparation, if I remember, was called casenit. That required heating the item to be hardened to dull red but did not necessarily give color to the item usually a dull grey. Was done to render something made of mild steel to have a hard surface. I have no idea HOW the beautiful colors that some produce now is done. I know it probably requires heat but to what temperatures I have no knowledge. SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

I just opened a package from the Half Moon gun shop. Its a nice bolt handle. A man I talked to once told me about positioning the handle about 1 degree back. He said he did this because if the handle is welded straight down then it will look like its bent forward. Is this true? Thanks | |||

|

| one of us |

I have heard that too. What I think is meant is that you do not want the front edge of the bolt handle to drop straight down. The arm of the bolt handle is tapered, so if you have the front edge dropping straight down, then it will look funky. What you want to do is visualize the centerline of the bolt handle and have that intersect the root on the bolt body at 90°. We all have our ways of making handles, with many inspired by Tom Burgess. | |||

|

| one of us |

Max, I had a straight oberndorf style welded to one of my bolts and if you look at the ejection port of the action, the handle does look like it leans a bit foward. I guess its an illusion since the mass of the action if foward of the bolt handle.Just my guess since the handle is perfectly straight. Bob | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia