The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Converted my Rossi 1892 to Take Down

Converted my Rossi 1892 to Take DownGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

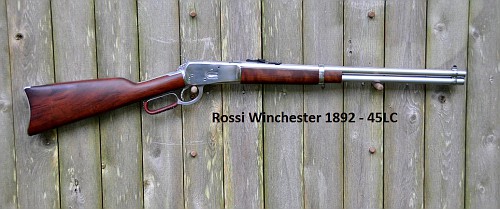

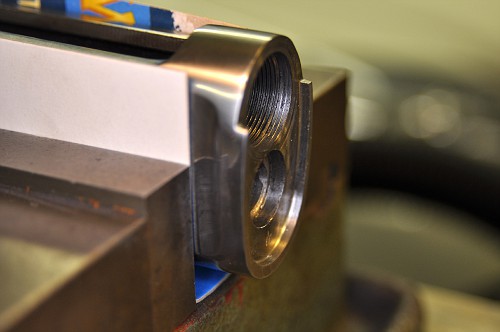

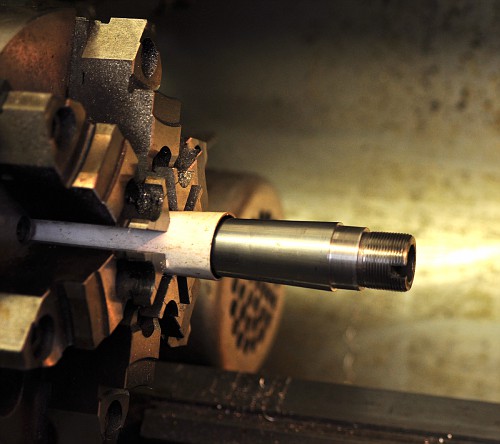

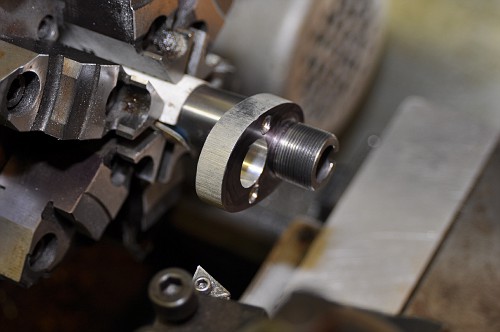

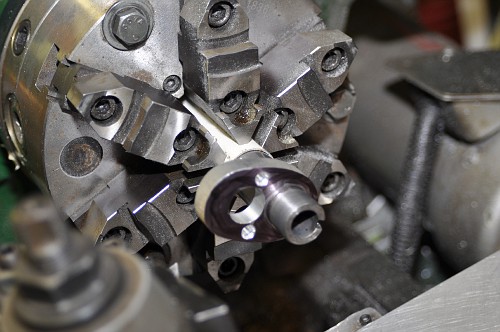

Well, I bought this rifle off a fellow here on this site. Picked it up Monday night in Maine. The sole purpose was to convert it to a Take Down. I love riding motorcycles long distances and this fall I'll be riding to Mo and possibly Montana to do a bit of Whitetail hunting. This rifle will fit nicely in my painers. Years ago I read an article in the NRA Gunsmith Digest on doing this to a Model 94. So with gun in hand, I had at it today. Here's what I started with:  First order of business was to remove the barrel. This was very easy. They are not on very tight. Once the barrel was removed you need to remove the "ears" on the front of the receiver:  I used the milling machine to remove most of the material:  And then a fine file cleaned it up:  Here's what the front of the receiver looked like:  Next I had to layout the plate that will hold the barrel and forend. And bore the holes in the milling machine:  The finished piece ended up looking like this. I used 7075 Aluminum as I wanted to keep the weight down and this piece does nothing but stop the barrel from turning.  The barrel needed to visit Mr Lathe and have a shoulder cut the thickness of the attachment plate:  A very tight fit was the goal. The attachment plate was heated with a heat gun and using the action and a large washer, the attachment plate was press fit onto the barrel shank:  The barrel was then indicated in and the face of the attachment plate was turned true and perfect headspace was achived:  A new "plug" was turned for the end of the magazine. This plug will have a spring loaded button to keep the magazine in place which stops the barrel from unthreading:  Finished assembly with the magazine tube retracted:  And extended:  And the retaining button on the other end:  And the button depressed and the tube retracted:  Nine turns and we are on:   And the finished project:   This project was a lot of fun and very quick. 6 Hours from beginning to end! The only thing I have left to do is figure out a way to retain the follower in the magazine tube as it needs to be retracted in some fashion so the barrel can be unscrewed. I'm open to suggestions. Hope you enjoyed this little article............. | ||

|

| One of Us |

Inspirational! Super job and neat project. | |||

|

| One of Us |

Hey - Thanks for posting, really practical work. | |||

|

| one of us |

Thanks Folks! It was a real fun afternoon project! | |||

|

| One of Us |

Nice job, looks good! I think the article was in the 1979 Aug. issue of the American rifleman. I have done several of those lever guns like that, nice fun project, and cool conversation piece. To retain the follower in the tube take a metal block about 1/2" thick and drill a hole part way through it the size of the tube or a little bigger, and make a plug with a shoulder to fit in the tube for the other end and tap with a small hammer the tube into the block and it will roll the end in-word to hold the follower in place. My last one I did was a marlin in 44 Mag. was a blast to shoot.    Don't forget the ball detent, everyone wants to hear the click as it tightens up. Extreme Custom Gunsmithing LLC, ecg@wheatstate.com | |||

|

| One of Us |

Roy, that was fabulous, thanks for posting it. Have you thought of doing an interrupted thread, or is that too much of a pain? What would you charge for that job on a customers gun? | |||

|

| one of us |

Great job Roy. Those 6 jaw chucks are the only way to go.  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

| One of Us |

How embarrasing-for me, that is. I couldn't find my milling machine in the time you did the conversion. My wife just informed me I do not own a milling machine. Oh well. Very nice piece of practical work. I need a nap. Stephen | |||

|

| One of Us |

Just beautiful. | |||

|

| One of Us |

Very nice work www.KLStottlemyer.com Deport the Homeless and Give the Illegals citizenship. AT LEAST THE ILLEGALS WILL WORK | |||

|

| One of Us |

so, is that operable by hand, or does one need a tool of some sort to take it down and put it back up? | |||

|

| one of us |

Now that is funny....... :-) The rifle comes apart totally by hand. No tools needed. I need to teach myself how to Broach so I can do interrupted threads. That is the way to go with these takedowns. I have an old Mauser I'm going to practice on. Thanks for the idea on stopping the follower. I'n going to see if I can make a cannular in the tube with a dull pipe cutter. Stay tuned. Ball detent is a nice add. Dully noted! | |||

|

| one of us |

Six hours, I'm impressed. Frank "I don't know what there is about buffalo that frightens me so.....He looks like he hates you personally. He looks like you owe him money." - Robert Ruark, Horn of the Hunter, 1953 NRA Life, SAF Life, CRPA Life, DRSS lite | |||

|

| one of us |

Well, I resolved the magazine plug issue! Using a very dull pipe cutter I turned a canular on the magazine tube. This created a little bump on the inside of the tube which will stop the magazine follower from popping out of the magazine tube.   Then I turned a new plug which is longer than the original:  To take down the rifle the magazine tube now extends further forward so the plug will clear the receiver:  Here is the barrel with the magazine tube in the "locked" position:  It feeds like the democrats at a budget meeting!  | |||

|

| Moderator |

very very cool! opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

Really nice! | |||

|

| One of Us |

Roy, Heck of a good job with this. And thanks for documenting and sharing it with us. Those projects that are start to finish in a single day are especially satisfying and enjoyable, or so I hear :-) So what is your favorite deer load in a .45 LC? Regards, Ian | |||

|

| Moderator |

fav deer/pig load for a 45 LC? mine is 250gr jacketed bullet at 1000FPS .. that's what i carry in my SW 625-9! mild, wickedly accurate, and works for head shots on most anything i'll be hunting opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

I don't have a fav load yet for deer. Still testing. I use cut down 454 Casull brass with a stiff load of H110 under a Cast Performance 335gr. WLNGC gas checked bullets with excellent accuracy and velocity. But I recently started casting my own bullets and Lyman #2 lead in a Lee 255g is also giving me great performance in my Marlin 1884 and my Puma 45LC/454 Casull. A 255g bullet might be a bit light for larger deer. I'm going to order a mold that duplicates the Cast Performance bullet with a gas check and continue the testing......... | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Converted my Rossi 1892 to Take Down

Converted my Rossi 1892 to Take Down

Visit our on-line store for AR Memorabilia