The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Chamber Reamer holder preference

Chamber Reamer holder preferenceGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

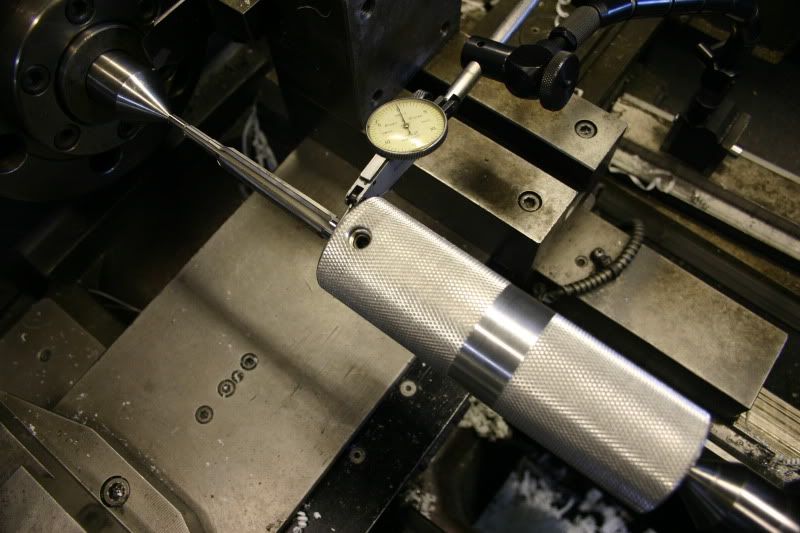

How do you like to hold your chamber reamer? With my set up I settled upon this, which I made:   Some prefer floating reamer holders, I have seen some that use no reamer holder and just put it on a center with a wrench. Anyone have a strong opinion? Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | ||

|

One of Us |

I've used damned near everything. I now use the PT&G Bald Eagle holder. Best I've found so far! _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

I have a Manson floating reamer holder and have had no problems. Never rode a bull, but have shot some. NRA life member NRA LEO firearms instructor (retired) NRA Golden Eagles member | |||

|

| One of Us |

I use a CR tiny vise grip for the first half of the chamber. This allows me to get a feel of how aggressive I can run the reamer with my floating reamer holder for the last half. The little vise grip works much better than a lathe dog for the first half, because when you run it too hard, the reamer just spins in the vise grip. I don't clamp on the flats. My floating holder in pieces.  | |||

|

| One of Us |

Nice piece of machine work. I'd be a little concerned about getting wrapped up in the knurling though. | |||

|

| One of Us |

Second the concern on the knurling. I was holding a knurled piece with my left hand a couple of years ago, and had just peeled off some sticky tape off of something, getting some of the goo on my hand. The work stuck, the knurling grabbed the sticky stuff on my hand, rolled my thumb around, and grabbed on the side of my thumbnail. Before I got loose of it, it had ripped off the skin on a tear line all along the edge of the nail and peeled it back around the thumb. Talk about bleeding and hurt! I don't think I'll do that again. Knurling held in your hand and power drive don't mix. dave | |||

|

| One of Us |

I have a similar large knurled piece made for me by my friend Fearless Frank. I turn it by hand for that last little shaving, but not under power. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

The knurling is more like flat chequering. I did not bring it to points partly because of the concern I had with it "tearing" part of my hand off. My camera just exemplifies the depth of the knurling. It is quite pleasant to work with. I am not strong enough to hold onto it under power if the reamer bites. I have only had that happen once. It just spins in your hand, no tearing of skin, fingernails :barf:, etc. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| Moderator |

You are chambering under power and hand holding? Or finishing by hand? opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

Chambering under power and finishing under power. Depending on the type of project depends on how the barrel is chambered. Precision stuff gets indicated in a 4 jaw and cat head, not as precision gets a concentric cut between centers then finish on a steady rest. When chambering it by hand I can feel the cutter, feel any chips underneath the cutter, and feel how fast/slow or easy/hard I can push the cutter. With finishing, indicating on the reamer holder I can ream the chamber within a few thousandths, check with gauges, indicate, ream to finish dimension, double check. Never done it that way? Every gunsmith I know chambers that way. Well, except one. He chambers barrels with a floating reamer holder and a collet. I do not like to consider him a gunsmith if possible Alright Jeff! Let it roll... Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| Moderator |

not going after you.. was an honest question .. i prolly wouldn't do it under power and hand held ... never thought of it ... but, hey, i get by with a floater (heh.. floater) .. that is, floating holder ... i am just kinda "wow, he's got WAY more hand strength than me" ... and i have a grip like a vise .. its always interesting the way people do stuff, and how they get good results from it, even if its not how other do the same opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

I use a JGS floating reamer holder and it works well for me. If the reamer I'm using won't fit into it I use a small lathe dog as a "handle" on the reamer. John Farner If you haven't, please join the NRA! | |||

|

| One of Us |

I really am not that strong. 130lbs, 6ft, I have strong hands... but by no means above average. That is what is nice about this method. It only takes moderate pressure. If you are feeding too hard the reamer digs and you start to loose your grip. Feed a little less and you have a full grip. I think it is a good method... I prefer it to pretty much every other method. I believe it allows a more accurate set up, truer chamber, and most importantly, a concentric throat. No floaters here... Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

6 ft 130?...sheesh I am 5"10" and I think my right leg is 130...LoL Mike Legistine actu quod scripsi? Never under estimate the internet community's ability to reply to your post with their personal rant about their tangentially related, single occurrence issue.  What I have learned on AR, since 2001: 1. The proper answer to: Where is the best place in town to get a steak dinner? is…You should go to Mel's Diner and get the fried chicken. 2. Big game animals can tell the difference between .015 of an inch in diameter, 15 grains of bullet weight, and 150 fps. 3. There is a difference in the performance of two identical projectiles launched at the same velocity if they came from different cartridges. 4. While a double rifle is the perfect DGR, every 375HH bolt gun needs to be modified to carry at least 5 down. 5. While a floor plate and detachable box magazine both use a mechanical latch, only the floor plate latch is reliable. Disregard the fact that every modern military rifle uses a detachable box magazine. 6. The Remington 700 is unreliable regardless of the fact it is the basis of the USMC M40 sniper rifle for 40+ years with no changes to the receiver or extractor and is the choice of more military and law enforcement sniper units than any other rifle. 7. PF actions are not suitable for a DGR and it is irrelevant that the M1, M14, M16, & AK47 which were designed for hunting men that can shoot back are all PF actions. 8. 95 deg F in Africa is different than 95 deg F in TX or CA and that is why you must worry about ammunition temperature in Africa (even though most safaris take place in winter) but not in TX or in CA. 9. The size of a ding in a gun's finish doesn't matter, what matters is whether it’s a safe ding or not. 10. 1 in a row is a trend, 2 in a row is statistically significant, and 3 in a row is an irrefutable fact. 11. Never buy a WSM or RCM cartridge for a safari rifle or your go to rifle in the USA because if they lose your ammo you can't find replacement ammo but don't worry 280 Rem, 338-06, 35 Whelen, and all Weatherby cartridges abound in Africa and back country stores. 12. A well hit animal can run 75 yds. in the open and suddenly drop with no initial blood trail, but the one I shot from 200 yds. away that ran 10 yds. and disappeared into a thicket and was not found was lost because the bullet penciled thru. I am 100% certain of this even though I have no physical evidence. 13. A 300 Win Mag is a 500 yard elk cartridge but a 308 Win is not a 300 yard elk cartridge even though the same bullet is travelling at the same velocity at those respective distances. | |||

|

| One of Us |

It is a family curse(blessing?). We have a family portrait of myself, my father, and my grandfather when I was... maybe a Junior in highschool? I probably weighed 120lbs soaking wet, my dad (5 11?) probably weighed 150-160, and my grandfather (5 11?) probably weighed 180 (strangely he put on weight through his last years battling cancer). Back to reamer holders! Westpac how do you like the PTG reamer holder? That was one I considered buying before I decided to make one. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

I'd be interested to see your holder with a reamer installed spun between centers. With a center in the reamer pilot and the other center in the back of the holder. Test indicate the round shank right next to the set screw. How far out is it? | |||

|

| One of Us |

The first question that needs to be answered, to then answer your question, is how true do reamers run? This particular reamer is a 6.5x55 with a removable pilot. For all of these tests I spun PTG’s reamer and my reamer holder between dead centers using two Brown and Sharpe BesTesT’s graduated in .0005. I used the larger faced one for clarity. Both gave the exact same readings. First the reamer. The shank was dead true all 360 degrees with almost no change. The marginal change that was seen was less than .0001 TIR. Same for the cutting edges. So we can state that the reamer is in effect “true”. Shank:  “zero”  “high”  So, onto the reamer holder. Here I indicated as Mr. Anderson directed. Total set-up and “zero”  After setting up the reamer and zero’ing I went through two rotations, stopping every 60 degrees on the shank between flutes to get a reading. My zero being zero degrees. 60 degrees  120 degrees  180 degrees  240 degrees  300 degrees  I did a second test with a different test indicator to double check. For this test I only took pictures of TIR.   So, to analyze, I had a TIR of .0013” to .0014” or .0007 from center. Obviously the bore has to have some tolerance to allow the reamer to be put in. When I bored it, it was a slip “vacuum” fit with the reamer… so I do not think I could make it any tighter. I would like to hear your feedback. I have a few points to make about this reamer holder vs other types, but I need to get some work done this morning! Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

Nat, It appears that you are giving us a chambering lesson. Why not start at the get go and tell us about your setup from the very start? Your indicator indicates about .0015 TIR. Would that mean that it might cut like a lathe tool and cut the chamber that amount larger at the base of the chamber? Just curious. Butch | |||

|

One of Us |

Nate, The Bald Eagle reamer holder works great! Picture a ball riding against a vertical plate. It is particularly handy when working with factory, or, someone elses pre-chambered barrels. At times like these you need something that can follow these holes. But 30 years of habit is hard to break, so on new stuff, after I pre bore the hole to within .020 of the final diameter, I will use the hand held lathe dog and live center setup to get things started and then switch to the Bald Eagle holder for the remainder. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

Butch, if you check out above, I described my procedure for chambering from start to finish. The pictures do make it look like .0015, it was hard to get above the dials to get a straight on picture. Yes, you are correct, my chamber reamer would cut the rear of the chamber .0015 oversize. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| Moderator |

.0015? pretty darn small .. could be improved, but pretty small i am more impressed about the hand held part than indicated runout opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

Nat, I read that you put it in the lathe with a cathead on one end and a 4jaw on the other. That really means nothing to me. Butch | |||

|

| One of Us |

I would be willing to bet it is less runout than any commercially available reamer holder. If I can find a way to post a video next time I chamber, I will do that. Just so you can see how real men chamber. (complete sarcasm)

If that means nothing to you, what would you like me to explain? In short the issue I see with floating reamer holders is based primarily on how they are driven. Now, I have not seen one of the reamer holders like what Westpac described, they may work very well. Most though drive on a pin system that has two pins driven by a plate. As the reamer can only “float” on one axis, it will be driven to one side by the lead pin as opposed to equally by both pins. Now, if instead this system was able to float on two axis, like say a u-joint, I think it would be much improved. Most gunsmiths do not do quite a few things that improve accuracy, reliability, feeding, etc. I am by no means saying I know it all, I have tons to learn, which is why I like this website. I am just trying to take what I know from my precision work and put it towards making nice custom rifles. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

Nat, How much do you cut off each end of a barrel blank. Is your barrel held directly by the 4 jaw? How and where do you indicate your barrel? Do you use a roughing reamer and if not what is your procedure? Do you rechamber BR rifles that are glued into the stock. If you do, how do you check headspace and bolt nose clearance? How would you check your threads? I don't think you went into how you indicate your barrels in. If you had rather respond off the website, my email is under my profile or you can send me a PM. Butch | |||

|

| One of Us |

Do you know what a 4-jaw chuck is? Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

Nat, I was a toolmaker back in the 60s. I have a couple 4 jaws in my shop along with both a 3 jaw and 6 jaw Tru Adjust chucks. I know my way around non CNC machine tools and have a pretty well equipped 30x30 climate controlled machine shop. I have always been curious as to how various people machine parts and also how they chamber. I imagine any part of chambering we discuss will be something that I am familiar with. It would be easier to discuss it by PM or email. I have absolutely no reason to give you a hard time. Butch | |||

|

| Moderator |

Nat, Butch is a real good guy ... give him a call opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Chamber Reamer holder preference

Chamber Reamer holder preference

Visit our on-line store for AR Memorabilia