The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Barrel marking options

Barrel marking optionsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Besides a Hermes or other expensive machine, what are others using for marking barrels? Preferably something affordable! Blagg Rifles, Eastern OR | ||

|

| One of Us |

Marking Methods electro-chemical etching system. NRA Patron Life Member Benefactor Level | |||

|

| One of Us |

How much are these systems Doc? Blagg Rifles, Eastern OR | |||

|

One of Us |

Just had to have it. I bought the super kit back in December but haven't unpacked it yet. http://www.etch-o-matic.biz/eom.htm _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

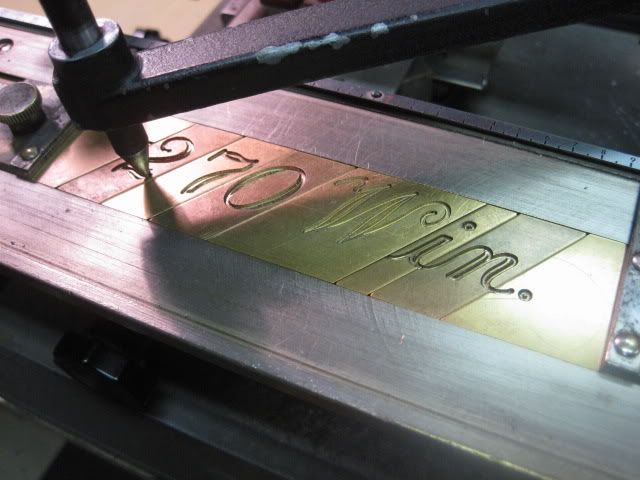

Here is a barrel I did yesterday with my New Hermes engraver. Got it off ebay for a couple hundred dollars three years ago. Well worth the money. Steve   | |||

|

| one of us |

Wow, that looks outstanding. Which model Hermes do you own? | |||

|

| One of Us |

Steve do you know what style fonts you have ? I realy like the scroll type numbers on the 1892 . Hal | |||

|

| One of Us |

The engraver is the New Hermes model GM. It will do diamond drag (scratch) engraving or you can use the motor and use a rorary cutter. The pics above were with the rotary cutter. The font style is called double line connecting script #33-337. Steve | |||

|

| one of us |

sdh600 can you post pics of the setup with the rotary cutter in place?  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

| One of Us |

I will try to take some tonight after work. Steve | |||

|

| One of Us |

Steve With the rotary cutter, do you use a High speed steel cutter ? Hal | |||

|

| One of Us |

Hal, Mine uses carbide. Butch | |||

|

| One of Us |

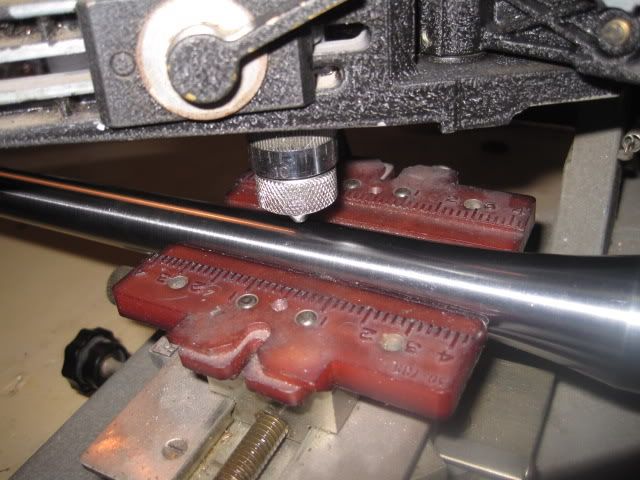

Here are some pics of my engraver. The cutters I have are high speed steel, but I would recommend carbide as mine dull very fast. Steve      | |||

|

| one of us |

I looked at the Etch-o-Matic and everything is shown on stainless or unfinished metal. Does anyone know how it looks on blued steel? And that's some nice work Steve. How long did it take you to master the Hermes? | |||

|

| One of Us |

The hermes is simple to use. Not much learning curve at all. I tried the electro chemical etchers, both the etch-o-matic and the Marking methods pro model, without much success. The problem may have been that I was trying to make my own stencils. I think if you invest in the professionally made stencils they work much better. They will even do deep etching which should work well on a blued barrel. The problem with etching is you need a stencil for every caliber you chamber in. With the engraver you can put anything on the barrel that comes up. Steve | |||

|

| one of us |

Is the cutter in the photo the one that you use while running the electric motor to engrave the Winchester 1892?  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

| One of Us |

I used one just like that one. The one in the picture is a spare. Steve | |||

|

one of us |

send it to an engraver Do it correctly! Roger Kehr Kehr Engraving Company (360)456-0831 | |||

|

| One of Us |

James Anderson uses his CNC and it does really nice work. I have a New Hermes GTX-3/ITX-3 free standing floor model.I have some carbide cutters for my motorized head, but I have only used the diamond scratching. I think I need to try the motor. Butch | |||

|

| One of Us |

I also have a New Hermes with both the scratch and a powered head. I was wondering how the powered tip would cut on a curved surface; it seems like it was made to do flat surfaces with a standard depth of cut. The scratch works because one can hold the diamond scratch onto the material with a little pressure. I would be afraid to try the powered tip for fear the depth would not be even. Tell me I am wrong or how you could control the depth on a round (barrel) surface. Jim Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Former Professional member American Custom Gunmakers Guild | |||

|

| One of Us |

The pictures of the engraving on the Win 92 barrel show what it looks like cutting on a curved surface. Since most of the engraving is done at the larger diameters of the barrel the thinning of the letters at the top and bottom isn't noticeable. I have done some test pieces on some half inch dia. stock and the letters do get thin at top and bottom. Consistant preasure on the cutter is the key to a good engraving. Steve | |||

|

| One of Us |

Laser engraving looks really good on a barrel. | |||

|

| One of Us |

I use a Hermes on occasion but I dont have one. They work nicely. But they are very expensive even used! I priced out the Marking Methods system, not cheap either. There has to be something out there besides stamps. They work and I have gotten pretty good at getting them even. Stamps are just not very proffesional when you are charging a premium price for metal work. Blagg Rifles, Eastern OR | |||

|

| One of Us |

If you will make an effort to call a bunch of trophy shops, you will find an affordable one. Most trophy shops have shoved them into the corner and use CNC now. I have found them this way. Butch | |||

|

| one of us |

You mean that when useing the motor you DON'T control the depth by the pressure you exert when holding down the red knob like you do when you just do the chicken scratch? What keeps the cutter from bouncing all over the place?  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

| One of Us |

I agree with all of that especially about not putting your cutter down before you are ready. I find my depth will vary a little bit if I put too much down preasure on the cutter. Have you ever tried using a burnishing tool to polish the cut grooves of the letters? A tool ground to the same angle as the cutter but without the cutting edge. Maybe run it over the lettering with some fine lapping compound. Just something I was thinking of trying. Steve | |||

|

| one of us |

SDH 600 Where do you buy your cutters? Jim 99% of the democrats give the rest a bad name. "O" = zero NRA life member | |||

|

| One of Us |

For New Hermes items call Carl Clouse. 972-226-3700. Carl is an elderly gentleman that was with New Hermes for many years. He is getting on in years, but should have a few fonts, cutters, and repair parts left. Butch | |||

|

| One of Us |

Jim, When I bought my engraver It came with a few of the rotary cutters. I have been resharpening and using them. I do see cutter for sale on ebay quite often. Steve | |||

|

| one of us |

Cutters and parts are availabe direct from New Hermes. Their service is quite good. John Farner If you haven't, please join the NRA! | |||

|

| one of us |

Jim I buy all of my cutters from, www.bitsbits.com . Also, great re-sharpening service and price. James | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia