The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  stockmaking from a blank

stockmaking from a blankGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Jerry Fisher published a couple of mechanical drawings that may be of help for laying out. I believe they're full sized, so measurements could be taken directly. Midway and Brownells have them. | |||

|

| One of Us |

Earlier this year I finished working on a stock that started out in a CNC machine from a laser scan, and the quality is undeniable (I'd do it again for sure), but you still need to know how to design and shape the pattern stock in the first place right? "If the women don't find you handsome, they should at least find you handy." | |||

|

| One of Us |

[QUOTE]Originally posted by Big Gorilla Gunworks: Hi, all. Long time lurker, first post here... I use a custom built dual duplicator- reluctantly I will add, primarily as part of a doing a full build. At some point, we need to acknowledge the rapid changes in the smithing and stock making businesses- as well as the possibility, IMO, that the legendary gunsmithing schools actually may not be in step with the automation of the industry and preparing students accordingly. Why the lack of "schools" teaching stockmaking? C'mon- there's no profit to be made anymore! Now, I know there are a few "purists" out there- but stock making -and stock inletting for precision bedding jobs, is increasingly being done by automated CNC setups with greater precision and quality, faster, and for the same cost or less than done manually. If you could have your Mauser barreled action 3D scanned/modeled, and a stock precision cut and inletted to tolerances that can't be dreamed of when done manually (without taking days to do it) why wouldn't you? If this service doesn't exist now- don't blink. CNC shops gobble up the more standardized work like re-barreling, leaving niche marketing, one-,off type jobs and repairs for the traditional "Gunsmith"; which I fear is going the way of the dinosaurs.[/QUOTE Better trade in your crystal ball. I do not know of a decent gunsmith that is not turning away work. Two and three year backlogs are common for a completed build. Indeed there are folks throwing in the towel due to political and licensing requirements, so the ranks are thinning...But in my opinion, many of those that have decided to bow out probably weren't serious anyway..just looking for a tax write off. | |||

|

| One of Us |

thanks for the tips Slivers and Lindy. My biggest problem on the layout was a piece of wood that was almost too small and chain sawed out of square nine ways to Sunday. But for my first stock; it probably won't scare off the deer. I have another blank that is larger and much more trued up. I figured I could try to learn what not to do on this one before I started inletting on the mauser. I would like it to look good. Mike | |||

|

| One of Us |

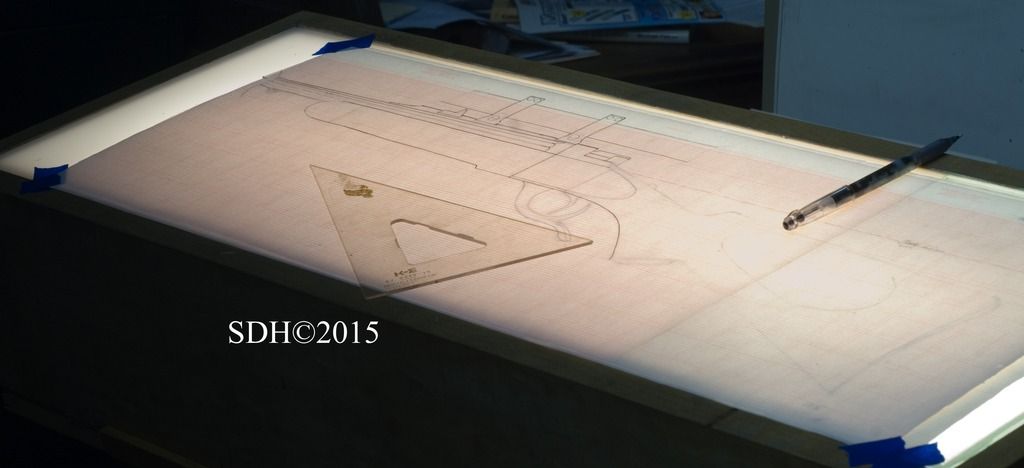

I teach how to make a full scale drawing as part of the stockmaking class. I also provide a Jerry Fisher's drawing to teach students. As much as they are a tremendous help, you can't take accurate measurement directly from the drawing. Jerry does provide a lot of measurement an cross-section views the most difficult to draw.  Drawing all begin with the bore line, but much more than that is required. I agree with Evan, someone has to make the original in order to have something to copy. The only guy I know that was using a scanned and programmable carver gave up and went back to more conventional methods as there was simply too much variation in the original metalwork and he had to scan each and ever piece of every job. IMO, it is going to be a long day before this scan and program technology is implemented in custom stockmaking. It flies in the face of why astute clients want custom work, the level of interest from hobbyists won't support it and there is no standardization anywhere in the industry, IMO. BTW: I'm not taking any new work either, but I do a lot of different things besides custom gunmaking. ACGG Life Member, since 1985 | |||

|

| One of Us |

Lost Okie, My first step is to go into town and visit the local mill work shop (custom entry way doors, cabinets and the like) and they 'true' the blank for me. I want the off cheek piece side and the top square to each other while removing as little wood as possible. They let me watch and I tell them when to STOP. This gives me an accurate place to measure from. I don't figure I can count on the blank being 'square' as I receive it from the supplier and it lays in the rafters of my shop (climate controlled) for years before I might use it. | |||

|

| one of us |

Stockmaking is a part of gunsmithing which people don't like to do, but it is the one thing which will keep you busy all the time if you learn it well. I took over when Ed Shulin retired back in '92. I found that only about 5% of the people had the ability to make a pro stock. Most of the students wanted to run the mills, lathes, and do bluing. A student approach me to checker his stock and I replied by telling him this was a learning curve for him while in school. One instructor at TSJC said the school was known for teaching how to make fine custom rifles and he was going to change the thought to more on repairs. I said that it would be a mistake. I stayed on for 2 yrs and 2 NRA summer classes. Dave Nolan took my place and has his shop in Trinidad now. I wrote how to make a stock by hand back about 6 yrs ago. Maybe it should by placed back on the sticky site so some of you can review how I make stocks. | |||

|

| one of us |

One thing that turns me off is someone trying to make a stock exactly like another by measuring and drawing a sketch etc...I saw a video of the modern "Rigby" doing this lately.They were taking measurements of what seemed like Corbett's rifle using a caliper and trying to make one identical.Obviously they failed.Why don't people make a stock simply as best as they know how and let the stock speak for itself. | |||

|

| one of us |

The problem I see for beginners is they don't have the dimensions needed to make a stock to fit properly for them or someone else. Maybe a discussion should be a topic of interest. I use three points to determine where to start the project. The first is the center of bore line drawn on paper large enough for the entire stock full size dimensions. Next the trigger location and then the length of pull. IF you have glasses you will need more drop depending on whether you are making a scoped rifle or open sights on the barrel. Shotguns are another project with the line of sight on top of the barrel. I always had trouble with these shooters as they all have a certain way to hold a stock. Trap and Skeet people need to hit targets at different locations. The amount of the sight seen by the person will control where the shot will end up down range. Just a few thoughts | |||

|

| new member |

I graduated in May. In my stockmaking class the first thing we did was to draw out our stock full size as Les stated. These were based off of measurements we took while learning stock fitting. We used a semi-inlet stock, they were duplicated way over sized so there was still a lot of shaping to do. In the Custom Gunmaking program they make stocks from a blank. The things are still taught at some schools. | |||

|

| one of us |

Regarding the stock blank shaped and inletted in 40 hours. A few years back I drove from Texas to Oregon with a friend to attend a small class consisting of myself Mark Pursell and Steve Nelson. Taught by Pete Grisel. Steve worked on a two piece rifle blank. Mark worked on stocking his Model 70 Win from a blank. I worked on stocking a 1909 Argentine model 98 from the blank. It has been a while but the best I remember we averaged working about 8 to 9 hours per day for five days. We started on a milling machine then finished up hand inletting with chisels. We forged one chisel each while there. Scrapers were discouraged. At the end of the week my friend Mark had his 100 % inletted shaped and was ready to sand. Fore end tip, steel grip cap, recoil pad and sling swivels. I had mine 100 % inletted, about 50 % shaped, ebony tip with widows peak, steel grip cap and pad. I don't recall how far along Steve got. Over all it was very educational. Craftsman | |||

|

| one of us |

When I started building stocks it had to be from a blank, hope I never have to do that again, (albeit Ive had to do a couple of Savage 99s last year) especially on two piece stocks with a hole to drill in the butt with a hand drill and braces.... Since I only build stocks for myself, and may sell them at some point, Im not in the business and have made a dozen pattern stocks to have them turned by a fellow that's really good at it..I have no desire to start with an axe these days. Although I could probably get by with the use of a mill. As to one post on here, if your pattern stock is a good average, and oversize you can make that stock to fit anyone, keeping in mind that its easy to remove wood but hard to put it back, you may have to use glass or bondo to change it around,AND always in the inletting, but leave a lot of wood everywhere can save the day. Making a custom fit is easy enough IMO and many of the best use the pantograph, some admit it and some don't according to my man.?? Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| one of us |

A few years later I attended a stock making class taught by Clayton Nelson. I have learned a great deal from Clayton, he is a very good instructor. He is the fastest stockmaker I ever saw. Highly talented in metal as well. Back then he had made over 800 custom stocks. He said he has inletted and shaped one in under 24 hours and I believe him. If you ever saw him use a chisel and mallet you would believe it too. We inletted with the Bridgeport then chisels then scrapers. Shaped with all the traditional hand tools. Craftsman | |||

|

| One of Us |

From a blank vs semi inlet is a never ending over flowing bucket of opinion I've watched that bucket overflow darn near 45 years and not much has changed. | |||

|

| One of Us |

Seems like the kind of guy that would be worth offering some money to watch him make a stock from the blank. | |||

|

| one of us |

If I were in the business I would build a stock for someone from scratch, but I wouldn't care to do so, and Id charge quite a bit for that option.. I think most would do the same..and IMO it would be a waste of time and money for the client..but to each his own on that, its just another historical conversation going back eons... Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  stockmaking from a blank

stockmaking from a blank

Visit our on-line store for AR Memorabilia