The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  stockmaking from a blank

stockmaking from a blankGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Are none of the Gunsmithing Schools (TSJ, MCC and the others) teaching stock making by hand from a blank, anymore? | ||

|

| One of Us |

My spin is they'd think you were describing a cartridge without a bullet | |||

|

| One of Us |

a stock blank; Usually made of figured hardwood, about 2 1/2" thick, 36" long (mol), about 6 1/2" wide at one end tapering to about 3" on the other end. | |||

|

| One of Us |

Must have flown over his head. SD Hughes is giving classes this summer. | |||

|

| One of Us |

Yes, I see that Butch. In one of his posts he states: "the only school teaching stock shaping by hand from a blank, a requirement to become an ACGG stockmaker",,,,, or words to that effect. Am curious to know if it's being taught at Trinadad, Montgomery Community College, the schools in Arizona and California and the others. I know they don't teach "from a stock blank" at Tishomingo (Murry State in OK.). | |||

|

| One of Us |

Tishomingo would be nice and close. | |||

|

| One of Us |

For you? I graduated from MCC 23yrs ago, stock making from a stock blank was a big part of the curriculum, then. Lots of whining about how much there was (classic rifle, California-Weatherby style rifle, through bolt 2 piece and tang style 2 piece) Just wondering if all the schools have dropped it, by now. Was just looking for current info. | |||

|

| One of Us |

It is about 1.5hrs from me, but I will stay with the metal work. I have done 3 or 4 stocks from the blank, but stocks ain't my cup of tea. I love a beautiful stock, but when somebody else carves them. | |||

|

| One of Us |

Never learned much from just watching, Lindy2. The written plan, given to us in school was a start. After that, I learned more from "hands-on" than could ever be learned from watching or reading in a book. Always took the 'hints' and suggestions the instructor offered. | |||

|

| One of Us |

My students begin with the metalwork fully inletted, installed and hopefully functioning. Then we have five days to Shape the stock from a blank. I have to crack the whip for them to complete the shaping in five days with lecture, demonstration and some toolmaking. Some students get it done, or nearly so, some don't but have the instructions to complete. Hopefully all get the shaping pretty close to a semi-inlet. I was taught by Ed Shulin at TSJC and use much of his instruction manual, but it is not self-explanetory and requires much additional instruction and demonstration. Check out some of the Seminar photos on my web site. To the best of my knowledge none of the GS schools teach this any longer.   ACGG Life Member, since 1985 | |||

|

| One of Us |

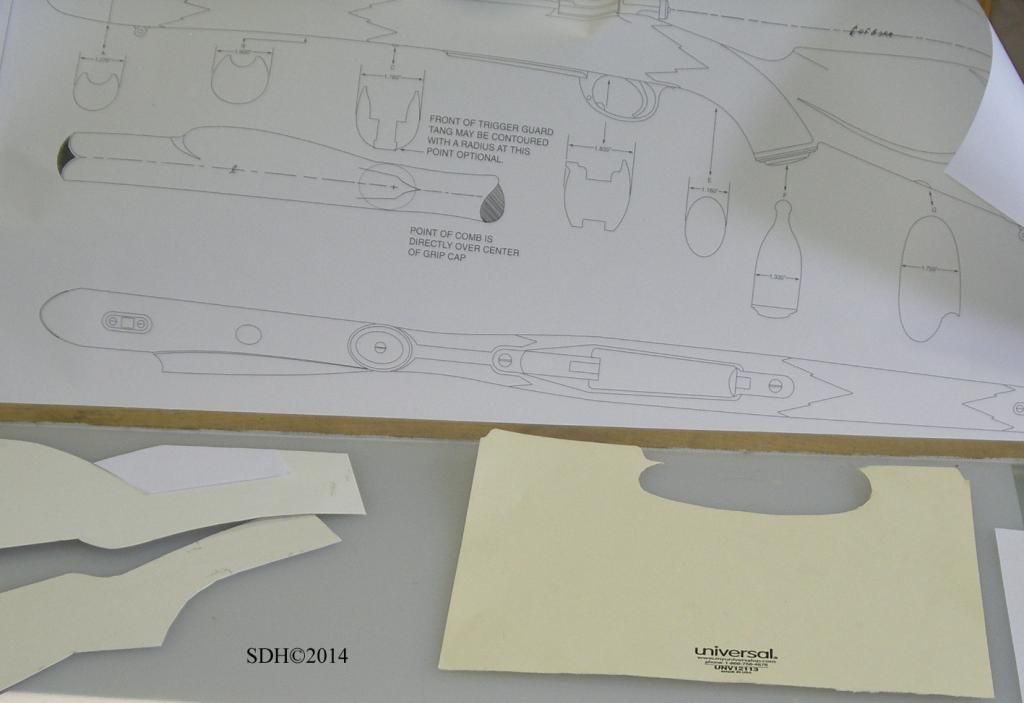

Making a stock from the blank is requirement for ACGG entrance as a stockmaker. This requirement is a major stumbling block for many would be members and some come to my class to learn the skill. Each of these guys shaped from the blank.  AS did all of these guys including Nick Hughes.  ACGG Life Member, since 1985 | |||

|

| One of Us |

Thanks for the reply, Steve. I followed your thread and noticed you'd said yours' is "the only school teaching shaping by hand", I just didn't want to "cut-in" on it. I though maybe some recent grads, from some of the schools, would relay where the curriculum is currently. The instructor at MCC (Gene Anderson) worked his 'tail' off teaching, instructing and demonstrating. Many in the class I was in ('91-'93) had very little interest, but he (Gene) worked hard to help them get their projects done on time. The only stationary power tools we used was the 8" jointer, to square the top to the off cheek-piece side, so that there was reference for accurate measurement, the band saw to cut away the 'excess' and the 12" disc sander to clean-up saw cuts. The rest was done with hand tools. The class that was to follow the one I was in was quit vocal about how much time was spent learning stock making (four 11 week quarters). I had graduated and had gone home before I got to see how the program was to change to meet the demands of the students (you have to keep enrollment up to keep the program alive- there were no 'waiting lists' for admission, then). I do know that the instructor took a NRA Summer class that taught finishing the synthetic stock blank, and I imagine that was then incorporated into the curriculum to keep the students happy. The only other gunsmithing school I've been around was at a NRA Summer Gunsmithing class, Color Case Hardening taught by Joe Beck, at Tishomingo. I've never had the opportunity to work around another stockmaker since I graduated and would imagine it/could be like two experienced machinists working together in a machine shop. One might learn the ways of the other. I was/am just looking for current info as to what is taught these days. Maybe we'll yet hear from a / some recent grads on the subject. I don't have a Photo Bucket account, or I'd post a pic, or two. | |||

|

| One of Us |

I'm a fairly recent graduate (6 yrs ago) from Yavapai College in Prescott, AZ. They did not teach stock making from a blank at that time. We had a great stock making instructor (Robert Szweda) who had us alter stock patterns to fit a certain build sheet, duplicate the stock, and go from there. This type of instruction was very helpful for me as it's what I do 95% of the time when I make a custom stock. For the handful of times I haven't have a suitable pattern and have had to start from a blank, I was able to do most of the inletting on the Bridgeport and shape the outside by hand following instruction from some who have posted on here and elsewhere on the interwebs. My understanding of Yavapai since I've left is that the administration doubled the enrollment numbers and removed stock making as a required course. I agree with Lindy; if you want to learn the trade, find a stock maker that you can apprentice under. It would be more bang for your buck than going to a gunsmithing school that has to dumb down the instruction to keep enrollment numbers high. The course from SDH sounds like a great opportunity to do just that. | |||

|

| One of Us |

I graduated CST in '76 and we did stocks from blanks then. Dean Wentworth and Sid Cross, Ken ,can't remember Ken's last name and a couple other guys were instructors then for stocks. CO School of Trades 1976, Gunsmithing | |||

|

| One of Us |

SDH: Steve, Just asking...Since inletting is such a major part of the job, how is that part accomplished within your program | |||

|

| One of Us |

Duane, Since we often have a few different stocks to inlet, I send the students to John Vest and he has worked up a semi-inlet type pattern for M-70s and Mausers for the inletting or inletting and rough shaping as the student desires. Students have done single shots and double shotguns in class. I only have one milling machine and five days so this is the best route for teaching/learning with 4 students. At Trinidad we did all our initial routing of the inletting largly by plunge cutting with a 1/2" mill cutter on a drill press. We had a whole 11 week(?) quarter to make a dozen inletting chisels, inlet and shape a Mauser stock and it was nip an tuck to get it all done. Only so much can be accomplished in 5 days and I have to tailor the instruction to fit the time. As it is, we have students that don't finish up in the week. I offer Inletting as the first term and Shaping as the second but always have students that haven't take one or the other and I have to accomodate them. Stockmaking instructor Ed Shulin always said, "Even if you are making a pattern stock you need to know how to make one from a blank." I wish I still had my first Mauser: a .270 on a Polish Radom action stocked with a $30 blank of Strawberry Point,Iowa American walnut in 1976. Alas, I sold it to fly to Las Vegas to join the ACGG about 1985. I'm still pondering that move??? Duane, do you recognize the gunsmithing preacher in the pic? Great Guy, great student! ACGG Life Member, since 1985 | |||

|

| One of Us |

Yes, I call Jim my "spiritual advisor" I remember when you joined the ranks of the ACGG . You were damn near dead with the flu! Thanks for the info,,,I was pondering how you got all that done in 5 days! Thought maybe time for me to sign up!!! | |||

|

| One of Us |

We learn stock layout and how the various dimensions add up to make the profile and determine the position of the buttplate and grip cap. How the hardware determines much of the layout and how to do a full scale drawing to design a gunstock. How to make butt and grip curve templates and how to correctly locate them on a blank.  The students draw the layout lines on the blank, then I do all the band sawing (for safety reasons) To Their Layout Lines.  Most of the contour shaping is done with wonderful French hand-stiched rasps. I teach how to layout and accommodate a cheekpiece, pitch, cast, cant, drop and the parameters determined by the metalwork, and classic style. We rely heavily on my Custom Rifle in Black & White book for design and details.  I try for a full week of Custom Gunmaking Immersion and we meet two nights after class in my office for Show & Tell with guns I have or specifically borrow, or the student that are driving here bring to show. Last year we had a 1920,.275 Rigby Mauser, claw mounted and cased a student brought.  I usually have a borrowed Jerry Fisher M-70, .270 circa 1990 and have it on my workbech with the metal in, or out to show the best quality work.  We learn in a working custom gunshop, and if a student doesn't have the right tool for a job, I hand them one of mine and show them how to use it. (There is still room for two students for Metal Polishing & Preparation, Rust & Nitre Bluing the last week in June 2017. Contact me at the website) ACGG Life Member, since 1985 | |||

|

| One of Us |

Lindy2, the layout is where it all starts. It is your 'plan'. When I was in school, four 11 week quarters= 4 stocks,,, 2 rifle and two 2 piece stocks. The second of those stockmaking quarters (classic rifle) I completed one and was wet sanding the second one. | |||

|

| One of Us |

lindy2, You still are trying to say that a stock can be inletted and shaped by hand from a blank in a matter of 7-10 days. Not scraped in to the standards of the best in the trade today,let alone a bunch of novices try to shape their first stock. | |||

|

| One of Us |

My buddy George said 40hr.. Of course, not in a row. | |||

|

| one of us |

So is there a difference anyone in the world would notice, aside from the wait time, between a stock cut from the blank by "hand" and one started with a duplicator? | |||

|

| One of Us |

Better yet, learn a few things in 5 days, go back to your own bench and work at it for year, take another course and learn a bit more...repeat as necessary. And as the reigning, all-time Slowest Learner in the history of the SDH Fine Gunmaking Academy, I can say the strategy has merit! | |||

|

| One of Us |

A duplicator can only made to be fit someone with what is already on hand. A hand built stock can be made to fit an individual. For me I think this is nonsense. My buddy makes 10-15 hand built stocks a year. He said it is a real battle to not have them fit him, but to fit what the person ordered. | |||

|

| One of Us |

Actually, if you built your pattern specific to each job like I do, you can build a stock to any measurement you like. More than one way to skin a cat. If I was as fast as Duane I would stock everything from a blank. I know how and have done it but building a pattern is more efficient for me. I'm really glad I learned the method SDH teaches at TSJC. Without understanding the whys the how becomes a moot point. I think SDH has enough chips under his chisel that he is able to give his students the most for the time they have to spend with him. While a long term apprenticeship has its merits, it is not practical for most people. If I was just starting out these classes would be very enticing. I took some short term double gun classes from Dennis Potter and learned more from him in a couple of weeks than you could imagine. Best of luck to SDH and his students. This is a very good opportunity for a motivated student. Steve | |||

|

| One of Us |

I didn't know that Steve was teaching at Trinidad. | |||

|

| One of Us |

He doesn't, although I believe he (SDH) has taught at the NRA summer classes. What SKB was referring to is the method of making a stock from a blank that was taught at Trinidad. I graduated from TSJC in 2009 and at that time we still did do a stock from a blank, taught by Dave Nolan who learned from Ed Shulin. We didn't make a complete set of chisels as was done in the past, but we did make a couple just to learn the process. I don't know whether they still teach it in the current program. -Eron Eron Ahmer Sulphur Gulch Gunsmithing | |||

|

| one of us |

I have made a few stocks from the blank, by hand although I do use some power tools (I slabbed out the last one with a Stihl chainsaw). I have no training so probably do everything wrong. I have watched a couple of pretty good stock makers (Martin Hagn and Klaus Hiptmayer)but never the whole operation. I am quite certain that either of these guys could start with a blank on Monday and have the finish on by Friday. I would have it done on some other Friday and it would be ugly in comparison. My last couple of stocks have been for silhouette rifles and about as free-style as it gets. I have never made anything which was, to me, any better than OK. Regards, Bill | |||

|

| One of Us |

Bill: Boy..I dunno...if you're talking 40 hours, that seems like warp speed to me! Some stocks...well, maybe, but 60 plus hours seems to be more in the ball park (for me and others I've discusses this with) | |||

|

| One of Us |

Thanks for all the comments. As for LRx above, he is the only one commenting that has taken classes with me, and the fellow that got it all started by asking me to teach them. His results are an exquisite Ruger #1 that he has stocked, finished with some help from professionals and killed several head of big game his ultimate goal in creating a custom rifle in the first place. He has completed another fine custom rifle for his lovely wife and she has killed a number of beasts with it. I'm sure he has enjoyed most of the process and all of the results. When doing anything there are certain parameters that one must abide by. When doing something that requires the participation of four other folks, with them traveling hundred to more than a 1000 miles to participate, the limitations increase. I've been teaching private lessons, months long one night a week classes, NRA classes at both Tdad and Lassen for more that 30 years, on and off. I enjoy teaching others some of the skills I've acquired, teaching is the main hope of the trade continuing and the majority of my students greatly enjoy the experience and a certain number return to advance their skills. Without the ability to accomplish defined goals in a given length of time, for an affordable about of investment it would not happen at all. Just like my technical writing, I often have people who haven't a clue what it takes to pull something like this off are often telling what I ought to write about, or how I ought to teach. Well this is my seventh year of Montana Fine Gunmaking Seminars, the Stock Shaping class is full-up with 4 students, one returning, we have a good crew that are very eager to learn, And Accomplish something they have only dreamed of doing. With good fortune, good health, a bit of luck and quite a dose of determination, we will see four nearly completely shaped custom gunstock at the end of September. Now if anyone is interested in learning and doing for next year, please contact me at my web site as most of this years students came off of a running list I keep of very interested folks. ..and there are still two benches open for the Metalwork Prep and Bluing the last week of June. Thanks, SDH ACGG Life Member, since 1985 | |||

|

| One of Us |

I've been keeping track of bench hours on all jobs for decades and I'll agree with Duane on this and admit i've never done one in that time. In my experience it is very difficult to be in a race with the clock and achieve extremely high quality. Martin Hagn is a close friend, I've been in his shop and he in mine. He began gunsmithing school in Ferlac at age 14, about the time I was born and has been doing it ever since. Martin is in a very distinguished and distinct class of his own. ACGG Life Member, since 1985 | |||

|

| One of Us |

Any one who has, and knows how to run a Bridgeport or sophisticated milling machine can figure out how to do the rough inletting. It is quite possibly the easiest part of the entire process, at least for bolt-actioned rifles. ACGG Life Member, since 1985 | |||

|

| one of us |

I've not watched Martin do a complete stock but have seen him do portions of the job in an amazingly short time and with no apparent effort. One time he stopped by the machine shop where I was working at the time and we were discussing the falling block double he wanted to make. three or four days later he was back with a working wooden model of the double rifle; complete with sights! One day he showed me how he made his checkering tools and, I swear, he made the tool and checkered the grip with it in less than an hour. The thing is, he does so much more than making stocks that he is always working on a number of projects at any given time. The amazing thing, to me, is the nonchalance with which he approaches every task. When he would ask my opinion about something (just to make me feel good, I think), I always felt this was much like me asking the cat except that the cat likely knew more. I worked alongside Klaus Hiptmayer (another Ferlach guy) for a while and, again, everything was done very quickly and with none of the time wasted studying on it that I require before I pick up a tool. Klaus did little but stock work and produced a lot of stocks. The only power tool I ever saw him use was a Black & Decker drill. Regards, Bill | |||

|

| one of us |

Good post! | |||

|

| One of Us |

I went to SDH's seminar in 2014 and went home with a great deal more knowledge on stocks and gunmaking in general. I don't have a milling machine and felt his approach was appropriate for my needs, I think it is safe to say my hand inletting abilities dramatically improved after the seminar. "If the women don't find you handsome, they should at least find you handy." | |||

|

| One of Us |

Evan K did a 40X rimfire stock for me and several here has seen it. He is a great young stocker. | |||

|

| One of Us |

Thanks Butch!   "If the women don't find you handsome, they should at least find you handy." | |||

|

| One of Us |

Evan was a good student, a quick learner and has followed up with several completed rifle projects since the seminar. The later work is a fine complement. His careful approach working with hand tools will serve him well. ACGG Life Member, since 1985 | |||

|

| One of Us |

Hi, all. Long time lurker, first post here... I use a custom built dual duplicator- reluctantly I will add, primarily as part of a doing a full build. At some point, we need to acknowledge the rapid changes in the smithing and stock making businesses- as well as the possibility, IMO, that the legendary gunsmithing schools actually may not be in step with the automation of the industry and preparing students accordingly. Why the lack of "schools" teaching stockmaking? C'mon- there's no profit to be made anymore! Now, I know there are a few "purists" out there- but stock making -and stock inletting for precision bedding jobs, is increasingly being done by automated CNC setups with greater precision and quality, faster, and for the same cost or less than done manually. If you could have your Mauser barreled action 3D scanned/modeled, and a stock precision cut and inletted to tolerances that can't be dreamed of when done manually (without taking days to do it) why wouldn't you? If this service doesn't exist now- don't blink. CNC shops gobble up the more standardized work like re-barreling, leaving niche marketing, one-,off type jobs and repairs for the traditional "Gunsmith"; which I fear is going the way of the dinosaurs. | |||

|

| One of Us |

I am in the process of my building first stock. Following this topic with interest. Some of the stocks posted on this site are incredible. Whatever some one charges to hand cut a stock is either fair or too little. What a job! From blown over tree nine years ago to my bench now. I thought inletting would be the hardest but so far the layout with proper lines and proportions has been the hardest part. Chain sawing out the blank almost too small dang sure didn't help. So far it is an embarrassment. If knowledge is gained from mistakes somebody besides me is soaking it up. | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  stockmaking from a blank

stockmaking from a blank

Visit our on-line store for AR Memorabilia