The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Double Rifles

Double Rifles  Monobloc barrel seam

Monobloc barrel seamGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

I was wondering if it is possible to have a double rifle finished so that the junction between the barrels and the block does not show. I often see this line engraved to dress it up but was wondering if the barrels can be finished better to hide this or will it always be an artifact for this type of barrel system Thanks Long Knife | ||

|

| One of Us |

My pet hate Browning 425 shotguns are built on a monoblock with no engraving, work fine and look nice – you really have to llok to see the join . Why other makers have to apply engraving is beyond me | |||

|

| new member |

I agree DPCD, it looks a little on the amature side that they are or cannot be finished to have the clean lines. I will not argue the points of which is stronger/better/cheaper ect. but it seams like they could dress this issue up and I would like to know if I am missing a "technical issue" for why this joint is visible. Long Knife | |||

|

| One of Us |

Mine too, for cosmetic reasons only - although your other techincal points are valid. I can't see why they can't make the join seamless and strike the barrels correctly so that it removes the need to engrave, stipple or whayever the fuck they seem to do. Just my HO. | |||

|

| One of Us |

Cheaper guns with monoblocks are soldered together, and the barrels are "knocked down" into the monoblock. It's VERY difficult to make the seam so tight it won't show with this method. So much so it would be less expensive to use shoe lumps. If the barrels are threaded into the monoblock, it is fairly easy to get a seam tight enough it is difficult to see. Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | |||

|

| new member |

Bailey, Just so I understand, the barrels are a relatively loose fit into the block to allow for the solder joint and the "gap" is what is what we see after the final finish? And as a follow on question, is the more common practice to press fit the barrels into the block or thread them. It would seem like threaded barrels are more work and would eliminate the "cost savings" over a shoe lump. Thanks Long Knife | |||

|

| One of Us |

HEY!!! I resemble that remark!!! NRA Lifer; DSC Lifer; SCI member; DRSS; AR member since November 9 2003 Don't Save the best for last, the smile for later or the "Thanks" for tomorow | |||

|

| One of Us |

Look, it's like wearing a girdle (or "back brace" for us guys who prefer not to admit it's really a girdle) under the tuxedo that no longer fits. You could eat less and work out more but if you could get away with the "back brace" and look good for the pictures ... NRA Lifer; DSC Lifer; SCI member; DRSS; AR member since November 9 2003 Don't Save the best for last, the smile for later or the "Thanks" for tomorow | |||

|

| new member |

Loose barrels, back braces, girdles, eating too much Now I am really confused------- | |||

|

| One of Us |

In the case of the monobloc, you can do it the hard way (chopper lumps) and have it look good or the easy way (monobloc) and add the engraving to cover it up ... But I know you knew that's what I meant ... just staving off the inevitable ball-buster ... NRA Lifer; DSC Lifer; SCI member; DRSS; AR member since November 9 2003 Don't Save the best for last, the smile for later or the "Thanks" for tomorow | |||

|

| One of Us |

Bailey is absolutely correct. If the barrels are threaded into the monoblock, thereby creating a crush fit, and the assembly is NOT polished on a wheel, after rust bluing the joint is virtually impossible to see. If you look at the thread on NitroExpress.com, Building double rifles, re the .303 double that I built a few years ago, you'll see what we are referring to. | |||

|

| One of Us |

It's great to have smiths and artisans like you and Bailey here to give first-hand information. NRA Lifer; DSC Lifer; SCI member; DRSS; AR member since November 9 2003 Don't Save the best for last, the smile for later or the "Thanks" for tomorow | |||

|

| new member |

So does the techniques you are talking about to hide the line basically negate the "cost savings" for the monobloc or could most manufactures still save enough time/labor cost to upgrade how they finish the barrels Thanks Long Knife | |||

|

| One of Us |

Quite frankly, on a production basis, with today's technology, neither threading nor soldering are necessary any more. Look at the new Beretta 470's. They are built on a monoblock and the tubes are electronically welded into the monoblock. There is no visible seam and no necessity to roll-engrave a pattern to disguise a seam. | |||

|

| One of Us |

Correct! Totally! In fact almost even the merest speck of trapped dust will cause the seem to show. The answer is to ribbon weld the join. As RON VELLA says in his post. But it costs! Personally I can live with it. They used to say, in the trade in England, that a sleeved double shotgun never handled as well after it was sleeved as it did before. | |||

|

| One of Us |

I guess that I should have explained in my post above that the new process that Beretta uses to join their barrels to the monoblock is not "welding" as we know it. There is no pool of molten metal created in their process. Rather, the two pieces of steel are electronically fused at the molecular level. I don't claim to be an expert on the process, but that is how Beretta's people explain it. | |||

|

| one of us |

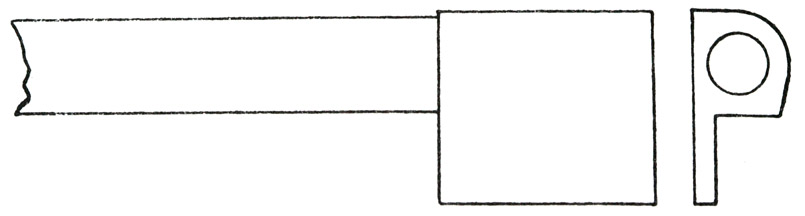

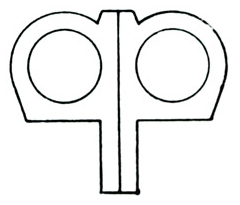

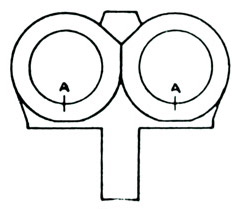

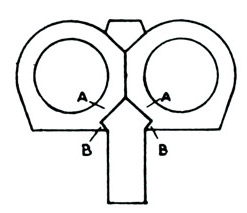

Fig #1 and 2   “chopper lump” barrels. Each barrel being forged, with half of the under lumps, and the quarter rib butt, integral to the barrels, looking sort of like a hatchet, hence the name CHOPPER lumps. These two are fitted together, with an amount of barrel convergence, by educated guess. They are then fluxed, and wired together, and brazed together at the first four inches or so, of the breech end of the barrels! Then a wedge is soldered in between the muzzles, and the full quarter rib is soldered in place, with an extension down between the barrels, to make a fore-end latch hook. Now the fitting of the barrels to the action can take place. This is the type of barrel joining that is, most times, used on British double rifles, and is considered, by most purists, to be the only way to build barrels, and is very expensive, compared to other methods. Here I’ll let you decide the value of the chopper-lump barrels over other methods, but I’m not convinced that it is as great as some people think! Never the less you will pay a premium for a rifle with chopper lump barrels. Fig #2  “PLATEFORM LUMP”, or “SHOE LUMP” barrels set. This barrel set is joined to a one-piece lump that is saddled to accept the barrels. The purists frown on this method of joining of barrels, but many very fine European double rifles are made this way, some with very high chamber pressure cartridges, seemingly with no problem long term! Rifles like HEYM, and MERKEL are made this way, and both are very respected makers, and there are others as well. In my opinion, this method, if done properly, is as good as it needs to be. I have double rifles made both ways, and have had zero problem from any of them. This method is cost effective, because much of the “HOG” work can be done by CNC machines. The final fitting has to be done by hand anyway, so it is not a strength, or quality killer. Fig #3  “DOVE TAIL” lump barrel set , and is not used much today, being a LEFT OVER from the black powder days. Today it is used mostly in the building of Black powder replicas, or cheap shotguns. In my opinion, this is the weakest of the joining methods. However, many of these old rifles still exist, and are doing fine in the hunting fields every day. #4 Could not find a good technical drawing of the mono-block system! “MONO-BLOCK”, method of barrel joining. This is a very modern way of building a barrel set, and takes the value of the old lump locking system, and combines it with the modern bolt action technology, by fitting a solid block of steel that acts as a reciever for the breech end of the barrel set, the under-lumps, and the quarter rib butt. The barrels are then threaded into side by side holes bored through the block, similar to installing barrels into a bolt action rifle. Then trimmed off flush with breech face of the block. This is a very strong method of barrel construction. This method of barrel joining is the most maligned, by the purists, and totally without cause, in my opinion. There seems to be a factor of nostalgia involved here, and in reality makes sense, when you realize the double rifle firearm has been around for a long time, and though the mono-block is just the latest change in construction, it is the NOW step child of the purists! The other methods had their dissenters, as they came along, however we seem to forget them when something new comes off the table. This is the case with mono-block. It’s new, and not trusted by many double rifle enthusiast, especially those who are British double rifle fans. I don't think any of the methods are without merit, and any of them done with modern steel, and fitted by hand regulated, and balanced properly are worth owning! Additionally before sticking ones nose in the air, be advised of the fact that any double rifle is better for it's purpose than a single barreled rifle when the crap hits the fan! ........................ ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| new member |

MacD37, Thanks as always for the information and yours is always informative on many of the subjects I have read on this forum. Do you think that the "line" will eventually get finished better to hide it on the monobloc types or will they just let this go in the interest of saving time and money. Thanks Long Knife | |||

|

| One of Us |

Thanks for the post Mac explaining the difference. I know nothing about doubles but am fascinated by them and was always stumped by what was meant by chopper lump, mono bloc etc. Makes more sense now. Thanks! Adam 30+ years experience tells me that perfection hit at .264. Others are adequate but anything before or after is wishful thinking. | |||

|

| one of us |

The line left by the connection of the barrels to the mono-block can be very well done with a little skill! If you look at the B.Searcys of late you will see that the seam is almost invisable. Like any double rifle feature it all boils down to the skill of the maker. This is not limited to the seam on the mono-block, but to the fitting of barr action side plates into the side of the barr, or the trigger plate in the belly of the action. This has been done with almost invisible seams for 100 years, and nobody seem to object to them! Still those seams are hidden on many occasions with engraving. I see absolutely do difference with the hiding the seam on the barrels with "GOOD" engraving, but it is not a necessary thing to do, if the fitteing is well done, I have no objection to the seam! ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| One of Us |

Just for everyone's info, the monoblock is not a new invention. It was patented by Henri Pieper in 1881 and has been one of the strongest methods for building shotguns, combination guns, and double rifles for many decades. I personally own two Pieper Cape Hammer Guns that are monoblocks and are both elegant and strong. Not sure why we want to hold on to chopper lump as "purists", as all 3 actions are durable and strong. Monoblocs are less expensive to produce since alot of the work is done by machining. Chopper lump is thought to be a part of a "best" gun. It's just not true that it's any better than shoe-lump or monoblock; it just requires more hand forging; thus extra cost. JP Sauer Drilling 12x12x9.3x72 David Murray Scottish Hammer 12 Bore Alex Henry 500/450 Double Rifle Steyr Classic Mannlicher Fullstock 6.5x55 Steyr Classic Mannlicher Fullstock .30-06 Walther PPQ H2 9mm Walther PPS M2 Cogswell & Harrison Hammer 12 Bore Damascus And Too Many More | |||

|

| One of Us |

Hallowells has a very good explaination of the different barrel attachment methods. http://www.hallowellco.com/lumps.htm NRA Life ASSRA Life DRSS Today's Quote: Give a man a fish and he eats for a day. Give a man a welfare check, a free cell phone with free monthly minutes, food stamps, section 8 housing, a forty ounce malt liquor, a crack pipe and some Air Jordan's and he votes Democrat for a lifetime. | |||

|

| one of us |

Mike all those drawings were in my article posted above but they wouldn't transfere from my word folder to this website! I wrote that article several years ago, and just cut and pasted it into this thread. As I said the drawings wouldn't transfere so I had to modify the article. I edited my article with the drawings once I found a way to get them in the website! ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| One of Us |

As long as it works out in the end Mac! NRA Life ASSRA Life DRSS Today's Quote: Give a man a fish and he eats for a day. Give a man a welfare check, a free cell phone with free monthly minutes, food stamps, section 8 housing, a forty ounce malt liquor, a crack pipe and some Air Jordan's and he votes Democrat for a lifetime. | |||

|

| one of us |

CORRECTION: The article in the Hallowell website is not what I posted, only the drawings. I didn't write the text in Hollowell's website! The article I posted was my own! In fact, there is one thing in Hollowell's text that shows there are a lot of things lost in translation from one language to another. EXAMPLE: Merkel states in their website that their double rifles are built on "DIMI-BLOCK" barrel sets, and they are clearly "SHOE LUMP" barrels on the early rifles, and are now "MONO-BLOCK" barrels on the newer Safari ejector models. The words "DIMI BLOCK" actually does mean the same thing as Chopper lump, as Hallowell states, (Literally "HALF BLOCK") but it seems Merkel didn't get the translation correctly.

To a collector the Chopper lump is a premium item that does command a premium price. It seems to be the Holley Grail of doubles in their minds, but not for any practical reason. Some of this is justified because the chopper lump are never on any double rifle or shotgun that is not top of the maker's line which will automaticlly bring a premium price. This is simply because the buyer who buys the top of the line is willing to pay the price for the extra work involved. It dosen't mean the rifle is stronger however. The chopper lump is only one item of a top of the line double that will bring a high price no matter what! Don't make the mistake of thinking that the Chopper lump is better, in practical terms, over Shoe lump, or Mono-block barrel sets. The reasons for the higher cost is because it requires a lot more man hours to build a chopper lump barrel set, not because it is necessarily better structurally. The other reason is because collectors want C/L barrels. much like collector muzzleloading rifles either made as a percussion cap or converted to percusion cap, bring lower price to a collector than a flitlock of equal quality of construction, even though the Cap lock is far superior, in practical terms, to the flint lock. Anything that requires more man hours to make will always cost more to the customer. Then there is the fact that the COLLECTOR'S idea of what is best, may be 180 degrees away from what is actually better, or just as good in practical terms. The two words "COLLECTOR" and "PRACTICAL" should never be in the same sentence, because one has absolutely nothing to do with the other! One of the most valuable firearms in the world is the Patterson Colt! Not because it is better but because it was a poor design that failed more than it worked, so as a result was few were made, and dropped from the colt line. It is rare BECAUSE is was not the best. The same amount of hand fitting of barrels to action is required for all the types,regardless of the method of joining the barrels together, and as far as strength of holding the barrels together is concerned,The Mon-block is the strongest of the lot, but is still the step child of double rifle construction. The person who said the Mono-block is not new, is correct, but very few were made that way till some of the makers started doing all their break top and over under shotguns and rifles that way many in the early 20th century. Still it is a newer method than the other types of barrel sets. Though it overlaps for some time, it is still newer than all the other methods. I have examples of all the types, and I simply don't find the Chopper lumps to be better than the others, other than the dove tail, structurally,but not over the monoblack or the shoelump. It just costs more! ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| One of Us |

That's a different story from what I've found. Over the years I've seen many very plain grade, basic boxlock DR's, which had chopper lump barrels. There are lots out there. Here is a classic example which is currently on Champlin's website. Jeffery Double Rifle Here's another, also from Champlins. Webley & Scott And yet another, again from Champlins. Another Jeffery | |||

|

| one of us |

OK, MOST of the double rifles with chopper lump barrels are NOTof the so-called "OFF THE SHELF" doubles, or simply working rifles! Out of 45 double rifles at Champlin’s only 11 had Chopper lump barrels, 34 without chopper lump, and the price range was as follows for the ones with chopper lump barrels. #2 $34,000 #8 $34,000 #20 $32,500 #25 $19,750 #30 $22,750 #31 $18,900 #34 $22.500 #36 $79,500 #40 $39,500 #42 $18,900 #45 $64,000 I would think that the above rifles, in most cases, were not made as simply working class rifles. You are right however, some of them are now in working class shape, but it didn't harm the COLLECTOR value! Partly because of the perceived notion that chopper lump barrels are worth two or three times what the same condition rifle without chopper lump barrels is. IMO that notion doesn't hold water! Of the 45 double rifles listed on Champlin's website, many of the 34 without chopper lump barrels have lasted just as long or longer and are still just serviceable as the ones with chopper lump barrels, and command a lower price today, and also commanded a lower price when new! That was my point! Structurally, the chopper lump guarantees no longer useful life than the other methods of combining barrel sets! They just require more man-hours to build, hence the price, and perception that if it cost more it has to be better! We all know that idea certainly doesn't hold water. ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| Moderator |

it can be made nearly invisible.. should face up well, and the join on both pieces slightly larger than finished specifications .. then peen and polish .. it'll look seamless opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

Mac, With modern doubles, you are probably right about chopper lump barrels being found mainly on the high end guns. In the past things were different though. Chopper lumps were the peak of development concerning the attachment of the lumps to the barrels. Many working class doubles were built with chopper lump barrels back in the day though. A good example would be the Webley PHV-1 of which many used that barrel type. PHV stood for PLAIN QUALITY HIGH VELOCITY, and in 1914 these rifles sold for not much more than half the price of Webley's High quality A&WC model.(40 British Pounds for PHV-1 compared to 72 British Pounds for A&WC 1st.) The PHV-1 was a basic working DR with no frills. A&D action with third bite, no sear interceptors or any other fancy items. It's a hell of a strong well made double though. The A&WC featured the awesome "Screw Grip" third fastener, as well as sear interceptors and other goodies. Thesedays the monobloc system is widely used as it allows huge cost savings over the chopper lump system. Chopper lumps do feature advantages over the monobloc system however. These are often overlooked though. | |||

|

| one of us |

A very informative post I must say! Thank you. Nobody is ever too old to learn something new, (or old) in this case! ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| new member |

5Seventy, "Chopper lumps do feature advantages over the monobloc system however. These are often overlooked though." Please tell us what the advantages are to further educate us newbies Thanks Long Knife | |||

|

| One of Us |

Here's a question for you then. Re the "lump" showing through the bottom of the action. I have always thought that the lower end Webley actions - PHV1 or Screw Grip - had the lump showing through the bottom but on higher end gun, this wasn't the case. Is that true ? Whenever I look at a Sidelock Screw grip, I always forget to look. Any comment ? . | |||

|

| One of Us |

I've seen through lumps on both PHV-1 and A&WC boxlock Webleys, but I've never handled a Webley sidelock of any type, so cannot answer your question. I'd reckon George Caswell, JJ, or 400 Nitro Express would be able to tell you though. | |||

|

| One of Us |

Thanks, "Through lump" - that's the word I was looking for. So few "high end" Webley's around, especially sidelocks - or maybe i just miss seeing them !!! LOL . | |||

|

| One of Us |

Guy's been watching this thread. http://forums.accuratereloadin...0101804/m/1501013531 The link is to a build I am having done. The seam is invisible in my build. I do not believe my smith plans on disguising the joint. So it can be done. Nitro "Man is a predator or at least those of us that kill and eat our own meat are. The rest are scavengers, eating what others kill for them." Hugh Randall DRSS, BASA 470 Krieghoff, 45-70 inserts, 12 ga paradox, 20 ga DR Simson/Schimmel, 12 ga DR O/U Famars, 12 ga DR SXS Greener | |||

|

| one of us |

Long Knife, I am not presuming to answer for 5seventy, he is more than capable of that himself. However, IMO, the only two “advantages” I can think of are both cosmetic. #1 is having no seam where the barrels are screwed into the mono-block, and #2 the barrels can be made a little narrower (trimmer rifle) with the chopper-lump, and the platform/shoe-lump because the outside of the chamber walls on the mono-block have to be wider to surround the chamber end of the barrels. Also IMO, in the strength of attachment of one barrel to the other, the mono-block is stronger! Still there is a 3rd advantage to the Chopper-lump rifle will cost you more, but will bring more on re-sale as well, while the mono-block will be cheaper to buy, but again will have a lower re-sale value, actually lower compared to it's new price, than the Chopper-lump, which most times will increase in re-sale price over time. There may be other advantages as well, but I can’t think of anything, directly tied to chopper-lump barrels, that offers any other advantage, except that the chopper lump usually comes in a higher grade rifle. There is no question that the chopper-lump is a selling point that some deem very valuable, I do not! ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| One of Us |

Long Knife, Firstly, in regard to your original question asking whether the barrel to monobloc join can be hidden, as others have posted, I agree that the seam can certainly be finished in a way that it is very hard to detect. A very good example would be Ron Vella's double rifle builds where he has done a fine job of concealing the join. I also believe that the Searcy doubles have very well concealed seams. Now, regarding the different lump systems on DR's, I am not going to offer an opinion on which is supposedly strongest or weakest. The only thing I'll say is that they all appear to be strong enough, so long as the fitting work is of a high standard. Personally I've owned double rifles with chopper lump, dovetail lump, and monobloc barrels. I've never owned a DR with the shoelump system, simply because the opportunity has not presented itself to buy one. The reason I believe chopper lump barrels have some advantages are as follows. 1... As Mac pointed out, there is NO seam to worry about trying to hide. They show one nice flowing unbroken line, on the outside barrel surface, all the way from breech to muzzles. 2... One solid ring of steel in the chamber wall surrounding the cartridge case, as opposed to two piece chamber wall where barrels are sleeved into a monobloc system. 3... With monobloc, shoelump and dovetail systems, the lumps are attached to the barrels with a join of one type or another, usually soldered, brazed, or threaded, or a combination of those. When the cartridge is fired, breech thrust is trying to push the barrels away from the standing breech, and the load will be applied at the barrels to lumps joint. With chopper lump barrels, the lumps are integral to the barrel forgings, and they don"t have any join. It's all one piece. The two chopper lumps are indeed brazed together, but that brazed joint merely attaches the two barrels to each other, and does not need to take any of the axial load imposed by breechthrust. As I said initially, I'm not suggesting that any system is stronger than another. They all appear to work fine. To back that statement up, I'll tell you that my Belgian .470 NE features dovetail lumps, which are usually rated as the least strong in articles written about DR jointing systems. It's a 1928 gun, and still seems to be holding together ok. Personally I'd be happy to own a DR with any of the lump attachment systems, so long as the workmanship was of a quality standard. | |||

|

| one of us |

....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia