The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Small Calibers

Small Calibers  Annealing: Stretching out Brass Life...

Annealing: Stretching out Brass Life...Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

have been playing with stretching out brass life quite a bit.. it was timely since all of this shortage and high prices of components came along... I have found that using a good neck sizing die and having a body die, instead of a full length sizing die is also helping stretch out brass life substantially...on a set of 223 brass I am now on 60 reloads! and it is going strong, although not nice and shiney.. the final thing I have learned is to Anneal... I was thinking that maybe once every 10th reload would suffice... however that still developed a few neck splits at 8 or 9 reloads... So it was actually a newbie that brought up that he anneals every 4th reload... so I thought I'd try that... needless to say, that turned out to be good advise... so for you folks that have not been annealing, it is a practice to worthwhile learn... I have reloaded for years but never annealed... brass was cheap, available etc...times change... got set up for what the cost of a bag of 100 pieces of say 17 fireball brass runs...and it has already yielded more than the return of my initial investment... especially if you are a varmint shooter who goes thru a high volume of shooting... 60 times on some 223 brass now, and just passed 40 reloads on some 22.250 brass... also just learned the joys of getting my first switch barrel for a Savage rifle I am setting up... one where I bought just the action they sell, and then got an aftermarket barrel in 7/08 and bought one on line here as a take off in 25/06, which I am having rechambered into a 257 Roberts... but that is another story! but I am also having a lot of fun doing all of this stuff... wife loves it too.. keeps me out of her hair..loL... | ||

|

| One of Us |

seafire2 I have read on another forum where some of the iK shooters are annealing every reload as it is not an inconvenience when set up to do so. It gives equal neck tension for every load as well as better brass life and more even neck tension usually means more accurate ammo all other things being equal. Von Gruff | |||

|

One of Us |

I have started doing this - it ensures that I don't miss any. If I do miss some cases, it will only be once so no case will be loaded more than twice before annealing. Seating bullets does seem more consitant. I also get the impression that the necks stay straighter when annealed. Regards 303Guy | |||

|

| One of Us |

Interesting point Von Gruff.. will have to try that out and see if it can result in better accuracy... | |||

|

| One of Us |

"every reload" is way too much work, specially if you load for 5-10 calibers each session. | |||

|

| One of Us |

The more I hear about it, the more I think I need to start doing it... Other than a pan of water and a propane torch, what gear is needed that creates the "cost to setup"? | |||

|

One of Us |

The way I do it, that's it. I stand all the cases in the pan of water to the 'correct' depth, with the spent primers still in and flame the necks. I then remove and wipe off the water and ready to decap and so on. I don't let water get inside the case. That's a pain to dry out and possibly the source of most of the effort. The brass does not get hot enough to anneal quite some distance from the water level so the 'ideal' water depth needs to be determined. I use a basket to hold the cases so they don't fall over into the water and it makes removal easy. Regards 303Guy | |||

|

| One of Us |

I made a stand to index a battery drill at about 30 degrees off the horrozontal with a deep socket on a shortened extension. With the torch being stationary the case is dropped into the socket and the drill set going as it is indexed on the stand. I use a count of four for the 20 Vartarg on a 221 case in a 10mm socket. the 7x57 in a 12 mm socket gets a count of 5 and the 404 in a 14mm socket gets a count of 6. The case is tipped out of the socket into a stainless bowl without water, and another case is placed in. Quick and non messy. The heat needed to anneal dose not require heating to red and the time taken is reflective of this.There is virtually no heat travel to the head so standing in water is not necessary. This is why annealing every load is not "way too much work" Von Gruff. | |||

|

| One of Us |

Anneal! anneal!! anneal!!! Very Important. | |||

|

| One of Us |

I haven't yet started to anneal. Hey 303! How do you spin the cases if they are in a pan of H20? Do you just flame the necks by moving the torch around them? How many do you stand up in the H20 at a time to anneal? A photo of your technique would be great, as I'd like to not have to let the inside of the case dry. I'm setting up to anneal, but I bought the Sinclair case holder with different shellholders. I thought I'd just put a case in, put the case holder in my cordless screwdriver, and turn it in the flame in the dark till it glowed, then dip it in some H20. Whada ya think? | |||

|

| One of Us |

Just for information, what is the proper annealing procedure? | |||

|

| One of Us |

It is not necessary to get the cases to red hot to anneal and it is not necessary to drop or stand in water. Have a look at any of the proprietry jigs and they are set to heat to below the point at which sufficient heat will travel to the head of the case ( a no - no) Use some scrap cases in a darkened area and a simple count of time till colour change will guide you in understanding the time needed in the flame to do the job. A careful check of the flame intensity and distance to case neck is necessary to bring consistant results. I am happy to email a pic of my set-up for someone to post. non messy, time efficient and effective. Edit. I meant to add that it is cheap to do as well. Von Gruff. | |||

|

| One of Us |

Hi guys, Just saw this thread and since I'm at work, I can't post the link but you should check out 6mmbr.com There is an excellent review of the process there and I think some important caveats to at least be aware of when annealing. Maybe someone can put the link up, otherwise I'll try when I get home. Best, Bill | |||

|

| One of Us |

When I anneal I place a bernzomatic torch on my workbench and holding each case down toward the web I rotate it in front of the torch until my fingers feel the temperature getting hot. I then let go of the case and drop it into a 5gal bucket that contains about 2" of water in the bottom. If you get a cherry red color on the necks you have gone too far. You are looking for a change in color and the tell tale blueish cast at the case neck after anealing. Remember....you can overannel and destroy your brass, but you can underanneal with no bad affect to the brass properties. I anneal every 4 reloads on 22-250, 7mm and 6mm cartridges with great extension of brass life. nary a split neck up to over 8-10 reloads. Then i toss them all at once. The was able to hone my method of sensing heat at the fingertips, by initially using thermal paint available from hornady. Finally, remember-- you are annealing the neck and pointing the torch at only where the neck and shoulder join. Heat applied farther down the case is not advised. | |||

|

| One of Us |

Thanks guys, I understood the process. I've seen the annealing machine the guy made on 6mmbr.com with the two torches and the brass automatically dropping out when done. Great, but more $ and trouble than I have. From 303's post, it sounds like he stands them all up in a pan of water that probably comes up to almost the shoulder/body junction or even lower to insure the case head doesn't anneal, then just takes his torch and waves it over the entire batch of brass necks (while in the dark room) and stops when all the brass gets a dull red glow. He probably eyeballs it to get them all even. This is just my guess from reading his post; I hope he responds to clarify and posts a pic. If that's the way he does it, it sounds very efficient. No water in the case and you can do the whole lot very quickly instead of one at a time spinning on a cordless screwdriver. | |||

|

| One of Us |

Spinning with a screw driver provides more uniform heating of the case down the shoulder. I like to see the gold color extend past the shoulder about .250. | |||

|

One of Us |

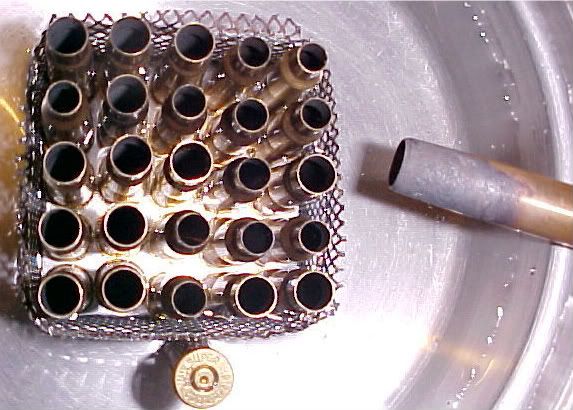

Yup! It takes quite a bit of heat to get enough teperature as brass is such a good conductor. I stand my cases in water in a basket with fired primers still in place. I use a propane torch to heat the necks until the colour changes or I can see a dull red on the neck interior. The annealing stops a way up from the water level so one has to figure out the correct standing depth. Once done, I remove the basket and that's it. No drying of cases and all that (other than an external wipe).  One can see the water level below the shoulders. Annealing reaches just past the shoulder. I'm not sure that I'm supposed to be annealing the shoulder but that's how mil brass is annealed so I just do the same. It does mean that if the case is a tad tight in the chamber, the bolt will cam it in! Regards 303Guy | |||

|

| One of Us |

Thanks 303! Sounds a lot faster than 1 at a time! | |||

|

One of Us |

It is faster but each case has to be individually heated from at least two directions. Regards 303Guy | |||

|

| one of us |

Here's a link to the article. Even if you can't afford the machine it has a lot of good information: The Art and Science of Annealing "Experience" is the only class you take where the exam comes before the lesson. | |||

|

One of Us |

Thanks for the link, tiggertate. I may have been over annealing mine! I wondered about the colour change thing but many folks had said a dull red in a dark room was good. Anyway, that's what I've done and I will live with it! Regards 303Guy | |||

|

| One of Us |

Thanks for the info, I may have to try this sometime. | |||

|

| One of Us |

It looks like on the anealing machine video, the case just drops out into a pan or something without water. Is it ok to anneal without droping the case into something to cool it quickly? I did about 50 .300 win mag cases and it seemed to take about 8-10 seconds rotating on a power screwdriver to get a dull red color at the neck. I didn't drop them into water. The case was damn hot at the head. I hope this was ok and the cases are safe to use. While reading the annealing link, I'm afraid of annealing the head of the case. Do you all think they're ok? | |||

|

| One of Us |

The case neck - shoulder dose not need to be heated to red hot. I believe about 700 degrees is uficient. As you say the anealing machines do not heat to this degree as it is not necessary. You have established how long it takes to get them red hot at 8-10 sec, and the simple solution is to reduce the time in the flame. I have established for MY TORCH and the distance between flame and case neck that for small 20 cal cases that 4 sec is suficient with 7x57 sized cases needing 6 and 404 cases about 7 or 8. I would not think you have damaged your 300 win cases as they air cool very quickly and you say dull red not cherry red. Von Gruff. | |||

|

| One of Us |

Thank you Von Gruff, I got the "dull red" as a barometer for the annealing on Varmint Al's website. He says that is proper. It seems that on the video with the annealing machine that the cases barely get heated. Check this out: http://www.varmintal.com/arelo.htm#Anneal When I did it, the case neck barely got a visible dull red but seemed to take more time to get to that point than what a lot of posters here say. | |||

|

One of Us |

From vamintal.com I like what Varmint Al says. It all makes sense to me. But I have one disagreement with what he says. That is this - He could be right and I would like to discuss it with him. I think what happens is the case grabs the chamber wall all right, but it progressively 'creaps' back as pressure builds and forces the case head back firmly against the bolt face. That means that the stretch in the case body is spread over the whole length of the case, keeping the stress below the yield point of the brass and probably reducing the load on the bolt face by reducing shock load as would likely happen should the case suddenly 'let go' if case to chamber friction is too high. Regards 303Guy | |||

|

| One of Us |

Right 303, I also remember on his reloading page he has a section on polishing your chamber with the question if it made good engineering sense. He says yes. He also states that the pressure is supposed to be on the bolt face. | |||

|

| One of Us |

I've been annealing now for a couple of days and I think I have a real good handle on how to do it consistently. I have the Sinclair case holder that fits in a cordless screwdriver. I lock in a case and spin it in the tip of the flame after dark in the garage until I just see the visible dull red, which takes about 8 seconds for my .300WM brass, then immediately dunk the case neck and shoulder in a little bowl of water to cool it for about a second. The case body and head are cool and can be removed with no issue from the case holder easily and quickly. Repeat. It's a lot easier than I thought it would be and I will be doing it for all the brass I reload to stretch the life and, from what I've read, improve accuracy by making neck tension consistent. | |||

|

One of Us |

Yeah - I think I will start doing it that way as well. Thanks for the thread! Regards 303Guy | |||

|

| One of Us |

I just finished prepping all my .300 Win Mag brass to start loading. I annealed, de-burred flash holes, primed and P-Neck sized it.  It's my first annealed brass and I'm proud! It was easy. I loaded some rounds up and damn the neck tension is consistent!! Normally when I seat bullets it's very difficult to have them all be consistent lengths within .005". With the freshly annealed and sized brass, I set the depth on the first round and all the other rounds were right on the money! As you can see, I don't polish my brass. | |||

|

One of Us |

Beauty! I find I get better alignment with annealed cases too! And thanks to this thread, I believe I will be doing a better job of annealing! Regards 303Guy | |||

|

| One of Us |

Hey 303, After shooting the great groups I'm getting, I'm convinced that the annealing played a big part in the accuracy. I can't get over how consistent the neck tension was while bullet seating. I can see now why the serious benchrest and long range shooters anneal on every reload. On Varmint Al's site, he has some info on neck tension and how it changes things...... http://www.varmintal.com/arelo.htm#Anneal It says the neck tension of 1/4 hard brass (brass that has been fired and loaded 5-6 times) will be twice that of new or freshly annnealed brass. This has to effect pressures and group size. I would like to hear some more information on this if any competitive shooters would please reply............. | |||

|

| One of Us |

But I do lube them before firing. Be aware lubing cases before firing can add dangerously to bolt thrust since the cases aren't gripping the chamber walls. TED === It is usually futile to try to talk facts and analysis to people who are enjoying a sense of moral superiority in their ignorance | |||

|

One of Us |

Aah! Someone noticed what I said! Yes, there is a lot of controversy about that one. I do keep my loads faily mild but realistically, the bolt is designed to take the full thrust of the cartridge. Lubing the loaded ammo does not eliminate case to chamber grip but it does prevent binding which can increase bolt face thrust by holding the case head off the bolt face until high pressure is reached when the case suddenly slips back and hits the bolt face with a hammer blow. Lubing loaded ammo prevents case stretch (for the above reason) and results in almost indefinate case life - even with the 'flexi-actioned' Lee Enfield. That and annealing and neck sizing only. Regards 303Guy | |||

|

One of Us |

(I just posted this on the thread under Reloading.) I finally got to range test my annealed cases. (I used the dull red glow on the inside of the neck as a guage while the cases stood in water.) Well, how does .6 MAO at 207yds sound? So for me it's a case of "Don't fix it if it aint broke". Regards 303Guy | |||

|

| One of Us |

I'm with you and Varmint Al! Mine shot a 1.13" group at 300 yards............5 shots!!!!! I annealed like you say, dull red on the spinning case, then dunk in H2O. | |||

|

One of Us |

Yikes! Very nice indeed! Regards 303Guy | |||

|

| new member |

I had problems with expensive unfired Gerhammn made 5,6x61 S.E. vom Hofe cases neck splitting when I ran them through a well made FL sizing die. I annealed them by immersing the neck / shoulder area in SAE 30-oil then moulten lead for 5 seconds. I made up a heat sink to do this to protect the head; a chunky square split brass block with a hole drilled in the middle about case diameter. The 2 blocks were attached each by a thread to a set of vice grip jaws. Closing the grips holds the case and it can also be quickly released. The heat sink works so well that the head and case sides remain ambient. I dunked the brass in the oil, then lead which was, of course, a consistent temperature, and then dropped each one in water. This technique is recommended by Nick Harvey's reloading book but I'd change one thing. Don't leave the primer out or lead balls will form inside the case as the lead pushes trapped air out the flash hole. To get these lead balls out, I needed to expand the necks up, remove the balls with an inertia bullet puller and then resize the necks down. Nothing split so clearly the neck brass elasticity was now very much different. No problems after firing either. With primer in, it's a very easy & fast process with no lead ball problems. Just some burnt oil smell, (not for appartments !). The lead melter is a Gameking (NZ made) shot maker and being shallow, it's easy to ensure the case is a consistent depth. Don't forget to use gloves, long sleeves, long trousers and safety glasses. Keep water, even drops of it, well away from molten lead. I wouldn't heat any case cherry red. Molten lead is much more case-friendly. | |||

|

| new member |

That's Gehmann cases. How did that typo slip past me ? | |||

|

| One of Us |

Since this got booted up to the top, thought I just throw in an update. the set of brass mentioned here in 223 for this experiment, I slowed down, but the test batch did reach the 100 reload point. and now has migrated to the 120 reloads! There has been 3 casualties at this point. None from neck splits, each has been operator error screw up at the reloading press. if also like to add, that contrary to every thing you read, that says to use water... I haven't! I just drop them into a little metal container, the size of a fat soup can, and let them air cool. reloading procedure is to neck size them with a Lee neck sizing die.. there has so far been no need to neck trim them! Shoulders are bumped back with a Redding Body Die, instead of a full length die. and the brass is annealed every 4th reload.. it is held into a flame over a propane torch with channel locks, as I count to ten.. and that is it. If one does the math on this... 120 reloads per case... a bag of 100 pieces of brass, would yield 12,000 shots! this brass is Remington Manufacture and was free as it was Range brass I picked up. the test has been done with a Remington Model 700 ADL. and just to piss off the "greenies" and tree huggers, via this test, I have literally cut down 3 trees in the local woods near my house that have served as back stops for 1200 rounds of ammo fired into their trunks. | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Small Calibers

Small Calibers  Annealing: Stretching out Brass Life...

Annealing: Stretching out Brass Life...

Visit our on-line store for AR Memorabilia