The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Sporterized Military Rifles

Sporterized Military Rifles  1903 reciever failures

1903 reciever failuresGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Yeh, but if the guy who was heading west was hit by the guy heading north, then it is almost a cinch that to be fatally injured, the impact had to be between the front of the Lumina and the driver's door of the older chevy. It's tough to survive getting whacked by an engine block, axles, etc. hitting your car just perhaps 8 inches (door thickness +) from your body no matter what you are driving. I think it may speak well for the '52 that its driver lived long enough to get to the hospital in Regina which is over 40 miles away. | |||

|

| One of Us |

True, I saw the results of a double fatality car - motor cycle accident. An old man in a 65 Impala pulled out in front of a guy on a crotch rocket. The motorcycle hit dead center in the driver's door killing both of them. | |||

|

| One of Us |

Now Dr Duc I am sure you are full of it. Care to name the year they were sold for $12 each?[/QUOTE] I bought one from the DCM for $12.00 as a kid, and they mailed it directly to me. It was back when one needed approval from a judge or law officer to join the NRA. | |||

|

| One of Us |

Yeah sure you did... | |||

|

| One of Us |

Well, I bought an '03A3 Remington/Springfield, brand new and unissued from DCM in 1964 for $14 including delivery, so there WAS a time not too long ago that they were relatively inexpensive. I've still got it. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| one of us |

I got very good remington 03-A3 just before GCA68 went into effect for 30.00 at the local sporting goods store. | |||

|

| One of Us |

I can well recall my father and couple of his friends and I travelled to I believe Norfolk,VA area and visited what was then called "Ye Old Hunter" store and we returned with a crate of some dozen of Springfield '03's and the bulk price was something in the range of 14.00 Key reason for me remembering this event was I was given the job of degreasing them with Varsol in our garage floor and it took one solid day of work. I got paid the princely sum of ten dollars for my labor. The store had what looked to be 55 gallon drums full of pistols from all over the world and price was 15.00 for three, your choice. Sad part of the 03's is that they all got sporterized, but in those days, a Springfield 30-06 with Bishop or Fajen stock including whiteline spacers was a good as it got for an "average joe" deer hunter in West Virginia. Whether they were low numbers or high numbers I have no idea and don't recall any discussion along those lines. Item that really caught my eye while there were some sort of tanks, yes real tanks, that were priced at 3500.00 Believe this business operation ended up with the name of Interarms. | |||

|

| One of Us |

i remember seeing tanks for sale in Shotgun News or a similar paper in the late 80's early 90's. I want to say Shermans, but can't be positive. as boys, my friend and I poured over those types of magazines with heads full of ideas! NRA Life Member Gun Control - A theory espoused by some monumentally stupid people; who claim to believe, against all logic and common sense, that a violent predator who ignores the laws prohibiting them from robbing, raping, kidnapping, torturing and killing their fellow human beings will obey a law telling them that they cannot own a gun. | |||

|

| one of us |

1903s by Springfield armorey below 800,000 and Rock Island under 285507 are call low numbered 03s...These guns have single heat treated receivers and should not be fires unless re heat treated I would assume. I have found this to be true in every respect. BTW I can wack ANY receiver with a hammer and break it, and what does hitting the rear ring prove? again absolutly nothing, that is simply absurd. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

You have not read the article or seen the hammer. I can assure you that you cannot break a 4140 receiver with an 8 oz plastic faced hammer. | |||

|

| One of Us |

There were certainly other factors in the failures of the low number '03s. The bolts were also brittle, the ammunition was not the best, and sometimes the bore got plugged. A low number in good condition, properly fitted with a late bolt, and good ammunition should not be a risk. You could also drill the larger gas relief in the left side of the rings for good measure as the arsenal did on the rebuilds. Remember we were also told how dangerous the damacus barreled shotguns are to shot. Then someone actually overloaded identical parkers - one fitted with steel barrels and one with damacus barrels - until they both failed. This was written up the double gun journal some years ago. Maybe someone should do a similaar test with some low numbers. The results may be surprising. | |||

|

| One of Us |

Ellner Co., Maple Avenue, Los Angeles - Springfield Model 03 advertised as "Original Low Numbers - New Low Price" at $29.85 each in October 1958 "Guns" magazine. Same edition of the magazine Gart Bros, Denver list "Safe High Numbers" Model 1903 at $39.95. But for just $29.95 and a "choice one" you could have bought a French Chauchat LMG from Service Armanent Co of Bogota, New Jersey! | |||

|

| One of Us |

I have a low nombered 03 Springfield. I know it's been rebarreled once, and I suspect twice or more. The current barrel is pretty much shot out, and dated 1944. I'm going to guess that if the action is unsafe, it would have let go in the last 100 plus years and multiple barrels. | |||

|

| One of Us |

The problem with the early receivers was not that they were improperly heat treated. The problem was that they were inconsistently heat treated - some correctly and some not. Because it is not possible to identify the "good ones" from the "bad ones" responsible experts don't recommend shooting any of the early ones. If you have an early Springfield and have "shot it for years" that doesn't say anything meaningful about the strength of the other hundreds of thousands that were produced. | |||

|

| one of us |

I just picked up my first Sedgley. Serial number puts it approximately at the transition point (around 800000 per the CMP website). I plan to shoot the crap out if it every chance I get. It's far too nice a rifle not to shoot. I am curious why only Sedgley's name comes up when ever the strength of 1903 actions is questioned. Contrary to what was stated earlier, not all of his rifles were built on "early" actions. Also, Griffin and Howe built a lot of very nice spotters on 1903 actions yet no one ever cautions against shooting one of their rifles. | |||

|

| One of Us |

Interesting to see this thread still carrying on. Since I posted about Ralph Walker and his experiences I have read Michael Petrov's book "Custom Gunmakers of the 20th Century", collected articles from Precision Shooting Magazine. A very enjoyable read for myself and full of information concerning early Springfield sporters. The rifles used by Roosevelt, White, Crossman, Whelen and used to bring fame to Wundhammer, Griffin (of later Griffin & Howe)and several others were all based on low numbered Springfields. They were shot extensively and collected many thousands of game animals. If there were any "blow-ups" among these rifles I am not aware of any reports of such. Petrov writes that 700,000 rifles were built before any reports of problems with brittleness began appearing and repeats the wartime production "burnt steel" issue. Most interesting to me was Petrov's report on the use of grease which was coated on the bullets by users to cut down on fouling from the cupro-nickel bullets used in the WW1 era. It is likely chamber walls became grease coated which greatly increased bolt thrust with resulting headspace increases. At the same time war production demands lead to much poorly annealed cartridge brass. Possibly the combination of excessive headspace and weak brass might be a major factor in the failures of the early recievers of 04' and other pre-war production as the "blow-up" problems appear unheard of until the war years. Sedgley annealed and re-heat treated thousands of low numbered Springfields and marketed a well made sporter based on them. Petrov writes of using many of these Sedgley's and reports favorably on them. Having never heard of any unmodified Sedgley failures he asks to be unformed of any if they exist. | |||

|

| One of Us |

Another thought: The early case hardened Springfields became famous for being very "slick" in operation. After the low numbered question was worked out the Springfield Armory would automatically replace the action of any low numbered rifle sent back to them for re-barreling. This made many unhappy as their super slick action was replaced with a said safer but less smooth nickel steel replacement. The Armory changed the policy and replace receivers only if requested. Given the age of the actions and perhaps extensive use I would have any low numbered receiver magna-fluxed for cracks but would consider using it now if OK. I bet the many Marines using the low numbered Springfields issued to them and used on Guadalcanal were not told how dangerous their rifles were. They might have been hesitant to fire the many thousands of rounds they did. If any of those rifle did fail during the battle I have not heard of it. | |||

|

| One of Us |

They are kind of brittle. With the cone breech a case head failure gets nasty fast. If you ever subscribed to Rifle Magazine back in the 1970s, Dave LeGate the artwork editor took a half a dozen 1903 receivers that he had collected and whacked them with a screw driver. He started with one that was pitted badly and it broke easily until he had broken all of them. The victims were all low numbers except one Springfield made receiver that was a few digits over 800,000 he was kinda shocked that he failed to look before whacking it. Just the same it broke too. He held the receiver in one while striking with the other. Use them if you want but the story was accompanied with a lot of photos.  | |||

|

| one of us |

I am still struggling with equating pounding receivers with a hammer or screw driver and shooting ammunition loaded within acceptable limits. It actually reminds me of the articles about how dangerous damascus barrels are on shotguns but what do I know. | |||

|

| One of Us |

I have read the article and likely still have the issue. I recall reports of Enfield 17's that also fractured when struck in the same fashion. I wonder what might happen if some Winchester 54's or pre-64 70's were whacked. These are also well liked for there very hard skin and subsequent slick operation. Could be a very expensive test. I did find the Rifle article and tests very alarming and came from it believing the early Springfields more dangerous then previously thought. I do not question LeGates findings in the least. I would not make ANY Springfield my primary go to rifle as I know it's design weakness's to well and am much more comfortable behind most any 98. My first centerfire was a 800,000's 03' which I fired much and with no concerns until learning of the lack of gas protection and stories of broken and wedged striker pins. The fact remains that the stress put on an action by a cartridge being fired and being struck by hardened steel are very different and need to be considered. There can be no denying that some low numbered Springfields failed even discounting greased cartridges, excessive handloads and poor brass. Also true is that these failures are EXTREMELY rare given the over 1,000,000 made and USED. This issue is close to a 100 years old now. I am through with it unless one of the sporters made by the likes of Wundhammer, Griffin, Hoffman, Sedgley etc. comes my way. | |||

|

| One of Us |

I think what should alarm any user is the texture of the failed metal surfaces. The fractures are completely brittle, meaning the metal is hard all the way through. Any failure will not involve any stretched or deformed metal. It will simply break apart. | |||

|

| One of Us |

Petrov is a major M1903 fan boy and does not countenance any idea there are any faults with the 03. Greased bullets are still in use, millions of moly lube bullets have been shot down range. The idea that grease on bullets causes increased bolt thrust is simply a misdirection from the 1921 Tin Can ammunition incident. In 1947, after he retired, Hatcher spends a couple of pages justifying an Army coverup in his book "Hatcher’s Notebook." In 1921 Col Townsend Whelen at Frankfort Arsenal makes National Match ammunition with a tin coated bullet. This was to cut down on fouling. What he, and I guess no one else knew, was that over time the tin on the bullet would migrate into the brass case neck creating a “cold weld”. This created a bore obstruction and it is obvious that rifles blew up on the line. A number of blowups with this ammunition are recorded in the failure list in Hatcher’s Notebook. Given that the vast majority of rifles on the firing line would have been single heat treat receivers, which many of which were marginal in strength, what you have here is a major cockup in the ammunition department. Unfortunately the Army, must have been lead by Whelen and Hatcher, decided not to fess up to the problems the Army created, but decided to push the blame on the civilian shooters of the period. For at least a decade, civilians had been greasing their bullets. But now, in 1921, the Army suddenly finds out it is a horrible problem. The Army ran some bogus tests, proved the civilians were at fault, banned greased bullets, and that was that. Today, we know the theories of incompressible grease and increased bolt thrust due to grease were a total fiction and the whole thing, as written by Hatcher, is a lie. The Swiss shot greased bullets up to the 80’s. Either the Swiss were blowing up their rifles for decades, setting the headspace back, and not knowing it, or Hatcher and Whelen lied. Take your pick:   Another thing, the cartridge case is made of brass, and it stretches. Anyone claiming that case to chamber friction somehow reduces bolt thrust is assuming that the case carries load. It does not. The caseis always in yield. In other words, the sidewalls stretch. At least when pressures start getting above 40 Kpsia. There may be some reduction in bolt face load, but it is inconsequential and is discounted in any mechanical design of bolt lug load. If single heat rifles were developing headspace with period loads, be they greased bullets or not, it is due to the poor metallurgy of the period combined with the poor process control at Springfield Armory. That is another misdirection by Hatcher, passing the buck to the forge shop workers. Why were the forge shop workers judging temperatures by eye? , why did they not have modern equipment? Who exactly is running Springfield Armory and why were they not aware of a systemic process problem, a problem that existed at the beginning of rifle production and took 15 years, and an ammunition supplier, to uncover? What is evident is a total lack of management oversight and management responsibility at Springfield Armory. Army management was out playing Polo on the Parade Grounds and not paying attention to what was going on in their rifle factory. Hatcher totally glosses over the mismanagement and incompetence of the Army leadership and makes you believe the fault is all that of the forge shop workers. | |||

|

| One of Us |

I am just wondering what would happen if a guy was to whack a low numbered type 38 arisaka action in the same manner? ______________________ Are you gonna pull those pistols or whistle Dixie? | |||

|

| One of Us |

What modern equipment was available in 1903 and a dozen years afterward to read even the surface temperatures of steel during its processing, let alone internal temps? I'm not saying there wasn't any...mine is a genuine question. What other equipment could they have used, had the arsenal (and Congress) been willing to purchase and supply it? I've always presumed that the folks in the heat-treating shop were not being blamed, but the lack of technology in general at THAT time was being identified as the culprit by Hatcher. P.S. - The world's first modern pyrometer was invented in 1901, and even it relied on the workman's eye judging the point at which the filament of the pyrometer dissolved. By 1939 a basic, workable, industrial pyrometer had become available, but it was highly susceptible to errors based on a number of things, such as metal density, alloy content and homogeneity, surface finish, etc. A brief history of pyrometers is here: http://en.wikipedia.org/wiki/Pyrometer Have fun | |||

|

| One of Us |

That was blown out of proportion. | |||

|

| One of Us |

A moderately close reading of Hatcher's writing does not show him suggesting it was the grease on the bullets during firing that caused the problems, but the fact that the grease got onto the outside of the cartridge cases and the walls of the chamber during loading the rifle and facilitated the sliding of the cases back against the bolt face when they were fired. The cartridge case is a form of piston when that happens, and delivers a harder blow at the end of its travel than it would if not greased. Not rocket science, just the basic physics of why we use oil on the cylinder walls in automobile engines and don't want to use it on cartridges during their firing. | |||

|

| one of us |

AC, You ain't never gonna get to the end of it It's an urban legend. Anything Worth Doing Is Worth Overdoing. | |||

|

| One of Us |

What frictional force is the cartridge case supposed to carry? Lets make this easy, lets pick two extremes: one where the case carries 100% of the load, and the other where the bolt/chamber carries 100 % of the load. So, how much load is the cartridge case supposed to take?, 100%, 75%, 50%, 25%, pick a number. Then think about these issues: How to maintain that frictional component between case and chamber in the field?. What if it rains?, or someone sneezes on the cartridge case, or worse, runs an oily patch through the barrel and does clean the chamber out with methyl ethyl ketone solvent? How does a dry chamber reduce radial loads? Why is anyone expecting the cartridge case to carry load when it is always under yield? The thing stretches and if it is not supported, it ruptures. A prudent designer assumes that the chamber, bolt carries 100% of the load and the cartridge case 0%. There were a number of fielded light machine guns that used oilers. The Schwarzlose machine gun was one, look at the wonderful pictures at this Swedish site, and of course, you can see the oiler. http://www.gotavapen.se/gota/a...sp14/schwarzlose.htm The Japanese Nambu used an oiler:   Oilers were designed out of mechanisms after WW2. The Germans captured a Russian machine gun that had a fluted chamber, copied it in their assault rifles, and that ended the need for oilers.  I don’t know why FN did not use chamber flutes, but on their 5.7 cartridges, they are using Teflon. I have read on other forums that injuries have occurred when shooters reloaded their cartridges and rubbed off the Teflon. It is likely the cartridges ruptured on extraction, but I really don’t know what happened. http://en.wikipedia.org/wiki/FN_5.7%C3%9728mm FN's 5.7×28mm cartridge cases are covered with a special polymer coating for easier extraction with the PS90 carbine due to the high chamber pressures and lack of case tapering.[32] In addition, this coating ensures proper feeding and function in the magazines.[32] As for those who claim case friction is necessary or the bolt will be overloaded, what do you do with these two piece polymer cases? Do notice the brass case head that provides the case seal. How much load can that polymer/brass joint actually carry?  It turns out not much. The problem with that ammunition was that the front of the case stayed in the chamber messing up function with the next round. So this is polymer case 2011, Oh there is a metal case head in there someplace, but the sidewalls are plastic.  | |||

|

| One of Us |

enough that kuhnhausen describes using lubed cases for proof loads. the oiler on MGs were a shitty solution to the lack-of-primary-extraction problem. and MGs are overbuilt anyways. as to the widespread adoption of polymer-cased ammo replacing brass-cased ammo, well what about that? a failed venture or two says as much as anything else on the subject. | |||

|

| One of Us |

Meaning what? There is no reasonable way to apprortion the back thrust loads to the case. Some percentace of the time the case or the chamber or both are going to be wet or oily. The Lee-Enfield is one rifle where the collectors and enthusiasts claim you cannot have a wet/oily chamber since the design depend on the brass taking some of the load. However the chambers are so large compared to most brass that one shot with standard pressures damages the case. Unfortunately one way to reduce some of the stretching is it oil the brass. Lee-Enfield connoisseurs say the oily brass may overload and damage the Lee-Enfield breech. Getting back to low number Springfields - this is not a totally imaginary Bigfoot. There are some dead carcasses to examine. | |||

|

| One of Us |

One can debate this subject for years and not convince all folks either way. The plain facts are that a number of machine guns, and some semi-auto rifles were designed to use oiled cartridges...even the Garand at one point in its very early development was designed to use oiled cartridges. But almost all such semi-autos were either dropped or re-designed so oiled cartridges were/are not needed in battle rifles. In the original designs using them, the oiling was needed because otherwise they did not extract/eject reliably, did not feed reliably, or both. Oiling the cartgridges increased the back thrust and lessened the case grip on the chamber walls enough to make extraction and ejection reliable. But, other than increased backthrust, which can be handled by added strength built into actions built for use with oiled cartridges, there are a number of other problems with oiled cartridges. The first problem is getting them oiled. To do the right amount of oiling, an oiler has to be built into the action, and it in turn needs to be supplied with the correct amounts of oil as the mechanism works, and put a determined amount onto each cartridge during the chambering process. That negatively complicates the design and operation of guns which must use oiled cartridges. A second major problem with oiled cartridges is that oil "glues" grit and dirt to the cartridges, which said dirt fouls chambers and makes extraction and feeding more difficult as the gun is fired in dirty field conditions .... exactly what was supposed to be cured by oiling. So, basically, it was not fully practical for long term use in the real life which is warfare down in the dirt. Several otherwise fine small arms, especially some Japanese machine guns and, IIRC off the top of my head, one or two early Russian semi-autos used oiled cartridges, but because of the jams caused by dirt, were not considered as good designs as those using rounds which did not need oiling. Anyway, we can And of course, that is why chambers are sometimes designed with flutes. Cases can float on gas, just like they do on oil, and it is much easier to supply a regulated amount of gas to a chamber than it is to place a regulated amount of oil on each cartridge. Floating the cartridge case on gas also increases backthrust, but again a firearm can rather easily be designed with enough strength to handle that increase. No great problemo there. Others have their own drums and drummers, and can march to whichever beat they like, but I don't use designs requiring the oiling of cartridge cases..and I certainly don't oil or grease ammo for use in designs not built to use it. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| One of Us |

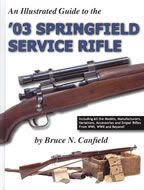

Just an additional source of information:  Your ultimate guide to the military '03 Springfield! Three times as large as the author's previous best selling book on this topic. Covers all models, all manufacturers and all conflicts, including WWI, WWII and beyond. http://www.brucecanfield.com/ PAPI | |||

|

| One of Us |

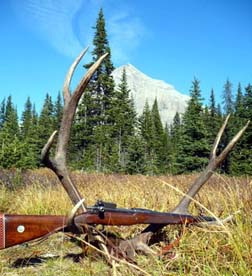

Canfield "the expert" ? The same expert who got conned a few years ago with a 100% fake rod bayonet 03'. Actually the best 03 book is one of a series on US military firearms "The Collectible '03" by J.C. Harrison. As for the "blowing up '03s" I doubt anyone but me actually created a complete database from all of Hatcher's data. Once you eliminate the WCC defective ammo, putting heavy grease on the 220 cupro nickle bullets (to cut down fouling), the shooting of 8x57 ammo, the plugged barrels: the number of "blown up" 03s becomes statically insignificant. Were anyone to have kept the same level of records on SMLEs, Mausers, M-1s and so on, we'd all be afraid to shoot them. Back when I was a really active 03 collector, I had a standing offer of $1000 to anyone who could produce a properly headspaced low number gun that had blown up using post WW II ammo. I still have the money and have shot 1000s of rounds of G.I. Ball and prudent handloads through my low number guns. No problems ever ! Hatcher is a God at the NRA so they keep repeating the same old line with no contemporary testing to support it. Perhaps the most telling examples I have owned were as a result of my 03' collection offshoot, R.F. Sedgley Springfield sporters. They both "owner supplied" actions (a Sedgley option). The first was a Mannlicher style carbine in 270 WCF (a lot hotter than any 06' of that era). The serial number was just over 100,000 (SA) and it had been shot so much with the nasty old hot high pressure loads that it had about 3" of throat erosion. Headspace was perfect and with 170 gr WRA bullets it would still hold 3" @ 100. No 2 was "one of one" built for my paternal Grandfather in 9.3x62. Again no pussycat round. While pics of the 270 have go astray, I have this montage of the 9.3:  If my eyes serve me the serial # is 16019 .... that's a rod bayonet action. Again perfect headspace and has digested many, many RWS and DWM 286 gr loads. So the low number myth lives on, much to the joy of collectors of 100% correct pre WW I 03s. | |||

|

| One of Us |

There is no myth. There are plenty of carcasses. The problem with the actions is brittle steel - not soft steel. Brittle steel shatters. Soft steel develops excessive head space. Your blow hard wager was never in danger because it you can not determine if the head space was correct after a failed receiver. Perhaps you need to study statistics a little. | |||

|

| One of Us |

| |||

|

| One of Us |

not statisctically insignificant if it blows up in your face, or the face of the guy next to you, etc. then it is bad for you, and becomes bad for morale. that's why the US salted VC ammo with rounds that would blow up a few guns, and that's why the US told the NK troops that the old mosins were unsafe junk, etc. your low-number guns are safe, because most of them were, and still are. the point is that too many of them were not, and still are not. your sample size is statistically irrelevent. Hatcher's observations, and the observations of others at the time, were likely based on statistically relevent information, even if we don't know what it was. I am glad your low-number guns have been safe and I hope they always are, but I feel no need to take that risk myself. there is just no need to, not in the world of cheap and plentiful guns we live in. even high-number 1903's are plentiful. | |||

|

| One of Us |

I've been following this thread for awhile now and thought I'd finally mention my thoughts, since I own a low number 1903 Springfield made around 1914. Found it at a local gun show a few years ago. It's stock had been chopped, but otherwise, it was still in original condition. Only thing wrong with it was extractor collar was broken. According to gun show dealer, rifle was owned by an uncle who used it for hunting for much of his life and that uncle had died and his wife asked him to sell it. True or not, I certainly do not know, but obvious to me the rifle had been well used and cared for. Dealer and I haggled, I pointed out it being a low number 1903, broken extractor collar, stock chopped and etc. Got the rifle for $130. Being somewhat of a surplus rifle collector, I restored it to its original military condition. Do I shoot it? Yes. But, mostly with cast bullets and sometimes some reduced loads jacketed ammo. Both kinds of ammo give me reasonable accuracy when shooting targets. Am I worried about shooting regular 30-06 loads in it like the ones I use in my Smith-Corona 1944 1903A03, not really. But, why chance it. Have fun with the lower pressure loads I shoot with it. | |||

|

| One of Us |

True the British proof system uses lubed cases, and the question should be why? Lets start not with an assumption but a fact, no designer designs his action assuming the case carries any load. This is a fact and if the people worrying about bolt thrust were mechanical engineers, they could look up the bolt design equations and understand that the only argument in bolt design is load diameter. Whether the load is calculated from the inside diameter of the case or the outside diameter, or something in between. So why would the British use a lube case and the Americans use a dry case? Arguments in favor of a lubed proof load are that you do eliminate any chance of case friction and binding and apply the absolute maximum load on the locking mechanism. Therefore the proof is a true test of the strength of the mechanism. Arguments against the lube proof load are, if you want more load, just add more powder, the British system is expensive, takes time to do, takes time to clean up, nice to do if you are testing the ultimate strength of an action, but once you have done that and are making millions of them, the proof test is simply a workmanship test and not a design test. Why waste a bunch of time and money on an expensive proof of design test for a production arm?

How much load can a plastic sidewall carry?

There will never be a complete military database of blown 03’s as all of the data is in the trash bin. It was an abnormally to have so many failure reports released at the same time. Hatcher ran the Ordnance Department and was able to make off with a section of failure investigation reports, but there are known military 03 failures after his data base. Something that people should understand that DoD safety investigation reports are only shared with criminal investigators, are not released to anyone other than higher management, not even other safety investigators, (unless higher management authorizes it) and are never, ever, ever released to the public. So people trying to make conclusions about failure rates or number of failures based on Hatcher’s Notebook will never have a complete set of failures and are drawing erroneous conclusions if they calculating failure probabilities. | |||

|

| One of Us |

The basics: Whelen never was an inspector of 03s' at any arsenal. Anyone who can read a cartouche knows that. #2 as for headspace you check FIRST (duh) and then watch it blow up. #3 Hatcher's notebook contains the most complete database available, to suggest it is of no value because it has not got every "blown up" 03' is silly. #4 all these current experts, who DNS about the stats on actual failures, hold forth as if they do. I'd like a citation of the source on Whelen's remarks. As I said, if the level of detailed records that Hatcher compiled were kept on any military rifle, they would all be wall hangers. If Hatcher were not an NRA God, some independent tester would have tested his claims, but no one who ever wants to be published in any NRA publication is going into that Lions' den. I'm still waiting to see the first documented "blown up" low number 03' with proper headspace and modern ammo. Reminds me of the hysteria surround twist steel shotgun barrels until some Englishman (all documented in Double Gun Journal) actually put pressure transducers on twist steel guns and developed SMOKELESS loads that performed better and had LOWER pressure than any black powder load. Many English twist steel shotguns carry NITRO proofs .... oops another myth down the drain. I use his loads in my Cannon Breech Ithaca 10 bore hammer gun (perfect bores BTW). Great trap gun, have yet to break 25 but up to 23. One "expert" says it and then it becomes repeated and repeated without ever being given a real test. Remember how the M1 Abrams was never gonna work in the Gulf wars and how the Bradley couldn't stand up to Iraq armor ...... funny as I recall we kicked their raghead azzes into next week. How bout the MIG 25 that had everyones shorts damp because it was gonna wipe us out ..... oops another Ruskie POS that would have lasted about 30 seconds agaist an F 14 or F 15. Anyone who has handles and fired a pre WW One 03 knows it is one of the greatest rifles ever made. Accurate, operates slicker than snot and the workmanship is unequaled. They make almost all contemporary commercial rifles look cheap and crude. Of course very few if any of the "experts" sounding off have ever had the pleasure of owning and shooting dozens (or even one) of these virtually hand made rifles from the genuine craftsmen and Springfield or Rock Island. Doubt 1 in 20 of the "experts" can even identify this very rare 03' (anymore than they could the previous two).  Not that they will have the sense to (pharaphrasing Clint) "know their limitations". BTW, there was no DoD (DOD) when hatcher was around. It was called The War Department. | |||

|

| One of Us |

Hatcher was there. NONE of us were. I believe this quoted line applies to EVERYONE equally. "Not that they will have the sense to (pharaphrasing Clint) 'know their limitations' ". This whole subject is kind of like arguing over what the Bible or the Quran teaches. It teaches what "true believers" believe it does, regardless what they believe. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| Powered by Social Strata | Page 1 2 3 4 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia