The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  Spear Hunting & Fishing

Spear Hunting & Fishing  Spear building

Spear buildingGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Spear-heads, My custom knife maker has agreed to build me a spear head. This will be a thrusting spear, not a thrower, thus my gut tells me it should be fairly heavy. Need some help on designs. 1) Ideas on blade length versus width at base of blade. 2) Ideal blade length for one of Juan's Water Buffalos. 3) Best shaft material; wood (if so, what type), aluminum, tubular steel, carbon fiber, fiberglass? 4) Weight...ball park figure here....5 lbs, 10 lbs?? Any suggestions will be appreciated. Thanks, Jeff | ||

|

| one of us |

I prefer hickory on my hand tools,,I'd use that for my pig poker if I ever decided to make one. When you get it finished,,Please post a pic.,,I'd really like to see it,,Clay | |||

|

| One of Us |

Clay... ...will do...I'm thinking Osage Orange laminated... ...talking with a bow maker friend of mine about flex versus breakage, versus weight... Laminated shaft will most likely be the answer. We'll laminate cross-grained pieces and turn it down on a lathe to get balance and feel dialed in. Will report as results are generated. JW | |||

|

one of us |

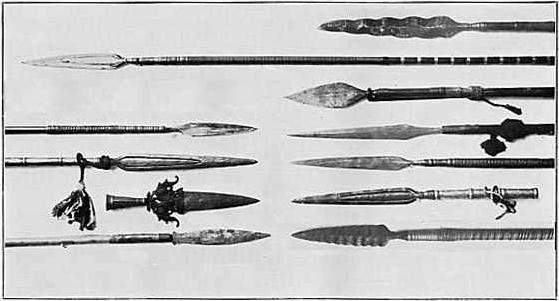

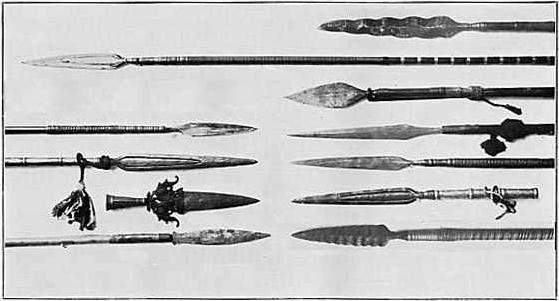

You have probably seen them, but I posted some pictures of spear heads in this thread just a little ways down the page. I would be very interested in seeing your project as it progresses. Good luck. | |||

|

| new member |

Hey guys, I'm new to the forum so HI! First off I think this is probably a bad Idea, but that said bamboo will give you the best strength to wieght ratio, the only problem is finding a heavy enough piece since bamboo in this country is ussually pretty small. It is used extensively in China as scaffolding. My next choice, though heavier would be ratan, like the furniture. 5 to 10 pounds would be huge try 1.5 to 2, if your currious take a 6 or 8 pound sledge hammer and try to control it while holding only the last 10 inches of handle. A spear shaft would be longer than that. Beauty is truth, and truth beauty. (Keats) | |||

|

| one of us |

Welcome Vernon!!I would'nt use bamboo,,It tends to dry out and split too much.There's lots of the stuff growing almost wild in the mid-atlantic area,,not hard to come by 3-4" stalks 20' tall,,Clay | |||

|

| One of Us |

We looked at Bamboo...Made same observations as "Claybuster"... ...We're going with a laminate....Most likely Osage Orange and Ash. JW | |||

|

| one of us |

Osage orange,,Brings back memories of my grandma making bathroom air fresheners by sticking cloves into the "oranges",,Every square inch of it,,When she was done with one there was no green visible,,Sold them at the church bazzar,,Grandpa muttering the whole time on how the wood was only good for fence poasts,,I think you're on the right track Jeff,,you want some weight,,Clay | |||

|

| One of Us |

Have you thought of Elm? I make canes out of Elm. Hard to find but it's nearly impossible to break. I don't know the diameter of the shafts used. Laminating would create a very strong shaft with little bending. Being a wood worker here, Ash would be good if it is new growth. Same as baseball bats are made. Strong and springy. Same as the Osage orange. | |||

|

| One of Us |

Shamus, et al... OK, we're all on the same page here. Weighty shaft, a little felxible and hell-for-stout! Now, about the head itself... ...Here's where we can make some serious errors. Anybody know of a reference point I can get some data about spear heads from? Not really concerned...but would like to read about anything that has been tried before we just plunge-in and start making metal chips fly! Otherwise we'll go for it...these days I like to narrow down the trial and error aspects of project as much as possible Y'all heve been there done that I'm sure... Thanks for the input thus far. JW | |||

|

| One of Us |

Shamus...OOPS! Elm...Hadn't thought of it...The only elm I have been exposed to Chinese Elm that grows out here in West Texas like weeds...Is this the stuff you're talking about... JW? | |||

|

| One of Us |

Claybuster... ...You have passed the "Hick-i-fied" test... ...Reckon your Granny was onto something and your Grandapa knew what he was talking about... ..."Horse-Apples" we call'em and it hurts like S#!T when you get nailed by one during one of those little battles us'ns used to have as kids! JW! | |||

|

| One of Us |

I'm in the northeast here. I've never seen Chinese Elm. Elm as a rule has an interlocking grain. Try to spilt it and you'll see what I mean. Our elm in the north east was decimated by the Dutch Elm disease. I come across it at different lumber yards once in a while. You can purchase red elm from Canada. It has a tendency to warp when dried. Since I'm a woodworker not a spear maker I don't know what moisture content you start with. I believe the canes I make and spear shafts have a lot in common. Another suggestion I think you could try is using PEG(ethylene glycol) to soak your shafts in while green. It displaces the water and leave your wood similiar to green wood. (springy with weight). I take it you are looking for good weight, fairly stiff with good toughness. You guys got me willing to try this. What type of metal for your spear point? What weight? | |||

|

| one of us |

Jeff im waiting for you ,i have a new cosecion full of buffalos and my dogos are hunting everyday .Juan www.huntinginargentina.com.ar FULL PROFESSIONAL MEMBER OF IPHA INTERNATIONAL PROFESSIONAL HUNTERS ASOCIATION . DSC PROFESSIONAL MEMBER DRSS--SCI NRA IDPA IPSC-FAT -argentine shooting federation cred number2- | |||

|

one of us |

For a spear head surplus bayonets are plentiful, and i'm in the process of making a spear using a SKS bayonet, i'll post pics when i'm finished. ILLEGITIMUS NON CARBORUNDUM | |||

|

| One of Us |

For what it's worth....I cut a few spars for bow making. I found a nice clump of old saskatoon bushes. The shafts about an inch and a half in diameter are 40 years old. This is one slow growing tree. It's absolutely amazing how tough this wood is once it's dried. I think Saskatoon is called serviceberry south of the border. the chef | |||

|

| one of us |

This is most interesting. The spear design and the wood talk as well. I have made a few items of wood,spoons, splitting wedges, and others. I'm looking at Osage for bow limbs. I missed the time to cut it this year. Maybe second growth Osage in the middle of the US would be good to start with. D2 tool steel for the head? Maybe. I saw a red elm flintlock stock once. It was too heavy for my tastes. Might also be good for the shaft. Good luck and keep us informed on your thoughts and progress. Packy | |||

|

One of Us |

What sort of spear head metal are you looking at? Stainless ? Carbon steel? Personally I looked at this and thought carbon steel would be fine. Easier to sharpen and as you won't be slicing with it all day, the fact that it blunts sooner probably does not matter. Are you considering a cross-guard like is normal on a boar spear? Normally there to prevent the boar "running up the shaft" but would it be deep enough for a 'buffalo'? Would a buffalo 'run up the shaft'? Myself I would make it for boars. *** I have actually looked at this again myself. Deferred it last time as I believe it or not, export approval of some sort is required to export spears from the USA. | |||

|

| One of Us |

You really should give some thought to cane. CANE NOT BAMBOO. Malaca cane comes in many diameters from 1/2" up It is almost impossible to break and is incredubally flexable. You can turn it down if you have a lathe with a long bed or you could make in sections for easy transportation. One other cane you should consider is Tontin or Tomkin for whatever spelling is correct. This the stuff that "Bamboo" fly rods are made from and I know that it is available in the US in many diameters. Both of these canes are serious stuff and almost indestructable For example I am holding now a 3/4" diameter piece of Malaca 24" long AND I CAN NOT BREAK WITH WITHOUT USE OF A FULCRUM. THIS IS VERY STRONG CANE AND WEIGHTS ONLY 2.5 OUNCES. "La vida no vale nada sin El Honor" Winggunner SCV, MOS&B | |||

|

| One of Us |

White wax for the shaft. I believe it is called white wax oak. True oak is strong but too brittle. Unless it soaks. If it can't handle a 90 degree bend, look again. Cane is great, but it splits like bamboo. You can get a pole and soak it for a year (ash or oak). Or you can get a white wax shaft. Just my view. Jim SCI Life Member DSC Life Member | |||

|

| One of Us |

For the spear head material I'd go with 1085 carbon steel. Harden and temper it to 48-55 HRc and it will be very tough and won't snap. It will be hard enough to take a razor edge and soft enough to touch up quickly in the field. As you won't be slashing with it or using as true knife this is hard enough. This is material is also hardenable in an oxygen furnace (woodstove) and can be hardened and tempered ina home shop; unlike D2 or A2 that needs a nuetral atmosphere (nitrogen), and crtitcal temperature control. You need to look at Buff anatomy, how long a blade do you need to get both lungs from a broadside hit. Rusty's Action Works Montross VA. Action work for Cowboy Shooters & Manufacturer of Stylized Rigby rifle sights. http://i61.photobucket.com/alb.../th_isofrontleft.jpg | |||

|

| one of us |

Out here in Oregon, folks build bows out of Pacific yew, Oregon ash and vine maple. I think I would go with the vine maple myself. As to steels, I'm no expert, but I have a tape on making tribal knives and the maker, Tim Lively, uses 5650 from 1950s Ford truck leaf springs to make incredibly strong blades. There is hope, even when your brain tells you there isn’t. – John Green, author | |||

|

| One of Us |

Car leaf springs would be perfect. Many are made from 1085 or 5650 or 9260. Another source for 1085 is mower knives. If you want to forge a spear head, automobile torsion springs will work very well too. Rusty's Action Works Montross VA. Action work for Cowboy Shooters & Manufacturer of Stylized Rigby rifle sights. http://i61.photobucket.com/alb.../th_isofrontleft.jpg | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia