The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Calculating pressure

Calculating pressureGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Since this thread is about measuring pressure, if a guy can only get 4-5 loads out of ANY brass, he's definitely got TOO MUCH PRESSURE no matter if you can measure it to the PSI or not!! | |||

|

| one of us |

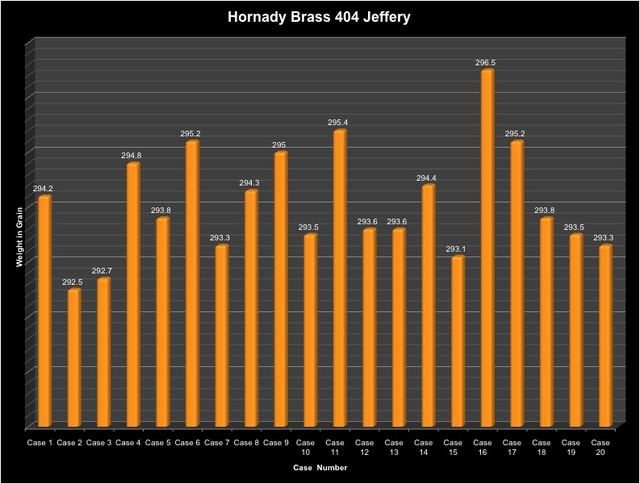

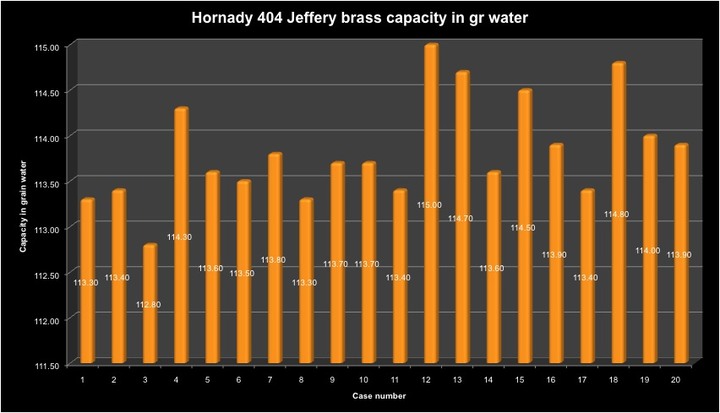

The consistancy of brass: 40 cases, Brand new Hornady cases for the 404 Jeffery, packed in two boxes. Each was run through a RCBC die and then weighed in two batches. One batch of 20 from each box. The they were primed with spent primers and capacity measured by filling each case with water with the meniscus just bulging above the case mouth. Here are the results: Case weight umprimed:  Case capacity in grains water:  And in lies lies the problem: Though the internal capacities are reasonably consistant the weight of brass is not, meaning that there is quite a variance in the amount in weight of brass in the walls and base of the case. | |||

|

| One of Us |

Actually Alf, in your example the case weight has a lower variance than the capacity:ES = 1.36% of average weight compared to 1.9% | |||

|

| One of Us |

Rcamuglia, would you mind dilating on your comment above. Why does getting only 4-5 reloads out of ANY brass,...definitely...TOO MUCH PRESSURE...? Regards, AIU | |||

|

| One of Us |

Sure. IMO, if your primer pockets can't hold a primer like that guy who was quoted after 3 loads for Norma brass and 4 for "Lapau" brass, the load is overpressure. That's just rediculous. | |||

|

| One of Us |

R, you still haven't explained why. If you can afford to buy the brass, what difference does it make? Regards, AIU | |||

|

| one of us |

Primer pocket expansion means that the web of the case is expanding. One of these days a load that expands the pocket enough to lose the brass in 3 will find a piece of brass that cannot contain the pressure for even one shot. Speaking from experience it is not pretty. Having pieces of brass stuck in your face and saftey glasses is not any fun at all. The other side to consider is the receiver and bolt are not meant to be subjected to a steady diet of 75-80000psi or more loads. I have seen actions where the bolt lugs are indented into the receiver, creating more headspace with each and every hot load, setting the stage for total failure of the cartridge and firearm. It is not a question of if, but one of when. So when shooting those extremely hot loads, just before touching the trigger, ask yourself. Do I feel lucky today? | |||

|

| One of Us |

Tell me if I'm wrong, but I don't think pressure cares how much money you have or what you can afford. Using that rationale, you should just shoot loads that blow your action up. I'm sure you can afford a new rifle for every shot. | |||

|

| One of Us |

A load that loosens Lapua primer pockets after 4 to 5 reloadings will not blow-up a well-made bolt action rifle. It is just a load that will consume brass more rapidly than usual. The PSIs that will do that are in the ~65000 PSI range. PSIs at 75,000 - 80,000 will blow a primer in one firing. A well-made bolt action rifle will tolerate PSIs in the 150,000 plus range. AIU | |||

|

| One of Us |

What "well made rifle" will tolerate loads of 150,000 psi?. Please let us know and the source of your information. | |||

|

One of Us |

Sighting them in is tough however! /////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

| one of us |

Some actions will/might tolerate 150000, but metal fatigue is a fact of life. A constant diet of 80,000psi and someday when you least expect it, you will pay the price. However, to each his own and if you enjoy wondering if the next shot is the one, go for it. I have been there and done that and am just relaying a personal experience for information. | |||

|

| One of Us |

ALF, did you trim those 40 cases to uniform length? IMO, three or four grains variation isn't a lot, especially in cases that large. | |||

|

| One of Us |

It's an awful lot when someone is claiming a pressure measurement method that measures the fired cases is:

| |||

|

| one of us |

Doubless: Yes they are fully prepped, the reason I did so was because some have dented mouths raw out of the box. I actually have copies of two early articles from American rifleman where cases were weighed and compared according to brand. Another where the authors subjected DWM brass to metallurgical analysis, this is quite interesting and proves as we should know that brass is hardly precision made. There is then always reference to the effect of subtle differences in components and pressure. The burning question is how large is the actual contribution of each of the contributing factors. CIP in arriving at their protocols have statistical validation of the magnitude of variance one can expect when say barrels are made with specs inside the minimum and maximum dimensions. A recent and the only published study and data on the contribution of small bore bullet resistance as used in the 5.56 Nato shows that though engraving pressure varies from brand to brand, bullet to bullet the actual effect on pressure is very small ! This study is the only one ever done on small bore bullets where bullet resistance to engraving in the bore is actually measured. | |||

|

| One of Us |

"Firearms Pressure Factors" by Wolfe Publishing Covers "jacket Factors" and many other variables. It is mostly Brownells work in the 90's. | |||

|

| One of Us |

H, Attached is a quote from a designer/engineer who worked for Winchester (reported as instrumental in designing the left-handed Win M70) and Kimber/Montana rifles. I won’t give up his name, because I want to protect his privacy, but here is the quote… “Modern bolt action rifles should take 150,000 psi or better. It also depends on the duration of the pressure, or impulse. Some of the new calibers have proof loads that may reach as high as 105,000 psi and still be in spec. Of course you do not want to subject them to a steady diet of these loads.” Hard to explain why a modern bolt action rifle would blow-up from one shot at 65,000 PSI (~44% of 150,000 PSI) – even following many shots at 65,000 PSI. When you exceed the 70,000 PSI range (i.e., ~75-80,000 PSI) you can count on blowing primers on a regular basis. The escaping gases from the primer pocket could cause harm to your eyes, hence always wear eye protection Regards, AIU | |||

|

| One of Us |

Here's another relevant article indicating that the brass case will fail long before the steel of the bolt action of a first-rate rifle. Thus, learning to read those signs of impending brass case failure and not exceeding those signs is what defines a safe reloader. The RiFles Of Dakota Arms: RiFles to dream on From the high plains by Dave Anderson Sturgis, South Dakota, is best known to the public for its annual motorcycle rally that draws over half a million bikers to the normally quiet little town. To shooters, hunters and collectors of fine firearms, Sturgis is known as the home of Dakota Arms -- maker of distinctive, elegant hunting rifles and shotguns of uncompromising quality. The company was founded by Don and Norma Allen. Don Allen is a former pilot, and since 1972 he has been making custom rifle stocks in his spare time. Allen noticed that pre-'64 Winchester M70 actions -- favorites with lovers of fine hunting rifles -- were getting more scarce and expensive. He also felt the M70's action could be improved. So with typical American entreprenurial spirit, he went ahead and built his own. Allen and Pete Grisel designed the Dakota 76 action. It is similar in function and appearance to the pre-'64 Model M70 but with more Mauser 98 influence. In discussing these changes, a brief digression is in order. Rifle enthusiasts like to argue about which action is the strongest: In fact, all current commercial actions have a huge margin of strength. Bolt-actions are typically strong enough to handle pressures of 150,000 psi or more. The brass cartridge case, however, will take pressures in the 80,000 psi range. Since commercial ammunition is usually loaded to maximum pressures of 55,000 to 65,000 psi, there is an ample margin of strength -- but the cartridge case will fail long before the action does. Why not use a stronger material such as steel for the cases? Because brass has an excellent combination of strength, pliability and elasticity. When the gun is fired, the pliability lets the case expand to tightly grip the chamber walls, which seals off the powder gases from coming back into the action. When the bullet exits and pressure drops, the elasticity of the case lets it spring back to near original dimensions, allowing the case to be extracted. Although strong, steel cases wouldn't seal off the chamber as well as brass, wouldn't extract as easily, and would be subject to rust. When comparing actions, it's not a question of strength. As stated before, steel is much stronger than the brass cartridge case. The question is, in the event of a case failure, how well does the action protect the shooter from the escaping gases? Occasionally we hear accounts of how someone had a rifle "blow up" but miraculously wasn't injured. Actually the rifle didn't blow up (if it did, the shooter likely wouldn't be around to talk about it). What really happened? The case failed and the action controlled and vented the escaping gases away from the shooter, just as its designers intended. A hundred years ago when technology was less advanced, case failures from poor brass were more of a concern. Today's manufactured cases are of such uniformly high quality that such failures are virtually unheard of. Now when a case fails, it is almost always a result of shooter error: firing the rifle with the bore obstructed, loading the wrong caliber cartridge, or poor handloads with excessive headspace or the wrong powder. The Mauser 98 action protects the shooter from failures as well as any, and better than most. It has a "flat" breech in which the cartridge case is enclosed by the steel chamber right up to the extractor groove. If the case does fail, escaping gases going down the firing-pin channel in the bolt are vented through two oblong slots in the bolt, down the left lug raceway in the receiver, and out to the left through the thumb slot (which facilitates magazine loading with stripper clips) in the left receiver wall. Gases going past the slot are deflected away from the shooter's face by a flange on the bolt sleeve. The pre-'64 Model M70 has several Mauser features but also some differences. Like the 1903 Springfield, it has the breech end of the barrel coned to enhance cartridge feeding, which leaves a small portion of the case unsupported by the steel of the chamber. However, the unsupported section is the area just ahead of the extractor groove where the case is thickest and strongest. Pressures high enough to cause it to fail would likely result in case failure at the primer with other actions. The pre-'64 action has a small hole in the right side of the receiver to vent escaping gases. The bolt has two holes that vent gases coming down the firing-pin channel into the left receiver raceway. Unlike military Mauser actions, the Model 70 does not have a thumb cut in the left receiver wall (which would allow a large volume of gas to escape) or a flange on the bolt sleeve. The bolt-stop partly blocks the raceway, but in the event of a case failure, gases coming through the left raceway would likely hit the shooter (one of the many reasons to always wear protective glasses when shooting any firearm). Frank de Haas, in his fine book Bolt Action Rifles, phrased it rather delicately: "... several arms experts... said that in case of a cartridge failure... they would rather have been firing some other rifle when this happened than the M70." Incidentally, the current Model 70 Winchester has a steel lug on the bolt (opposite the extractor), which blocks off the left raceway to deflect gases away from the shooter. I own several pre-'64 M7Os and shoot them regularly. I certainly wouldn't do this if I thought it was dangerous. With these or any rifles, I shoot either factory ammunition or carefully prepared handloads -- and I treat the cartridge cases with tender loving care. Reloaders who do any of the following are likely to get into trouble with any cartridge: use brass of questionable or unknown origins; don't understand headspace; don't measure, trim, and anneal cases as needed; or try and get just a bit more velocity or one more reload. Designers and manufacturers do their best, but with any action there is the possibility of serious injury if a case fails. Designed To Be Better The Dakota 76 receiver is similar to that of the M70. It is a flat-bottomed receiver with a substantial, integral recoil lug. It has the slanted bolt handle of the M70, the same excellent three-position wing safety, and the same fine trigger. Like the M70 and the Mauser 98, it has a large external extractor, controlled round feeding, and mechanical ejection. The Dakota differs from the pre-'64 M70 in that it has the flat breech of the Mauser 98. "The breeching system we use is very similar to the Mauser," says Allen. "The bolt face is squared off like the Mauser and we've pulled the barrel back further into the receiver... the bolt actually fits into the rear portion of the barrel, forming an inner ring around the bolt." The Dakota action, like the M70, has a vent hole in the right side of the receiver ring. The bolt stop is a precise, finely fitted part that blocks the left raceway to deflect gases and brass particles away from the shooter. Other changes include a redesigned firing-pin, beefier safety, and what Dakota calls "reverse round feeding." This means that the first round in the magazine is held by the left feed rail instead of the right. The advantage is that it is easier and faster if the shooter ever has to load a round in a hurry. The quality of materials and workmanship is equally important. Actions can be made in various ways, all of which produce good actions if the work is done well. Dakota Arms receivers are machined from high-grade, heat-treated steel. The advantage of this method is that there is no concern about warping, which can happen if the steel is machined and then hardened. Parts can be machined to extremely close tolerances. The disadvantage to this is that it is much more time-consuming and costly to machine steel after it has been heat-treated. As Don Allen says, "We start with a 10-pound block of steel and we end up with a 2pound receiver and 8 pounds of steel shavings on the floor." Great pains are taken during manufacture to keep everything straight and concentric; bolts are matched to receivers and receiver threads are cut so that the barrel is properly centered and aligned. Currently there are a number of gunsmiths who cater to accuracy enthusiasts by specializing in "blueprinting" actions. They take standard actions of various makes, square and true them, fit barrels square to the action, and lap the locking lugs to bear evenly. Dakota Arms rifles are made with all these features right from the beginning and have always featured high-grade barrels, which are currently supplied by Lothar Walther | |||

|

| One of Us |

rcmuglia is correct, it is rediculous. No need to push a case to that limit. If you want higher velocity get a larger case and burn more powder at a reasonable pressure. Modern magnums have MAPs of 65,000 psi but that does not mean most factory ammunition is loaded to that psi. To load to the point where case heads expand and primer pockets loosen exceeds the MAPs for those cartridges. Risking the damage from a case failure is fool hardy at best, stupid at worst. Just my opinion but those who want to put Darwins theory to the test may certainly do so. Larry Gibson | |||

|

| One of Us |

Larry, There is no need to drive down the highway at 70 mph, but many people do and do it safely. Driving 80 mph is more risky than driving 70, but many people do and do it safely. People vary in how much risk they want to take in life, but that's their decision. Maybe you feel uncomfortable driving over 60 mph. People die in car crashes at 60 mph too. Running reloads at 65,000 PSI is not that risky with a first-rate bolt-action rifle and combined with the ability to read PSI signs and reload knowledgeably and reproducibly. I don't shoot many loads at this level, because they are hunting loads to be used during season. Thus, I shoot fewer that 20 per year. There's a tendency on this forum to create unnecessay hysteria over reloading in the 65,000 PSI range. Regards, AIU | |||

|

| One of Us |

AI, I have a former load for my .338 that an old book said was within safe limits. But for some reason I was only getting about 4 loading out of the cases before the primers pockets became loose. Blown primers do not always start in the 70k psi range. I've seen instances where it took an extimated 90k to blow a primer..... PS I do not recommend trying this at home. | |||

|

| One of Us |

You're stuck in the "Velocity is most important" stage. You're wearing out your barrels, actions, and brass unnecessarily and prematurely. Probably sacrificing accuracy as well. A reasonable, below max-accurate load in any rifle will kill anything or hit any distant target just as well as an overpressure bomb that will shorten the life of your favorite rifle and bank account.

| |||

|

| One of Us |

Can't argue with that. Warrior | |||

|

| One of Us |

AS, I'm saying that blown primers start in the 75-80,000 PSI range. Also, QL only estimates PSI, and it can be off by a goodly margin. If you're using a first-rate bolt action rifle, the risk of loading at the 65,000 PSI (and slightly above range), is not that the gun will blow-up, but that you might get some hot gases in your eyes from a blown primer and/or get a stuck bolt and case, while that life-time trophy walks over the hill and you can't get off a second shot. Regards, AIU | |||

|

| One of Us |

Sounds like fun. | |||

|

| One of Us |

It my be that a case head lets go ruins the stock and the trigger guard breaks your finger. can happen, has happened. | |||

|

| One of Us |

I've had blown primers many times and case head separations - gases escape, no damage, removed the case, kept shooting, no problems. But, I use first-rate bolt action rifles, but maybe you guys don't. In which case you should not use hot loads. Indeed, you're wise to be carefull, when using questionable or inferior equipment and/or loading techniques. Also, if you're of the nervous anxiety riden type personality, then using hot loads will likely make you flinch and shoot poorly. I would not want you guys to change your habits. Regards, AIU | |||

|

| One of Us |

AIU, Please tell us the advantages of using 65K to 70K PSI loads over 60K and less loads in the same rifle. Thanks. | |||

|

| One of Us |

Rick, I've never considered 65-70k PSI to be obnoxiously hot for a moderm bolt action rifle. Spec on the US Armie's new 300 WM load is 68K PSI. That's one of the things I like about QL. As an example, CIP spec on the 30.06 is 58k PSI. Now that might be a good limit for an old springfield, but I see no reason to limit a new Carolina Winchester M70 to 58k PSI. I imagine a large percentage of handloads for the .06 are in that 65-70k range. But going too much above that might not be the best idea. The stress effects of pressure on steal are logarithmic, not linear. Untimalty, when you don't have your own personal lab, and enought time to do pear reviewed studies of every load, in every rifle, reading all the signs to determine when and where to stop is as much art as science. And even is someone did have their own lab, and performed peer reviwed studies of every load they shot in every rifle they had, somebody here would still bitch that it was not good enough. | |||

|

| One of Us |

R, Where did I advocate running loads in th 70,000 PSI range? - I didn't. I said in the 65,000 PSI range, if you want to because you get better accuracy or more performance is needed for long range shooting, etc. R, if you feel uncomfortable running PSIs at 65,000, then don't. But, don't exaggerate the risk at 65,000 PSI. There's risk in reloading at all PSIs, especially if you can't read pressure signs or, heaven forbid, make a mistake such as inadvertent substitution of a fast burning powder for a slow burning powder. Then castrophic results could result. Regards AIU PS. I completely agree with Antelope Sniper comments above. My only concern about QL is that "weighting factor". AS, do you understand how to calculate it? Finally, IMO one can reliably read pressure signs. We can go there if you want. Maybe it's worth an extensive discussion here. | |||

|

| One of Us |

This here is the dilemma ... what is "inferior equipment" ... the dilemma for the novice and even the average or common shooter. He believes his rifle is up to spec ... made according to SAAMI or CIP specs ... it bear a quality control stamp on the label and proof marks ... yes, and the salesman told him that this one is a good one, and so he bought it ... brand new out of the box ... shining. It may be his first rifle and eager to see how fast it can run. Accidents are most always a surprise ... never thought it would happen. Having a slight saving margin of around 3,000 psi can never hurt. Just a few variables coming together may give you an extra 6000 psi pressure and more. Like - changing the brass, softer brass or smaller capacity, non detecion of insipient case head separation, a new lot of the same powder, going to a warmer climate, a rifle baking in the sun on the dash whilst driving, a bullet moving further into the case down the magazine through the recoil impulse, etc. Just like I am not riding my car with its rev-counter in the red all the time, I am not pushing and using my rifle on the edge as a matter of course. Warrior | |||

|

| One of Us |

AUI, I've had quickload for about 6 months now. It's a valuabe tool, and I've learned alot from it, but I'm still in the process of deciding where all this new data fits in with my 30 years of loading experience, and 4" binder of chronograph data. As for the weighing factor, I understand the factors that effect it, but can't say I totally understand everything that goes into it. It's related to the general rule that the greater the difference between the diameter of the case, and the diameter of the bullet, more pressure will be created. That's why a 30.06 is a .55, but a .270 Win is .50. It's a smaller hole for the pressure to escape from. Yes, I understand the priciple, but can't say I know how to calculate it. So long as I can understand the principle and the system works, the weighing factor doesn't bother me, but it is something to remember when QL doesn't agree with other avaliable data. | |||

|

| One of Us |

AS, if you play with the "weighting factor" with any specific cartridge (e.g., 30-06), you'll notice that as the value drops below 0.5 the relative performance of the cartridge increases, the reverse as you go above 0.5. In other words, you can within limits, get the result you want by changing this factor. It is supposed to take into consideration the flow of unburned powder down the barrel behind the bullet. Accelerating unburned powder down the barrel will take energy, hence robbing energy that would otherwise be available to accelerate the bullet. But, at the same time powder burning down the barrel would seem advantagous, because it would create a more desireable pressure/time curve (you want the area under that curve to be as large as possible without exceeding maxium desired PSI). Although a complex problem, it seems to me that at least several factors would affect the flow of accelerating unburned powder down the barrel - that is, 1) the bore or caliber diameter, 2) the total amount of powder in the case, and 3) the relative burn rate of the powder. Large bore diameter relative to the case diameter, more total powder, and slow burning powders should all increase the relative amounts of unburned powder accelerating behind the bullet, and thus robbing energy from bullet acceleration. Yet, this weighting factor is a fixed value. It seems to me, it should change with each load depending upon powder amount and burn rate and, even, bullet weight. But, it appears to only take into account the cartridge geometry. Bottom line - the mysterious "weighting factor," which is poorly explained, makes me nervous. Regards, AIU PS. My advice - learn to read pressure signs in your cases as you work up a load!!! The cases will tell you when things are getting HOT. Case excessive pressure signs are more predictable and reliable than many posting on the Board would lead you to believe. | |||

|

| One of Us |

Did that 30 years ago. That was before most books printed pressures in books, I'd ever heard of SAAMI, or copper crush vs psi. Throghout the years we keep getting new tools that expand our understanding. With QL, my current focus in on more hands on variables, such as variations in case capacity across manufactures, and variations in primers. Last weekend I shot two different .308 loads against each other. Only thing I changed between the two was primers. With cci 200, the primers were flattened, but beyound that, no significant pressure signs. With WMRP's, the primers BLEW.....Something tells me that the pressure between those two (almost) identical loads was a little different..... | |||

|

| One of Us |

AS, fantastic!! Great to know I'm corresponding with someone who knows what he's doing. I've been reloading since I was a little boy with my dad and brother, who were competitive shooters. I got started very early and have been doing it nonstop for 50 yrs. My application is long-range shooting, which requires accuracy and performance. I have enough data on Ackley improved cartridges to write a book. Maybe I will when I retire. Warm regards, AIU | |||

|

| One of Us |

Here is a relative ranking of commonly available primers by flame heat, from highest to lowest: 1. Fed Match GM215M 6.12 2. Federal 215 LRM 5.69 3. CCI 250 LRM 5.66 ---------> 4. Winchester WLRM 5.45 5. Remington 9 1/2 LRM 5.09 6. Winchester WLR 4.8 7. Remington 9 1/2 LR 4.75 8. Fed Match GM210M 4.64 9. Federal 210 LR 4.62 10. CCI BR2 4.37 11. CCI 200 LR 4.28 ---------> 12. KVB 7 LR Russian 4.27 Primers differ - not all large rifle primers have the same power. You can see that the CCI Large Rifle primer is cooler than almost all others but the Wolf primer. That does not mean that it will not ingnite the powder. What it means is that the flame characteristics will impact the consistency of the load - in other words, your standard deviation will be wider for certain powders. That is why they recommend the LRM primer in certain situations. Also, match primers are more consistent due to more stringent quality control measures. Warrior | |||

|

| One of Us |

The graph of the case weights is very misleading if you just look at the picture and do not analyze the actual data. The graph is not to scale so it magnifies the percentage difference. That is one of the fallacies or techniques highlighted in the booklet "How to Lie With Statistics". Another thing to consider is the difference in the specific gravity of brass and gun powder. Brass has about 8 times the weight per CC that powder does. When comparing weight to volumes remember that it takes 8X as much powder to take up the volume of 1 grain of brass.... | |||

|

| one of us |

SR 4759: ??????? No attempt at lying or anything, raw data of cases weighed, no more no less. I did not subject any of the data to statistical analysis so there is no fudge factor ! The parameters of the graph are shown plain for all to see ! Make of it what you wish ! fact is no matter how you try and explain it's signifcance the weight from piece to piece and capacity piece to piece is not the same ! If they were we not hardly need to have primer pocket and flash hole uniformers would we now, nor neck turners etc etc. As I say of all the components used the case is likely the most inconsistant component in the lineup. They are for the most cheap, mass produced cilinders of brass. Some more: Ken waters: case capacities Shooting times 1967: He measured various calibers and found as much as 6% variance in capacity case to case same brand and lot, That is significant ! | |||

|

| One of Us |

ALF- The booklet "How to Lie with Statistics" is merely a bit of wisdom on the pit falls of statistics. The graph is there to see but it is way out of scale. Regardless of what a case is or is not - brass is very dense compared to powder. The variation in weight is not as significant as it may seem when people are used to weighing in grains. BTW the little book is the most widely read book on statistics in history and for good reason. You will find an example of your graph pointed out there. | |||

|

| One of Us |

Warrior good chart. What do the numbers mean? Different powders certainly have different primer preferences. On average, sticks like a cool primers, where ball powders tend to prefer something on the high end of the scale. So in a .308 case, how much difference in pressure do you think there is between a CCI 200, and something like a WMRP? AIU, I think my Dad loading bench still has some of my teething marks on it. | |||

|

| Powered by Social Strata | Page 1 2 3 4 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia