The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Doughnuts on neck?

Doughnuts on neck?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

Having some dougnuts/bulges on the neck just above the shoulder on 2nd fired brass after full length resizing. It's a 280 ackley improved, using nosler 280AI brass. Any feedback on preventing and what causes this. Thanks guys. Brent | ||

|

| One of Us |

What brand of dies are you using and how did you set them? We need to call this the Texas AR forum... | |||

|

| one of us |

Common problem with wildcats formed from parent brass that gets necked up so the new neck incorporates some of the old shoulder, where the brass was thicker, etc. What brass case are you forming the 280 AI from? Study of the brass and the shoulder and neck relationships before and after fireforming should tell the mechanism of the donut. Is your "dreaded doughnut" on the inside of the neck after firing, then becomes actually visible on the outside after sizing? When I neck up .338 Lapua to .375, a donut forms at the neck/shoulder juncture. I seat a boattail Sierra 300-grainer down as far as it will go without expanding the donut. I fireform it. This is an excellent load itself. Then I inside-neck ream the fireformed brass with a .375-caliber Forster neck reamer. Then I full length size the brass. I am then ready for any bullet, donut gone. | |||

|

| Moderator |

If I had to guess, it sounds like the cartridge is not getting pushed up into the sizer die far enough. You can verify by "smoking" the brass and running it up into the die. My favorite way of smoking is to use a piece of masking tape- fold it on itself and then light it, it puts a nice layer of soot where you want it. Just remember to lube the case first! Anyway, run it up into the die and I bet you'll see the base of the neck is not getting sized. If the sizer die is down all the way against the shellholder, verify the shellholder brand is the same as your die. I recently (well, about 2 years ago) had this happen to me with a 243 small base die set and I had to grind a tiny amount off the top of the shellholder but it fixed the problem. for every hour in front of the computer you should have 3 hours outside | |||

|

One of Us |

Hey thor, welcome to the forum I develop do-nuts on my 280AI using Nosler 280AI brass. My question is, are they interior do-nuts or exterior do-nuts and can you post a pic? Mine are interior do-nuts and I have to ream to get rid of them. It sounds like you are talking about something visible from the outside. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| new member |

My doughnuts are visible on the outside. I can't tell if they are on the inside. I use redding full length S die, RCBS shellholder, the parent brass is NOSLER 280 Ackley Improved brass, the brass was new and neck turned to get .012" wall thickness. The die is set by running it down to touch the shellholder at the top of the stroke and I back it off a quarter turn. The doughnuts do not appear till after sizing. In looking at the same brass after one firing I notice that OD of the neck is consistent from the shoulder to the top of the neck. So it seems the problem is occurring during sizing. I am relatively new to reloading and been working on developing a load for my 280AI. I don't post much but really enjoy and appreciate this forum, the information provided, and the community. I'm not to computer savvy but will try and get a pic posted later today. Any more info will be helpful. I don't follow the "smoke" process and what I'm looking for. Thanks, Brent | |||

|

| One of Us |

The first thought that came to me when reading this thread was, did you outside neck turn the cases? You will have to go back and eliminate the exterior donut using the outside neck turning tool. That's how I get rid of it. I set the cutter up so I don't thin the necks any more than they are, and then run the cutter up to just kiss the case shoulder, eliminating the donut. | |||

|

| One of Us |

Sounds like something to do with your bushing die especially if you have a bulge at the base of the neck. | |||

|

One of Us |

The way to tell if you have interior do-nuts (which are very common on 280AI) is to take a bullet and try to insert it into an unsized neck. If the bullet stops at the neck/shoulder junction then you are developing do-nuts. Also, pin gauges are great for measuring interior neck dimensions and will detect the do-nuts. Since the do-nut is on the outside then there are 2 possibilities, one good and one bad. If your bushing is not set to size all the way down to the shoulder then it is leaving part of the neck fire formed size  and that won't bother a thing and may even be beneficial. I would not outside neck turn that off as that would make your brass thinner there. I neck turn only on new cases which is not the case here. If you are actually pushing brass up with the die (which I have never done or seen happen without buckling the whole case) then you would have a problem. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

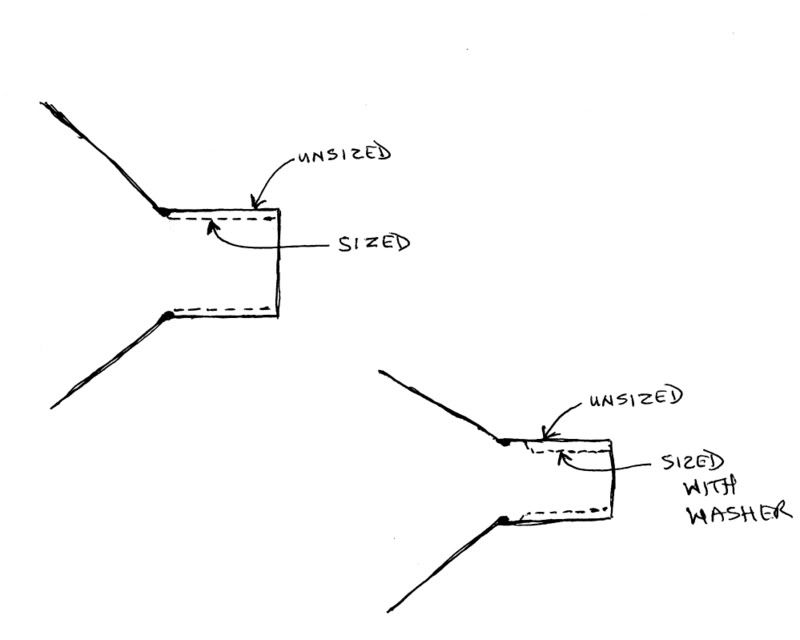

I'm of the school of thought that the EXTERIOR donut is caused by a portion of the neck that is not being resized by the die and is in fact beneficial (assuming it's only a small portion of the neck, like Wood's drawing)as it helps align the bullet with the center line of the bore. If you would imagine a cut away of the drawing you would see that the inside walls of the neck followed the outside contour so where the neck bulged out, the inside of the neck would also bulge out. If you were to neck turn the outside of the neck so it was even from mouth to shoulder, you would thin the portion where the doughnut was too much. | |||

|

one of us |

Necks shouldn`t be turned until the brass has been fire formed to your chamber. The difference in headspace from a new case to a formed one will vary a bit on the short side. The cut when turning the necks should just "touch" the shoulder neck juction, the edge of the cutter is radiused to allow this. Most of what I believe you are seeing is the thicker case wall where the cut stopped that has moved foreward from forming and sizing. You need to recut that portion as DMB suggested or ream after sizing without an expander and moving the "donut" to the inside of the neck. ------------------------------------ The trouble with the Internet is that it's replacing masturbation as a leisure activity. ~Patrick Murray "Why shouldn`t truth be stranger then fiction? Fiction after all has to make sense." (Samual Clemens) "Saepe errans, numquam dubitans --Frequently in error, never in doubt". | |||

|

| one of us |

THis occurs w/ my 338-06 but I partial FL size & it leaves a slight shoulder, I don't think it's a true doughnut of thickened brass, just unsized. LIFE IS NOT A SPECTATOR'S SPORT! | |||

|

| One of Us |

Fredj338, Exactly!! | |||

|

| One of Us |

Aah, the Dreaded Donut....the dreaded donut occurs when you neck turn but do not cut slightly into the shoulder where the neck joins the shoulder. You should cut slightly into the neck/shoulder juncture. Without cutting into neck/shoulder there is excess brass that flows into the neck when firing and forms inside the case because the case forms against the chamber and pushes the donut inside. When you neck or FL size the sizing button pushes the donut from inside back outside. Just use your neck turning tool to remove the donut without cutting deeper into neck. Also, K&M makes a carbide cutter to remove the donut from inside the case if you prefer. Either way doesn't matter but I recommend you remove the Dreaded Donut due to powder gas flow. | |||

|

| One of Us |

he ain't sizing all the neck. skip the full length sizer buy a hornady 7mm neck sizer. your brass will last longer,you will be happier,make up some hunting loads and leave them sit in their boxes. and use the rest of the brass to shoot till you need to anneal them. about 6 loads on them should be about right. more if you just wanna throw the brass away. | |||

|

| one of us |

Lots of good speculation above. It may have something to do with how Nosler makes the brass. The AI shoulder-neck junction is below the standard 280 Rem. location. Potential donut dough there. Ream Inside-neck after first firing, before resizing. Maybe that will prevent the donut. | |||

|

| One of Us |

Buliwyf, question: once the case is resized is this doughnut only on the outside? (I know nothing about AI cases) So there is nothing to hinder a bullet from being seated a whatever depth you wished? The situations I am familar with is when a F/L die is used to partially resize a case and a small portion of the neck isn't resized. From what you describe, there is actually an excess of material at the junction of the neck and the shoulder. Is that correct? What would happen if you fire formed you brass and didn't neck turn. You wouldn't get the doughnut would you? | |||

|

| One of Us |

Like any other handloading phenomenom, "donuts" are not a simple 100% good or 100% bad thing, anyway. I would guess that usually, donuts are not thickening of the brass, but something else. With shooters who outside neck turn brass, the first firing after case turning blows the outside wall of the case neck up against the wall of the rifle chamber, both where it was turned, and where it wasn't. That means the part that was turned ends up with a larger inside diameter than the part which was not turned. The part that wasn't turned did not necessarily thicken any at all. But, it WILL be a step in the case, except after firing the step is on the inside of the neck rather than on the outside, where it was after turning but before firing. If the throat is short enough that the bullet needs to protrude down below the base of the neck into the powder area, then the step MAY need to be removed to let the bullet pass. But, if the chamber throat (leade) is long enough that the bullet does not need to protrude below the bottom of the case neck when fully seated, then a step on the inside of the case neck can be a distinct advantage! By controlling how far down the case neck the outside neck turning goes, one can control exactly where the step is on the inside after firing, and use it as a bullet seating stop. Some folks think such a step [donut] will screw up the flow of burning/burnt powder gas and reduce accuracy. That has not been my experience. I have shot consecutive 10-shot groups in matches with .30 caliber 210-gr CAST BULLETS using such cases, where the groups were under 1/2" center to center at 100 yards. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

One of Us |

I love it! That's fantastic shooting, not to mention all the homework involved. Inspiring! Regards 303Guy | |||

|

| One of Us |

Hi stillbeeman, 1. No difference in treatment between an AI case design or any other bottleneck case i.e. wssm, wsm, 6mmBR, standard .30-06, or belted magum or .416 Rigby. 2. When case is resized the donut is pushed to the outside by the sizing ball inside the sizing die so there is nothing to hinder a bullet being seated to whatever depth you want. However, when the case is fired the donut is pushed inside due to the case forming against the chamber wall. 3. When a case is partial neck sized there is no "excess" material only sized and unsized case because brass thickness is similar. However, when you neck turn you remove brass to create uniformity and this creates the Dreaded Donut because brass flows from the shoulder area into the neck. By cutting slightly into the shoulder where the neck joins the case you create a "containment zone" for brass flow when the case is fired. 4. You would not get the Dreaded Donut if you fire formed the case and did not neck turn. The Dreaded Donut only occurs from incorrect neck turning created by not cutting slightly into the shoulder. Notes: a. Neck turning is performed to create uniformity in neck thickness for even release pressure. b. Factory rifles should only be neck turned to "clean up" the neck. Say 70%-80% of the neck touched. c. This is not speculation. This is Engineering. Whatever you do, DO NOT inside neck ream your Nosler brass. d. If you make one cartridge from another i.e. making .264 Winchester Magnum brass from 7mm Remington Magnum brass that is a different process than we are taking about here. My experience with Nosler brass has been outstanding. This topic has absolutley nothing to do with how Nosler makes brass. | |||

|

| One of Us |

http://www.6mmbr.com/260AIforming.html From: http://www.the-long-family.com/260AI.htm http://www.redding-reloading.c...ages/caseforming.htm http://home.comcast.net/~jesse99/6XC_DonutCutter.html http://www.aushunt.com.au/main...articleid=c710eefe62 http://shootersforum.com/showthread.htm?t=52949 http://blog.sinclairintl.com/2...-for-factory-rifles/ http://www.snipersparadise.com.../sept03/sept03_1.htm http://6mmbr.websitetoolbox.co...8211&highlight=donut When I bought my 6mmBR reamer, I got it custom for a certain bullet [87 gr Vmax] that almost touches the donut, but not quite. | |||

|

| One of Us |

Uuhhh, wait a minute. When you outside neck turn a case, you uniform the thickness of the neck so there would be no step to be pushed anywhere. | |||

|

One of Us |

It looks like in tnekkcc picture that the neck get progressively thicker as it approaches the neck/shoulder junction. If that were the case the best way to uniform the neck thickness and cure the problem would be neck reaming. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Stillbeeman, You remove brass when you cut the neck by neck turning. Thus, the neck is thinner than the shoulder area and must expand more in a factory chamber because the factory chamber is cut at max tolerance. Therefore, the brass will flow from the shoulder area into the neck area causing the Dreaded Donut. By cutting slightly into the shoulder when neck turning you create an area where the brass will flow instead of flowing into the neck. Therefore, no Dreaded Donut will form because the brass flow when firing will be into the slight shoulder cut area. Hi woods, in tnekkcc's example he is fireforming a .243 Win. to a 260 AI not neck turning. This is a different process as you know. Most of the time additional thickness occurs when forming down in caliber. In this case thickening is occuring from the steep AI shoulder angle and shorter AI neck length compared to the .243. tnekkcc's example may or may not be a problem based on rifle chamber neck diameter. If 260 brass had been used to make .243 brass and the resulting neck was to thick to seat a .243 bullet, then inside neck reaming would be the answer. Inside neck reaming is not the answer for thor45. | |||

|

One of Us |

I do turn a little into the necks  It is a little skeery to start turning into neck brass with no way to measure how far you are going. Perhaps I did not turn enough, but it did not prevent the do-nuts in the 280AI Nosler brass. The regular Nosler 280 rem brass does not develop do-nuts. However, I think we are hijacking the thread here since the OP probably had the exterior do-nut caused by not sizing the entire neck. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Sorry, stillbeeman, but to assume that is not necessarily going to be correct. (You know what "ass-u-me" can do to us all...) It depends on how far down the neck you turn. If you turn all the way down the neck and a bit into the shoulder, it is correct. But a lot of folks don't necessarily do that. One reason shooters turn necks, is to thin the brass sufficiently to let a loaded round go into a "tight-neck" chamber. For instance, many 6 PPC rifles have .262" chamber necks. A pretty fair amount of factory brass has .014" thick necks as it comes out of the box. So, two times .014" neck thickness + .243" bullet diameter = what? Well, it equals .271", so pretty clearly a loaded round with an un-turned or un-reamed neck will not go into the chamber of that .262" tight-neck PPC rifle. A typical benchrester faced with that dilemma will turn the outside of his case necks down to .009" thick, which gives him a nice close fit in the .262" neck chamber, but WILL chamber and fire safely. That loaded neck diameter then equals .009" + .009" + the .243" bullet diameter, or a total of .261" neck diameter when ready to fire. Because of the urban myth that any donut screws up gas flow, many benchresters turn the full length of the neck and slightly into the shoulder...just in case the myth is founded on fact...as some of them truly and honestly believe it is. However, many of them do not trim the entire length of the neck, instead they turn the neck down just far enough to allow them to seat the bullet and still put the cartridge into the chamber...which means there is a step on the outside of the neck before the initial firing. The first firing transfers the step to the inside of the case neck, thus creating a "donut". (If the turned neck is run into a proper die for sizing necks to .261", the thinner front part of the neck will still accept a .243" bullet, while the rear portion of the neck will chamber even with its .014" thickness as there is no bullet to push the thicker rear portion out to interfere with the chamber's neck walls. And the whole assembly will work fine in the .262"-neck chamber.) My experience has been that the so-called "dreaded donut" has not hurt MY shooting in the least, so I do NOT turn the full length of the case neck. Instead, I turn just as far down the case neck as I want to seat the bullets I will be using. Then the first firing transfers the step to the inside of the neck, where it serves as a bullet-stop for me. That doesn't even suggest anyone has to do it the way I or many of my benchrest competitor friends do...there are always several ways to skin any kat, either a wild one or a SAAMI-tamed critter. But, it does appear to mean that the dreaded donut isn't necessarily a bad thing, and does not always have to be reamed out. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| One of Us |

I don't have good control on the data, but is seems to me whenever I am seating a bullet, and I feel the bullet hit the donut, and then I seat deeper, those are not my accurate loads. I am not saying the donut upsets the gas, but pinches the bullet, and scratches it up going in and coming out. We know that case mouth scratches hurt accuracy, so donut scratches probably do too. | |||

|

| One of Us |

Tnekkcc - I suspect your entire post is very correct. Whenever a bullet base is forced past a "donut", I think it not only scratches up the bullet, but likely deforms the bullet's base as well. Deformed bullet bases can range anywhere from slightly harmful to accuracy, all the way to disasterous. IF a person has a donut on the inside of his case neck, but wants to seat the base of the bullet deeper than where the donut is, then I can only suggest to him that he had best remove the donut. What I was trying to impart is that one does not automatically have to remove donuts in all instances. It is not simply having a donut which is harmful ("bad"), it is having one that interferes in proper bullet seating or harms the bullet that is the undesireable situation. If the bullet base is not seated past the start of the donut, I have never found any bad "donut-effect" on accuracy IN THAT SPECIFIC SITUATION. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| One of Us |

woods: you determine how far you are going with gauges. Nothing scary out there just engineering. Based on your photo you did not turn enough. The Dreaded Donut occured because you did not turn enough into the shoulder . Nothing more or less. Has nothing to do with AI case design. No we are not hi-jacking this thread. You never, ever, size the entire neck. you want to partial neck size. The unsized neck provides chamber alignment. thor45's problem occured because he did not cut into the shoulder just like you didn't in your photo. Alberta Canuck: | |||

|

| One of Us |

Alberta Canuck comment:

Alberta Canuck: You are not professionally qualified to comment as per your own addmission of "guessing". Donunts are a 100% bad engineering result. Handloading is not a "phenomenom". Handloading is the application of science. So is medical study.... | |||

|

One of Us |

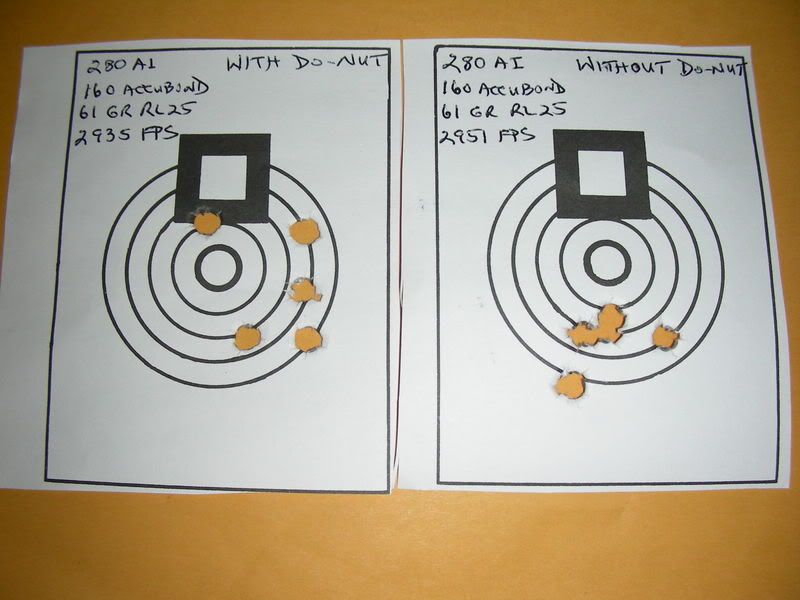

Buliwyf, OK, I'll bite. Exactly what gauge and how do you use it to measure the remaining thickness of the shoulder brass you are cutting into? Do you think it might be a problem if you cut too deep? If you knew the exact measurement from the case mouth to the inside of the shoulder at the neck/shoulder junction then you could measure the distance from the stop on the neck turning mandrel to the point on the cutter where it is cutting into the shoulder. AC, the do-nut you are creating runs longitudinally along the neck for a longer distance than a typical do-nut. I wonder if you are gettin a do-nut on your do-nut? tnekkcc, in my 280AI the 160 gr Accubond I use goes well past the do-nut and it does make a difference in my tests  I'm not sure if it is the gas flow problem or just the inconsistancy of the "rear crimp". ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Woods - I'm afraid I didn't quite understand the "donut on a donut" part of your last post, so I have no answer for that. For some reason, I also received only the top half of your posted targets. Would have liked to see them entirely. However, if your rifle is more accurate without the donuts, espcially if the bullet bases ARE being forced past the donuts, then in my opinion you need to determine why you are getting the donuts and eliminate them. As my comments have apparently irked some of the thread participants, I will venture no more comments in that respect Whatever theories any advice giver may hold to, your rifle and your loads will always tell you which is the best way to go. Sometimes we just need to learn how to decipher what they are saying. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| One of Us |

Wow, Buliwyf, Do you have to be a professional to post in here? That was pretty strong! How does one become a Professional reloader?? I'd say folks posting their different empirical knowledge gives one a good, broad overveiw of the various facets of reloading. The pix of the reformed brass posted by tnekkcc doesn't look like it has been neck turned as it appears tapered from mouth to shoulder. | |||

|

One of Us |

I would say that bad engineering is when the bullet needs to be seated past the neck/shoulder junction into the powder space. The case wall thickness is going to change at such junctions - that's science. Reloading for accuracy is a skill. "... consecutive 10-shot groups in matches with .30 caliber 210-gr CAST BULLETS using such cases, where the groups were under 1/2" center to center at 100 yards ..." is proof of that skill. But most importantly, shooting is fun! (It's cirtainly challanging). Regards 303Guy | |||

|

One of Us |

Hey AC, I am doing great with you posting whatever your opinion is. I certainly do not give any more credibility to any other posters "guesses". There are certain "assertions" in Buliwyf's posts that I am taking with a "grain of salt" as we should all treat information shown here. Essentially one of your ideas was something new to me that I had not heard before; only neck turning as far as you are going to seat the bullet base. New information like that is what I read these posts for, epiphany's large and small. So please continue. With the do-nut on a do-nut thing; when you only partial neck turn then you have the front part of the neck thinner than the part of the neck closer to the neck/shoulder junction. This will be of a dimension that is of your choosing but could be in the tenths of an inch. When you fire the load that thickness is going to be on the inside of the neck. That thicker part could develop a do-nut just like any other fired neck. IOW, your do-nut is a much longer thickness of brass going from the neck/shoulder junction toward the case mouth and you could still develop a do-nut "ring" at the neck/shoulder junction. I've got a question; how do you size the necks with the disparate thicknesses? Upon tnekkcc's advise, I now have a set of pin gauges which are indispensable in dealing with do-nuts    I am still in the process of measuring the necks of fired loads on different rifles, factory and custom, so do not want to post any results yet. But I will tell you that do-nuts develop in other rifles as well and are not consistant. IOW, I found one on a 300 win mag case and it was the only one in 20 fired loads that had all been fired the same number of time. The do-nut measured .311" and could not be found by the conventional method of inserting a bullet, only with the pin gauges. I don't think a do-nut that is not below caliber dimension is bothersome anyway. I made this illustration a long time ago and do not know if it is a true representation but may lead to further discussion  BTW, the pics of the target show fine on my computer. Is anyone else having a problem with the target pics of the 280AI? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| new member |

So I head out Saturday morning after posting to run some errands, then reload a bunch of .308, and study my 280AI situation in which I became consumed and didn't log back on till first thing this morning. WOW! I can't thank all of you enough for the valuable information and knowledge. Like I said, it's great to have a forum like this for a resource and opinions. To clear a few things up: When I neck turned the brass I did slightly cut on the the shoulder. After studying my situation I believe that I may have had to much play with the bushing in the die. I tightened up and resized and it almost eliminated all of the doughnut. It's now not noticeable to the naked eye, but the OD is .005 to .007" larger. My reason for neck turning the new brass was an experimentation as I'm doing load development on this rifle as it's fairly new. It is a hunting a gun and doesn't have a tight nk. chamber. Just my experimentation. I'm actually going to the range this evening and will be doing brass prep later in the week. Should I run into the problem again it's not coincidence or the play in the bushing. Then I will revisit. Thanks again guys. I will repost in appropriate forum but any load data on 280AI for 140 & 150 would be appreciated. Brent | |||

|

| One of Us |

Wood's sketch... Is that why my best accuracy with 257 Roberts Ackley Improved has been with the full length die adjusted for 3/4 neck sized? | |||

|

| One of Us |

Buliwyf- Unfortunately, your opinion has gotten in the way of your logic and the facts as you perceive them...not to mention augmenting your rather obvious arrogance. Although donuts may offend your theoretical sense of professional engineering, if they do not harm accuracy then it is rather difficult to accept that they are 100% bad...especially when they can also be used to serve positive purposes in handloads, when PROPERLY APPLIED. To me it appers you do not even understand what science is. Medicine is both an ART and a science. What appears to be proved by studies today is inevitably found to be incomplete knowledge or even incorrect in some circumstances tomorrow...simply because virtually no studies allow for and "correctly" weight all variables. As time passes and more "scientific" research is done, we always end up discovering more facets of theory and application which we need to take into account to correct our previously accepted theories and applications. It is in that context that I use the word "guess" sometimes when I write....i.e. "this (whatever) appears to be the fact NOW, but it will doubtless change at least partially as I learn more....perhaps from someone here...." Handloading, likewise, is both science-based and a learned ART. Whether you can accept that or not isn't really important to me. As to my professional standing as a handloader, that is a moot question. My shooting speaks to the quality of my handloads; I hope yours does as well for you. A last comment to this specific post... I still stand by my estimate that brass thickening is not the primary source of "donuts". I suspect the primary cause of donuts is "thinning" of some parts of the brass, while other parts remain their original thickness. Whether the thinning occurs as the result of neck reaming, neck turning, or prolonged case use doesn't really matter when it comes to estimating frequency of the occurance. | |||

|

| One of Us |

Woods - I now understand your inquiry about a "donut on a donut". Yes, a person could end up with that situation, if they neck turned a case, fired it and moved the "step" to the inside of the neck, and then partially neck-sized the case neck. Then they COULD end up with a donut on the inside and another on the outside. That might prove to be a bad thing, but not necessarily so. IF the bullet still seated deeply enough in the case neck without being forced into or past the inside donut, and the outside donut only served to center the case in the chamber, it might all work just fine. As to how I size the cases with their differing neck thicknesses... IF I size them at all, I just use a conventional die. As the step I was referring to in the fired case is on the inside, the only reasons I am sizing at all is to make sure the case rechambers easily, and to make sure case neck tension is enough to hold the bullet. If I have been careful in determining how thick I need the case neck to be where the bullet is when I turned my cases, that will automatically occur when I do the regular sizing. In fact, though, with my cases in BR rifles, I never size them after fire-forming. Indeed, in matches where the time limits are adequate to do so, I only use one cartridge case, depriming, repriming, charging with powder, and seating a new bullet after every shot. Few people do that, because they are anxious to be able to fire as many shots as possible when they get a "patch" of wind they find favourable. That, of course, requires pre-loaded ammo, in enough quantity to cover both sighters and "record" shots. I enjoy doing it my way because: 1. It forced me to learn to shoot...i.e., I had to learn to read the wind for every shot, no matter how it might change. In the short term, I got my socks beaten off of me. In the long run, it proved very beneficial and won me a lot of matches as I learned how to deal with any conditions out there. I didn't have to try to "wait out" the wind. Thousands of rounds where I had to learn how to hold off for conditions enabled me to shoot without praying for God to give me a favourable wind. 2. If consistency is really the name of the game in shooting small groups, well, just using one case is the very best way to get shot-to-shot case consistency. That is one of the reasons I like the "inside donut" (step) in the neck. By determining my case neck dimensions to the .0001" of an inch, I can seat the bullet quickly and accurately with no need for a die of any kind. It is just de-prime, re-prime, charge with powder, and push a bullet in by hand. Quicker than it takes to say it, once you have got the routine taught to your reflexive, subconscious, mind. Of course that approach is totally inappropriate and unfitting for almost all hunting and other field shooting with sporting rifles. It is even not a viable approach for most factory rifle shooting from the bench, as most factory rifles have necks too large in diameter for it to work. (Note- for those who claim it is not possible to accurately turn case necks to .0001" dimensions, there ARE neck-turners which make it pretty easy (the Nielson "Pumpkin", for instance). And, while it is true that varying ambient conditions will change cartridge dimensions by that much or more...if a person makes several cases with .0001" differences in neck size, then he can try some cases just before beginning a match. Believe it or not, you can learn to tell by the feel of how the bolt closes on those cases, which is the one to use in that day's ambient conditions. It is also possible when using a nice tight chamber and closely fitted cases, to wear out a match rifle barrel with just two or three cases.) Now you know why I say handloading can be an ART as well as a science. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| one of us |

I've gotten those and wondered where they came from.They occur when the neck in the chamber has just shot-out and brass fired in this chamber is resized or neck sized with a bushing die.Unfortunately, to solve the issue,you need a new barrel. | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia